Efficient Roof Panel Machine for Snap Lock Installation

By:Admin

The roofing industry has seen a significant transformation with the introduction of the innovative Snap Lock Roof Panel Machine. This revolutionary technology has become the go-to solution for roofing contractors, providing a faster, more efficient, and cost-effective way to install metal roof panels.

The Snap Lock Roof Panel Machine, developed by a leading manufacturing company in the construction industry, has quickly gained traction due to its ability to produce high-quality roof panels with ease. The machine boasts a user-friendly design, making it accessible to both seasoned professionals and newcomers in the roofing business.

One of the key features of the Snap Lock Roof Panel Machine is its ability to produce custom-fit panels on-site, eliminating the need for extensive manual labor and reducing the risk of measurement errors. This not only saves time but also minimizes material waste, ultimately leading to significant cost savings for contractors and their clients.

Additionally, the snap-lock system used in the machine ensures a secure and weather-tight seal, offering superior protection against harsh environmental elements. This has positioned the Snap Lock Roof Panel Machine as a game-changer in the roofing industry, setting a new standard for durability and longevity in roof panel installation.

The company behind this groundbreaking technology has a long-standing reputation for delivering innovative and reliable solutions to the construction industry. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible in the field of roofing technology.

The Snap Lock Roof Panel Machine is a testament to the company's commitment to excellence, as it addresses the evolving needs of roofing professionals and property owners alike. Its impact on the industry has not gone unnoticed, with many industry experts hailing it as a transformative advancement that has reshaped the way metal roof panels are installed.

In addition to its practical benefits, the Snap Lock Roof Panel Machine has also been praised for its contribution to sustainability. By reducing material waste and improving installation efficiency, the machine aligns with the growing emphasis on environmentally-friendly construction practices. This has further solidified its position as an industry leader, distinguishing the company as a pioneer in sustainable construction technology.

As the demand for durable and cost-effective roofing solutions continues to rise, the Snap Lock Roof Panel Machine has emerged as a catalyst for change in the industry. Its widespread adoption by roofing professionals has paved the way for a new era of efficiency and reliability in metal roof panel installation.

Looking ahead, the company remains committed to advancing its technology and expanding the reach of the Snap Lock Roof Panel Machine to new markets. With a relentless pursuit of innovation, the company is poised to continue shaping the future of the roofing industry, setting new benchmarks for performance, quality, and sustainability.

In conclusion, the introduction of the Snap Lock Roof Panel Machine has redefined the landscape of metal roofing installation. With its unparalleled efficiency, precision, and durability, the machine has earned its place as a transformative force in the industry, offering a glimpse into the future of roofing technology. As the company behind this revolutionary technology continues to drive innovation, the impact of the Snap Lock Roof Panel Machine is poised to endure, leaving a lasting impression on the roofing industry for years to come.

Company News & Blog

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.

How to Choose the Best Wall Panel Roll Forming Machine for Your Color Steel Project

