High-Quality Metal Coil Slitting Machine for Efficient Production

By:Admin

{Company's Name} has recently enhanced its manufacturing capabilities with the addition of a state-of-the-art Metal Coil Slitting Machine. This new machine is set to significantly improve the efficiency and precision of the company's metal processing operations, further solidifying {Company's Name} as a leader in the industry.

The Metal Coil Slitting Machine is designed to precisely cut large coils of metal into narrower strips, enabling {Company's Name} to meet the specific size requirements of its customers. This advanced piece of equipment is equipped with high-speed blades and cutting-edge technology, ensuring that each strip is cut with utmost accuracy and consistency.

The addition of the Metal Coil Slitting Machine is a testament to {Company's Name}'s commitment to investing in cutting-edge technology to deliver the highest quality products to its customers. With this new machine, the company will be able to effectively process a variety of metal coils, including steel, aluminum, and stainless steel, offering greater flexibility and versatility in its manufacturing capabilities.

In addition to its precision cutting capabilities, the Metal Coil Slitting Machine is equipped with advanced safety features and automation technology, allowing for seamless operation and minimizing the risk of human error. This not only ensures the safety of {Company's Name}'s employees but also contributes to the overall efficiency of the manufacturing process.

{Company's Name} takes great pride in its ability to provide customized solutions to its customers, and the addition of the Metal Coil Slitting Machine further strengthens this commitment. With the ability to process metal coils into precise strips of varying sizes, the company will be able to meet the specific requirements of each customer, catering to a wide range of industries such as automotive, construction, and manufacturing.

Furthermore, the Metal Coil Slitting Machine will enable {Company's Name} to streamline its production processes, reduce lead times, and improve overall productivity. This will ultimately result in enhanced customer satisfaction and a competitive edge in the market.

The investment in the Metal Coil Slitting Machine also aligns with {Company's Name}'s dedication to sustainability and environmental responsibility. By optimizing its manufacturing processes, the company will be able to minimize material waste and energy consumption, contributing to a more sustainable operation.

{Company's Name} has always been at the forefront of innovation, and the addition of the Metal Coil Slitting Machine is a testament to its commitment to staying ahead of industry trends. By continuously investing in advanced technology and equipment, the company aims to maintain its position as a leading provider of metal processing solutions.

The Metal Coil Slitting Machine has already been integrated into {Company's Name}'s manufacturing facility and is fully operational. The company is excited about the opportunities this new addition brings and is looking forward to delivering even greater value to its customers.

As {Company's Name} continues to expand and evolve, the addition of the Metal Coil Slitting Machine underscores its dedication to excellence, innovation, and customer satisfaction. With this new state-of-the-art equipment, the company is well-positioned to further elevate its capabilities and maintain its leadership in the industry.

