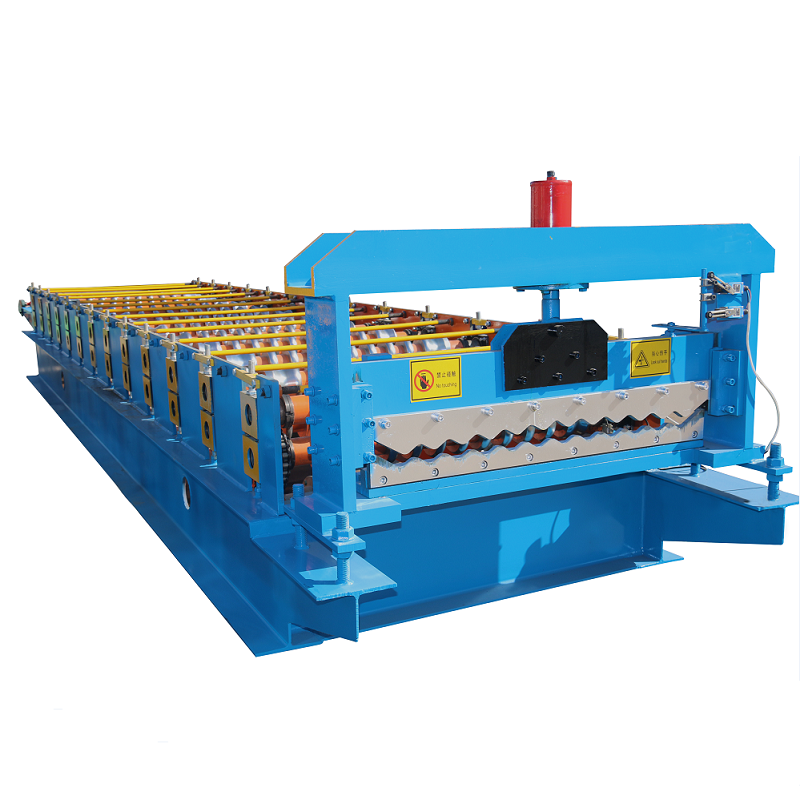

High-Quality Drip Edge Roll Forming Machine: Everything You Need to Know

By:Admin

Roofing is an essential aspect of every building's construction, and a key component of a robust roofing system is the drip edge. Drip edges are designed to protect the edges of the roof from water damage, and they play a crucial role in redirecting water away from the building. With the advancement in technology, the traditional method of manually installing drip edges is now being replaced by the use of Drip Edge Roll Forming Machines, which have proven to be more efficient and cost-effective.

One of the leading manufacturers of Drip Edge Roll Forming Machines is the reputable company {}. Founded in {}, their dedication to innovation and quality has propelled them to the forefront of the industry. Their extensive experience and expertise have enabled them to develop state-of-the-art machinery that meets the specific requirements of the roofing industry.

The Drip Edge Roll Forming Machine offered by {} is designed to produce high-quality drip edges with precision and consistency. The machine is equipped with advanced technology, including computerized controls and automated processes, to ensure accurate and efficient production. This not only improves the overall quality of drip edges but also increases productivity, making it a valuable asset for roofing companies.

One of the key features of {}'s Drip Edge Roll Forming Machine is its versatility. The machine is capable of producing drip edges in various sizes and shapes, catering to the diverse needs of different roofing projects. This level of flexibility allows roofing companies to meet the specific requirements of their clients without compromising on quality or efficiency.

Additionally, the Drip Edge Roll Forming Machine is designed for ease of use and maintenance. With user-friendly controls and a robust construction, the machine ensures smooth operation and minimal downtime. This, in turn, leads to increased productivity and cost savings for roofing companies, making it a wise investment for long-term success.

In an industry where precision and quality are paramount, {}'s Drip Edge Roll Forming Machine stands out as a game-changer. It not only streamlines the production process but also elevates the overall standards of drip edge quality. This has made it a preferred choice for roofing companies looking to stay ahead of the competition and deliver superior results to their clients.

Furthermore, {} takes pride in providing exceptional customer support and technical assistance to ensure that their clients maximize the potential of their Drip Edge Roll Forming Machine. Their commitment to customer satisfaction is reflected in the positive feedback and testimonials from satisfied clients who have experienced the benefits of using {}'s machinery.

