- Home

- Blog

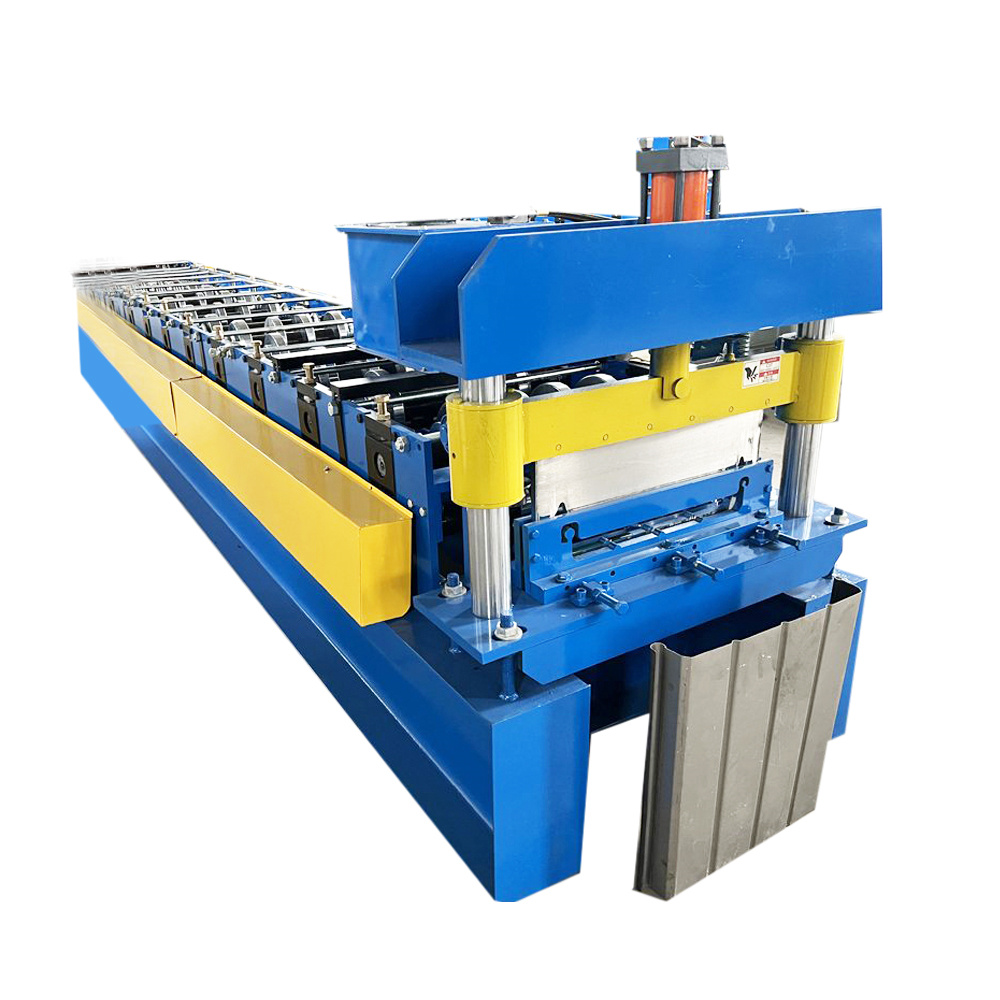

- High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Efficient Production

High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Efficient Production

By:Admin

In today's rapidly evolving construction industry, the demand for efficient and high-quality manufacturing equipment is at an all-time high. With the need for faster production and higher precision, companies are constantly seeking the latest technology to stay ahead of the curve. That's where the new Glazed Tile Panel Roll Forming And Corrugation Machine from {Company Name} comes in.

With a rich history of serving the construction industry with top-notch machinery, {Company Name} is proud to introduce the latest addition to their lineup - the Glazed Tile Panel Roll Forming And Corrugation Machine. This state-of-the-art machine is designed to revolutionize the manufacturing process for glazed tile panels, offering unparalleled precision and efficiency.

The machine is equipped with advanced roll forming and corrugation technology, allowing for seamless production of glazed tile panels with consistent quality and precise measurements. This innovative technology not only streamlines the manufacturing process but also ensures that every panel produced meets the highest industry standards.