Company News & Blog

How to Build a Sheet Metal Barn in 6 Simple Steps

Title: How to Build a Sheet Metal Barn in 6 Easy StepsIntroduction:Sheet metal barns provide an excellent solution for storage and shelter needs. Not only are they durable and cost-effective, but they can also be constructed relatively easily. In this article, we will outline a step-by-step guide on how to build a sheet metal barn in six simple steps. Whether you have experience in construction or are a DIY enthusiast, this guide will help you create your very own sheet metal barn.Step 1: Planning and PreparationBefore starting any project, careful planning is essential. Determine the size and design of your barn based on your requirements. Take measurements of the desired area and sketch out the barn's layout. Consult local building codes and acquire any necessary permits. Once you have a clear plan, gather the required materials.Step 2: Foundation and Frame ConstructionCreate a solid foundation for your sheet metal barn. Excavate the area, level the ground, and lay a sturdy foundation using concrete or treated wood. Next, construct the frame using the plywood pallets. Cut them to the desired size and connect them securely using screws and nuts, ensuring stability and durability.Step 3: Installing RoofingSelect the appropriate sheet metal for the roofing of your barn. Galvanized sheet metal provides excellent protection against rust and corrosion. Measure and cut the sheet metal to fit the roof frame, leaving a slight overhang for drainage. Secure the roofing sheets to the frame using screws or nails, ensuring proper alignment and sealing.Step 4: Wall ConstructionMeasure and cut additional plywood panels to serve as walls for your sheet metal barn. Attach them securely to the frame, leaving space for doors and windows as needed. Ensure tight joints and smooth surfaces for a professional finish.Step 5: Doors and WindowsInstall suitable doors and windows into the wall structure. Depending on your requirements, you can choose ready-made options or customize your own. Ensure proper insulation and weatherproofing to protect your belongings from the elements.Step 6: Finishing TouchesTake time to inspect your sheet metal barn for any loose screws or nails. Replace or tighten them as necessary. Consider adding ventilation systems, gutters, or additional storage options such as shelves or hooks. Apply a protective finish, such as paint or weather-resistant coatings, to increase the longevity and aesthetics of your barn.Conclusion:Building a sheet metal barn is a satisfying project that offers both functionality and durability. By following these six easy steps, you can construct your own barn and enjoy the benefits of efficient storage and shelter. Whether you are a DIY enthusiast or a seasoned builder, creating a sheet metal barn can be achieved with the right materials, tools, and patience. Embrace your creativity and get started on your own sheet metal barn project today!

Top Quality Roll Forming Machines: Your Ultimate Guide

Roll Forming Machines are efficient and reliable machines that are used in the manufacturing process of various products. They are an essential tool in the industry, as they can produce high-quality and precise products with ease. These machines are used in various industries such as automotive, construction, and manufacturing, to name a few.Roll Forming Machines are used to create products with long lengths and in large quantities. They can be used to produce a wide range of products, including roofing panels, garage doors, and storage racks, among others. The machines use a series of roll stands to gradually shape a flat strip of metal into the desired profile. This process can be done with different types of metal, including steel, aluminum, and copper.One of the leading manufacturers of Roll Forming Machines is {}. They have been in the business for decades and have established themselves as experts in the field. Their machines are known for their high precision, durability, and efficiency. Their Roll Forming Machines are used by many companies worldwide, and they have a strong reputation for providing top-quality products and excellent customer service.The company, {}, was founded in 1980 and has since grown to become a global leader in roll forming technology. They have a team of highly skilled engineers who are constantly working on improving their machines and developing new technologies. Their machines are designed to meet the specific needs of their customers, and they offer a wide range of customization options.With a strong focus on innovation and quality, the company has earned the trust of many customers around the world. They have a strong commitment to customer satisfaction and strive to provide the best solutions for their clients. Their machines are widely used in various industries, and they have a strong track record of delivering top-quality products.In addition to their Roll Forming Machines, the company also offers a range of other products and services to support their customers' needs. They provide technical support, training, and maintenance services to ensure that their machines are running smoothly and efficiently. They also offer custom design and engineering services to help their customers create unique and specialized products.The company's Roll Forming Machines are designed to be user-friendly and easy to operate. They are equipped with advanced technology to ensure high precision and efficiency. The machines are also built to last, with high-quality materials and components that are designed to withstand the rigors of industrial production.With a strong focus on research and development, the company is constantly working on new advancements in roll forming technology. They are dedicated to staying at the forefront of the industry and providing their customers with the latest and most advanced solutions. Their commitment to innovation and excellence has earned them a strong reputation in the industry.In conclusion, Roll Forming Machines are an essential tool in the manufacturing industry, and {} is a leader in the field. They have established themselves as a trusted provider of top-quality machines and services, and their commitment to innovation and customer satisfaction sets them apart from their competitors. With a strong reputation and a dedication to excellence, {} is a reliable partner for companies looking for high-quality roll forming solutions.

