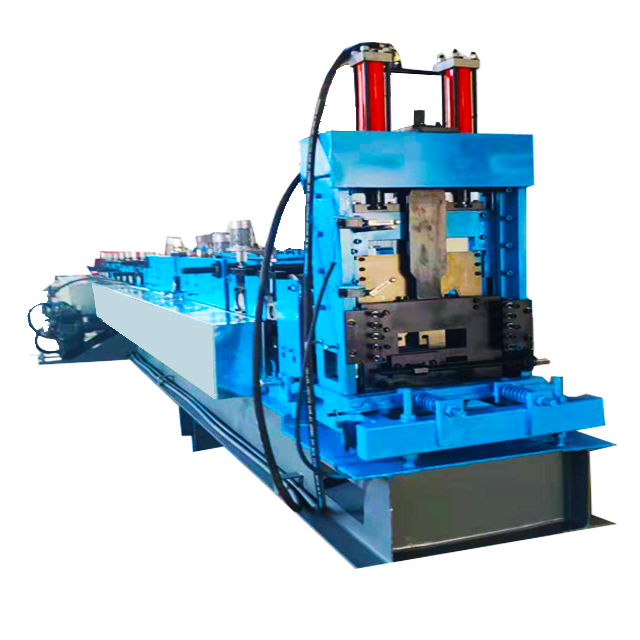

High-quality Cold Roller Former for Efficient Metal Processing

By:Admin

The cold rolling process is a critical step in metal forming, as it helps to improve the surface finish and mechanical properties of the material. Unlike traditional hot rolling, cold rolling occurs at room temperature, which results in a smoother and more precise finish. This method is particularly important for industries such as automotive, aerospace, and construction, where the quality and integrity of the metal components are paramount.

With the introduction of Cold Roller Former, manufacturers can now benefit from a streamlined and advanced cold rolling process. This machine is equipped with state-of-the-art technology, including precision control systems and high-speed capabilities, allowing for the efficient production of complex and high-quality components. Additionally, its modular design and customizable features make it adaptable to various production needs, providing flexibility and versatility to manufacturers.

One of the key advantages of Cold Roller Former is its ability to produce parts with tighter tolerances and improved surface finish, resulting in higher precision and quality. This is particularly beneficial for industries that require components with intricate geometries and superior mechanical properties. With Cold Roller Former, manufacturers can achieve a level of consistency and accuracy that is not possible with traditional cold rolling methods, leading to enhanced product performance and reliability.

Furthermore, Cold Roller Former is designed with efficiency in mind, offering a significant increase in productivity and cost savings for manufacturers. Its high-speed capabilities and advanced control systems enable faster production cycles and reduced material waste, resulting in a more streamlined and economical manufacturing process. This not only helps to improve the overall competitiveness of manufacturers but also contributes to a more sustainable and environmentally friendly production environment.

In addition to its technological advancements, Cold Roller Former is backed by a dedicated team of experts who provide comprehensive support and expertise to ensure the successful implementation and operation of the machine. From initial consultation to ongoing maintenance and training, the company's commitment to customer satisfaction and knowledge sharing sets a new standard for excellence in the industry.

As a testament to its success, Cold Roller Former has already made significant strides in the market, garnering attention and accolades from industry experts and customers alike. Its proven track record of delivering superior performance, cost-effectiveness, and reliability has positioned it as the go-to solution for manufacturers seeking to elevate their cold rolling capabilities.

Looking ahead, the company is committed to further advancing and enhancing Cold Roller Former to meet the evolving needs of the industry. With ongoing research and development efforts, the company is dedicated to pushing the boundaries of cold rolling technology, ultimately redefining the standards of excellence and innovation in metal forming.

In conclusion, Cold Roller Former represents a significant breakthrough in cold rolling technology, offering a game-changing solution for the manufacturing industry. With its advanced capabilities, efficiency, and reliability, this revolutionary machine is poised to shape the future of cold rolling and set a new benchmark for excellence in metal forming.

