Durable Standing Seam Metal Roofing Rollers: A Complete Guide

By:Admin

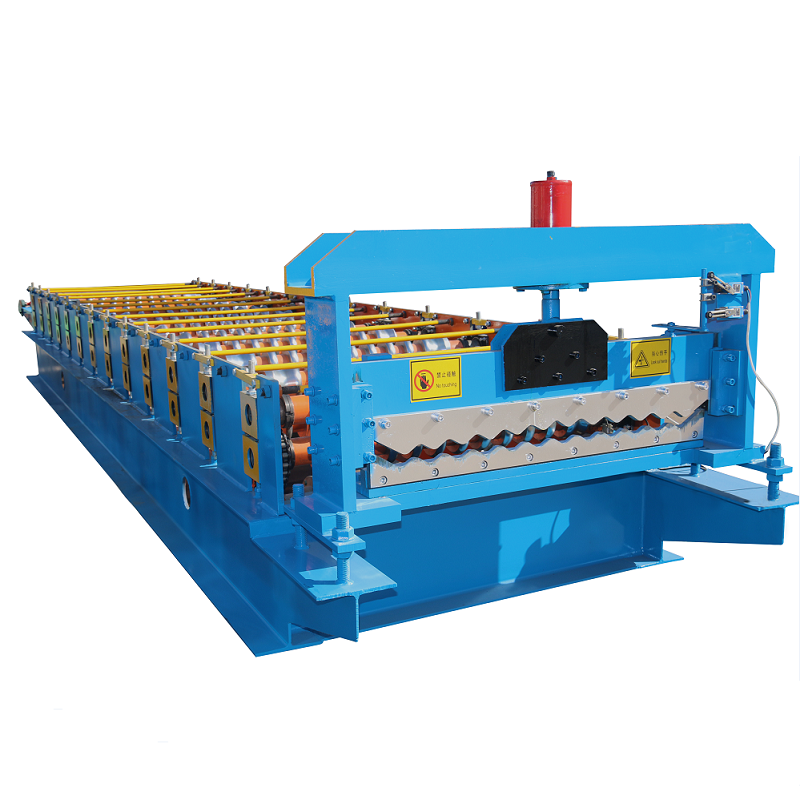

The Standing Seam Metal Roofing Roller produced by {Company Name} is designed to meet the highest standards of quality and performance. With advanced technology and precision engineering, the roller is capable of producing perfectly formed seams that provide a strong and watertight seal for metal roofs. This ensures that the finished roofs are able to withstand the harshest weather conditions and provide long-lasting protection for buildings.

One of the key features of the Standing Seam Metal Roofing Roller is its versatility. It is capable of producing a variety of seam profiles to suit different architectural styles and design requirements. Whether it's a traditional standing seam or a more contemporary snap-lock system, the roller can accommodate a wide range of specifications, making it an ideal choice for a diverse range of roofing projects.

In addition to its versatility, the roller is also known for its efficiency and reliability. It is powered by a high-performance motor and equipped with precise controls, allowing for smooth and consistent operation. This not only ensures that the roofing panels are produced with accuracy and consistency, but it also helps to increase productivity and reduce installation time for contractors and builders.

{Company Name} takes pride in the quality and durability of its products, and the Standing Seam Metal Roofing Roller is no exception. Constructed from robust materials and built to withstand heavy-duty use, the roller is designed to provide years of reliable service. This not only gives customers peace of mind knowing that their roofing projects are in good hands, but it also helps to minimize maintenance and repair costs over the long term.

Furthermore, {Company Name} is dedicated to providing comprehensive support to its customers. From initial consultation to after-sales service, the company's team of experts is committed to assisting clients at every stage of their projects. This includes providing technical expertise, offering training and guidance on equipment operation, and delivering prompt and responsive assistance whenever it is needed. This level of support helps to ensure that customers are able to achieve their roofing goals efficiently and effectively.

As a leading manufacturer in the industry, {Company Name} is also committed to sustainability and environmental responsibility. The Standing Seam Metal Roofing Roller is designed to minimize material waste and energy consumption, helping to reduce the carbon footprint of roofing projects. Additionally, the company adheres to strict environmental standards in its manufacturing processes, ensuring that its products are as eco-friendly as possible.