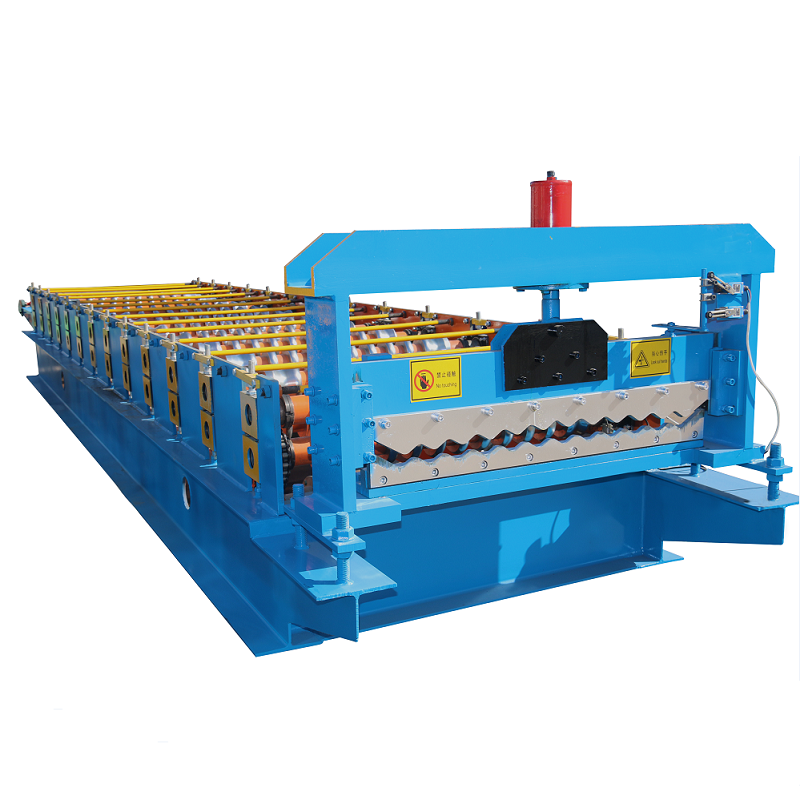

High-Quality Glazed Tile Profile Corrugating Machine for Color Steel

Color Steel Glazed Tile Profile Corrugating Machine is a modern and innovative piece of equipment that has revolutionized the manufacturing industry. With its state-of-the-art design and advanced features, this machine has become a vital asset for companies looking to produce high-quality color steel glazed tiles for architectural and construction purposes. This efficient and reliable machine has been developed to meet the growing demand for durable and aesthetically pleasing roofing and cladding materials, and it has quickly become a popular choice for manufacturers around the world.The Color Steel Glazed Tile Profile Corrugating Machine is designed to produce high-quality glazed tiles with precision and speed. Its advanced technology allows for the accurate shaping and corrugation of color steel sheets, resulting in tiles that are not only visually appealing but also resistant to corrosion and wear. The machine is also capable of producing a wide range of tile profiles, giving manufacturers the flexibility to meet the specific requirements of their clients.One of the key features of this machine is its automated control system, which allows for seamless operation and consistent quality. The machine is equipped with programmable logic controllers (PLCs) and touch screen interfaces, making it easy for operators to set and adjust parameters such as sheet length, corrugation depth, and production speed. This level of automation not only ensures high accuracy and repeatability but also increases the efficiency of the manufacturing process.In addition to its advanced technology, the Color Steel Glazed Tile Profile Corrugating Machine is also designed with user safety and convenience in mind. The machine is equipped with safety guards and emergency stop buttons to protect operators from potential hazards, and its modular design allows for easy maintenance and servicing. This ensures that the machine operates reliably and consistently, minimizing downtime and maximizing productivity.The company behind the Color Steel Glazed Tile Profile Corrugating Machine, [company name], has established itself as a leading manufacturer of roll forming and metal processing equipment. With a strong focus on innovation and quality, the company has developed a diverse range of machines that cater to the needs of various industries, including construction, automotive, and manufacturing. Its commitment to providing reliable and efficient solutions has earned the company a solid reputation and a loyal customer base.[Company name] takes pride in its ability to customize its machines to meet the specific requirements of its clients. Whether it's a small-scale operation or a large-scale manufacturing facility, the company works closely with its customers to understand their unique needs and deliver tailored solutions that optimize productivity and profitability. This customer-centric approach has enabled [company name] to build strong and long-lasting relationships with its clients, positioning it as a trusted partner in the industry.The Color Steel Glazed Tile Profile Corrugating Machine is a testament to [company name]'s dedication to innovation and excellence. With its cutting-edge technology, reliable performance, and user-friendly design, this machine has set a new standard for the production of color steel glazed tiles. As the demand for high-quality roofing and cladding materials continues to grow, it is clear that the Color Steel Glazed Tile Profile Corrugating Machine will play a crucial role in meeting the needs of manufacturers and contractors around the world.In conclusion, the Color Steel Glazed Tile Profile Corrugating Machine represents a significant advancement in the manufacturing of color steel glazed tiles. Its advanced technology, automated control system, and user-friendly design make it a valuable asset for companies looking to produce high-quality and durable roofing and cladding materials. With [company name]'s commitment to innovation and customer satisfaction, the machine is poised to make a lasting impact on the industry and contribute to the development of modern and sustainable construction practices.