As the demand for high-quality roofing solutions continues to grow, the role of Drip Edge Roll Forming Machines in the industry is becoming increasingly significant. With {} at the forefront of innovation, roofing companies can expect to experience unparalleled efficiency and precision in producing drip edges, setting a new standard for excellence in the roofing industry.

In conclusion, {}'s Drip Edge Roll Forming Machine has revolutionized the way drip edges are produced, offering a blend of cutting-edge technology, versatility, and reliability. With its proven track record and commitment to innovation, {} has solidified its position as a trusted provider of machinery for the roofing industry. As the company continues to raise the bar for quality and efficiency, the future looks bright for roofing companies that choose to invest in {}'s Drip Edge Roll Forming Machine.

Company News & Blog

Cutting-Edge Metal Roof Tile Making Machinery: Simplifying Roofing Solutions

[CompanyName], a leading manufacturer of metal roof tile making machines, has recently launched their latest innovation in the field of roofing technology. The new machine, which combines cutting-edge features with utmost reliability, is set to revolutionize the roof tile manufacturing industry.With an increasing demand for durable and energy-efficient roofing solutions, Metal Roof Tile Making Machine is designed to meet the evolving needs of builders and homeowners alike. This innovative machine utilizes state-of-the-art technology to produce high-quality metal roof tiles that are both visually appealing and highly functional.One of the key features of this advanced machine is its ability to produce roof tiles with precision and consistency. Equipped with cutting-edge automation technology, every tile produced by the machine is perfectly shaped and sized, ensuring seamless installation and a uniform appearance on the roof. This precision is highly valued by customers, as it eliminates the need for manual adjustments and guarantees a hassle-free roofing experience.Moreover, Metal Roof Tile Making Machine emphasizes the importance of durability in their product. The machine is engineered to withstand the rigors of continuous operation and is built to last. Every component of the machine is robustly constructed, ensuring that it can handle heavy workloads without compromising its performance or reliability. This feature is particularly essential for manufacturers who aim to maximize productivity and reduce downtime.In addition to its durability, this cutting-edge machine incorporates various energy-saving features that align with global efforts to promote sustainability. Metal Roof Tile Making Machine emphasizes the use of eco-friendly materials and processes, ensuring that the production of roof tiles has a minimal impact on the environment. By implementing energy-efficient practices, manufacturers can reduce their carbon footprint and contribute to a greener future.Furthermore, Metal Roof Tile Making Machine ensures customer satisfaction by offering technologically advanced controls that enable easy operation and optimization of the machine's performance. The intuitive user interface allows operators to monitor and adjust various parameters, ensuring that the machine operates at its optimal efficiency. This feature enables manufacturers to maximize their output while maintaining the highest quality standards.Metal Roof Tile Making Machine has established itself as a trusted brand in the industry. With years of experience and a commitment to excellence, the company has garnered a loyal customer base that spans across the globe. By consistently delivering superior products and exceptional customer service, Metal Roof Tile Making Machine has become a go-to choice for manufacturers and contractors seeking reliable and efficient roof tile manufacturing solutions.As the demand for metal roof tiles continues to rise, Metal Roof Tile Making Machine remains at the forefront of innovation in the industry. The company's unwavering dedication to research and development ensures that their machines embody the latest advancements in technology and meet the evolving needs of customers. With their latest offering, Metal Roof Tile Making Machine has once again set a new standard for excellence in the roofing industry.In conclusion, Metal Roof Tile Making Machine has launched a state-of-the-art machine that combines advanced features, durability, and energy efficiency. This innovation is set to revolutionize the roof tile manufacturing industry by providing manufacturers with a reliable and efficient solution to meet the growing demand for metal roof tiles. With its commitment to quality, sustainability, and customer satisfaction, Metal Roof Tile Making Machine continues to cement its place as an industry leader in roofing technology.