In summary, the Standing Seam Metal Roofing Roller from {Company Name} is a testament to the company's dedication to excellence and innovation. With its exceptional quality, versatility, efficiency, and reliability, the roller has become a go-to choice for contractors and builders looking for top-tier roofing solutions. Backed by a team of experts and a commitment to sustainability, {Company Name} continues to set the standard for the industry, providing customers with the tools and support they need to achieve outstanding results in their roofing projects.

Company News & Blog

High-Quality Metal Slitting Line for Sale – Different Gauges Available at SteelSlitter.com

RISHBIN Emerges as a Leading Slitting Line Machine Manufacturer Offering High-Quality Metal Slitting Line for SaleIn the dynamic world of manufacturing, industries are constantly seeking efficient and reliable solutions to meet their production needs. RISHBIN, a prominent player in the market, has emerged as one of the best slitting line machine manufacturers, offering high-quality metal slitting lines for sale. With a wide range of machines catering to different gauge requirements, RISHBIN continues to revolutionize the industry with its cutting-edge technology and exceptional product offerings.Slitting lines are a vital component of the metal processing industry, enabling precise cutting and resizing of coils into narrower widths. When it comes to manufacturing slitting line machines, RISHBIN stands out for its commitment to delivering superior quality and innovative features. With an experienced team of engineers and technicians, the company is at the forefront of technological advancements, ensuring that their machines meet the highest industry standards.RISHBIN's metal slitting lines are designed to handle various gauge requirements, ensuring flexibility and versatility for a wide range of applications. The availability of machines suitable for light, medium, and heavy gauge materials makes RISHBIN the go-to manufacturer for businesses operating in diverse sectors. Whether it's the automotive, construction, or packaging industry, RISHBIN's slitting lines provide optimal performance and accuracy.What sets RISHBIN apart from its competitors is its continuous focus on research and development. The company invests heavily in innovation, constantly enhancing its product offerings to meet evolving industry demands. By staying up-to-date with the latest technological advancements, RISHBIN ensures that its slitting line machines provide the most efficient and reliable solutions for its customers.In addition to its dedication to quality and innovation, RISHBIN is also renowned for its exceptional customer service. The company believes in establishing long-term relationships with its clients, prioritizing their needs and exceeding their expectations. RISHBIN's team of experts assists customers throughout the entire purchasing process, offering valuable guidance and support to help them make informed decisions.RISHBIN's commitment to quality and customer satisfaction is further reflected in its post-sales services. The company offers comprehensive maintenance and technical support to ensure that its machines continue to perform optimally throughout their lifespan. By providing timely servicing and spare parts availability, RISHBIN helps its customers maximize their productivity and minimize downtime.With its robust manufacturing capabilities, RISHBIN ensures that each slitting line machine is crafted to perfection. The company utilizes high-quality materials and rigorous quality control processes to guarantee the durability and efficiency of its products. RISHBIN's metal slitting lines are built to withstand heavy usage and deliver consistent performance, making them a reliable investment for businesses looking to enhance their manufacturing processes.As a socially responsible organization, RISHBIN is committed to sustainability and environmentally friendly practices. The company implements energy-efficient measures throughout its manufacturing processes, reducing its carbon footprint and promoting a greener future. By choosing RISHBIN's slitting line machines, customers not only benefit from high performance but also contribute to global sustainability efforts.In conclusion, RISHBIN has established itself as a leading slitting line machine manufacturer by delivering high-quality solutions tailored to different gauge requirements. With its focus on innovation, customer service, and sustainability, RISHBIN continues to drive the industry forward. As businesses strive for excellence in their manufacturing processes, RISHBIN's metal slitting lines emerge as the ideal choice, ensuring efficiency, accuracy, and long-term reliability.