China Offers Comprehensive Roll Forming Solution for Diverse Applications

, Roll Forming Machine, Cold Roll Forming, China Roll Forming, One-Stop Solution, Consultation, Training, Applications.Roll forming is a common metal forming process used to shape metal into a specific profile or shape. It is achieved through a series of roll forming machines that progressively shape the metal until it reaches the desired shape. This process is commonly used in the production of metal building components, automotive parts, and consumer products.China is a major player in roll forming technology, with many domestic manufacturers providing roll forming machines and solutions. One of the leading manufacturers in China is MTC, which has built a reputation for providing high-quality roll forming machines and a one-stop solution for a range of applications.The MTC roll forming machine is a cold roll former, which means that it operates at room temperature. This is in contrast to hot roll forming, which requires the metal to be preheated before forming. The advantage of cold roll forming is that it can be used on a wider range of materials, including aluminum, steel, and other metals.MTC provides a comprehensive range of roll forming machines, including panel roll forming machines, roof panel machines, wall panel machines, and more. Each machine is tailored to the specific needs of the application, ensuring optimal performance and quality.One of the unique features of MTC is its one-stop solution for roll forming applications. This includes consultation, design, manufacturing, installation, and training. The MTC team works closely with clients to understand their needs and requirements, and then provides a tailored solution that meets those needs.The consultation phase is critical in determining the most appropriate roll forming machine for the specific application. MTC’s team of experts analyze factors such as the material being used, desired throughput, and other factors to recommend the best machine for the job.Once the design has been completed, MTC manufactures the roll forming machine to the highest standards. The company uses state-of-the-art equipment and processes to ensure maximum performance and reliability.Installation is carried out by MTC’s team of trained technicians, who work closely with the client to ensure that the machine is correctly installed and fully operational.Training is also a critical component of the MTC one-stop solution. The company provides comprehensive training to clients, ensuring that they are fully versed in the operation and maintenance of the roll forming machine. This ensures that clients are able to operate the machine to its full potential, and that any maintenance or repair needs are quickly identified and addressed.MTC’s one-stop solution has been successfully implemented across a range of applications, including building construction, automotive manufacturing, and consumer goods production. The company’s expertise and commitment to quality have made it a trusted partner for businesses around the world.In summary, MTC provides a one-stop solution for roll forming applications, including consultation, design, manufacturing, installation, and training. The company's cold roll forming machines are designed to deliver the highest levels of performance and reliability, and its team of experts works closely with clients to ensure that their specific needs are met. With a focus on quality and customer service, MTC is a trusted partner for businesses seeking roll forming solutions.

