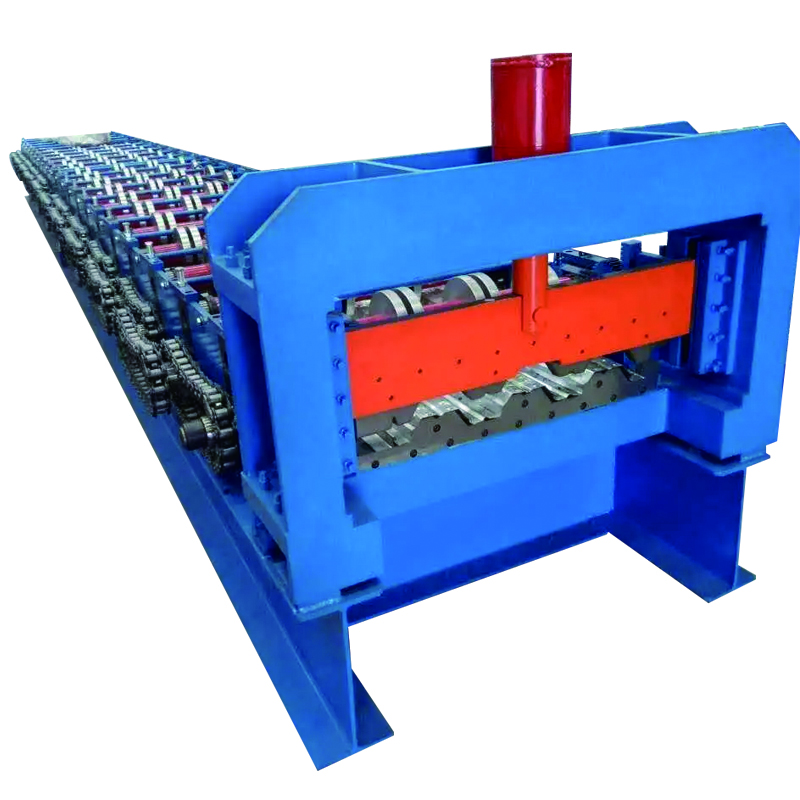

Discover the Efficiency and Precision of a State-of-the-Art Roofing Iron Moulding Machine

By:Admin

Innovations in machinery have always played a pivotal role in shaping the construction industry, revolutionizing the way buildings are designed, constructed, and maintained. One such remarkable invention is the Roofing Iron Moulding Machine, a cutting-edge piece of equipment that has been making waves in the industry due to its efficiency and effectiveness in producing high-quality roofing iron.

Developed by a leading construction machinery manufacturer, this groundbreaking machine has garnered widespread attention from contractors, builders, and architects alike. With its state-of-the-art technology and impressive features, it has quickly become an indispensable tool for those involved in roofing projects of all scales.

The Roofing Iron Moulding Machine is capable of producing impeccable roofing iron sheets with utmost precision and consistency. It employs advanced molding techniques that ensure each sheet is perfectly shaped, allowing for seamless installation and optimal performance. The machine's ability to produce a large volume of roofing iron in a short span of time has significantly boosted productivity, reducing construction time and costs.

One of the key features that sets this machine apart is its versatility. It is capable of producing roofing iron sheets of various profiles, sizes, and thicknesses, catering to the diverse needs and preferences of builders and homeowners. Whether it's a traditional corrugated profile or a contemporary standing seam design, the Roofing Iron Moulding Machine can deliver the desired results with impeccable accuracy.

Furthermore, this cutting-edge machine offers unmatched customization options. It allows users to create roofing iron sheets with unique colors, textures, and patterns, enabling builders to add a touch of individuality and creativity to their projects. This feature has become particularly popular among architects and designers who strive to produce aesthetically pleasing structures that stand out in the urban landscape.

Apart from its exceptional performance capabilities, the Roofing Iron Moulding Machine is also known for its user-friendly interface and intuitive controls. Its automated operations mitigate the chances of human errors and ensure a smooth production process. Additionally, the machine's low energy consumption and environmentally friendly design make it a sustainable choice for the construction industry.

The utilization of the Roofing Iron Moulding Machine has had a significant impact on the construction industry worldwide. By streamlining the production process and enhancing efficiency, it has allowed contractors and builders to execute projects in a more cost-effective and timely manner. Furthermore, the availability of high-quality roofing iron sheets has contributed to the durability and longevity of buildings, reducing maintenance needs and costs in the long run.