Fully Automatic C Purlin Roll Forming Machine: A Complete Guide

Fully Automatic C Purlin Roll Forming Machine Revolutionizing the Steel Structure IndustryThe steel structure industry has been revolutionized by the introduction of the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field. This innovative machine has significantly enhanced the efficiency and productivity of producing C purlins, which are essential components in the construction of steel buildings.With the increase in demand for steel structures due to their durability, cost-effectiveness, and flexibility, the need for advanced manufacturing equipment has become more critical. The Fully Automatic C Purlin Roll Forming Machine meets this demand by automating the production process, reducing manual labor, and increasing output.The machine's advanced technology allows for precise and accurate forming of C purlins, ensuring consistent quality and dimensional accuracy. This level of precision is essential for the seamless assembly and construction of steel buildings, where even the slightest deviation in the dimensions of components can result in installation challenges and structural issues.The Fully Automatic C Purlin Roll Forming Machine is designed to handle a wide range of materials, including galvanized steel, stainless steel, and aluminum, making it versatile for various construction requirements. This flexibility has made it an ideal choice for manufacturers, contractors, and construction companies looking to streamline their production processes and deliver high-quality steel structures to their clients.In addition to its advanced technology, the machine's fully automated operation has significantly reduced production time, allowing for faster turnaround times and increased production capacity. This has had a direct impact on the overall efficiency and profitability of steel structure manufacturing companies, enabling them to meet deadlines and fulfill orders more effectively.Furthermore, the machine's automated operation has also improved workplace safety by reducing the need for manual handling of heavy materials and minimizing the risk of work-related injuries. This has not only created a safer work environment for employees but has also contributed to the overall productivity of production facilities.The company behind the Fully Automatic C Purlin Roll Forming Machine has a long-standing reputation for delivering high-quality and reliable manufacturing equipment to the steel structure industry. With a team of experienced engineers and technicians, the company has been at the forefront of innovation, continuously developing and refining its products to meet the evolving needs of the industry.The company's commitment to research and development has resulted in the creation of cutting-edge technologies that have set new standards for efficiency, reliability, and performance in the manufacturing of steel components. The Fully Automatic C Purlin Roll Forming Machine is a testament to this dedication, as it represents the pinnacle of modern engineering and design in the steel structure industry.In addition to its technological expertise, the company also takes pride in its commitment to customer satisfaction, providing comprehensive support and service to ensure the seamless integration of its equipment into production facilities. This customer-centric approach has earned the company a loyal clientele and a reputation for being a trusted partner in the success of steel structure manufacturing businesses.Looking ahead, the Fully Automatic C Purlin Roll Forming Machine is poised to continue shaping the future of the steel structure industry, driving greater efficiency, precision, and profitability for manufacturers and construction companies. As the demand for steel structures continues to grow, this innovative machine will play a crucial role in meeting the industry's evolving needs and delivering exceptional results to clients around the world.In conclusion, the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field, has set new benchmarks for efficiency and productivity in the manufacturing of steel structures. With its advanced technology, automated operation, and versatile capabilities, this innovative machine has become an indispensable asset for the industry, driving greater precision, safety, and profitability for businesses. As the steel structure industry continues to evolve, the Fully Automatic C Purlin Roll Forming Machine stands ready to lead the way towards a future of excellence and innovation.