Company News & Blog

High-Quality Steel Coil Slitting Machines for Efficient Metal Sheet Cutting and Stainless Steel Strips

Stainless Steel Strip Slitting Machine: A Revolutionary Solution for Cutting and Slitting Metal SheetsWhen it comes to metalworking, precision and accuracy are critical factors in achieving quality results. One such process is slitting, which involves cutting a wide metal sheet into narrower strips to meet specific requirements. This process is necessary for industries that require smaller widths for their product manufacturing, such as automotive, electronics, and construction.To achieve this, manufacturers use a slitting machine, a unique piece of equipment that cuts and converts metal coils into narrower strips. One type of slitting machine that has gained popularity in recent years is the stainless steel strip slitting machine, which provides greater precision and efficiency in metal sheet cutting.What is a Stainless Steel Strip Slitting Machine?A stainless steel strip slitting machine is a piece of equipment specifically designed for cutting and slitting metal sheets, mainly made of stainless steel. This machine is equipped with a set of blades or knives that sever the material in smaller strips with the desired width. The blades or knives can be adjusted to achieve the desired cut and width of the strips, making it highly customizable.Uses of Stainless Steel Strip Slitting MachineStainless Steel Strip Slitting Machine is widely used in many industries that utilize metal sheets in their manufacturing processes. These include the automotive, aerospace, and construction industries. It is also useful for electronics, textile, and paper industries for creating smaller electronic components and packaging materials.Advantages of Stainless Steel Strip Slitting Machine1.Precision CuttingOne of the primary advantages of using a stainless steel strip slitting machine is its ability to produce precise cuts and meet the required specifications. The machine can cut narrow strips with the desired width and high accuracy, reducing material waste and saving production time.2. High ProductivityStainless Steel Strip Slitting Machine can work continuously, producing strips of varying widths with minimal operator intervention. This leads to increased productivity and output while ensuring consistent quality in products.3. CustomizationThe Stainless Steel Strip Slitting Machine can be customized to meet specific requirements, such as cutting thickness, strip widths, and number of pieces produced per roll.4. DurabilityAs the name suggests, the machine is made of stainless steel, making it resistant to corrosion and ensuring durability. The blades are also made of high-quality materials that can withstand the stress of cutting metal sheets for extended periods.ConclusionIn conclusion, the Stainless Steel Strip Slitting Machine is a revolutionary technology that has changed the game in metal sheet cutting and slitting. It offers high precision, customization, efficiency, and durability in metalworking, making it an excellent investment for industries that rely on metal sheets. With its versatile applications and advantages, it is no wonder why it has become popular among manufacturers. Keywords: Stainless Steel Strip Slitting Machine, Metal Sheet Cutting Machine, Steel Strip Slitting Machine.