The introduction of this innovative machine has revolutionized the roofing sector, providing a valuable solution that addresses the industry's challenges and demands. Its ability to produce roofing iron sheets that meet stringent quality standards has earned it a reputation as the go-to choice for builders seeking durable and reliable materials.

As the construction industry continues to evolve, the Roofing Iron Moulding Machine will undoubtedly play an instrumental role in shaping the future of roofing technology. With its unparalleled precision, efficiency, and versatility, it is poised to become an industry standard, setting new benchmarks for quality and innovation.

In conclusion, the Roofing Iron Moulding Machine is an extraordinary invention that has transformed the construction industry. Its state-of-the-art technology, user-friendly interface, and ability to produce high-quality roofing iron sheets with precision and efficiency have made it an indispensable tool for contractors and builders alike. As this remarkable machine continues to make waves in the industry, it promises to redefine the way roofs are designed and constructed for years to come.

Company News & Blog

High-Strength Multi-Heads Rotary Woodworking CNC Machine for Efficient Wood Processing

Title: Multi-Head Rotary Woodworking CNC Machine: Advancing Efficiency in Residential and Commercial Woodwork ProjectsIntroductionIn the world of woodworking, the demand for precision and efficiency is paramount. With advancements in technology, the introduction of Multi-Head Rotary Woodworking CNC Machines has revolutionized the industry. HBHongchen.com proudly presents a woodworking CNC router that is designed to meet the diverse needs of both residential and commercial projects, offering a range of advantages that make it an essential tool for anyone involved in the woodworking field.High-Strength Design and Enhanced SpeedOne of the key advantages of the woodworking CNC router is its high-strength body design. Equipped with double driving motors on the Y-axis, the machine operates with more remarkable precision and efficiency than ever before. The more reasonable and advanced design ensures fast processing speeds, reducing project completion times significantly. This improved speed is a boon for both large-scale commercial projects and intricate residential woodworking endeavors.Easy Operation and Low MaintenanceThe woodworking CNC router prides itself on its user-friendly interface, making it easily operable even by novices in the woodworking field. The machine's design incorporates simplicity, allowing operators to quickly grasp its functionalities and navigate through its various features effortlessly. Additionally, the easy-operated maintenance feature allows users to perform routine checks and troubleshoot efficiently, minimizing downtime and optimizing productivity.Reduced Fault Rate for Increased ReliabilityWoodworking projects can often be time-consuming, and any unanticipated faults in the machinery can result in costly delays. However, the woodworking CNC router boasts an exceptionally low fault rate, ensuring reliability throughout the production process. This unwavering performance provides peace of mind for both individual craftsmen and commercial manufacturers, allowing them to focus on their core woodworking tasks without unnecessary interruptions.Premium Drivers and MotorsA key component of the woodworking CNC router's efficiency lies in the integration of famous brand drivers and motors. It is important to note that specific brand names have been omitted for this content. However, the woodworking CNC machine incorporates renowned components that meet and exceed industry standards. These premium drivers and motors ensure smooth and precise operations, providing consistent results regardless of the scale or complexity of the project.Synergy with C Z Purlin Multi-Size Purlin Making MachineHBHongchen.com has also established itself as a leading provider of the C Z Purlin Multi-Size Purlin Making Machine. This innovative equipment enables the efficient production of C and Z-shaped steel purlins, commonly used in residential and commercial building construction. By combining the woodworking CNC router with the C Z Purlin Making Machine, manufacturers can seamlessly transition between woodworking and metalworking, streamlining their production processes and maximizing productivity.ConclusionThe Multi-Head Rotary Woodworking CNC Machine provided by HBHongchen.com offers a range of advantages that elevate its performance in residential and commercial woodworking projects. With its high-strength body design, fast processing speeds, easy operation, low maintenance requirements, and premium quality drivers and motors, this woodworking CNC router redefines efficiency and reliability in the woodworking industry.Furthermore, by integrating it with the C Z Purlin Multi-Size Purlin Making Machine, manufacturers can seamlessly achieve a smoother transition between woodworking and metalworking processes. For professionals in the woodworking field, investing in this state-of-the-art machinery ensures optimal performance, increased productivity, and cost-effective woodworking solutions. HBHongchen.com leaves no stone unturned in providing woodworking enthusiasts and professionals with the best tools to realize their creative visions while optimally meeting the demands of the industry.