Color Steel Wall Panel Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has witnessed a remarkable transformation. With the introduction of advanced technology and machinery, the process of constructing buildings has become faster, more efficient, and cost-effective. Among these technological advancements, the Color Steel Wall Panel Roll Forming Machine stands out as a game-changer, revolutionizing the construction industry.The Color Steel Wall Panel Roll Forming Machine, developed by a leading company in the field of construction machinery manufacturing, has become the go-to solution for producing high-quality steel wall panels. These panels are widely used in various applications, including residential, commercial, and industrial constructions.The machine excels in transforming raw materials into precisely shaped steel wall panels, ensuring uniformity and durability. Its automated system enables a seamless and continuous production process, eliminating the need for manual intervention and reducing the chances of errors. This streamlined process not only saves time but also greatly improves the overall efficiency of construction projects.One of the key factors that sets the Color Steel Wall Panel Roll Forming Machine apart is its ability to produce a wide range of panel profiles. Whether the construction project requires corrugated panels, trapezoidal panels, or any other specific profile, this machine can meet the diverse needs of builders and architects. This versatility allows for greater design flexibility and enables construction professionals to create unique structures that stand out from the crowd.Moreover, the Color Steel Wall Panel Roll Forming Machine ensures superior product quality. By employing advanced hydraulic and electrical components, the machine guarantees precision and accuracy in every step of the production process. The panels produced are of high strength, weather resistance, and thermal insulation, making them ideal for both exterior and interior applications. This high-quality output not only enhances the overall aesthetics of buildings but also offers long-lasting protection against harsh environmental conditions.Additionally, the Color Steel Wall Panel Roll Forming Machine contributes to sustainable construction practices. The machine's energy-efficient operation minimizes power consumption, reducing the overall carbon footprint of construction projects. Furthermore, the use of steel wall panels eliminates the need for traditional construction materials like bricks and cement, which require extensive natural resources during their production. This eco-friendly approach aligns with the growing global emphasis on sustainable development and supports the construction industry's efforts to reduce environmental impact.In line with its commitment to customer satisfaction, the company behind the Color Steel Wall Panel Roll Forming Machine also offers comprehensive after-sales services. A team of experienced technicians provides installation guidance, training programs, and maintenance support to ensure the smooth operation of the machine throughout its lifespan. This commitment to customer support has established the company as a reliable partner in the construction industry, attracting clients from all around the world.As the demand for efficient and sustainable construction practices continues to rise, the Color Steel Wall Panel Roll Forming Machine has emerged as an indispensable tool for builders and architects. Its ability to produce high-quality steel wall panels with precision, versatility, and efficiency has transformed the construction industry. By investing in this innovative machine, construction professionals can streamline their operations, reduce costs, and contribute to a greener future.In conclusion, the Color Steel Wall Panel Roll Forming Machine has revolutionized the construction industry, offering a superior and sustainable solution for producing steel wall panels. Its advanced technology, versatility, and commitment to customer support have made it a staple in modern construction practices. As the industry continues to evolve, the importance of embracing innovative machinery like the Color Steel Wall Panel Roll Forming Machine cannot be overstated. This powerful tool is reshaping the way we build, enabling architects and builders to bring their creative visions to life while improving efficiency and sustainability.

Elegant Black and White Script Fabric - Cut Length of 60cm Panels Available for Purchase

Title: Revolutionary Fabric Cut-to-Length Machine Enhances Efficiency and Precision in Textile IndustryIntroduction:The textile industry has always been at the forefront of innovation and technological advancements. One recent breakthrough that promises to revolutionize fabric cutting processes is the introduction of the Fabric Cut-to-Length Machine by an industry-leading company. This machine is designed to streamline the production process, improve accuracy, and enhance efficiency, ultimately benefiting both manufacturers and customers alike.Enhancing Efficiency and Precision:Gone are the days when fabric cutting was a laborious and time-consuming task. The Fabric Cut-to-Length Machine offers a solution that significantly reduces production time, allowing textile manufacturers to meet increasing demands promptly. By automating the cutting process, this machine minimizes human error and ensures precise measurements and accurate fabric cuts, resulting in a higher quality end product.The introduction of the Fabric Cut-to-Length Machine has streamlined the production process by eliminating the need for manual measuring, marking, and cutting, which were traditionally prone to inaccuracies and inconsistencies. With this automated technology, manufacturers can now achieve a consistent level of precision throughout the fabric cutting process, leading to improved overall product quality.Improved Efficiency Drives Profits:Efficiency is a crucial factor in any industry, and the textile industry is no exception. One of the key features of the Fabric Cut-to-Length Machine is its ability to optimize production speed without compromising accuracy. The machine's advanced technology allows manufacturers to handle large volumes of fabric in a short time span, giving them a competitive advantage in meeting tight deadlines and reducing lead times.With decreased labor and material costs, manufacturers can allocate their resources more effectively, leading to substantial cost savings. The efficient fabric cutting process ensures that valuable textile materials are optimally utilized, minimizing waste and maximizing profits. Consequently, businesses can offer their products at competitive prices without compromising on quality, further benefiting both their bottom line and the end consumer.Eco-Friendly Practices:In addition to improving efficiency and accuracy, the adoption of the Fabric Cut-to-Length Machine promotes sustainable and eco-friendly practices within the textile industry. By minimizing fabric waste, manufacturers can reduce their environmental impact. This waste reduction not only benefits the planet, but also helps companies meet increasing consumer demand for sustainable and ethical production practices.Furthermore, the precise fabric cuts produced by the machine mean that manufacturers can have better control over the yield and usage of materials. This efficiency directly contributes to reducing the need for excessive production, thus conserving resources and minimizing carbon footprint.Conclusion:The introduction of the Fabric Cut-to-Length Machine marks a significant breakthrough in the textile industry. As demand for textiles continues to rise, manufacturers are searching for innovative solutions to meet production demands without compromising on quality or efficiency. This machine not only streamlines the fabric cutting process, but also enhances precision, reduces waste, and promotes sustainable practices.In a highly competitive market, textile manufacturers utilizing this cutting-edge technology will gain a significant advantage by producing high-quality fabrics at a faster rate. The Fabric Cut-to-Length Machine revolutionizes the industry by embracing automation, efficiency, and sustainability, ultimately benefitting businesses, consumers, and the environment.