One of the key features of the Glazed Tile Panel Roll Forming And Corrugation Machine is its versatility. With the ability to produce a wide range of panel sizes and shapes, this machine can cater to the diverse needs of the construction industry. Whether it's for residential, commercial, or industrial applications, the machine can adapt to various requirements, making it a valuable asset for manufacturers.

In addition to its impressive capabilities, the Glazed Tile Panel Roll Forming And Corrugation Machine also prioritizes user-friendly operation. With intuitive controls and a user-friendly interface, operators can easily navigate through the machine's functions, ensuring smooth and hassle-free production. This not only saves time but also minimizes the risk of errors, resulting in a more efficient manufacturing process.

Furthermore, {Company Name} is committed to providing exceptional after-sales support for their customers. From installation and training to maintenance and troubleshooting, their team of experts is dedicated to ensuring that the Glazed Tile Panel Roll Forming And Corrugation Machine operates at its best, maximizing productivity and minimizing downtime.

{Company Name} has a long-standing reputation for delivering cutting-edge machinery to the construction industry, and the Glazed Tile Panel Roll Forming And Corrugation Machine is a testament to their commitment to innovation. By investing in this state-of-the-art equipment, manufacturers can expect to elevate their production capabilities and stay ahead of the competition.

With the introduction of the Glazed Tile Panel Roll Forming And Corrugation Machine, {Company Name} continues to be at the forefront of providing advanced solutions to the construction industry. Their dedication to excellence and customer satisfaction sets them apart as a trusted partner for manufacturers seeking the best-in-class machinery.

In conclusion, the Glazed Tile Panel Roll Forming And Corrugation Machine from {Company Name} is set to make a significant impact on the manufacturing process for glazed tile panels. Its advanced technology, versatility, user-friendly operation, and exceptional support make it a must-have investment for construction industry manufacturers. As the industry continues to evolve, {Company Name} remains a reliable source for innovative solutions, empowering manufacturers to achieve new heights of success.

Company News & Blog

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

High-quality Roll Forming Machine for B Decking: A Guide

B Decking Roll Forming Machine is a revolutionary piece of machinery that has been making waves in the construction industry. Developed by a leading roll forming machine manufacturer, this cutting-edge piece of equipment has been designed to meet the demands of modern construction projects.With the ability to produce high-quality B deck profiles, this machine offers a fast and efficient solution for creating structural floor and roof decking. Its advanced technology and precise engineering ensure that the profiles are produced accurately and to the highest standards, meeting the requirements of even the most complex construction designs.The B Decking Roll Forming Machine is an essential tool for construction companies, as it enables them to create strong and durable decking systems with ease. The machine's high-speed production capabilities make it ideal for large-scale projects, allowing construction firms to meet tight deadlines and deliver exceptional results.With its user-friendly interface and intelligent control system, the B Decking Roll Forming Machine is easy to operate and requires minimal training. This ensures that construction crews can quickly adapt to using the machine, maximizing productivity and minimizing downtime.In addition to its impressive performance, the B Decking Roll Forming Machine is also designed with sustainability in mind. It is built to minimize waste and optimize material usage, reducing the environmental impact of construction projects.The company behind the B Decking Roll Forming Machine is renowned for its dedication to innovation and quality. With a strong focus on research and development, the company has consistently delivered cutting-edge solutions for the construction industry, earning a reputation as a leading provider of roll forming machinery.The company's commitment to excellence is reflected in the design and construction of the B Decking Roll Forming Machine. Each machine is built to the highest standards using the finest materials and components, ensuring long-lasting durability and reliable performance.Furthermore, the company provides comprehensive technical support and maintenance services for the B Decking Roll Forming Machine, ensuring that construction firms can rely on their equipment to perform at its best for years to come.The B Decking Roll Forming Machine is the result of extensive research and development, as well as a deep understanding of the needs and challenges faced by construction companies. By addressing these needs with innovative solutions, the company has positioned itself as a key player in the roll forming machinery industry.In conclusion, the B Decking Roll Forming Machine is a game-changer for the construction industry, offering a fast, efficient, and sustainable solution for creating structural floor and roof decking. With its advanced technology, user-friendly interface, and commitment to quality, this machine is helping construction companies to achieve exceptional results and meet the demands of modern construction projects.