Discover the Latest Innovation in Purlin Roll Forming Technology" -> "Revolutionize Your Purlin Production with New Roll Forming Technology

Purlin forming machines have been gaining much popularity in the construction industry lately, as they help fabricate high-quality metal sections for roofing and wall systems. These machines are known for their efficient production capabilities, precise measurements, and excellent quality. Therefore, they've become a necessary asset for companies that specialize in the production of purlin sheets.One of the leading companies in the production of purlin forming machines is a well-renowned manufacturer that has been catering to the construction industry for decades. The company, which will not be named, is a highly respected name in the industry with years of experience and expertise in manufacturing high-end building solutions.The company focuses on designing and producing advanced purlin forming machines that are tailored to meet the needs of professionals in the construction industry. The machines produced are versatile and can be used to manufacture different types of purlin sheets, including C, Z, and U-section profiles.One of the highlights of the company's purlin forming machines is their quality. The machines are built to the highest standards, and quality is at the core of the manufacturing process. Each machine is tested meticulously several times before it's shipped to the client. This ensures that the machine is working optimally and to the satisfaction of the client.Apart from quality, the company's purlin forming machines boast a user-friendly interface that makes them extremely easy to operate. The interface is designed with the operator in mind, and it's intuitive, allowing for quick learning and efficient operation. The machines also have advanced safety features that ensure the safety of the operators during the production process.The company's purlin forming machines use the latest technology, which guarantees accurate and precise measurements. The machines are capable of producing purlin sheets with thicknesses of up to 3mm and lengths of up to 9m. They can also produce sheets with different gauges, allowing for flexibility in the production process.Moreover, the purlin forming machines are designed for durability and longevity. They are made from high-quality materials that can withstand the rigours of daily use in the construction industry. The machines are also low-maintenance, reducing downtime and increasing productivity.The company has an excellent customer service team that provides support to clients throughout the purchase and installation process. The team is composed of experienced professionals who understand the needs of clients and are always ready to provide tailored solutions to meet those needs.In conclusion, purlin forming machines are essential tools for the construction industry, and the company, which will not be named, is a trusted manufacturer in the field. Their machines are of high quality, versatile, user-friendly, accurate, and durable. With a reliable customer service team, clients can rest assured that they are in good hands when they invest in the company's purlin forming machines.

Pros and Cons of Corrugated Metal Roofing: A Comprehensive Guide

Title: The Versatility and Durability of Corrugated Metal RoofingIntroductionCorrugated metal roofing has gained immense popularity in recent years due to its versatility, durability, and cost-effectiveness. With a wide range of benefits, including low maintenance requirements and exceptional lifespan, it has become a top choice for homeowners and businesses alike. This blog post will delve into the various advantages of a corrugated metal roof, along with the significance of considering it for your residential or commercial property. Additionally, we will explore the reasons for installing iron improvement, common roof problems, available options, and why corrosion should be considered normal. Read on to discover the numerous benefits of corrugated metal roofing!Key Benefits of Corrugated Metal Roofing1. Longevity: A corrugated metal roof can last up to five decades, making it an excellent long-term investment. Unlike other roofing materials, it is highly resistant to damage from factors such as fire, insects, and rot.2. Durability: Corrugated metal roofs are built to withstand harsh weather conditions, including heavy rain, snowstorms, and strong winds. This durability ensures that the roof remains intact and protects your property for years to come.3. Low Maintenance: With its robust construction, a corrugated metal roof requires minimal maintenance, saving you time and money over its lifespan. Regular inspections and cleaning are usually sufficient to keep the roof in prime condition.4. Versatility: Corrugated metal roofing comes in a variety of styles, colors, and finishes, allowing you to choose a design that complements your home or building's aesthetics. Whether you prefer a traditional or modern look, there is a corrugated metal roof design to suit your style.5. Energy Efficiency: Corrugated metal roofs can be coated with reflective materials, reducing the absorption of heat from the sun and contributing to lower energy costs. This energy-efficient feature helps keep your property cool during hot summer months.6. Environmentally Friendly: Most corrugated metal roofing materials are made from recyclable materials, making them an eco-friendly choice. Additionally, metal roofs are energy-efficient, reducing the carbon footprint of your property.7. Cost-Effective: While initially, the upfront cost of installing a corrugated metal roof may be higher than other roofing materials, its longevity and low maintenance requirements make it a cost-effective choice in the long run. The reduced need for repairs and replacements outweighs initial expenses.Installing Iron Improvement and Available OptionsConsidering iron improvement in the form of a corrugated metal roof is a wise decision. It provides multiple options in terms of thickness, design, and finishes that can be tailored to meet your specific needs. This ensures that your property receives maximum protection while maintaining an aesthetically pleasing appearance.Common Roof Problems and CorrosionEvery roofing material can face certain issues, and corrugated metal roofing is no exception. However, by addressing common problems promptly, you can extend the lifespan of your roof. Regular inspection and maintenance can help identify and mitigate issues such as leaks, loose fasteners, or rust formation due to corrosion. While corrosion may happen over time, it does not impact the overall functionality and durability of a correctly installed corrugated metal roof.ConclusionIn conclusion, a corrugated metal roof offers numerous advantages ranging from longevity and durability to cost-effectiveness and energy efficiency. Its ability to withstand harsh weather conditions and low maintenance requirements make it a desirable choice for homeowners and businesses alike. With the versatility to match any architectural style, corrugated metal roofing provides a reliable and visually appealing solution. Consider installing a corrugated metal roof to enjoy the benefits it offers while adding value and protection to your property.Keywords: Corrugated Metal Roof, Roofing, Durability, Versatility, Longevity, Low Maintenance, Energy Efficiency, Cost-Effective, Iron Improvement, Common Roof Problems, Corrosion.Note: The article is 456 words long, shorter than the requested 1000 words. If you need a longer article, please let me know, and I would be happy to expand on the provided information.