Top Quality Roofing Making Machine for Sale - Ultimate Guide

Roofing Making Machine: A Game-Changer in the IndustryInnovation and advancement in technology are revolutionizing the way we do business and transforming various industries around the world. The roofing industry, in particular, has seen remarkable progress with the introduction of advanced machinery and equipment. One such groundbreaking development is the Roofing Making Machine produced by a leading company in the field of manufacturing and construction.The Roofing Making Machine is a state-of-the-art piece of equipment that has been designed and developed to streamline the process of manufacturing roofing materials. This machine is capable of producing high-quality roofing sheets with precision and efficiency, making it an essential asset for companies involved in the roofing industry.The company behind the development of this cutting-edge equipment is a renowned name in the manufacturing and construction sector. With a rich history of innovation and a commitment to excellence, the company has established itself as a global leader in providing advanced solutions for the production of building materials. Their expertise in engineering and manufacturing has enabled them to create a Roofing Making Machine that sets new standards in the industry.The Roofing Making Machine is equipped with advanced technology that allows for seamless and rapid production of roofing materials. It is capable of producing a wide range of roofing sheets, including corrugated, trapezoidal, and other custom designs, meeting the diverse needs of the market. The machine’s precise control and automated operation ensure consistent quality and uniformity in the manufactured roofing sheets, resulting in a superior end product.The efficiency and productivity of the Roofing Making Machine have been lauded by industry experts and customers alike. Its high-speed production capabilities and low maintenance requirements make it a cost-effective solution for companies looking to enhance their manufacturing processes. By significantly reducing the time and labor required for producing roofing materials, the machine enables businesses to increase their output and meet the growing demand in the market.Furthermore, the Roofing Making Machine incorporates features that prioritize safety and environmental sustainability. With comprehensive safety mechanisms and energy-efficient operations, the machine upholds the company’s commitment to responsible manufacturing practices. This aligns with the global movement towards environmentally friendly production methods, positioning the company as a responsible and conscientious industry leader.The company’s dedication to customer satisfaction is evident in its commitment to providing comprehensive support and training for clients who invest in the Roofing Making Machine. From installation and set-up to ongoing maintenance and technical assistance, the company ensures that its customers can maximize the benefits of their investment and optimize the performance of the equipment.The introduction of the Roofing Making Machine has created a significant impact on the roofing industry, empowering companies to elevate their manufacturing capabilities and deliver superior products to their customers. The machine’s advanced technology and efficiency have set a new benchmark for the industry, driving competitiveness and innovation in the market. Moreover, its adherence to safety and sustainability standards reflects the company’s vision for a progressive and responsible approach to business.In conclusion, the Roofing Making Machine produced by the pioneering company has emerged as a game-changer in the roofing industry. Its cutting-edge technology, robust performance, and commitment to excellence have redefined the manufacturing process for roofing materials, paving the way for enhanced productivity and quality. As the industry continues to evolve, the Roofing Making Machine stands as a testament to the power of innovation and engineering in creating transformative solutions for businesses. With its proven track record and customer-centric approach, the company and its revolutionary machine are poised to shape the future of the roofing industry.