Advanced Length Cutting Machine for Precision Cuts

Automatic Length Cutting Machine Revolutionizes Manufacturing Process for [Company Name][City, State] - [Company Name], a leading manufacturing company in the [industry] sector, has recently introduced a state-of-the-art Automatic Length Cutting Machine to their production line. This cutting-edge technology has revolutionized the manufacturing process, allowing for more efficient and precise cutting of materials, ultimately enhancing the overall product quality and production output.The Automatic Length Cutting Machine, which is designed and developed in-house by [Company Name] engineers, utilizes the latest automation and software technology to accurately measure, cut, and process various materials such as steel, aluminum, and other metals. The machine is equipped with advanced sensors and controls that ensure precise cutting according to the required specifications, reducing material waste and minimizing human error."We are thrilled to introduce this cutting-edge Automatic Length Cutting Machine to our production line," said [Name], CEO of [Company Name]. "This technology represents a significant advancement in our manufacturing capabilities, allowing us to achieve higher levels of precision and efficiency in our production processes. It also reflects our commitment to innovation and delivering high-quality products to our customers."The implementation of the Automatic Length Cutting Machine has had a profound impact on [Company Name]'s manufacturing operations. With its ability to accurately cut materials to the required length and specifications, the company has experienced a significant reduction in production time and costs. Additionally, the machine's automation capabilities have freed up labor resources, allowing employees to focus on more intricate and value-added tasks within the production process.Furthermore, the precise cutting enabled by the Automatic Length Cutting Machine has resulted in a higher quality end product. This has been well-received by [Company Name]'s customers, who have noted the improvement in the consistency and accuracy of the materials used in their projects.In addition to the technical capabilities of the Automatic Length Cutting Machine, [Company Name] has also focused on the machine's user-friendly interface and easy integration with their existing production systems. This has allowed for a seamless transition and adoption of the new technology within their manufacturing facility."We have been thoroughly impressed with the performance and reliability of the Automatic Length Cutting Machine," said [Name], a production manager at [Company Name]. "The machine's intuitive interface and seamless integration with our existing systems have made the transition smooth, and we have seen tangible improvements in our production efficiency and product quality."Looking ahead, [Company Name] is committed to further enhancing the capabilities of the Automatic Length Cutting Machine, with plans to integrate more advanced features and functionalities in future iterations. The company also aims to explore opportunities to customize the technology to meet the specific needs of different industries and applications, expanding its market reach and potential impact.The introduction of the Automatic Length Cutting Machine has firmly positioned [Company Name] as a pioneer in the industry, setting new standards for manufacturing efficiency and quality. With its focus on innovation and commitment to delivering exceptional products, [Company Name] continues to lead the way in transforming the manufacturing landscape.As [Company Name] looks to the future, the Automatic Length Cutting Machine will undoubtedly play a pivotal role in driving the company's growth and cementing its reputation as a trusted partner for high-quality, precision-engineered products in the [industry] sector.For more information about [Company Name] and its range of products and services, please visit [company website].Contact:[Name][Title][Company Name][Phone Number][Email Address]

Durable Standing Seam Metal Roofing Rollers: A Complete Guide

Standing Seam Metal Roofing Roller is a key component of the roofing process, and it plays a crucial role in creating seamless and durable metal roofs. As a leading manufacturer in the industry, {Company Name} has been providing high-quality roofing solutions to customers around the world. With a commitment to innovation and excellence, {Company Name} has established itself as a trusted partner for contractors and builders seeking reliable and efficient roofing products.The Standing Seam Metal Roofing Roller produced by {Company Name} is designed to meet the highest standards of quality and performance. With advanced technology and precision engineering, the roller is capable of producing perfectly formed seams that provide a strong and watertight seal for metal roofs. This ensures that the finished roofs are able to withstand the harshest weather conditions and provide long-lasting protection for buildings.One of the key features of the Standing Seam Metal Roofing Roller is its versatility. It is capable of producing a variety of seam profiles to suit different architectural styles and design requirements. Whether it's a traditional standing seam or a more contemporary snap-lock system, the roller can accommodate a wide range of specifications, making it an ideal choice for a diverse range of roofing projects.In addition to its versatility, the roller is also known for its efficiency and reliability. It is powered by a high-performance motor and equipped with precise controls, allowing for smooth and consistent operation. This not only ensures that the roofing panels are produced with accuracy and consistency, but it also helps to increase productivity and reduce installation time for contractors and builders.{Company Name} takes pride in the quality and durability of its products, and the Standing Seam Metal Roofing Roller is no exception. Constructed from robust materials and built to withstand heavy-duty use, the roller is designed to provide years of reliable service. This not only gives customers peace of mind knowing that their roofing projects are in good hands, but it also helps to minimize maintenance and repair costs over the long term.Furthermore, {Company Name} is dedicated to providing comprehensive support to its customers. From initial consultation to after-sales service, the company's team of experts is committed to assisting clients at every stage of their projects. This includes providing technical expertise, offering training and guidance on equipment operation, and delivering prompt and responsive assistance whenever it is needed. This level of support helps to ensure that customers are able to achieve their roofing goals efficiently and effectively.As a leading manufacturer in the industry, {Company Name} is also committed to sustainability and environmental responsibility. The Standing Seam Metal Roofing Roller is designed to minimize material waste and energy consumption, helping to reduce the carbon footprint of roofing projects. Additionally, the company adheres to strict environmental standards in its manufacturing processes, ensuring that its products are as eco-friendly as possible.In summary, the Standing Seam Metal Roofing Roller from {Company Name} is a testament to the company's dedication to excellence and innovation. With its exceptional quality, versatility, efficiency, and reliability, the roller has become a go-to choice for contractors and builders looking for top-tier roofing solutions. Backed by a team of experts and a commitment to sustainability, {Company Name} continues to set the standard for the industry, providing customers with the tools and support they need to achieve outstanding results in their roofing projects.