Efficient Metal Stud Roll Former for Construction Projects

In the world of construction, the use of metal stud roll formers has become increasingly popular due to their efficiency and durability in producing metal studs for framing. One company at the forefront of this technology is leading the way in providing high-quality metal stud roll formers.Based in [Location], the company has been a prominent player in the construction industry for over [number] years. With a strong focus on innovation and quality, they have consistently provided top-notch machinery and equipment for construction professionals around the world. With a dedicated team of engineers and designers, the company has continuously pushed the boundaries of what is possible in the construction industry.Their metal stud roll former is a prime example of their commitment to excellence. Utilizing state-of-the-art technology and advanced manufacturing processes, the roll former is capable of producing precision-engineered metal studs with unparalleled speed and accuracy. This not only saves time but also ensures that the resulting metal studs are of the highest quality.One of the key advantages of their metal stud roll former is its versatility. It is capable of producing a wide range of metal studs, including different sizes and thicknesses, making it suitable for a variety of construction projects. This flexibility has made it a popular choice among construction professionals who require different types of metal studs for their projects.In addition to its versatility, the metal stud roll former is also known for its durability and low maintenance requirements. This ensures that construction professionals can rely on the roll former for years to come, maximizing their investment and reducing downtime due to maintenance issues.Furthermore, the company provides comprehensive training and support for their metal stud roll former, ensuring that customers are able to maximize its potential and operate it with confidence. With a team of knowledgeable experts on hand, they are able to provide guidance and assistance to customers, whether they are setting up the roll former for the first time or require troubleshooting support.The company's commitment to customer satisfaction is evident in the positive feedback they have received from their clients. Many construction professionals have praised the performance and reliability of the metal stud roll former, citing it as a crucial asset in their operations. This positive reputation has helped the company establish itself as a trusted provider of construction machinery and equipment.Looking towards the future, the company continues to innovate and develop new technologies to further enhance the capabilities of their metal stud roll former. With a focus on efficiency and sustainability, they are dedicated to providing cutting-edge solutions for the construction industry, helping their clients stay ahead of the curve and succeed in an ever-evolving market.Overall, the metal stud roll former from [Company Name] has set a new standard for efficiency and quality in metal stud production. Its versatility, durability, and support services make it a top choice for construction professionals around the world, and the company's commitment to innovation ensures that it will continue to be a leader in the industry for years to come.

Ultimate Guide to Corrugated Color Steel Tile Production Line

The Corrugated Color Steel Tile Production Line is an advanced manufacturing system that has been recently introduced by a leading player in the steel industry. This production line is designed to produce high-quality, durable corrugated color steel tiles that are widely used in the construction and roofing sectors.The company, known for its expertise and innovation in the steel manufacturing sector, has invested heavily in research and development to bring this cutting-edge production line to the market. The Corrugated Color Steel Tile Production Line is equipped with state-of-the-art technology and automation systems, ensuring high efficiency and precision in the manufacturing process.The production line is capable of handling a wide range of steel materials, including galvanized steel, pre-painted steel, and aluminum-zinc coated steel. This versatility allows the company to cater to the diverse needs of its customers, providing them with a wide variety of options in terms of colors, finishes, and coating materials.One of the key features of the Corrugated Color Steel Tile Production Line is its ability to produce custom-designed steel tiles according to the specific requirements of customers. This flexibility is made possible by the advanced software and control systems integrated into the production line, allowing for quick and easy adjustments in the manufacturing process.The company takes pride in its commitment to sustainability and environmental responsibility. The Corrugated Color Steel Tile Production Line is designed with energy efficiency in mind, minimizing waste and emissions during the manufacturing process. Additionally, the production line is equipped with recycling systems to ensure that any scrap materials are effectively reused, further reducing the environmental footprint of the manufacturing operation.In addition to its advanced technology and environmental considerations, the company's production line is also designed with the safety and well-being of its workers in mind. The production line is equipped with safety features and protocols to ensure that all manufacturing processes are carried out with the highest standards of occupational health and safety.The introduction of the Corrugated Color Steel Tile Production Line represents a significant milestone for the company as it continues to strengthen its position as a leading provider of high-quality steel products. With this new manufacturing capability, the company aims to meet the growing demand for durable, visually appealing steel tiles in the construction and roofing sectors, both in domestic and international markets.The company's investment in this advanced production line is also a testament to its long-term vision and commitment to innovation. By continuously investing in research and development, the company is able to stay ahead of the curve in terms of technology and product offerings, ensuring that it remains a preferred partner for customers seeking high-quality steel products.As the construction and roofing industries continue to evolve, the demand for innovative, high-quality steel products is expected to grow. The Corrugated Color Steel Tile Production Line positions the company to meet this demand, offering customers a reliable source for durable and visually appealing steel tiles that meet their specific requirements.In conclusion, the introduction of the Corrugated Color Steel Tile Production Line represents a significant advancement for the company, showcasing its commitment to innovation, sustainability, and customer satisfaction. With its advanced technology, flexible manufacturing capabilities, and commitment to quality, the company is well-poised to meet the evolving needs of the construction and roofing industries, both domestically and internationally.