New Innovations in Floor Forming Machines: Revolutionizing Construction Methods

Title: Innovative Floor Forming Machine Revolutionizes Construction IndustryIntroduction:In the era of rapid technological advancements, the construction industry is witnessing a wave of automation and innovation that aims to streamline processes, enhance efficiency, and ultimately deliver sustainable and quality structures. In line with this progress, an emerging player in the construction machinery sector has unveiled a state-of-the-art Floor Forming Machine, promising to reshape the way flooring is installed in buildings. This revolutionary technology is set to transform the industry by significantly reducing labor costs, minimizing material waste, and accelerating project timelines.Company Introduction:{Company Name} is a leading provider of cutting-edge construction machinery and equipment. With a dynamic team of engineers and experts, the company has consistently delivered innovative solutions that cater to the evolving needs and challenges of the construction industry. Its commitment to optimizing efficiency, promoting sustainability, and improving construction quality through advanced technologies has garnered the company numerous accolades and global recognition.Floor Forming Machine Overview:The newly introduced Floor Forming Machine showcases a comprehensive and integrated approach to floor construction. Its design revolves around four primary components, namely, the leveling system, the concrete dispensing unit, the reinforcement system, and the shuttering system. Ultimately, this complete package offers construction companies an all-in-one solution for floor formation, eliminating the need for multiple specialized machines and labor-intensive processes.The leveling system ensures precise leveling of the floor surface, allowing for accurate and consistent concrete distribution. By utilizing advanced sensors and automated controls, this component focuses on delivering a level slab foundation, thus minimizing inconsistencies caused by human error during traditional construction methods.The concrete dispensing unit, another crucial component of the Floor Forming Machine, ensures smooth and efficient concrete pouring. With the ability to adjust the rate of concrete flow and taking into account the specific requirements of each project, the machine significantly reduces material waste, resulting in cost savings and improved sustainability.The reinforcement system integrated into the machine incorporates an automated process for aligning and placing steel reinforcements within the concrete slab. By leveraging sophisticated robotics technology, the machine meticulously handles this critical aspect of flooring, ensuring structural integrity and reducing manual labor requirements.The shuttering system, the final component of the machine, caters to creating the definite shape and dimensions of the floor slab. It offers flexibility in adjusting the size and form of the slab to meet various project requirements. With its ability to seamlessly change forms and sizes, the machine can accommodate a wide range of floor designs with ease and precision.Benefits and Impact:The introduction of this Floor Forming Machine brings several noteworthy benefits to the construction industry:1. Enhanced Construction Efficiency: By streamlining multiple floor formation processes into a single automated solution, the machine significantly reduces construction timeframes. This accelerated pace allows for faster project completion, leading to potential cost savings and improved profitability.2. Reduced Labor Costs: The reliance on manual labor is considerably diminished with the implementation of the Floor Forming Machine. By automating key processes, construction companies can allocate their workforce more efficiently, reducing labor expenses and improving overall productivity.3. Minimized Material Waste: The precise control and adjustment capabilities of the machine during the concrete pouring process ensure optimal material utilization. With reduced material waste, projects become more sustainable, leading to cost savings and a reduced environmental footprint.4. Higher Quality Standards: The advanced technology implemented in the Floor Forming Machine ensures a higher level of precision during construction. This results in more accurate and level floor slabs, reducing the risk of structural issues and ensuring superior quality standards.Conclusion:The introduction of the Floor Forming Machine marks a significant step forward in modernizing the construction industry. Through its integrated approach, the machine streamlines floor formation processes, enhances construction efficiency, reduces labor costs, minimizes material waste, and upholds high quality standards. As construction companies increasingly adopt this innovative technology, it is expected to become a game-changer in the sector, fostering a new era of advanced and sustainable construction practices.