Steel Coil Slitting Line: Streamlining Precision Cutting and Efficiency in the Manufacturing Industry

Steel Coil Slitting Line is one of the most important machines for the steel industry. It is a machine that is used to cut large coils of steel into smaller strips of the required width. This process is necessary for various applications, such as manufacturing of pipes, tubes, metal sheets, and so on. In this regard, machine suppliers, including {brand name removed}, are vital for the steel industry.{Supplier name removed} is a leading supplier of steel processing machines that includes Steel Coil Slitting Line. The company is a prominent entity in the industry and has carved a niche for itself in the international market. It has established a reputation for quality, durability, and reliability, which has made the company a preferred choice for organizations that deal in the manufacture of steel products.The Steel Coil Slitting Line from {supplier name removed} is built to cater to the diverse needs of customers worldwide. It is designed with cutting-edge technology and equipment that makes it highly productive, efficient, and accurate. This machine is easy to operate and requires minimal maintenance, which further enhances its reliability and durability.Furthermore, this Steel Coil Slitting Line is versatile and capable of handling different types of steel coils. It can process various types of steel materials and thicknesses with ease. Its high precision and accuracy ensure that customers are provided with consistent cuts, which is crucial for the successful production of quality steel products.{Supplier name removed} understands the significance of customer satisfaction and strives to provide top-notch products and exceptional after-sales support to its customers. They have a team of experts who are always available to assist their clients, ranging from machine installation, training, maintenance, and upgrades.Steel Coil Slitting Line has numerous benefits that make it a necessary machine for the steel industry. Firstly, it allows for efficient utilization of steel coils, which reduces the cost of production and waste. Secondly, it is flexible and can accommodate different widths and thicknesses of coils, which offers flexibility in production processes. Thirdly, its high precision and accuracy ensure that customers receive products with consistent quality.In conclusion, Steel Coil Slitting Line is a vital machine for the steel industry. It facilitates efficient and consistent production processes, reduces waste, and enhances the overall quality of steel products. {Supplier name removed} is a renowned supplier of high-quality steel processing machines, and their Steel Coil Slitting Line is one of the best in the market. The company's commitment to excellence, reliability, and customer satisfaction makes them a preferred choice for organizations that require the best steel processing machines in the industry. With {supplier name removed}, customers can count on getting the best value for their investment in steel processing machines.

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

Clear and Transparent Corrugated Plastic Roofing Sheets for Your Home or Greenhouse

{Name Removed} Introduces New, High-Performance Horizontal Corrugated Roofing Material{Name Removed}, a leading manufacturer of roofing materials, has launched a new product that is set to revolutionize the industry - the Horizontal Corrugated Roofing Material. This high-performance roofing material is designed to provide unmatched durability, weather resistance, and ease of installation, making it perfect for a wide range of roofing applications.One of the standout features of the Horizontal Corrugated Roofing Material is its unique design. Unlike traditional corrugated roofing materials that are installed vertically, this product is installed horizontally. This design allows for superior water shedding, making it ideal for areas with heavy rainfall or snow.The Horizontal Corrugated Roofing Material is made from high-quality PVC and boasts exceptional strength and durability. It also has excellent UV resistance properties, making it ideal for use in areas with high sunlight exposure. The material is also resistant to corrosion and chemicals, ensuring it will retain its quality and appearance for many years.Another benefit of this product is its ease of installation. The Horizontal Corrugated Roofing Material is lightweight, making it easy to handle and transport. It can also be easily cut to size on-site using a common circular saw, reducing installation time and costs. Additionally, the product requires minimal maintenance, which means less time and money spent on repairs and upkeep.This new product from {Name Removed} has also been designed with environmental sustainability in mind. The material is 100% recyclable and free from harmful chemicals, making it an eco-friendly choice for homeowners and businesses.The Horizontal Corrugated Roofing Material comes in a range of attractive colours and finishes, making it a versatile and stylish roofing solution. It is also cost-effective, providing customers with a high-quality solution that won't break the bank.Commenting on the launch of the new product, a spokesperson for {Name Removed} said, "We are thrilled to introduce the Horizontal Corrugated Roofing Material to the market. This product is the result of our commitment to providing our customers with the best possible roofing solutions. We believe that this product is perfect for anyone looking for a durable, weather-resistant, and easy-to-install roofing option that offers exceptional value for money."In conclusion, if you are looking for a high-quality, durable, and eco-friendly roofing option, you should look no further than the Horizontal Corrugated Roofing Material from {Name Removed}. With its unique design, exceptional strength and durability, and ease of installation, this product is sure to be a game-changer in the roofing industry.