Top Color Steel Glazed Tile Corrugation Equipment for Efficient Production

Color Steel Glazed Tile Corrugation Equipment Meeting Increasing Demand for Premium Building MaterialsAs the global construction industry grows in size and complexity, the demand for high-quality building materials continues to increase. In an effort to meet this demand and drive industrial innovation, Color Steel Glazed Tile Corrugation Equipment (Name of brand removed) has designed and produced a cutting-edge system that delivers premium roofing sheets and wall panels with remarkable precision and efficiency.With over 20 years of experience in manufacturing and engineering, Color Steel Glazed Tile Corrugation Equipment is a trusted leader in the industry that helps companies around the world transform their construction operations. From metal sheets and glazed tiles to corrugated panels and roof ridges, their equipment excels in delivering high-performance building materials that are essential to the construction of modern-day structures.The new Color Steel Glazed Tile Corrugation Equipment is no exception. This innovative production line takes advantage of advanced technologies to create materials that are not only visually appealing but also highly durable and weather-resistant. With a wide range of customization options, clients can easily adapt the equipment to meet their specific requirements to create roofing and wall panel products that stand out in the market.One of the key features of the Color Steel Glazed Tile Corrugation Equipment is its high level of flexibility. The production line can be used to create a wide variety of roofing and wall panel products in various shapes and sizes, including classic corrugated panels, glazed tiles, and classical tiles, both with and without an insulated core. This flexibility enables clients to offer a diverse range of products to their customers while maintaining exceptional quality and speed of production.Another major benefit of the equipment is its high level of accuracy. The production line is computer-controlled, ensuring that products are manufactured to precise standards every time. This accuracy results in dimensional stability, consistency, and perfect curvature of the final products, each of which is important to the successful completion of any construction project.At the heart of the design is the automatic color steel coil feeding and cut-to-length system, which guarantees that materials are processed quickly and efficiently with minimal waste. Additionally, the equipment features an automatic roll forming system and a pressing system for easy panel finishing and shaping.Color Steel Glazed Tile Corrugation Equipment takes pride in its machines' quality and longevity. Each production line component is made from high-quality materials and is designed by a team of experienced engineers to ensure consistent performance and long service life. Regular maintenance and customer service are also available to ensure that the equipment is operational and exceptionally dependable throughout its lifespan.Commenting on this new equipment, a spokesperson for Color Steel Glazed Tile Corrugation Equipment said, "Our innovative production line is designed to offer exceptional performance and versatility across various applications in the construction industry. Through the delivery of high-quality materials and products, we aim to provide cutting-edge solutions to our clients that enable them to stay ahead of the competition and meet the ever-increasing demands of their customers."In conclusion, the Color Steel Glazed Tile Corrugation Equipment is a versatile production line designed for the creation of high-quality building materials. With its cutting-edge technology, precision engineering, and flexibility, it is an essential tool for construction companies looking to innovate and deliver premium products to their customers. As demand for exceptional building materials continues to grow, Color Steel Glazed Tile Corrugation Equipment's new production line will provide construction companies with the competitive edge they need to succeed.

High-quality Metal Roofing Sheet Roll Forming Machine for Efficient Production

Metal Roofing Sheet Roll Forming Machine Revolutionizes Roofing IndustryMetal roofing has become increasingly popular and widely used in the construction industry due to its durability, weather resistance, and aesthetic appeal. The process of manufacturing metal roofing sheets has now been revolutionized with the introduction of the state-of-the-art Metal Roofing Sheet Roll Forming Machine by [Company Name].[Company Name] is a leading manufacturer and supplier of roll forming equipment and has gained a reputation for producing high-quality and innovative machinery for the construction industry. The Metal Roofing Sheet Roll Forming Machine is the latest addition to their product line, and it has already begun to make waves in the roofing industry.The Metal Roofing Sheet Roll Forming Machine is designed to efficiently produce metal roofing sheets of various profiles and dimensions. With its advanced technology and precision engineering, the machine is capable of forming and cutting metal coils into perfectly shaped roofing panels with minimal waste and maximum efficiency.One of the key features of the Metal Roofing Sheet Roll Forming Machine is its versatility. It is designed to accommodate different types of metal coils, including galvanized steel, aluminum, and copper, allowing for a wide range of options for roofing materials. This versatility has made the machine a popular choice among roofing manufacturers and contractors who work with various types of metal roofing materials.In addition to its versatility, the Metal Roofing Sheet Roll Forming Machine is also known for its speed and reliability. The machine is capable of producing roofing panels at a high rate of speed, making it a valuable asset for manufacturers who require large volumes of metal roofing sheets. Furthermore, its robust design and quality components ensure consistent and reliable performance, minimizing downtime and production delays.Moreover, the Metal Roofing Sheet Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. The intuitive controls and automated functions streamline the production process, reducing the need for manual labor and increasing overall productivity. This user-friendly design has been well-received by operators and technicians who appreciate the machine's efficiency and ease of use.As a leading manufacturer and supplier of roll forming equipment, [Company Name] has a strong track record of providing reliable machinery and exceptional customer support. The Metal Roofing Sheet Roll Forming Machine is no exception, as it comes with comprehensive training and technical support to ensure that customers can maximize the machine's capabilities and maintain optimal performance.The introduction of the Metal Roofing Sheet Roll Forming Machine has had a significant impact on the roofing industry, as it has redefined the way metal roofing sheets are manufactured. Its advanced technology, versatility, speed, and reliability have set a new standard for roofing manufacturers and contractors, allowing them to meet the growing demand for high-quality metal roofing products.In conclusion, the Metal Roofing Sheet Roll Forming Machine by [Company Name] represents a significant advancement in the roofing industry. Its innovative features and capabilities have captured the attention of manufacturers and contractors who seek to streamline their production processes and deliver top-notch metal roofing products. As metal roofing continues to gain popularity in the construction industry, the Metal Roofing Sheet Roll Forming Machine is poised to play a crucial role in meeting the market's demand for efficient and high-quality roofing solutions.