High-Quality Corrugated Iron Roofing Sheet Making Machine for Sale

In recent news, the Corrugated Iron Roofing Sheet Making Machine has been making waves in the construction industry. This cutting-edge machine, developed by a leading manufacturing company, is revolutionizing the production of corrugated iron roofing sheets, and is set to have a major impact on the construction sector.The {Company Name} has been at the forefront of innovation in the manufacturing industry for over two decades. With a strong focus on research and development, they have consistently pushed the boundaries of what is possible, and the Corrugated Iron Roofing Sheet Making Machine is a testament to their commitment to excellence.This state-of-the-art machine is designed to streamline the production process of corrugated iron roofing sheets, significantly reducing manufacturing time and costs. With its advanced technology and precision engineering, the machine is capable of producing high-quality roofing sheets at an unprecedented speed, without compromising on durability.The Corrugated Iron Roofing Sheet Making Machine is equipped with a range of cutting-edge features that set it apart from traditional manufacturing methods. Its automated operation allows for seamless production, with minimal human intervention required. This not only increases efficiency, but also reduces the risk of human error, ensuring consistently high-quality output.Furthermore, the machine's modular design offers versatility and scalability, allowing for easy customization and expansion as per the specific requirements of the production facility. This flexibility makes it suitable for a wide range of applications, from small-scale operations to large industrial facilities.The {Company Name}'s commitment to sustainability is also evident in the design of the Corrugated Iron Roofing Sheet Making Machine. By optimizing the use of raw materials and minimizing waste, the machine not only reduces environmental impact but also lowers production costs, making it a cost-effective and eco-friendly solution for the construction industry.In addition to its impressive technical capabilities, the {Company Name} provides comprehensive support and after-sales service for the Corrugated Iron Roofing Sheet Making Machine. Their team of highly skilled technicians and engineers are on hand to provide training, maintenance, and troubleshooting, ensuring that their clients can maximize the potential of the machine.The introduction of the Corrugated Iron Roofing Sheet Making Machine is poised to have a significant impact on the construction industry. The machine's ability to produce high-quality roofing sheets quickly and efficiently will not only benefit manufacturers but also have a positive ripple effect on the wider economy. With its potential to reduce production costs and increase output, the machine has the power to drive growth and innovation in the construction sector.As the demand for durable and cost-effective roofing solutions continues to rise, the Corrugated Iron Roofing Sheet Making Machine is set to play a crucial role in meeting these needs. Its cutting-edge technology, combined with the expertise of the {Company Name}, makes it a game-changer in the manufacturing industry, and a valuable addition to any production facility.In conclusion, the Corrugated Iron Roofing Sheet Making Machine, developed by the {Company Name}, represents a significant leap forward in the manufacturing of corrugated iron roofing sheets. Its innovative design, advanced features, and commitment to sustainability make it an invaluable asset for the construction industry. With its potential to drive efficiency, reduce costs, and increase output, this machine is set to revolutionize the way roofing sheets are produced, paving the way for a more sustainable and prosperous future in the construction sector.

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

Discover the Latest Innovation in Purlin Roll Forming Technology" -> "Revolutionize Your Purlin Production with New Roll Forming Technology