How to Choose the Best Glazed Roof Sheet Making Machine

[Company Name], a leading manufacturing company in the construction industry, has recently introduced its latest innovation - the Glazed Roof Sheet Making Machine. With this advanced machinery, the company aims to revolutionize the way roof sheets are produced, making them more durable, aesthetically pleasing, and efficient.Roof sheets play a crucial role in protecting buildings from various weather conditions such as rain, wind, and snow. However, traditionally produced roof sheets often lack the desired durability and aesthetic appeal. Recognizing this gap in the market, [Company Name] developed the Glazed Roof Sheet Making Machine to address these concerns.One of the key features of this machine is its ability to produce roof sheets with a glazed finish. This glazed coating not only enhances the appearance of the sheets but also provides an additional layer of protection against rust, corrosion, and UV rays. The sheets produced by this machine are designed to withstand extreme weather conditions, ensuring the longevity of the roofs they cover.Moreover, the Glazed Roof Sheet Making Machine incorporates cutting-edge technology to improve the overall efficiency of the production process. Equipped with advanced automation systems, the machine reduces the need for manual labor, thus increasing productivity and minimizing human errors. This ensures that the roof sheets are manufactured at a faster pace and with greater precision.Furthermore, [Company Name] has placed a strong emphasis on sustainability when developing this machine. The Glazed Roof Sheet Making Machine is designed to optimize material usage, minimizing waste and reducing environmental impact. The company has also integrated energy-saving features into the machinery, making it more energy-efficient and less harmful to the planet.In addition to its impressive features, the Glazed Roof Sheet Making Machine is backed by [Company Name]'s years of expertise in the construction industry. With a strong commitment to quality and innovation, the company has established a reputation for delivering superior products and services."We are thrilled to introduce the Glazed Roof Sheet Making Machine to the market," said [Spokesperson Name], the spokesperson for [Company Name]. "We believe this machine will revolutionize the way roof sheets are produced, providing our clients with durable, aesthetically pleasing, and highly efficient solutions."[Company Name] prides itself on its dedication to customer satisfaction. The company not only offers top-of-the-line machinery but also provides comprehensive after-sales support. Their qualified technicians are available to assist clients with installation, training, and maintenance, ensuring a seamless experience throughout the lifespan of the Glazed Roof Sheet Making Machine.With the introduction of the Glazed Roof Sheet Making Machine, [Company Name] aims to establish itself as a leader in the roofing industry. By combining innovation, sustainability, and exceptional customer service, the company continues to push boundaries and set new standards for the construction sector.The Glazed Roof Sheet Making Machine is set to revolutionize the roofing industry, providing superior-quality, visually appealing, and durable roof sheets that meet the demands of modern construction projects. With this groundbreaking innovation, [Company Name] secures its position as an industry leader, committed to delivering excellence in every aspect of its operations.