Double Column Punching Machine for Aluminum Extrusion: Get Efficient Processing with Hydraulic Two Cylinder Punching Machine LY2-160

Title: Revolutionary Double Column Punching Machine Revolutionizes Aluminum Extrusion ProcessingIntroduction:Tjjunchiwy.com, a leading manufacturer of industrial machinery, introduces their latest innovation in the field of aluminum extrusion processing - the Hydraulic Two Cylinder Punching Machine LY2-160. This state-of-the-art machine is designed to simplify the hole and notch punching and processing of various plain profiles, enabling greater efficiency and precision in the production of aluminum windows and doors.Innovative Features and Specifications:The Hydraulic Two Cylinder Punching Machine LY2-160 incorporates a number of cutting-edge features that set it apart from its competitors. Here are some key specifications that make it a game-changer in the aluminum extrusion industry:1. Advanced Functionality: Equipped with a double column structure, the machine provides enhanced stability and rigidity throughout the punching process. This innovative design significantly reduces vibrations, resulting in high-quality, precise punching and processing of aluminum profiles.2. Versatility: The machine is designed to cater to a wide range of punching requirements for both single and assembled dies. Whether it's hole punching or notch processing, the LY2-160 can handle it all, ensuring streamlined operations in the production of aluminum doors and windows.3. Efficient Performance: With a punching force of up to 160 tons and a stroke length of 40mm, this robust machine guarantees efficient and accurate processing of aluminum profiles. It delivers consistent performance, allowing manufacturers to meet tight deadlines and achieve high production volumes.4. Intuitive Control System: The LY2-160 features a user-friendly control panel that allows operators to easily adjust punching parameters, such as punching depth, speed, and positioning. This intuitive interface ensures optimal productivity and minimizes errors during the manufacturing process.5. Advanced Safety Measures: Safety is paramount in any industrial setting, and this punching machine doesn't compromise in this aspect. Equipped with emergency stop buttons and safety guards, the system ensures operator safety during operation, reducing the risk of accidents.Company Overview: Tjjunchiwy.com has established itself as a renowned name in the machinery manufacturing industry, specializing in aluminum extrusion processing equipment. With a commitment to innovative solutions, the company has become a trusted partner for manufacturers worldwide, offering cutting-edge machines that enhance production efficiency and quality.Conclusion:The introduction of the Hydraulic Two Cylinder Punching Machine LY2-160 by Tjjunchiwy.com promises to revolutionize aluminum extrusion processing in the fabrication of windows and doors. Its exceptional features and specifications bring a new level of efficiency, precision, and versatility to the industry. With this state-of-the-art machine, manufacturers can expect increased productivity, reduced downtime, and improved product quality. As Tjjunchiwy.com continues to push technological boundaries, the future of aluminum extrusion processing looks brighter than ever before.