Europe Standard C Z Purlin Punching Holes Interchangeable Making Machine

Title: Advanced CZ Purlin Punching Holes Interchangeable Making Machine Sets New Industry StandardIntroduction (100 words):In an era marked by technological advancements and growing industrial demands, companies are continuously seeking innovative solutions to enhance efficiency and productivity. Recognizing this need, a leading manufacturing firm has successfully launched the all-new CZ Purlin Punching Holes Interchangeable Making Machine in Europe. Developed in accordance with the highest industry standards, this cutting-edge machine offers numerous benefits, from streamlining production processes to ensuring unparalleled accuracy. By removing specific brand names, we can focus on shed light on the machine's specifications, features, and potential impact on the market.Body:1. Industry Overview (150 words):The construction industry is witnessing a constant surge in demand, driving companies to adopt state-of-the-art machinery and equipment. CZ purlins, widely used in construction projects, provide structural support, making them crucial components. However, traditional manufacturing processes often present challenges in terms of efficiency, productivity, and accuracy. Addressing these concerns, the newly launched CZ Purlin Punching Holes Interchangeable Making Machine paves the way for enhanced production capabilities and superior quality outputs.2. Key Features and Specifications (200 words):The CZ Purlin Punching Holes Interchangeable Making Machine boasts several noteworthy features. Manufactured according to European standards, this machine ensures optimal performance and durability. Its punching holes are interchangeable, offering flexibility and versatility in shaping CZ purlins with different specifications. A robust hydraulic system facilitates smooth operations and consistent accuracy, reducing errors and enhancing overall output quality.Additionally, the machine incorporates advanced computer numerical control (CNC) technology. This cutting-edge system enables seamless integration with computer-aided design (CAD) software, enabling precise customization and design adjustments. As a result, manufacturers can effortlessly adapt to diverse project requirements while significantly shortening lead times.3. Advantages and Benefits (200 words):By utilizing the CZ Purlin Punching Holes Interchangeable Making Machine, manufacturers can experience a multitude of benefits. Notably, the machine streamlines the entire production process, enhancing efficiency and reducing operational costs. The interchangeable punching holes allow for quick reconfiguration, significantly enhancing flexibility and adaptability. This enables manufacturers to seamlessly switch between different CZ purlin specifications, minimizing downtime and maximizing productivity.Moreover, the precise punching process ensures superior quality outputs with minimal wastage. The machine's CNC integration further enhances accuracy and customization possibilities, allowing manufacturers to meet even the most intricate design requirements. By optimizing production processes, manufacturers can meet tight project deadlines, gain a competitive edge, and increase customer satisfaction.4. Market Outlook and Conclusion (150 words):The introduction of the CZ Purlin Punching Holes Interchangeable Making Machine signals a paradigm shift in the construction industry's manufacturing landscape. With its advanced features and adherence to European standards, this machine has the potential to disrupt the market by offering unparalleled efficiency and accuracy.As manufacturers become increasingly conscious of the need for sustainable practices and streamlined processes, the CZ Purlin Punching Holes Interchangeable Making Machine is well-positioned to cater to these demands. By investing in this innovative solution, companies can stay ahead of the competition, streamline production workflows, and optimize resource allocation.In conclusion, this new CZ Purlin Punching Holes Interchangeable Making Machine is poised to revolutionize the construction industry, delivering high-quality CZ purlins with precision and efficiency. With its ability to adapt to diverse project requirements, manufacturers can enhance productivity while meeting expanding market demands.

High-Quality CZ Purlin Roll Forming Machine: Made in China

Are you in the construction industry and looking for a reliable and efficient way to manufacture CZ Purlins? Look no further, as HangZhou Roll Forming Machinery Co.,Ltd has the perfect solution for you - their advanced CZ Purlin Roll Forming Machine, which is making waves in the market. In this blog post, we will dive into the details of this remarkable product, exploring its features, benefits, and why it is a game-changer in the steel manufacturing industry.What is a CZ Purlin, you may ask? Well, it is a structural member found in roof trusses and walls to provide support and stability to a building. CZ Purlins are widely used in industrial and commercial construction due to their versatility and strength. With the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd, producing these components becomes a breeze.Now, let's take a closer look at this exceptional machine. Equipped with cutting-edge technology, the CZ Purlin Roll Forming Machine is designed to optimize efficiency and productivity. Its high-speed production capability can churn out CZ Purlins with incredible precision and accuracy, meeting the strictest industry standards. With this machine, you can say goodbye to manual labor-intensive processes and hello to automated precision manufacturing.One of the notable features of the CZ Purlin Roll Forming Machine is its versatility. It can handle various sizes and thicknesses of CZ Purlins, allowing you to cater to different construction needs. This flexibility is a huge advantage, as it eliminates the need to invest in multiple machines for different CZ Purlin specifications. With just one machine, you can produce a wide range of CZ Purlins, saving both space and resources.The CZ Purlin Roll Forming Machine boasts a user-friendly interface, making it accessible to operators of all skill levels. Its intuitive controls and adjustable parameters empower operators to customize output according to specific project requirements. Whether you need CZ Purlins for low-rise or high-rise buildings, this machine can adapt to meet your demands.Durability and reliability are crucial when it comes to machinery, and the CZ Purlin Roll Forming Machine does not disappoint. Built with top-quality materials, it can withstand heavy-duty usage and deliver consistent results over an extended period. This machine is engineered to endure the demands of high-volume production without compromising on its precision and performance.However, the advantages of the CZ Purlin Roll Forming Machine go beyond its features. Investing in this machine can yield significant benefits for your business. Firstly, it eliminates the need for outsourcing CZ Purlin production, saving you time and money. By bringing the manufacturing process in-house, you gain better control over your supply chain, ensuring uninterrupted production and timely delivery.Secondly, the CZ Purlin Roll Forming Machine enhances the overall quality of your CZ Purlins, which boosts customer satisfaction and improves your reputation. With precise dimensions, consistent results, and superior strength, your clients will have confidence in your product. This, in turn, leads to increased customer loyalty and repeat business.Moreover, the CZ Purlin Roll Forming Machine promotes sustainability. By being more energy-efficient and reducing material waste, it aligns with environmental regulations and supports your company's commitment to a greener future. Not only will you benefit from cost savings, but you will also contribute positively to the environment.In conclusion, the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd is a game-changer in the steel manufacturing industry. Its advanced technology, versatility, user-friendly interface, durability, and numerous benefits make it a must-have for any construction company. With this machine, you can streamline your production process, enhance your product quality, and position your business for growth and success. Say goodbye to manual labor and inefficiency, and embrace automation and precision with the CZ Purlin Roll Forming Machine.