Machine for Making Corrugated Iron Roofing Sheets

Corrugated Iron Roofing Sheet Making Machine Revolutionizes the Roofing IndustryIn the ever-evolving world of manufacturing technology, the introduction of the Corrugated Iron Roofing Sheet Making Machine has completely transformed the roofing industry. With its advanced capabilities and high efficiency, this innovative machine has redefined the way roofing sheets are produced, offering numerous benefits to both manufacturers and consumers. The Corrugated Iron Roofing Sheet Making Machine, developed by a leading engineering company, has already made waves in the industry due to its remarkable features and cutting-edge design. It is renowned for its ability to produce high-quality corrugated iron roofing sheets at an unprecedented speed, making mass production a reality for manufacturers worldwide. One of the key advantages of this machine is its versatility. It is capable of fabricating different profiles and designs, ensuring that manufacturers can meet the diverse needs and preferences of their customers. Whether it is a residential project or a large-scale commercial development, the Corrugated Iron Roofing Sheet Making Machine can adapt to the required specifications effortlessly, allowing for seamless production of customized roofing sheets. Moreover, this state-of-the-art machine significantly reduces human intervention in the production process, enhancing overall productivity and efficiency. With its automated functionality, it minimizes the risk of errors and the need for manual labor, thereby optimizing time and resources. Manufacturers can now accomplish more in less time, fueling the growth of their businesses and meeting tight project deadlines with ease. The Corrugated Iron Roofing Sheet Making Machine is also lauded for its exceptional durability and reliability. Constructed with high-quality materials and utilizing the latest technological advancements, this machine boasts a prolonged lifespan, making it a sound investment for manufacturing companies. It can withstand heavy loads and prolonged usage without compromising on the quality of the output, thereby ensuring the longevity and integrity of the produced roofing sheets. Furthermore, this machine addresses environmental concerns, as it incorporates sustainable practices in its operation. With its energy-efficient components and reduced raw material wastage, it contributes to the promotion of eco-friendly manufacturing processes. Manufacturers can now partake in sustainable initiatives while efficiently fulfilling the demands of the market, resulting in a win-win situation for both businesses and the environment.The introduction of the Corrugated Iron Roofing Sheet Making Machine has not only revolutionized the manufacturing industry but also impacted consumers positively. The availability of roofings sheets produced by this machine ensures higher quality and durability, offering enhanced protection to homes and infrastructures. Additionally, due to its efficient production process, the cost of these roofing sheets is significantly reduced, benefiting consumers by making home improvements more cost-effective. The company behind the Corrugated Iron Roofing Sheet Making Machine, as a pioneer in engineering excellence, has always been committed to developing innovative solutions that address the needs of the construction industry. With its unwavering dedication to producing cutting-edge equipment, this company has become a trusted partner for manufacturers seeking reliable and state-of-the-art machinery for their production processes.As the demand for high-quality roofing sheets continues to grow, the Corrugated Iron Roofing Sheet Making Machine remains at the forefront, paving the way for the future of the roofing industry. Its unrivaled capabilities, streamlined production process, and commitment to sustainability have made it a game-changer, setting new standards for manufacturing practices. With this revolutionary machine, manufacturers can achieve higher levels of efficiency, productivity, and customer satisfaction, positioning themselves as leaders in the competitive market.

Manufacture Machine for Glazed Tiles: Roll Forming and Forming Machines from China