Plastic Corrugated Roof Tile Making Machine for Efficient Roofing Tile Production

If you are considering venturing into the roof tile manufacturing business, then it might be a good idea to invest in a plastic corrugated / glazed roof tile making machine. The equipment is versatile and can produce a range of roofing tiles with different styles and designs.At Jiangsu Acemien Machinery Co., Ltd. (ACEMIEN for short), we offer state-of-the-art PVC+ASA co-extrusion roof tile making machines that are designed to meet the demands of modern roofing tile production. Our machines are compact and efficient, and can produce tiles with high quality and accuracy.One of the primary advantages of our corrugated roll making machine is that it uses PVC and ASA materials in the co-extrusion process. PVC (polyvinyl chloride) is a plastic material that has excellent toughness, chemical resistance, and weatherability. ASA (acrylonitrile-styrene-acrylate) is a thermoplastic material that combines the properties of acrylics and styrene plastics.When the two materials are co-extruded, the resultant roofing tiles exhibit superior resistance to weather, UV radiation, and impact. They are also easy to install and maintain, which makes them a popular choice for homeowners and commercial property owners alike.Our PVC+ASA co-extrusion roof tile making machines can produce tiles with various shapes, sizes, colors, and textures. The corrugated roll forming machine can create tiles with a corrugated or waved surface, while the glazed roof tile making machines can generate tiles with a smooth or glossy finish.Our machines are equipped with advanced PLC control systems, which enable the operator to control the various parameters of the production process. The machines also come with automatic cutting and stacking devices, which facilitate a smooth and efficient production workflow.At ACEMIEN, we prioritize the quality and durability of our machines, which is why we use high-grade materials and components in their manufacture. Our machines are designed to operate continuously for long periods, and they have low maintenance requirements, which means that they can help you save time and money in the long run.In conclusion, if you are looking to invest in a high-quality plastic corrugated / glazed roof tile making machine, then ACEMIEN is the right company for you. Our machines are versatile, efficient, and reliable, and can help you meet the demands of the modern roofing tile market. Contact us today to learn more about our PVC+ASA co-extrusion roof tile making machines, and let us help you take your business to the next level!