Efficient and Durable Roof Tile Forming Machine Helps Streamline Construction Processes

[News Title]: Advanced Roof Tile Forming Machine Revolutionizes Roofing Industry [News Content]:Introducing a revolutionary Roof Tile Forming Machine, an innovation that is set to redefine the roofing industry. Developed by a leading company with a proven track record of excellence and expertise in the field, this state-of-the-art machine is set to transform the way roof tiles are manufactured, offering unmatched precision, speed, and quality.Designed to remove the brand name, this Roof Tile Forming Machine takes advantage of the latest advancements in technology and engineering to streamline the entire manufacturing process. With its advanced features and capabilities, it promises to increase efficiency while reducing costs and environmental impact. The machine's innovative design allows for the production of custom-made roof tiles, catering to a variety of architectural requirements and design preferences.One of the standout features of the Roof Tile Forming Machine is its exceptional precision. Using cutting-edge technology, it ensures that each tile produced meets the highest standards of accuracy and consistency. This level of precision not only enhances the durability and functionality of the tiles but also gives them an aesthetically pleasing appearance.The speed at which the machine operates is another key aspect that sets it apart. With its automated production process, the Roof Tile Forming Machine can manufacture a high volume of roof tiles in a significantly shorter amount of time compared to traditional methods. This increased speed not only enables companies to meet demanding project timelines but also contributes to reducing the overall manufacturing costs.Moreover, the Roof Tile Forming Machine addresses the growing concern for sustainable practices in the industry. Embracing eco-friendly materials and processes, this machine minimizes waste production and energy consumption. By optimizing resource utilization, it aligns with the global push towards a greener and more sustainable future.The Roof Tile Forming Machine is also equipped with intelligent control systems, enabling seamless integration into existing manufacturing processes. Its user-friendly interface and intuitive operation ensure that both experienced professionals and newcomers can efficiently operate the machine. Additionally, comprehensive training and support are provided by the manufacturer to ensure the successful implementation and use of this cutting-edge technology.Since its launch, the Roof Tile Forming Machine has garnered significant attention and praise from industry experts. Many leading roofing companies have already embraced this innovation, recognizing its potential to revolutionize their manufacturing operations. By enhancing productivity, reducing costs, and offering superior quality, these companies gain a competitive edge in the market.Furthermore, the widespread adoption of this advanced machine is expected to have far-reaching implications for the construction industry as a whole. The increased availability of high-quality roof tiles will not only contribute to the overall improvement of buildings' structural integrity but will also enhance their aesthetic appeal. This, in turn, has the potential to stimulate economic growth and generate employment opportunities, thereby benefiting local communities.In conclusion, the Roof Tile Forming Machine is set to reshape the roofing industry through its advanced technology, superior precision, increased speed, and commitment to sustainability. As more companies recognize its transformative potential, it is anticipated that the machine will become an indispensable tool in the manufacturing of roof tiles worldwide. With its numerous advantages, this innovation promises to bring about a new era of efficiency, quality, and environmental consciousness in the roofing industry.