Efficient Cut-To-Length Machine Revolutionizes Fabric Industry

Title: Cutting-edge Fabric Cut-to-Length Machine Revolutionizes Textile IndustryIntroduction:The fabric cut-to-length machine, a groundbreaking innovation in the textile industry, is set to transform the way fabrics are processed and cut. Developed by a leading company in textile machinery (), this cutting-edge technology promises to enhance efficiency, precision, and productivity in fabric manufacturing while reducing waste and operational costs. By focusing on revolutionary design and incorporating advanced features, this machine is poised to revolutionize fabric cutting processes globally.Paragraph 1:Manufacturers in the textile industry have long been facing challenges relating to efficient and accurate fabric cutting. Traditional cutting methods often result in time-consuming, labor-intensive processes that lead to inconsistencies and inaccuracies. The introduction of the fabric cut-to-length machine aims to overcome these hindrances and provide an automated solution that streamlines the entire cutting process.Paragraph 2:The fabric cut-to-length machine utilizes state-of-the-art technology to deliver high precision cutting, reducing material waste and optimizing fabric utilization. With programmable settings and a user-friendly interface, the machine enables manufacturers to achieve precise dimensions consistently. This innovation not only saves time but also eliminates errors, ensuring uniformity throughout the production process.Paragraph 3:One of the key features of this machine is its ability to accommodate a wide variety of fabric types. Whether it is delicate silk, robust denim, or intricate lace, the machine's advanced cutting mechanisms deliver clean, accurate cuts without compromising the integrity of the fabric. Such versatility enables fabric manufacturers to expand their product lines and cater to diverse customer needs, significantly enhancing their competitiveness in the market.Paragraph 4:In addition to its cutting precision, the fabric cut-to-length machine incorporates efficiency-enhancing mechanisms, such as conveyor systems and automated fabric feeders. These features enable continuous processing and seamless integration with other textile machinery, minimizing downtime and maximizing productivity. Furthermore, its intuitive control panel allows operators to monitor and adjust settings easily, fostering a smoother workflow.Paragraph 5:Environmental sustainability is a growing concern in the textile industry. The fabric cut-to-length machine tackles this issue through material optimization, reducing fabric wastage significantly. By eliminating manual errors and ensuring efficient use of fabric, the machine helps manufacturers reduce their carbon footprint and minimize the environmental impact of fabric production.Paragraph 6:The impact of the fabric cut-to-length machine extends beyond the manufacturing floor, as it also positively influences the bottom line. By reducing fabric waste and increasing productivity, manufacturers can experience significant cost savings over time. Additionally, the machine's longevity and durability contribute to its cost-effectiveness, making it a valuable investment for textile companies seeking to optimize their operations in the long run.Paragraph 7:The introduction of this innovative fabric cut-to-length machine marks a new era in the textile industry, establishing new standards of quality, efficiency, and sustainability. Through its intelligent design, versatility, and ability to streamline fabric cutting processes, manufacturers are now empowered to meet the growing demands of customers while staying competitive in a rapidly evolving market.Conclusion:The fabric cut-to-length machine developed by () is poised to revolutionize the textile industry, simplifying and automating the fabric cutting process. With its precision, versatility, and cost-effectiveness, this cutting-edge technology has the potential to reshape the fabric manufacturing landscape, enabling manufacturers to optimize their operations and meet the ever-growing demands of the market. As the textile industry continues to evolve, the fabric cut-to-length machine will empower companies to embrace change, improve efficiency, and remain at the forefront of innovation.

Discover the Latest in Color Steel Roll Forming Machines for Factory Manufacturing