How an Aluminum Profile Bending Machine Can Benefit Your Business

Aluminum Profile Bending Machine: A Marvel in the Metal Fabrication IndustryMetal fabrication is one of the most important sectors of the manufacturing industry, and its importance cannot be overemphasized. Metal fabrication provides a host of products that are part of our daily lives, from automobiles to household appliances, construction materials, and everything in between. However, metal fabrication is not an easy job. It requires an array of specialized tools and equipment, especially when it comes to bending aluminum profiles. This is where Aluminum Profile Bending Machine comes into play.Aluminum Profile Bending Machine is a revolutionary piece of equipment that has revolutionized the metal fabrication industry. It is designed to bend aluminum profiles with precision and accuracy, creating complex shapes that were once considered impossible. Thanks to this machine, fabricators can now bend aluminum profiles with ease, speed, and efficiency.At its core, an Aluminum Profile Bending Machine utilizes a combination of pressure and heat to bend aluminum profiles into the desired shape. The machine consists of a series of rollers, each of which has a unique shape that corresponds to the desired shape of the end product. The rollers apply pressure to the aluminum profile, gradually bending it into the desired shape.One of the most significant advantages of Aluminum Profile Bending Machines is their versatility. They can bend aluminum profiles in a range of shapes and sizes, from simple curves to complex forms. This machine has made it possible for companies to create custom-designed aluminum profiles that are tailored to their specific needs.The Aluminum Profile Bending Machine is also incredibly efficient. Fabricators can bend numerous profiles with the same machine, which significantly reduces production time and costs. This level of efficiency enables manufacturers to produce high-quality aluminum profiles in large quantities, thereby meeting market demand.One aluminum profile bending machine that stands out from the crowd is the one produced by Rolla-V. Rolla-V is a leading manufacturer of advanced and innovative machines that are used in the metal fabrication industry. Rolla-V's machine is designed to bend aluminum profiles with high precision and speed.Rolla-V's Aluminum Profile Bending Machine is equipped with the latest technology, including hydraulic actuators, an intuitive control panel, and a digital readout system. The hydraulic actuators enable the machine to apply a considerable amount of pressure, which is necessary for bending aluminum profiles. The control panel is user-friendly and allows operators to adjust the settings based on the desired bend angle. The digital readout system is incredibly accurate, ensuring that the aluminum profile is bent to the exact angle specified.Furthermore, Rolla-V's machine is incredibly versatile, capable of bending aluminum profiles in a range of shapes and sizes. The machine's rollers can be changed to accommodate different profiles, making it possible to fabricate custom-designed profiles.Rolla-V's Aluminum Profile Bending Machine is also highly efficient. It can bend numerous profiles in a short amount of time, significantly reducing production costs and increasing profitability. The machine's high level of efficiency has made it a popular choice among fabricators worldwide.In conclusion, the Aluminum Profile Bending Machine is a remarkable piece of equipment that has revolutionized the metal fabrication industry. It has made it possible to bend aluminum profiles with precision, speed, and efficiency, creating complex shapes that were once impossible. Rolla-V's machine is one of the most advanced and innovative machines in the market, providing fabricators with the tools they need to fabricate custom-designed aluminum profiles with ease.

Efficient Sheet Roll Forming Solutions for Your Business

The Sheet Roll Forming Process: A Revolution in Metal FabricationMetal fabrication has long been an essential part of the manufacturing industry, with various methods and technologies continually evolving to meet the increasing demands of modern production. One such innovation is the sheet roll forming process, a highly efficient and versatile method that has revolutionized the way metal sheets are manipulated and shaped.Sheet roll forming involves feeding a metal sheet through a series of roll forming stations, where it is gradually bent, shaped, and formed into the desired profile. Unlike traditional metal fabrication methods such as cutting, stamping, or punching, sheet roll forming allows for continuous and precise shaping of the metal, resulting in a superior quality of the finished product.The process begins with a flat metal sheet being fed into the first set of rolls, where it is gradually bent and formed into the desired shape. As the sheet progresses through each roll forming station, additional features such as holes, slots, and flanges can be added, resulting in a fully formed and customized metal component. The entire process is controlled by a series of precision-engineered rollers and dies, ensuring that the final product meets the exact specifications of the design.The advantages of sheet roll forming are numerous, making it an indispensable tool for a wide range of industries. Due to its ability to produce complex and intricate shapes with minimal waste, sheet roll forming is highly cost-effective and can significantly reduce manufacturing time and labor costs. Additionally, the process allows for the use of a variety of metals, including steel, aluminum, and copper, further expanding its applicability across different industries.The benefits of sheet roll forming are not lost on the manufacturing industry, prompting companies to invest in state-of-the-art roll forming equipment to capitalize on its advantages. One such company that has embraced sheet roll forming is {}, a leading provider of metal fabrication solutions. With a strong focus on innovation and technology, {} has integrated sheet roll forming into its manufacturing processes, allowing for the production of highly intricate and customized metal components.{}'s sheet roll forming capabilities have enabled the company to expand its product offerings and cater to a wider range of industries, including automotive, construction, and aerospace. By leveraging the efficiency and precision of sheet roll forming, {} has been able to meet the exacting requirements of its customers, delivering high-quality metal components that meet or exceed industry standards.In addition to its manufacturing capabilities, {} has also invested in research and development to further enhance its sheet roll forming processes. By staying at the forefront of technological advancements, {} continues to push the boundaries of metal fabrication, offering innovative solutions that address the evolving needs of the industry.As the demand for complex and customized metal components continues to grow, sheet roll forming is poised to play a pivotal role in shaping the future of metal fabrication. With its ability to produce high-quality, intricate, and cost-effective metal components, sheet roll forming has become an indispensable tool for manufacturers seeking to stay ahead in a competitive marketplace.In conclusion, sheet roll forming represents a significant advancement in metal fabrication, offering unparalleled efficiency, precision, and versatility. With companies like {} at the forefront of this technology, the future of metal fabrication looks promising, as sheet roll forming continues to drive innovation and excellence in manufacturing.