Double Column Punching Machine for Aluminum Extrusion: Get Efficient Processing with Hydraulic Two Cylinder Punching Machine LY2-160

Title: Revolutionary Double Column Punching Machine Revolutionizes Aluminum Extrusion ProcessingIntroduction:Tjjunchiwy.com, a leading manufacturer of industrial machinery, introduces their latest innovation in the field of aluminum extrusion processing - the Hydraulic Two Cylinder Punching Machine LY2-160. This state-of-the-art machine is designed to simplify the hole and notch punching and processing of various plain profiles, enabling greater efficiency and precision in the production of aluminum windows and doors.Innovative Features and Specifications:The Hydraulic Two Cylinder Punching Machine LY2-160 incorporates a number of cutting-edge features that set it apart from its competitors. Here are some key specifications that make it a game-changer in the aluminum extrusion industry:1. Advanced Functionality: Equipped with a double column structure, the machine provides enhanced stability and rigidity throughout the punching process. This innovative design significantly reduces vibrations, resulting in high-quality, precise punching and processing of aluminum profiles.2. Versatility: The machine is designed to cater to a wide range of punching requirements for both single and assembled dies. Whether it's hole punching or notch processing, the LY2-160 can handle it all, ensuring streamlined operations in the production of aluminum doors and windows.3. Efficient Performance: With a punching force of up to 160 tons and a stroke length of 40mm, this robust machine guarantees efficient and accurate processing of aluminum profiles. It delivers consistent performance, allowing manufacturers to meet tight deadlines and achieve high production volumes.4. Intuitive Control System: The LY2-160 features a user-friendly control panel that allows operators to easily adjust punching parameters, such as punching depth, speed, and positioning. This intuitive interface ensures optimal productivity and minimizes errors during the manufacturing process.5. Advanced Safety Measures: Safety is paramount in any industrial setting, and this punching machine doesn't compromise in this aspect. Equipped with emergency stop buttons and safety guards, the system ensures operator safety during operation, reducing the risk of accidents.Company Overview: Tjjunchiwy.com has established itself as a renowned name in the machinery manufacturing industry, specializing in aluminum extrusion processing equipment. With a commitment to innovative solutions, the company has become a trusted partner for manufacturers worldwide, offering cutting-edge machines that enhance production efficiency and quality.Conclusion:The introduction of the Hydraulic Two Cylinder Punching Machine LY2-160 by Tjjunchiwy.com promises to revolutionize aluminum extrusion processing in the fabrication of windows and doors. Its exceptional features and specifications bring a new level of efficiency, precision, and versatility to the industry. With this state-of-the-art machine, manufacturers can expect increased productivity, reduced downtime, and improved product quality. As Tjjunchiwy.com continues to push technological boundaries, the future of aluminum extrusion processing looks brighter than ever before.

Revolutionizing the Metal Roofing Industry: Innovative Roofing Machines For A Faster Installation Process