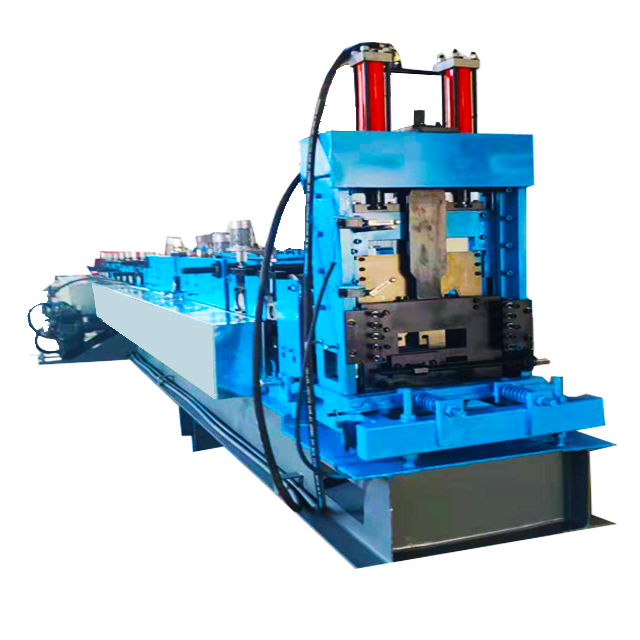

Purlin forming machines have been gaining much popularity in the construction industry lately, as they help fabricate high-quality metal sections for roofing and wall systems. These machines are known for their efficient production capabilities, precise measurements, and excellent quality. Therefore, they've become a necessary asset for companies that specialize in the production of purlin sheets.One of the leading companies in the production of purlin forming machines is a well-renowned manufacturer that has been catering to the construction industry for decades. The company, which will not be named, is a highly respected name in the industry with years of experience and expertise in manufacturing high-end building solutions.The company focuses on designing and producing advanced purlin forming machines that are tailored to meet the needs of professionals in the construction industry. The machines produced are versatile and can be used to manufacture different types of purlin sheets, including C, Z, and U-section profiles.One of the highlights of the company's purlin forming machines is their quality. The machines are built to the highest standards, and quality is at the core of the manufacturing process. Each machine is tested meticulously several times before it's shipped to the client. This ensures that the machine is working optimally and to the satisfaction of the client.Apart from quality, the company's purlin forming machines boast a user-friendly interface that makes them extremely easy to operate. The interface is designed with the operator in mind, and it's intuitive, allowing for quick learning and efficient operation. The machines also have advanced safety features that ensure the safety of the operators during the production process.The company's purlin forming machines use the latest technology, which guarantees accurate and precise measurements. The machines are capable of producing purlin sheets with thicknesses of up to 3mm and lengths of up to 9m. They can also produce sheets with different gauges, allowing for flexibility in the production process.Moreover, the purlin forming machines are designed for durability and longevity. They are made from high-quality materials that can withstand the rigours of daily use in the construction industry. The machines are also low-maintenance, reducing downtime and increasing productivity.The company has an excellent customer service team that provides support to clients throughout the purchase and installation process. The team is composed of experienced professionals who understand the needs of clients and are always ready to provide tailored solutions to meet those needs.In conclusion, purlin forming machines are essential tools for the construction industry, and the company, which will not be named, is a trusted manufacturer in the field. Their machines are of high quality, versatile, user-friendly, accurate, and durable. With a reliable customer service team, clients can rest assured that they are in good hands when they invest in the company's purlin forming machines.

Highly Efficient and Advanced Roll Forming Machine for Light Gauge Steel Keels

Light Gauge Steel Keel Roll Forming Machine – Revolutionizing the Construction Industry{Company Introduction}The construction industry has seen significant advancement in recent years with the introduction of new technologies and equipment. One such innovation that has gained tremendous popularity is the light gauge steel keel roll forming machine. These machines are used to produce steel keels that are widely used in construction projects.As the name suggests, light gauge steel keel roll forming machines are designed to produce lightweight steel keels that are used for various purposes in construction projects, such as drywall partitioning, suspended ceilings, and wall framing. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy.The Advantages of Light Gauge Steel Keel Roll Forming MachinesOne of the biggest advantages of light gauge steel keel roll forming machines is their ability to produce steel keels of various sizes and shapes. This means that these machines can produce steel keels that are tailor-made to suit specific construction needs. The use of steel keels produced by these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects.Another significant advantage of light gauge steel keel roll forming machines is their efficiency. These machines are designed to operate at high speeds, which results in a higher production rate and reduced labor costs. Additionally, the use of these machines reduces the need for on-site welding, which not only saves time but also results in higher quality work. Furthermore, these machines can produce steel keels continuously, which means that the production process is faster, more efficient, and more streamlined.Light gauge steel keel roll forming machines are also highly versatile. These machines can produce steel keels of different thicknesses, lengths, and shapes, which means that they can be used in a wide range of construction projects. Moreover, these machines are easy to set up, operate, and maintain, which ensures that they can be used by both large-scale and small-scale construction companies.The Future of Light Gauge Steel Keel Roll Forming MachinesThe demand for light gauge steel keel roll forming machines has been steadily increasing in recent years. This trend is expected to continue in the future as more construction companies realize the benefits of using these machines. The rapid urbanization and industrialization of many countries have also contributed to the growing demand for these machines as they can produce high-quality steel keels that are essential for modern construction.Given these factors, it is safe to say that the future of light gauge steel keel roll forming machines looks bright. Advances in technology are expected to make these machines even more efficient, versatile, and user-friendly than they already are. As a result, more construction companies are expected to adopt these machines, leading to increased productivity, reduced labor costs, and improved quality of work.ConclusionThe light gauge steel keel roll forming machine has revolutionized the construction industry by making the production of steel keels more efficient, versatile, and cost-effective. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy, making them ideal for a wide range of construction projects. Additionally, the use of these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects. With the growing demand for these machines, it is safe to say that they will continue to play a major role in the construction industry for years to come.