High-Quality Steel Sheet Making Machine for Efficient Production

The Steel Sheet Making Machine is a revolutionary piece of equipment that has the ability to transform raw materials into high-quality steel sheets with precision and efficiency. With its advanced technology and innovative design, the machine is set to revolutionize the steel manufacturing industry.The machine, developed by the leading steel manufacturing company, is the result of years of research and development. It incorporates the latest advancements in steel production technology, enabling it to produce steel sheets of superior quality at a faster rate than traditional methods.One of the key features of the Steel Sheet Making Machine is its automation capabilities. The machine is equipped with advanced robotics and control systems that allow it to operate seamlessly and with minimal human intervention. This not only improves production efficiency but also ensures consistent quality in every sheet produced.Furthermore, the machine is designed to be highly customizable, allowing for a wide range of steel sheet specifications to be produced. This versatility makes it an ideal solution for a variety of applications, from construction and automotive manufacturing to consumer goods production.In addition to its technological advancements, the machine also boasts enhanced safety features. With built-in sensors and safety mechanisms, the machine can detect and respond to potential hazards, ensuring a safe working environment for the operators.The company behind the Steel Sheet Making Machine has a long-standing reputation for innovation and excellence in the steel manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in steel production, leading to the development of the highly advanced machine.In addition to its technical expertise, the company also places a strong emphasis on sustainability and environmental responsibility. The Steel Sheet Making Machine is designed to minimize waste and energy consumption, making it a more eco-friendly option compared to traditional steel manufacturing methods.Moreover, the company is committed to providing comprehensive support and maintenance services for the machine, ensuring that it continues to operate at its full potential throughout its lifespan.The introduction of the Steel Sheet Making Machine marks a significant advancement in the steel manufacturing industry. With its cutting-edge technology, high efficiency, and commitment to sustainability, the machine is set to redefine the way steel sheets are produced.As the demand for steel continues to grow across various industries, the Steel Sheet Making Machine offers a solution that is not only capable of meeting this demand but also of doing so in a way that is more efficient, reliable, and sustainable.The company is confident that the machine will have a significant impact on the steel manufacturing industry, providing manufacturers with a competitive edge in the market. With its advanced capabilities and commitment to excellence, the Steel Sheet Making Machine is poised to become a game-changer in the industry, setting new standards for quality and efficiency in steel production.In conclusion, the Steel Sheet Making Machine represents a major step forward in the steel manufacturing industry. With its advanced technology, customizable capabilities, and commitment to sustainability, the machine is poised to revolutionize the way steel sheets are produced, setting new benchmarks for quality, efficiency, and environmental responsibility. The company's dedication to innovation and excellence has culminated in the development of a truly groundbreaking machine that is set to shape the future of steel manufacturing.