Introducing New State-of-the-Art Steel Roll Forming Machine Factory(CITY NAME), (DATE) - (Company Name), a leading manufacturer in the industrial machinery sector, is pleased to announce the launch of its newest venture, a cutting-edge Color Steel Roll Forming Machine Factory. With a focus on innovation and excellence, this factory aims to revolutionize the production of steel roll forming machines, catering to the growing demands of the construction and manufacturing industries.The newly established Color Steel Roll Forming Machine Factory embodies the rich history and expertise that (Company Name) holds within the machinery manufacturing field. This facility is equipped with state-of-the-art technology and advanced machinery, enabling the production of high-quality steel roll forming machines that meet international standards. By combining precision engineering with the use of premium-grade materials, the Color Steel Roll Forming Machine Factory ensures the durability and reliability of its products.One of the key features that sets this factory apart is its dedication to research and development. (Company Name) understands that innovation plays a crucial role in staying ahead in the competitive market. Consequently, the factory has established a specialized R&D department staffed with highly skilled engineers and technicians. This team is responsible for continuously improving the existing designs and developing new solutions to enhance the performance and versatility of steel roll forming machines.The Color Steel Roll Forming Machine Factory prioritizes sustainability and environmental responsibility. By implementing energy-efficient practices and utilizing eco-friendly materials, the factory minimizes its carbon footprint. Additionally, the production processes adhere to strict quality control measures, ensuring that each machine meets the highest industry standards. This commitment to sustainability sets an example for future industrial manufacturing practices.(City Name) is the ideal location for this factory due to its strategic geographical position and access to a robust transportation network. This advantageous positioning allows for efficient distribution and timely delivery of the steel roll forming machines to customers worldwide. Additionally, the factory's close proximity to suppliers and raw materials helps streamline the manufacturing process and reduces lead times.The Color Steel Roll Forming Machine Factory has been designed to maximize efficiency and productivity. By adopting lean production techniques and incorporating automation into assembly lines, the factory is capable of producing a large volume of machines without compromising on quality. The implementation of advanced computer systems and robotic technology enhances accuracy and precision during the manufacturing process.Furthermore, customer satisfaction lies at the heart of (Company Name)'s philosophy. The dedicated customer service department ensures that clients receive unparalleled support throughout their purchasing journey. With a team of knowledgeable professionals, customers can rely on prompt assistance, technical guidance, and after-sales service, guaranteeing the smooth operation of their newly acquired steel roll forming machines.The establishment of the Color Steel Roll Forming Machine Factory reinforces (Company Name)'s commitment to its customers and the industry as a whole. By leveraging its expertise and embracing innovation, the factory sets a new standard in the production of steel roll forming machines. With a focus on quality, sustainability, and customer satisfaction, this facility is poised to become a leading player in the manufacturing sector.About (Company Name):(Company Name) is a renowned manufacturer in the industrial machinery sector, specializing in the production of innovative and high-quality machinery. With a rich history of excellence, (Company Name) has been at the forefront of the industry, serving customers globally. By constantly pushing boundaries and embracing technology, (Company Name) aims to provide customers with reliable solutions that enhance productivity and profitability.For media inquiries:Contact Person: (Contact Name)Phone: (Phone Number)Email: (Email Address)

High-Quality C/Z Purlin Roll Forming Machine for Sale - Complete Guide

C/Z Purlin Roll Forming Machine: Revolutionizing the Construction IndustryIn recent years, there has been a significant shift in the construction industry towards more efficient and cost-effective building materials and methods. One of the key innovations that has emerged to meet this demand is the C/Z Purlin Roll Forming Machine. This machine is revolutionizing the way that steel purlins are manufactured, offering a faster, more accurate, and more cost-effective method for producing these essential building components.The C/Z Purlin Roll Forming Machine, manufactured by {company name}, is designed to produce high-quality steel purlins with incredible speed and efficiency. The machine is capable of forming both C and Z shaped purlins, which are essential components in the construction of steel-framed buildings. These purlins are used to provide structural support and stability to the building, making them a critical component in the construction process.The traditional method of manufacturing steel purlins involved cutting and punching individual pieces of steel, which was a time-consuming and labor-intensive process. However, the C/Z Purlin Roll Forming Machine has completely transformed this process. The machine uses a continuous rolling process to form the steel into the desired shape, eliminating the need for cutting and punching individual pieces. This not only speeds up the manufacturing process but also results in a more accurate and consistent product.Additionally, the C/Z Purlin Roll Forming Machine is highly versatile, capable of producing purlins in a wide range of sizes and thicknesses. This makes it suitable for a variety of construction projects, from small-scale residential buildings to large industrial structures. The machine can also be easily adjusted to accommodate changes in production requirements, making it a highly adaptable and efficient tool for any construction project.One of the key advantages of the C/Z Purlin Roll Forming Machine is its cost-effectiveness. By streamlining the manufacturing process and reducing the amount of labor required, the machine significantly lowers the production costs associated with steel purlins. This not only benefits the manufacturers but also makes steel-framed construction more affordable for builders and developers. As a result, the machine is helping to make steel-framed construction more accessible and attractive to a wider range of customers.{Company name} has gained a strong reputation as a leading manufacturer of roll forming machines, with a commitment to innovation and quality. The company's C/Z Purlin Roll Forming Machine is a testament to their dedication to developing cutting-edge technology that meets the evolving needs of the construction industry. With a focus on precision engineering and high-quality components, {company name} has positioned itself as a trusted partner for construction companies looking to improve their manufacturing processes.The C/Z Purlin Roll Forming Machine is not only revolutionizing the way steel purlins are manufactured but is also contributing to the overall advancement of the construction industry. By offering a more efficient, cost-effective, and versatile method for producing these essential building components, the machine is helping to drive innovation and progress in the field of construction.In conclusion, the C/Z Purlin Roll Forming Machine is a game-changer for the construction industry. Its speed, efficiency, versatility, and cost-effectiveness are revolutionizing the way steel purlins are manufactured, making steel-framed construction more accessible and attractive to a wider range of customers. As a leading manufacturer of roll forming machines, {company name} is at the forefront of this transformation, with a commitment to delivering cutting-edge technology that meets the evolving needs of the construction industry. With the C/Z Purlin Roll Forming Machine, {company name} is not just shaping steel, it's shaping the future of construction.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