Quality Corrugation Sheet Steel Tile Roll Forming Machine: Manufacturer and Exporter from China

Corrugation Sheet Steel Tile Roll Forming Machine - A Game-Changer in the Manufacturing IndustryChina is a leader in the manufacturing industry, and one of the key drivers of this success is innovation. Roll forming machines are a prime example of this innovation. The Corrugation Sheet Steel Tile Roll Forming Machine is one such machine that is making waves in the manufacturing sector with its ability to create tiles of various shapes, sizes, and designs.The Corrugation Sheet Steel Tile Roll Forming Machine is developed by a leading Chinese manufacturer of roll forming machines. The company has a long-standing reputation for its high-quality equipment and its commitment to innovation. This new machine is a testament to their commitment to providing customers with the latest and most innovative equipment.The Sheet Corrugation Machine company has been in operation for several years and has established itself as a leading provider of roll forming machines. The company's machines are highly efficient, durable, and versatile, making them ideal for use in a wide range of manufacturing applications.The Corrugation Sheet Steel Tile Roll Forming Machine is designed with high precision to ensure that it produces tiles of unmatched quality. The machine uses advanced technology and automation to produce tiles of various shapes and sizes with high accuracy. The machine has a fully computerized control system that allows operators to set the parameters of the machine to achieve the desired results.One of the key advantages of the Corrugation Sheet Steel Tile Roll Forming Machine is its speed. The machine can produce tiles at high speed, ensuring that manufacturers can meet their production targets and deadlines. This speed is achieved through a combination of advanced technology and the machine's design.The Corrugation Sheet Steel Tile Roll Forming Machine is also highly efficient, which means that it consumes less energy and produces less waste compared to traditional production methods. This efficiency helps manufacturers to reduce their production costs while improving the quality of their products.Another advantage of the Corrugation Sheet Steel Tile Roll Forming Machine is its versatility. The machine can be used to produce tiles of various shapes, sizes, and designs, giving manufacturers the flexibility to meet the requirements of different customers. This versatility makes the machine an ideal option for small and large-scale manufacturers alike.In summary, the Corrugation Sheet Steel Tile Roll Forming Machine is a game-changer in the manufacturing industry. Its advanced technology, speed, efficiency, and versatility make it an ideal option for manufacturers who want to improve the quality of their products while reducing their production costs. The machine's development is a testament to the innovation and commitment to excellence of the Sheet Corrugation Machine company. With this machine, manufacturers can take their production capabilities to the next level and stay ahead of the competition.