High-quality Metal Roofing Sheet Roll Forming Machine for Efficient Production

Metal Roofing Sheet Roll Forming Machine Revolutionizes Roofing IndustryMetal roofing has become increasingly popular and widely used in the construction industry due to its durability, weather resistance, and aesthetic appeal. The process of manufacturing metal roofing sheets has now been revolutionized with the introduction of the state-of-the-art Metal Roofing Sheet Roll Forming Machine by [Company Name].[Company Name] is a leading manufacturer and supplier of roll forming equipment and has gained a reputation for producing high-quality and innovative machinery for the construction industry. The Metal Roofing Sheet Roll Forming Machine is the latest addition to their product line, and it has already begun to make waves in the roofing industry.The Metal Roofing Sheet Roll Forming Machine is designed to efficiently produce metal roofing sheets of various profiles and dimensions. With its advanced technology and precision engineering, the machine is capable of forming and cutting metal coils into perfectly shaped roofing panels with minimal waste and maximum efficiency.One of the key features of the Metal Roofing Sheet Roll Forming Machine is its versatility. It is designed to accommodate different types of metal coils, including galvanized steel, aluminum, and copper, allowing for a wide range of options for roofing materials. This versatility has made the machine a popular choice among roofing manufacturers and contractors who work with various types of metal roofing materials.In addition to its versatility, the Metal Roofing Sheet Roll Forming Machine is also known for its speed and reliability. The machine is capable of producing roofing panels at a high rate of speed, making it a valuable asset for manufacturers who require large volumes of metal roofing sheets. Furthermore, its robust design and quality components ensure consistent and reliable performance, minimizing downtime and production delays.Moreover, the Metal Roofing Sheet Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. The intuitive controls and automated functions streamline the production process, reducing the need for manual labor and increasing overall productivity. This user-friendly design has been well-received by operators and technicians who appreciate the machine's efficiency and ease of use.As a leading manufacturer and supplier of roll forming equipment, [Company Name] has a strong track record of providing reliable machinery and exceptional customer support. The Metal Roofing Sheet Roll Forming Machine is no exception, as it comes with comprehensive training and technical support to ensure that customers can maximize the machine's capabilities and maintain optimal performance.The introduction of the Metal Roofing Sheet Roll Forming Machine has had a significant impact on the roofing industry, as it has redefined the way metal roofing sheets are manufactured. Its advanced technology, versatility, speed, and reliability have set a new standard for roofing manufacturers and contractors, allowing them to meet the growing demand for high-quality metal roofing products.In conclusion, the Metal Roofing Sheet Roll Forming Machine by [Company Name] represents a significant advancement in the roofing industry. Its innovative features and capabilities have captured the attention of manufacturers and contractors who seek to streamline their production processes and deliver top-notch metal roofing products. As metal roofing continues to gain popularity in the construction industry, the Metal Roofing Sheet Roll Forming Machine is poised to play a crucial role in meeting the market's demand for efficient and high-quality roofing solutions.