Rent Wood Deck Sanding Machine for Your Next Project

Wood Deck Sanding Machine Rental Now Available at {Company Name}{City, State} - {Company Name} is pleased to announce the addition of wood deck sanding machine rentals to their extensive list of offerings. As a leader in the equipment rental industry, {Company Name} is continually expanding their inventory to provide customers with the tools they need to complete any project.The wood deck sanding machine is the latest addition to {Company Name}'s rental fleet, and it is already generating significant interest from homeowners and contractors alike. With the ability to quickly and efficiently sand and refinish wooden decks, this machine is a game-changer for anyone looking to improve the appearance and longevity of their outdoor living space."Our goal at {Company Name} is to provide our customers with the best tools and equipment to help them take on their projects with confidence," said {Spokesperson Name}, {Title} at {Company Name}. "With the addition of the wood deck sanding machine to our rental fleet, we are excited to offer a solution to anyone looking to revitalize their outdoor space."The wood deck sanding machine is designed for ease of use, with features that make it suitable for both novices and experienced contractors. Its powerful motor and ergonomic design allow for efficient and precise sanding, resulting in professional-quality finishes. Additionally, the machine's dust collection system ensures a clean and safe work environment.{Company Name} is proud to offer flexible rental options for the wood deck sanding machine, including daily, weekly, and monthly rates to accommodate projects of any size. Their team of knowledgeable staff are available to assist customers in selecting the best equipment for their specific needs and provide guidance on how to use it effectively.In addition to the wood deck sanding machine, {Company Name} offers an extensive range of equipment for rent, including construction tools, landscaping machinery, and maintenance equipment. With a commitment to customer satisfaction, they strive to provide a seamless rental experience from start to finish."Whether you are a homeowner looking to tackle a DIY project or a professional contractor in need of specialized equipment, {Company Name} is here to support you," said {Spokesperson Name}. "We take pride in offering top-quality rentals and exceptional customer service to ensure that every customer has a positive experience with us."{Company Name} is excited to bring the wood deck sanding machine rental to {City, State} and looks forward to empowering customers to enhance their outdoor spaces with this innovative tool. For more information about the wood deck sanding machine or to inquire about other rental offerings, customers are encouraged to contact {Company Name}.About {Company Name}:{Company Name} has been a trusted name in the equipment rental industry for [number] years. With a wide selection of tools and machinery available for rent, they serve customers in {City, State} and beyond. {Company Name} is dedicated to providing exceptional rentals, expert guidance, and reliable service to support customers in achieving their project goals.For media inquiries, please contact:{Contact Person}{Company Name}Phone: [Phone Number]Email: [Email Address]Website: [Website]