Metal Roofing Machines Expands to Meet Growing Demands for Quality Roofing SolutionsWith the growing demand for durable and energy-efficient roofing solutions, Metal Roofing Machines has expanded its manufacturing capabilities, offering high-quality and dependable metal roofing machines for contractors and builders across the United States.Metal Roofing Machines is a family-owned and operated business that has been in the roofing industry for over two decades. The company has established a reputation for producing state-of-the-art metal roofing machines that are designed to meet the needs of contractors and builders of all sizes.The company's metal roofing machines are manufactured to the highest standards of quality and durability, using only top-grade materials and cutting-edge technology. Metal Roofing Machines' products are designed to offer maximum longevity and performance, while ensuring that they are easy to operate and maintain."We understand the importance of having access to reliable and efficient metal roofing machines," says the company spokesperson. "Our products are designed to meet the needs of the modern roofing industry, where time and efficiency are critical factors."Metal Roofing Machines' range of products includes portable roll formers, standing seam roll formers, roofing panel roll formers, gutter machines, and other specialty machines for the metal roofing industry. The company's machines are suitable for use in a variety of applications, including residential roofing, commercial roofing, and agricultural roofing.The standing seam roll former is the most popular machine distributed by Metal Roofing Machines. This machine is designed to produce standing seam roofing panels, which are popular for their clean, modern look and superior weather resistance. This machine is capable of producing high-quality panels quickly, ensuring that contractors are able to complete their roofing projects efficiently.In addition to manufacturing and distributing metal roofing machines, Metal Roofing Machines also provides education and training to contractors and builders who want to learn more about the metal roofing industry. The company offers a range of resources, including online tutorials, webinars, and in-person training sessions, designed to help contractors and builders improve their skills and stay up-to-date with the latest trends and technologies."We are committed to providing our customers with the best possible support," says the company spokesperson. "We believe that by educating our customers and providing them with the resources they need to succeed, we can help them grow their businesses and provide top-quality roofing solutions to their clients."Metal Roofing Machines has established itself as a leader in the metal roofing industry, thanks to its commitment to quality, innovation, and customer support. With its expanded manufacturing capabilities and growing range of products, the company is well-positioned to meet the demand for high-quality and reliable metal roofing solutions in the years to come.

How to Choose a Reliable Glazed Tile Corrugation Machine for Color Steel Roofing Projects

Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes the Roofing Industry[date][City], [State] - [Company Name], a leading provider of advanced manufacturing solutions, has introduced a groundbreaking Color Steel Glazed Tile Corrugation Machine that is set to revolutionize the roofing industry. This cutting-edge technology is poised to transform the way roofing materials are produced, offering numerous benefits in terms of efficiency, durability, and aesthetics.The Color Steel Glazed Tile Corrugation Machine, designed and developed by [Company Name], incorporates state-of-the-art features that not only enhance productivity but also improve the overall quality of glazed tile roof panels. The machine is capable of producing perfectly corrugated tiles with a smooth surface finish, offering unmatched visual appeal and longevity to any building structure.One of the key advantages of the Color Steel Glazed Tile Corrugation Machine is its high efficiency. With advanced automation and precision engineering, this machine drastically reduces the time and effort required for tile production. This translates into higher output levels for manufacturers, enabling them to fulfill the growing demands of the market in a shorter span of time.Furthermore, the machine's ability to produce uniform and precise corrugated tiles ensures consistent quality throughout the manufacturing process. This consistency contributes to the overall durability of the finished roofing material, making it highly resistant to wear and tear, extreme weather conditions, and other external factors. The Color Steel Glazed Tile Corrugation Machine is built to last, providing long-lasting protection and aesthetic appeal to buildings.In addition to improving efficiency and durability, this innovative machine also offers enhanced aesthetic options. With a wide range of customizable features, manufacturers can now produce glazed tile roofs in various colors, patterns, and designs. This flexibility caters to diverse architectural needs and allows builders to create visually striking structures.The Color Steel Glazed Tile Corrugation Machine is equipped with advanced technology that facilitates quick and easy set-up, operation, and maintenance. Its user-friendly interface and intuitive controls ensure seamless integration into existing manufacturing processes and minimize downtime. This feature proves invaluable to manufacturers, who can now achieve optimal production levels without investing substantial time and resources into training employees.Moreover, [Company Name] stands out as an industry leader due to its commitment to sustainability. The Color Steel Glazed Tile Corrugation Machine is designed with eco-friendly measures, reducing waste generation, and optimizing energy efficiency. By adopting this machine, manufacturers can contribute to a greener future, aligning their operations with the global sustainability agenda.The introduction of the Color Steel Glazed Tile Corrugation Machine by [Company Name] marks a significant milestone in the roofing industry. Its cutting-edge features, including increased efficiency, enhanced durability, and improved aesthetics, provide manufacturers with a competitive edge. This machine is slated to reshape the roofing materials market and redefine industry standards.With its commitment to innovation, quality, and sustainability, [Company Name] continues to lead the way in the manufacturing sector. The Color Steel Glazed Tile Corrugation Machine is a testament to their dedication to developing advanced solutions that improve efficiency, durability, and aesthetics in roofing production.As the roofing industry embraces this revolutionary technology, buildings worldwide are set to benefit from the exceptional performance and appeal of glazed tile roofs. With the Color Steel Glazed Tile Corrugation Machine, [Company Name] has paved the way for a new era of excellence in the roofing industry.