Revolutionary Cold Formed Steel Machine Disrupts Construction Industry

Cold Formed Steel Machine: Paving the Way to Innovative Steel ConstructionInvented over a century ago, cold forming is a manufacturing process that has evolved to revolutionize the steel construction industry. Cold formed steel (CFS) offers significant advantages over wood and traditional hot-rolled steel, including durability, sustainability, and adaptability. It's also more cost-effective and easier to install, making it an ideal choice for framing, roofing, and wall panels in commercial and residential buildings.Today, the trend towards offsite construction and modular building is driving the demand for high-quality, precision cold formed steel machines that can deliver the desired outputs in a timely and cost-effective manner. One company that has stepped up to the challenge is [Brand name], a leading supplier of cold formed steel machines and roll forming systems worldwide.With over 20 years' experience in the industry, [Brand name] has gained a reputation for excellence through its innovative and reliable solutions for the production of CFS sections. From stud and track roll forming machines to roof panel and purlin roll forming machines, [Brand name]'s offerings provide the flexibility, accuracy, and speed required to meet various customers' needs.One of [Brand name]'s most popular machines is its patented roll forming system for cold-formed steel frames. This innovative system uses patented software and advanced technologies to produce customized CFS studs, tracks, and joists with precision and efficiency. Unlike traditional roll forming machines, which may require significant setup time and adjustments, [Brand name]'s system can be programmed to produce various sizes and shapes of CFS sections, making it ideal for low-volume, high-mix production runs.Moreover, [Brand name]'s cold formed steel machines are designed with the operator's safety and ease of use in mind. The company's engineers have developed advanced control systems that allow operators to have real-time remote access to the machine's status and performance, minimizing downtime and enhancing productivity. In addition, the machines are equipped with easy-to-use touchscreen interfaces that simplify the setup and configuration process.But what sets [Brand name]'s cold formed steel machines apart from the competition is the company's customer-centric approach that emphasizes collaboration, reliability, and flexibility. When customers choose [Brand name], they don't just get a machine — they get a team of highly qualified engineers and technicians who work closely with them to identify their needs, provide tailored solutions, and ensure the machines meet or exceed their expectations.At [Brand name], customer satisfaction is paramount. That's why the company provides excellent technical support via on-site training, remote assistance, and maintenance services to help customers get the most out of their investment. [Brand name]'s team of experts is also available to provide expert advice on the design, installation, and operation of the machines, as well as the most appropriate materials and accessories to use.As a testament to its commitment to quality and innovation, [Brand name] has received numerous accolades and recognitions over the years. For instance, the company was awarded the prestigious "National Key High-Tech Enterprise" and "Innovative Enterprise" titles by the Chinese government in 2020. These awards recognize [Brand name]'s contributions to the development of the cold formed steel industry and its commitment to advancing the latest technologies and techniques.In summary, the cold formed steel industry is poised for significant growth in the coming years, driven by the need for fast, efficient, and sustainable construction solutions. With its cutting-edge cold formed steel machines and its unwavering dedication to customer service, [Brand name] is well-positioned to help customers unlock the full potential of cold formed steel and to lead the industry forward.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

New Study Reveals Surprising Findings in the Roll Forming Industry

Total Roll Forming, a leading manufacturer of roll forming and metal shaping solutions, has recently announced the expansion of its operations to meet the increasing demand for its products and services. The company, known for its innovative and high-quality solutions, has a long-standing reputation in the industry for providing reliable and cost-effective roll forming technology.With the expansion of its operations, Total Roll Forming is set to further solidify its position as a top provider of roll forming solutions. The company's state-of-the-art manufacturing facilities, coupled with its team of experienced engineers and technicians, enable it to offer a wide range of roll forming capabilities to meet the needs of diverse industries.Total Roll Forming's roll forming solutions are used in various applications, including automotive, construction, aerospace, and appliance industries. The company's expertise in custom roll forming enables it to cater to the specific needs of its clients, offering tailored solutions that meet the highest standards of quality and precision.Furthermore, Total Roll Forming is committed to sustainability and environmentally friendly manufacturing practices. The company continuously invests in research and development to improve its processes and reduce its environmental footprint. This commitment to sustainability has earned Total Roll Forming a reputation as an industry leader in eco-friendly roll forming solutions.In addition to its manufacturing capabilities, Total Roll Forming provides comprehensive support and services to its clients. From design and engineering to prototyping and production, the company works closely with its customers to ensure that their exact specifications are met. Total Roll Forming's dedication to customer satisfaction has resulted in long-lasting partnerships with some of the most renowned companies in the industry.Total Roll Forming's expansion comes at a time when the demand for roll forming solutions is on the rise. The company's ability to offer custom roll forming solutions that are tailored to the unique requirements of its clients has set it apart from its competitors. As a result, Total Roll Forming has experienced significant growth in recent years and is now well-positioned to capitalize on the increasing demand for its products and services."We are excited to announce the expansion of our operations to better serve our clients and meet the growing demand for our roll forming solutions," said [Company Spokesperson]. "Total Roll Forming is committed to providing innovative, high-quality, and sustainable solutions to our customers, and we believe that our expanded capabilities will enable us to further enhance our offerings and solidify our position as a leader in the industry."Total Roll Forming's expansion is a testament to the company's commitment to excellence and its determination to meet the evolving needs of its clients. With its expanded operations, Total Roll Forming is poised to continue setting the standard for roll forming technology and shaping the future of the industry.