Steel Glazed Tile Profile Corrugating Machine: Latest News and Updates

Color Steel Glazed Tile Profile Corrugating Machine Unveiled by Leading ManufacturerThe global leader in the manufacturing of high-quality steel processing equipment has recently introduced its latest innovation, the Color Steel Glazed Tile Profile Corrugating Machine. This cutting-edge machine is designed to meet the growing demand for glazed tile profile corrugated steel sheets within the construction and architectural industry.With a focus on precision engineering and innovative technology, the company has been at the forefront of the steel processing equipment industry for over two decades. By consistently delivering top-of-the-line machinery and unparalleled customer service, they have established a reputation as a trusted partner for companies in need of reliable and efficient steel processing solutions.The Color Steel Glazed Tile Profile Corrugating Machine is the latest addition to their extensive portfolio of advanced equipment and is poised to set a new standard for glazed tile profile corrugated steel sheet production. This innovative machine is capable of producing high-quality corrugated steel sheets with a glazed tile profile, offering superior durability and aesthetic appeal for a wide range of architectural and construction applications.Equipped with state-of-the-art technology, the Color Steel Glazed Tile Profile Corrugating Machine is designed for seamless integration into existing production lines, providing a cost-effective solution for companies looking to enhance their manufacturing capabilities. The machine's advanced features include precision control systems, high-speed processing, and a user-friendly interface, ensuring optimal efficiency and productivity.Furthermore, the company's commitment to sustainability is evident in the Color Steel Glazed Tile Profile Corrugating Machine, as it is designed to minimize energy consumption and waste generation, aligning with the industry's increasing focus on environmental responsibility.In addition to its advanced capabilities, the Color Steel Glazed Tile Profile Corrugating Machine is backed by the company's comprehensive support services, including installation, training, and ongoing maintenance, ensuring seamless integration and long-term reliability for its customers.With its launch, the Color Steel Glazed Tile Profile Corrugating Machine is expected to meet the growing demand for high-quality glazed tile profile corrugated steel sheets in the global market. Its introduction reflects the company's dedication to staying ahead of industry trends and providing cutting-edge solutions that empower its customers to succeed in a competitive market landscape.In response to the unveiling of the Color Steel Glazed Tile Profile Corrugating Machine, the company's CEO emphasized the importance of innovation and customer-centric solutions, stating, "We are proud to introduce the Color Steel Glazed Tile Profile Corrugating Machine as the latest addition to our lineup of advanced steel processing equipment. This innovative machine is a testament to our ongoing commitment to delivering high-performance solutions that empower our customers to achieve their production goals with precision and efficiency."As the global construction and architectural industries continue to evolve, the demand for high-quality glazed tile profile corrugated steel sheets is expected to rise. The introduction of the Color Steel Glazed Tile Profile Corrugating Machine positions the company as a driving force in meeting this demand, providing a reliable and efficient solution that addresses the evolving needs of its customers.With its rich history of innovation and a track record of delivering best-in-class steel processing equipment, the company is well-positioned to set a new industry standard with the Color Steel Glazed Tile Profile Corrugating Machine. As companies seek to enhance their production capabilities and meet the increasing demand for high-quality steel products, this innovative machine is poised to play a pivotal role in shaping the future of the construction and architectural industries.

Quality Roll Forming Machine for Making Tiles: Find Out More!

The leading provider of tile roll forming machines, [company name], has recently announced the launch of their newest and most advanced machine yet. With a strong focus on innovation and quality, the company has set new standards in the industry with their state-of-the-art equipment that is designed to meet the needs of modern construction and roofing projects.The new tile roll forming machine is a result of years of research and development, as well as extensive testing and feedback from industry professionals. It is engineered to provide maximum efficiency and precision, allowing for seamless production of high-quality tile profiles. With the ability to handle a wide range of materials, including steel, aluminum, and copper, this machine is truly versatile and suitable for a variety of applications.One of the key features of the new tile roll forming machine is its speed and accuracy. Equipped with advanced servo technology, it is capable of producing tiles at a fast pace without compromising on the quality of the end product. This will not only help companies to increase their production capacity, but also deliver superior results to their clients.Furthermore, the machine is designed with user-friendly controls and interfaces, making it easy for operators to set up and operate. This not only saves time and effort, but also minimizes the risk of errors, ensuring consistent and reliable performance. Additionally, the machine is equipped with safety features to protect operators and prevent accidents in the workplace.In addition to its impressive performance, the tile roll forming machine is also designed with sustainability in mind. By optimizing material usage and minimizing waste, it helps companies to reduce their environmental impact and operate more responsibly. This aligns with the company's commitment to sustainable practices and their dedication to supporting a greener future.[Company name]'s dedication to quality and innovation has made them a trusted partner for many companies in the construction and roofing industry. With a strong emphasis on customer satisfaction, they offer comprehensive support and services to ensure that their clients get the most out of their equipment. This includes training, technical assistance, and aftermarket services to keep their machines running smoothly.With a global presence and a strong track record of success, [company name] has established itself as a leading provider of roll forming solutions. Their commitment to excellence and continuous improvement has helped them to stay ahead of the curve and deliver cutting-edge products to their clients. The new tile roll forming machine is a testament to their ongoing efforts to push the boundaries of what is possible in the industry.As the construction and roofing industry continues to evolve, the demand for efficient and reliable equipment is stronger than ever. With the introduction of their latest tile roll forming machine, [company name] has once again demonstrated their ability to meet these demands and anticipate the needs of their clients. This will undoubtedly solidify their position as a go-to source for high-quality roll forming solutions.