High-Quality Standing Seam Roof Panel Machine: All You Need to Know

[Company Name] Introduces Innovative Standing Seam Roof Panel Machine[Company Name], a leading manufacturer of metal forming and fabrication machinery, is excited to announce the release of their latest innovation, the Standing Seam Roof Panel Machine. This revolutionary new machine is designed to streamline the production of standing seam roof panels, providing a cost-effective and efficient solution for metal roofing manufacturers and contractors.The Standing Seam Roof Panel Machine is equipped with advanced technology and precision engineering, allowing for the seamless production of high-quality roof panels. The machine features an automated process for feeding, forming, and cutting metal sheets, significantly reducing the time and labor required for panel production. Additionally, the machine is capable of producing a variety of panel profiles and sizes, providing versatility for a range of roofing projects.With a focus on durability and performance, the Standing Seam Roof Panel Machine is built to withstand the rigors of continuous use in a manufacturing environment. The machine's rugged construction and reliability make it a valuable investment for metal forming businesses looking to enhance their production capabilities."We are thrilled to introduce our Standing Seam Roof Panel Machine to the market," said [Company Name] CEO. "This machine represents a significant advancement in metal forming technology, offering unprecedented efficiency and quality for standing seam roof panel production. We believe that this machine will be a game-changer for roofing manufacturers and contractors, allowing them to take their business to the next level."In addition to its innovative features, the Standing Seam Roof Panel Machine is designed with user-friendly controls and intuitive operation, making it accessible for operators of all skill levels. The machine's easy setup and minimal maintenance requirements further contribute to its appeal as a practical and reliable investment for metal roofing businesses.As an industry leader in metal forming machinery, [Company Name] has a proven track record of delivering cutting-edge solutions that meet the evolving needs of the market. With a commitment to quality and customer satisfaction, the company's Standing Seam Roof Panel Machine is backed by comprehensive support and service, ensuring that customers can maximize the machine's performance and longevity.The introduction of the Standing Seam Roof Panel Machine solidifies [Company Name]'s position as a pioneering force in the metal forming industry, with a dedication to innovation and excellence. Metal roofing manufacturers and contractors can now take advantage of this groundbreaking technology to elevate their production capabilities and meet the growing demand for high-quality standing seam roof panels in the construction industry. [Company Name] invites interested parties to learn more about the Standing Seam Roof Panel Machine and explore the possibilities it offers for enhancing their metal roofing operations.[Company Name] is a leading manufacturer of metal forming and fabrication machinery, specializing in innovative solutions for the production of a wide range of metal components. With a strong focus on quality, performance, and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses across the metal forming industry. The company's diverse portfolio of machinery includes roll forming machines, panel roll formers, and CNC metal forming equipment, all designed to deliver superior results and efficiency for manufacturers and fabricators. Based on a foundation of engineering expertise and a passion for innovation, [Company Name] continues to set the standard for excellence in metal forming technology. For more information about [Company Name]'s Standing Seam Roof Panel Machine and their full range of metal forming machinery, please visit [website].

High-Quality Steel Coil Slitting Machines for Efficient Metal Sheet Cutting and Stainless Steel Strips