Flat Roof Rubber Sheet: Unparalleled Corrugated Metal Roof for Pergolas Unmatched Corrugated Metal Roofing Sheets in Scotland Tile Effect Metal Roofing Sheets, Radiant Barrier Material, Galvanized Steel Sheet Metal, Wood Support Brackets, Eagle Carports, Target Stand, Colored Metal Panels, Mono Pitch Roof Calculator, Tom Roof, Charcoal Roof Tiles, Corrugated Colorbond Sheets: The Ultimate Solution Premium Quality Flat Roof Rubber Sheet for Your Roofing Needs

Title: A New Approach to Roofing Solutions: Horizontal Corrugated Roof PanelIntroduction:In a world where sustainability and durability are becoming paramount, the roofing industry has witnessed tremendous advancements. This article focuses on an innovative product, the Horizontal Corrugated Roof Panel, offered by (need to remove brand name), which aims to revolutionize traditional roofing solutions. With its exceptional features and benefits, this unique product has garnered significant attention in the market.A Versatile Solution for All: The Horizontal Corrugated Roof Panel offers versatility in terms of its applications. The product is designed to cater to various roofing needs, including pergolas, carports, and commercial and residential buildings. Whether it's a traditional or contemporary architectural design, this panel effortlessly complements any structure, showcasing its adaptability.Unmatched Durability and Longevity:One significant advantage of the Horizontal Corrugated Roof Panel is its exceptional durability. Made of high-quality galvanized steel sheet metal, this product offers unparalleled strength and resistance against harsh weather conditions, including heavy rains, intense UV exposure, and strong winds. Additionally, the panel's unique design ensures its longevity, offering a sustainable roofing solution that requires minimal maintenance.Enhancing Energy Efficiency:The Horizontal Corrugated Roof Panel is a high-performance roofing material that integrates a radiant barrier material within its structure. This innovative feature reflects heat away from the structure, reducing the amount of heat transferred inside. As a result, buildings experience improved energy efficiency, reducing the reliance on HVAC systems and resulting in substantial energy cost savings.Aesthetically Pleasing and Customizable:Gone are the days when roofing sheets were merely utilitarian. The Horizontal Corrugated Roof Panel embraces contemporary design trends, presenting itself as a visually appealing option. With its tile effect metal roofing sheets, buildings can achieve a desirable aesthetic appeal that replicates the beauty of traditional tile roofs. Additionally, the product comes in a variety of colors, allowing for customization and personalization to suit individual preferences.Easy Installation and Cost-Effective Solution:Not only does the Horizontal Corrugated Roof Panel offer exceptional durability and aesthetics, but it also provides an easy and hassle-free installation process. With its wood support brackets, the panels can be quickly assembled, reducing labor costs and project timelines. This efficiency makes it an ideal option for both small-scale residential projects and large-scale commercial installations.Environmental Sustainability:In a time when sustainability is of paramount importance, the Horizontal Corrugated Roof Panel stands out for its environmentally conscious approach. Made with recyclable materials such as galvanized steel, this product is an eco-friendly alternative to traditional roofing options. Additionally, its ability to enhance energy efficiency contributes to reducing carbon emissions and overall environmental impact.Conclusion:The Horizontal Corrugated Roof Panel offered by (need to remove brand name) is revolutionizing roofing solutions with its durability, energy efficiency, aesthetic appeal, and sustainability. As the need for reliable and cost-effective roofing materials grows, this innovative product emerges as a game-changer in the industry. Whether for residential or commercial applications, this versatile and long-lasting roofing solution provides a viable alternative for those seeking excellence in both functionality and design.