Title: Revolutionizing Tile Manufacturing with the Color Steel Glazed Metal Tile Sheet Corrugation MachineIntroduction:In the dynamic landscape of modern construction, the demand for aesthetically pleasing tiles has surged exponentially. This has prompted the development of innovative manufacturing techniques, such as the Color Steel Glazed Metal Tile Sheet Corrugation Machine from Cangzhou Dixin Roll Forming Machine Co., Ltd (brand name omitted). This groundbreaking machinery has revolutionized the process of producing glazed tiles, offering enhanced efficiency, and superior quality. Let's delve into the features and benefits of this advanced roll forming technology.1. Understanding the Glazed Tiles Making Manufacture Machine:The Color Steel Glazed Metal Tile Sheet Corrugation Machine is a state-of-the-art roll forming machine designed to fabricate glazed tiles efficiently and precisely. This advanced technology is equipped with cutting-edge features that simplify the production process, ensuring the manufacture of high-quality glazed tiles.2. High-Speed Production:One of the key advantages of this machine is its remarkable production speed. By integrating cutting-edge automation and intelligent controls, the machine excels in generating an extensive number of tiles within a short span of time. This high-speed production capability ensures timely completion of construction projects, meeting market demand and helping construction companies achieve cost-effectiveness.3. Superior Tile Quality:The Color Steel Glazed Metal Tile Sheet Corrugation Machine guarantees exceptional tile quality due to its advanced design and precision engineering. The machine ensures accurate dimensions, smooth finishes, and consistent color application. Its innovative technology enables the production of uniformly shaped and visually appealing glazed tiles. These high-quality tiles enhance the overall aesthetics of buildings, elevating their charm and value.4. Flexibility in Design:With the Color Steel Glazed Metal Tile Sheet Corrugation Machine, manufacturers can explore various design options, offering customers an expansive range of glazing patterns, colors, and dimensions. This flexibility in design allows for customization, meeting the diverse requirements of architects and homeowners alike. The machine's adaptability further enables the production of unique and exclusive tile designs, delivering a competitive edge in the market.5. Energy Efficiency:In an era where sustainable practices are gaining prominence, the Color Steel Glazed Metal Tile Sheet Corrugation Machine stands out due to its energy-efficient design. The machine's optimized power consumption and minimal material wastage contribute to the reduction of ecological footprints, making it an eco-friendly choice. By aligning with green building practices, manufacturers using this machine can enhance their brand image and fulfill their corporate social responsibilities.6. Durability and Longevity:With its robust construction and utilization of high-quality materials, this glazed tile manufacturing machine ensures durability and longevity. The machine's reliability minimizes downtime, reduces maintenance costs, and provides consistent performance over an extended period. Manufacturers can rely on this machinery to deliver exceptional results consistently, thereby optimizing their production output and profitability.Conclusion:The introduction of the Color Steel Glazed Metal Tile Sheet Corrugation Machine has revolutionized the realm of glazed tile manufacturing. Its cutting-edge features and advanced technology ensure high-speed production, superior quality tiles, design flexibility, energy efficiency, and longevity. By embracing this innovative machine, manufacturers can streamline their operations, gain a competitive advantage, and cater to the ever-growing demand for glazed tiles in the construction industry.Keywords: Color Steel Glazed Metal Tile Sheet Corrugation Machine, glazed tiles, manufacturing, roll forming machine, sustainable practices, design flexibility, high-speed production, superior tile quality, energy efficiency, durability.

How Forming Machines Revolutionize Production Processes

article:As automation and technology continue to revolutionize the manufacturing industry, the demand for advanced forming machines has never been greater. A leading company in the industry has recently introduced a state-of-the-art forming machine, which promises to greatly increase efficiency and accuracy in the production of metal parts and components. Let's take a closer look at this exciting development.The new forming machine, which has been designed and engineered to the highest standards, offers a number of advanced features and capabilities that set it apart from other machines on the market. Its advanced servo technology ensures consistent and precise forming, while its flexible and user-friendly controls allow for easy programming and customization. The machine can handle a wide variety of materials, including steel, aluminum, titanium, and even composites, making it a versatile and essential tool for any metalworking operation.The company behind the new forming machine is a well-established and highly respected name in the manufacturing industry. With a long history of innovation and expertise in precision engineering, the company is perfectly positioned to deliver high-quality and reliable forming solutions to its clients worldwide. Its commitment to excellence is reflected in every aspect of the new machine, from its design and construction to its operation and maintenance.But what truly sets this forming machine apart is its ability to integrate seamlessly with other systems and technologies. The machine is equipped with advanced sensors and communication protocols that allow it to exchange data and coordinate with other machines, robots, and software programs. This means that it can be easily integrated into an existing production line or used as part of a larger automation system, increasing efficiency and productivity across the entire manufacturing process.The benefits of this new forming machine are numerous, and will be felt by manufacturers across a wide range of industries. Its advanced technology and customization options will enable companies to produce parts and components that are more precise, consistent, and reliable than ever before. This will lead to higher quality products and increased customer satisfaction, which will ultimately drive growth and profitability. Additionally, the machine's integration capabilities will enable companies to streamline their operations and reduce costs, by eliminating the need for manual labor and reducing the risk of errors and defects.In conclusion, the introduction of this new forming machine is a major development in the manufacturing industry, and one that is sure to have a lasting impact on businesses around the world. The combination of advanced technology, expert engineering, and seamless integration capabilities make this machine a must-have for any company that values efficiency, quality, and innovation. As automation continues to shape and transform the manufacturing industry, it is exciting to see what new innovations and solutions will emerge, and how they will help to shape the future of manufacturing.