Stainless Steel Strip Slitting Machine: A Revolutionary Solution for Cutting and Slitting Metal SheetsWhen it comes to metalworking, precision and accuracy are critical factors in achieving quality results. One such process is slitting, which involves cutting a wide metal sheet into narrower strips to meet specific requirements. This process is necessary for industries that require smaller widths for their product manufacturing, such as automotive, electronics, and construction.To achieve this, manufacturers use a slitting machine, a unique piece of equipment that cuts and converts metal coils into narrower strips. One type of slitting machine that has gained popularity in recent years is the stainless steel strip slitting machine, which provides greater precision and efficiency in metal sheet cutting.What is a Stainless Steel Strip Slitting Machine?A stainless steel strip slitting machine is a piece of equipment specifically designed for cutting and slitting metal sheets, mainly made of stainless steel. This machine is equipped with a set of blades or knives that sever the material in smaller strips with the desired width. The blades or knives can be adjusted to achieve the desired cut and width of the strips, making it highly customizable.Uses of Stainless Steel Strip Slitting MachineStainless Steel Strip Slitting Machine is widely used in many industries that utilize metal sheets in their manufacturing processes. These include the automotive, aerospace, and construction industries. It is also useful for electronics, textile, and paper industries for creating smaller electronic components and packaging materials.Advantages of Stainless Steel Strip Slitting Machine1.Precision CuttingOne of the primary advantages of using a stainless steel strip slitting machine is its ability to produce precise cuts and meet the required specifications. The machine can cut narrow strips with the desired width and high accuracy, reducing material waste and saving production time.2. High ProductivityStainless Steel Strip Slitting Machine can work continuously, producing strips of varying widths with minimal operator intervention. This leads to increased productivity and output while ensuring consistent quality in products.3. CustomizationThe Stainless Steel Strip Slitting Machine can be customized to meet specific requirements, such as cutting thickness, strip widths, and number of pieces produced per roll.4. DurabilityAs the name suggests, the machine is made of stainless steel, making it resistant to corrosion and ensuring durability. The blades are also made of high-quality materials that can withstand the stress of cutting metal sheets for extended periods.ConclusionIn conclusion, the Stainless Steel Strip Slitting Machine is a revolutionary technology that has changed the game in metal sheet cutting and slitting. It offers high precision, customization, efficiency, and durability in metalworking, making it an excellent investment for industries that rely on metal sheets. With its versatile applications and advantages, it is no wonder why it has become popular among manufacturers. Keywords: Stainless Steel Strip Slitting Machine, Metal Sheet Cutting Machine, Steel Strip Slitting Machine.

How to choose the best smartphone for your needs

[Company Name] Launches New Technology to Revolutionize Data Analysis[City, Date] - [Company Name] has recently announced the launch of their groundbreaking [product name], promising to revolutionize the way data is analyzed and processed. This new technology is set to disrupt the current market, providing faster and more accurate results for businesses and organizations around the world.The [product name] is a sophisticated data analysis tool that utilizes advanced algorithms and machine learning techniques to process and interpret large volumes of data. It is designed to offer businesses a comprehensive and user-friendly platform for all their data analysis needs.[Company Name] is a global leader in innovative technology solutions, specializing in data analytics, artificial intelligence, and machine learning. Their team of experts has been working tirelessly to develop the [product name], which has the potential to transform the way businesses harness and utilize their data.The [product name] is equipped with a range of powerful features, including predictive analytics, data visualization, and real-time monitoring. This allows businesses to gain deeper insights into their data, enabling them to make better informed decisions and drive business growth."We are excited to introduce the [product name] to the market," said [Company Name]'s CEO. "This new technology represents a significant milestone in the field of data analysis, and we believe it has the potential to empower businesses with a deeper understanding of their data."The [product name] also offers seamless integration with existing data management systems, allowing businesses to streamline their data analysis processes and eliminate the need for multiple tools. This will not only save time and resources, but also improve the overall efficiency of data analysis within organizations.In addition to its advanced features, the [product name] is also designed to be user-friendly, with an intuitive interface that enables users to easily navigate and utilize its capabilities. This makes it accessible to a wide range of businesses, regardless of their size or industry.With the launch of the [product name], [Company Name] aims to empower businesses with the tools they need to extract valuable insights from their data, driving innovation and growth. The company is confident that the [product name] will set new industry standards and lead the way in data analysis technology."We believe that the [product name] has the potential to transform the way businesses approach data analysis," added the CEO of [Company Name]. "We are committed to empowering organizations with the insights they need to thrive in today's data-driven world."The [product name] is now available for businesses worldwide, and [Company Name] is offering a range of flexible pricing options to suit the needs of different organizations. Businesses can now experience the power of the [product name] and take their data analysis capabilities to the next level.For more information about the [product name] and [Company Name]'s other innovative solutions, visit their website at [company website]. With their dedication to pushing the boundaries of technology, [Company Name] continues to be at the forefront of innovation in the data analysis industry.