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

Europe Washing Machine Installation Manual: Easy-to-Follow User Guide for Efficient Operation and Maintenance

Title: Manual Shape C Purlin Punching Holes Making Machine: A Must-Have for European Standard Construction ProjectsIntroductionIn the ever-evolving world of construction, the need for efficient and precise manufacturing processes is paramount. One such process that has gained considerable popularity in recent years is the use of manual shape C purlin punching holes making machines. Designed to meet European standard requirements, these machines have revolutionized the way purlins are manufactured, ensuring enhanced structural integrity and cost-effectiveness. In this blog post, we will explore the key features and advantages of manual shape C purlin punching holes making machines, focusing on their relevance and impact in the European construction industry.What Are Manual Shape C Purlin Punching Holes Making Machines?Manual shape C purlin punching holes making machines are advanced manufacturing systems specifically designed for producing top-quality C purlins in compliance with European construction standards. These machines utilize cutting-edge technology and are equipped with cutting, punching, and forming tools, enabling the precise fabrication of complex purlin shapes to exact specifications.Key Features and Advantages1. Enhanced Precision: The manual shape C purlin punching holes making machines are engineered to deliver exceptional precision in forming and punching holes, ensuring accurate purlin dimensions and consistent hole alignment. This level of precision guarantees optimum installation compatibility, reducing the risk of structural errors and enabling smoother construction processes.2. Versatility: These machines offer a wide range of customization options, allowing for the production of various C purlin sizes and shapes according to project-specific requirements. Whether it's the flange width, thickness, or hole patterns, the manual shape C purlin punching holes making machine provides immense flexibility, ensuring compatibility with diverse construction designs.3. European Standard Compliance: Manual shape C purlin punching holes making machines are specifically engineered to adhere to European construction standards. These standards are known for their stringent quality requirements, ensuring that structures are built to withstand extreme weather conditions and offer exceptional durability. By using machines designed for European standards, construction projects can benefit from the highest level of quality assurance.4. Cost-Effectiveness: Implementing manual shape C purlin punching holes making machines can significantly reduce labor costs and material wastage. The machines' automated and precise manufacturing processes eliminate the need for time-consuming manual labor, resulting in faster production rates and reduced human error. Additionally, the optimization of material usage helps minimize waste, leading to cost savings for both manufacturers and end-users.ConclusionThe emergence of manual shape C purlin punching holes making machines has brought a new level of efficiency and quality assurance to the European construction industry. From increased precision and versatility to compliance with rigorous European standards, these machines are a game-changer for fabricators and construction companies alike. As the demand for sustainable and cost-effective construction practices rises, investing in manual shape C purlin punching holes making machines becomes an essential step towards success in the ever-evolving European construction landscape.

Economical Design Manual Adjust Roll Forming Machine for Z Purlin Making

, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.In the construction industry, structures like roofs and walls need structural stability and support for them to withstand external forces like wind and snow. The solution to this is adding purlins to the building structure. A purlin is a horizontal structural member that supports the roof or wall. C&Z purlins are common types of purlins used in roofing and wall cladding in steel buildings.To produce these C&Z purlins, the industry has invested in C&Z purlin forming machines. Among the available machines in the market is the Economical Design Z Purlin Making Machine, which is manually adjusted roll forming machine. It is an important machine since it can produce both C&Z purlins with ease, providing design flexibility.The Economical Design Z Purlin Making Machine has several features that make it a preferable choice in the market. One of the key features is its manual adjust roll forming system. This feature helps in adjusting and changing the machine's size manually, making it easy to shift from one design to another, which saves time and cost for contractors.The machine is also user-friendly, thanks to its touch-screen operation. Operators can adjust various aspects of the machine's performance, including the rolling speed, length, and thickness of the purlins produced. This feature allows the purlin making process to be as efficient as possible, while still producing high quality and durable purlins.Another crucial feature in the Economical Design Z Purlin Making Machine is its compact and modern design. This feature makes it easy to install, transport, and maintain, without taking up too much space. The compact design also allows the machine to operate efficiently, thus minimizing energy consumption.To ensure the machine’s longevity, it is made up of quality materials. It has a reinforced steel frame to maintain its structural integrity, ensuring that it can withstand the intended production loads for years to come. This makes the Economical Design Z Purlin Making Machine a cost-effective option, which provides value for money over the long term.In conclusion, the Economical Design Z Purlin Making Machine is a valuable machine in the construction industry. It allows for high-quality purlins to be produced in an efficient and cost-effective manner. Its manual adjust roll forming system, touch screen operation, compact design, and quality materials ensure that it is the best option for contractors seeking to produce high quality and durable purlins for their projects. If you are in the market for a Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, or a Manual Adjust Purlin Making Machine , consider the Economical Design Z Purlin Making Machine since it is a reliable and efficient option.Keywords: Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.