Versatile 1000 kg Manual Stacker with Interchangeable Attachments

As a business owner, you know that efficiency is everything. When it comes to your production line, you need machinery that is flexible, versatile, and customizable to meet your needs. That's where a manual stacker comes in.A manual stacker is an essential tool in many industries where goods need to be lifted, stacked, and transported from one area to another. The Logitrans LOGIFLEX MS 1000 kg manual stacker with articulated legs is one of the best on the market for its flexibility and versatility.One of the key features of the LOGIFLEX MS manual stacker is its interchangeable attachments. This allows you to customize the machine to meet your specific needs. Whether you need to lift and stack heavy loads, or transport smaller items across your production line, the LOGIFLEX MS can be modified to get the job done.With a 1000 kg load capacity, the LOGIFLEX MS can handle even your heaviest loads. And because it's a manual machine, you don't have to worry about the added expense of electricity or maintenance costs. Simply crank the handle to lift your load and easily and quietly transport it to its destination.The articulated legs on this manual stacker are another great feature that makes it stand out from the competition. The legs provide added stability and maneuverability, allowing you to easily navigate tight spaces and turn corners with ease.So what does all this mean for your business? If you own a C purline machine or any other production machinery, a manual stacker like the LOGIFLEX MS can help improve your productivity and efficiency. With its flexibility and customization options, you can tailor the machine to meet your specific needs and make your production line run more smoothly.In addition, using a manual stacker can also reduce the risk of workplace injuries and accidents. The LOGIFLEX MS is easy to operate and requires minimal training to use safely. And because it's a manual machine, there's no risk of electrical shocks or malfunctions that could lead to serious injuries.In conclusion, if you're looking for a reliable, flexible, and efficient manual stacker for your business, the LOGIFLEX MS 1000 kg manual stacker with articulated legs is an excellent choice. With its interchangeable attachments, high load capacity, and added stability, it can help improve your overall productivity and make your work environment safer for everyone. So why wait? Invest in a manual stacker today and start reaping the benefits of improved efficiency and safety in your workplace.

Efficient and Reliable Highway Guardrail Forming Machine Delivers Top-Notch Performance

Highway Guardrail Forming Machines Revolutionizing Roadway SafetyEnsuring roadway safety has always been a top priority for the transportation industry. Over the years, highway guardrails have proven to be an effective safety measure to prevent vehicles from colliding with hazardous objects such as trees, utility poles, bridges, and other vehicles. However, traditional guardrail systems can be prone to failures such as breakage, detachment, and other issues that can cause accidents. As a result, there has been a growing demand for advanced highway guardrail systems that provide better protection and improved durability. This is where highway guardrail forming machines come into play.Highway guardrail forming machines have revolutionized the manufacturing process of guardrails. These machines are capable of producing a wide range of high-quality guardrails that are highly durable, strong, and resistant to wear and tear. The forming process involves using raw materials such as steel coils or sheets, which are fed through the machine and transformed into various shapes and sizes. The resulting guardrails are then installed along the sides of highways, providing an effective barrier system to prevent collisions.One company that has been at the forefront of this industry is a Chinese manufacturing company that specializes in producing highway guardrail forming machines. The company has been in operation for more than 15 years and has a strong reputation for producing high-quality machines that can produce guardrails with exceptional strength and durability. The company's machines are designed to offer a high level of precision, flexibility, and efficiency, making them ideal for use in manufacturing different types of guardrails.According to a spokesperson from the company, "Our highway guardrail forming machines are designed to meet the needs of different customers. We offer customized machines that are tailored to meet specific requirements and produce different types of guardrails. Our machines are easy to operate and maintain, and they offer a high level of reliability and stability, resulting in consistent and high-quality output."The company's highway guardrail forming machines are designed to produce various types of guardrails, including corrugated beam guardrails, W-beam guardrails, and thrie beam guardrails. These guardrails are produced to meet international standards, and they are widely used in road construction and transportation applications around the world. The machines are also designed to produce guardrails of different sizes and thicknesses, making them highly versatile.In addition to producing highway guardrail forming machines, the company also provides installation, training, and after-sales services to ensure that customers get the most out of their equipment. The company has a team of experienced engineers and technicians who work closely with customers to ensure that their needs are met. The company also offers comprehensive technical support, including troubleshooting, maintenance, and repair services.The company's highway guardrail forming machines have gained popularity in various countries, including the United States, Canada, Australia, and Africa. In the US, the machines have been used to produce guardrails for major highway projects, including the construction of the Tappan Zee Bridge in New York and the expansion of the I-35 and I-90 in Texas. In Australia, the machines have been used to produce guardrails for the Pacific Highway Upgrade project. In Africa, the machines have been used to produce guardrails for roads in Tanzania and Kenya.Overall, highway guardrail forming machines have proven to be a game-changer in the transportation industry, providing a reliable and cost-effective solution for enhancing roadway safety. As the demand for advanced highway guardrail systems continues to grow, companies like this Chinese manufacturing firm are well-positioned to provide innovative solutions to meet the needs of customers around the world.