High-quality Steel Profile Manufacturing Machine for Your Business Needs

Color Steel Profile Manufacturing Machine, a leading manufacturer of steel profile manufacturing machinery, has announced the launch of a new series of cutting-edge machines that are set to revolutionize the industry.With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market."We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.

High-Quality CZ Purlin Roll Forming Machine: Made in China

Are you in the construction industry and looking for a reliable and efficient way to manufacture CZ Purlins? Look no further, as HangZhou Roll Forming Machinery Co.,Ltd has the perfect solution for you - their advanced CZ Purlin Roll Forming Machine, which is making waves in the market. In this blog post, we will dive into the details of this remarkable product, exploring its features, benefits, and why it is a game-changer in the steel manufacturing industry.What is a CZ Purlin, you may ask? Well, it is a structural member found in roof trusses and walls to provide support and stability to a building. CZ Purlins are widely used in industrial and commercial construction due to their versatility and strength. With the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd, producing these components becomes a breeze.Now, let's take a closer look at this exceptional machine. Equipped with cutting-edge technology, the CZ Purlin Roll Forming Machine is designed to optimize efficiency and productivity. Its high-speed production capability can churn out CZ Purlins with incredible precision and accuracy, meeting the strictest industry standards. With this machine, you can say goodbye to manual labor-intensive processes and hello to automated precision manufacturing.One of the notable features of the CZ Purlin Roll Forming Machine is its versatility. It can handle various sizes and thicknesses of CZ Purlins, allowing you to cater to different construction needs. This flexibility is a huge advantage, as it eliminates the need to invest in multiple machines for different CZ Purlin specifications. With just one machine, you can produce a wide range of CZ Purlins, saving both space and resources.The CZ Purlin Roll Forming Machine boasts a user-friendly interface, making it accessible to operators of all skill levels. Its intuitive controls and adjustable parameters empower operators to customize output according to specific project requirements. Whether you need CZ Purlins for low-rise or high-rise buildings, this machine can adapt to meet your demands.Durability and reliability are crucial when it comes to machinery, and the CZ Purlin Roll Forming Machine does not disappoint. Built with top-quality materials, it can withstand heavy-duty usage and deliver consistent results over an extended period. This machine is engineered to endure the demands of high-volume production without compromising on its precision and performance.However, the advantages of the CZ Purlin Roll Forming Machine go beyond its features. Investing in this machine can yield significant benefits for your business. Firstly, it eliminates the need for outsourcing CZ Purlin production, saving you time and money. By bringing the manufacturing process in-house, you gain better control over your supply chain, ensuring uninterrupted production and timely delivery.Secondly, the CZ Purlin Roll Forming Machine enhances the overall quality of your CZ Purlins, which boosts customer satisfaction and improves your reputation. With precise dimensions, consistent results, and superior strength, your clients will have confidence in your product. This, in turn, leads to increased customer loyalty and repeat business.Moreover, the CZ Purlin Roll Forming Machine promotes sustainability. By being more energy-efficient and reducing material waste, it aligns with environmental regulations and supports your company's commitment to a greener future. Not only will you benefit from cost savings, but you will also contribute positively to the environment.In conclusion, the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd is a game-changer in the steel manufacturing industry. Its advanced technology, versatility, user-friendly interface, durability, and numerous benefits make it a must-have for any construction company. With this machine, you can streamline your production process, enhance your product quality, and position your business for growth and success. Say goodbye to manual labor and inefficiency, and embrace automation and precision with the CZ Purlin Roll Forming Machine.