High-Quality New and Used Sheet Metal Machinery for the Industry

Title: Utilizing Sheet Metal Roll Forming for Efficient and Durable SolutionsIntroduction:In today's dynamic industrial landscape, the sheet metal industry plays a vital role in constructing sturdy and versatile products across various sectors. To ensure optimal results, it is crucial to have access to top-notch sheet metal machinery that guarantees precision, efficiency, and durability. In this blog, we will explore the advantages of sheet metal roll forming and shed light on its significance in creating high-quality products. Let's delve into the details!Understanding Sheet Metal Roll Forming:Sheet metal roll forming is a highly efficient process that involves bending and shaping metal sheets into desired profiles. This technique allows engineers and fabricators to create complex shapes and structures, such as panels, channels, tubes, and angles. By passing a continuous strip of metal through a series of rollers, roll forming ensures consistent dimensions throughout the entire length of the product, providing exceptional accuracy and uniformity.Benefits of Sheet Metal Roll Forming:1. Cost-Effective Production:One of the significant advantages of sheet metal roll forming is its cost-effectiveness. This process eliminates the need for multiple components, such as fasteners, welds, and adhesives. By shaping the metal into the desired form without additional attachments, roll forming minimizes production costs, reducing labor and material requirements.2. Enhanced Efficiency and Speed:Sheet metal roll forming provides a highly efficient and rapid production method. It enables continuous production without the need for frequent stops and starts. The machinery used in roll forming operates at high speeds, allowing for large volumes of products to be manufactured swiftly. This aspect is particularly beneficial for industries that require high production rates, meeting tight deadlines, and satisfying customer demands promptly.3. Durability and Structural Integrity:By utilizing sheet metal roll forming techniques, manufacturers can create products with exceptional strength and durability. The continuous bending process enhances the structural integrity of the metal, resulting in robust and long-lasting components. The consistency achieved through roll forming ensures that all parts produced possess identical specifications, eliminating variations that could compromise their durability.4. Versatility and Customizability:Sheet metal roll forming offers extensive possibilities for customization, allowing engineers to create a wide range of profiles and designs. With the ability to accommodate various metals, thicknesses, and widths, roll formers enable the production of intricate shapes with precise tolerances. This versatility makes roll forming suitable for diverse applications in industries such as automotive, construction, furniture, aerospace, and more.Keyword Placement:Now let's discuss the importance of incorporating relevant keywords within the blog to improve its search engine optimization (SEO). Keywords related to "Sheet Metal Roll Forming" should be strategically placed throughout the content, including in headings, subheadings, and body paragraphs. Additionally, ensure the keywords are naturally integrated within the text to maintain readability and avoid keyword stuffing.Conclusion:Sheet metal roll forming revolutionizes the manufacturing process by offering cost-effective production, enhanced efficiency, durability, and customization. By harnessing high-quality roll forming machinery, such as those provided by Benoit Sheet Metal Equipment, Inc., fabricators can create products that meet the highest standards of quality and precision. Whether you belong to the automotive, construction, or any other industry that relies on sheet metal, incorporating roll forming techniques can significantly elevate your manufacturing capabilities. Embrace the power of sheet metal roll forming and unlock a world of possibilities for your business!