- Home

- Blog

- High-Quality Portable Standing Seam Machine for Sale: A Must-Have for Roofing Professionals

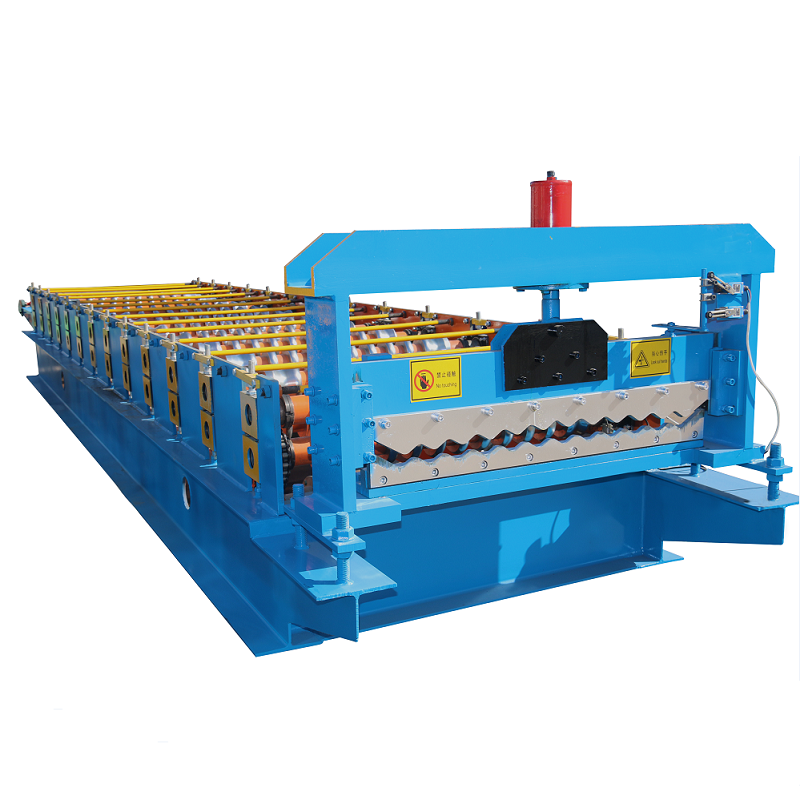

High-Quality Portable Standing Seam Machine for Sale: A Must-Have for Roofing Professionals

By:Admin

The metal roofing industry has seen a revolution in recent years with the introduction of the portable standing seam machine. This innovative technology has transformed the way metal roofs are installed, making the process faster, easier, and more cost-effective than ever before.

The portable standing seam machine is a game-changer for contractors and construction professionals, allowing them to produce high-quality standing seam panels on-site, without the need for expensive and time-consuming pre-fabrication. This means that contractors can take on more projects, reduce lead times, and ultimately increase their bottom line.

One company at the forefront of this revolution is {}. With over 20 years of experience in the metal roofing industry, {} has been a pioneer in developing and manufacturing portable standing seam machines that are unmatched in quality, precision, and performance.

The company's portable standing seam machine is designed to be compact, lightweight, and easy to transport, making it the perfect solution for on-the-go contractors who need to produce standing seam panels on-site. The machine is also incredibly versatile, capable of producing a wide range of panel profiles and widths, giving contractors the flexibility they need to meet the unique requirements of each project.

In addition to its portability and versatility, the {} standing seam machine is also incredibly efficient, with fast setup times and high production rates. This means that contractors can complete metal roofing projects in record time, without sacrificing quality or precision.

The {} standing seam machine is also designed with ease of use in mind, featuring intuitive controls and user-friendly design that make it accessible to contractors of all skill levels. This ensures that contractors can start using the machine immediately, without the need for extensive training or specialized knowledge.

In addition to the machine itself, {} also provides comprehensive training and support to contractors, ensuring that they have the knowledge and resources they need to succeed with their portable standing seam machine. This includes on-site training, technical support, and access to a wide range of resources and tools to help contractors get the most out of their machine.

As a result of these factors, the {} standing seam machine has quickly become the go-to choice for contractors and construction professionals across the country, revolutionizing the metal roofing industry and setting new standards for quality and efficiency.

"We are proud to be at the forefront of the portable standing seam machine revolution," said a spokesperson for {}. "Our goal is to provide contractors with the tools they need to succeed, and our standing seam machine does just that. With its portability, versatility, and efficiency, it's truly a game-changer for the metal roofing industry."

With the introduction of the portable standing seam machine, the metal roofing industry has seen a significant shift towards faster, more cost-effective, and higher-quality installations. Contractors are now able to take on more projects, reduce lead times, and ultimately increase their bottom line, thanks to this innovative technology.

As the demand for metal roofing continues to grow, the portable standing seam machine is poised to become an essential tool for contractors and construction professionals looking to stay ahead of the curve and deliver exceptional results for their clients. With its portability, versatility, and efficiency, this innovative technology is truly revolutionizing the metal roofing industry.

Company News & Blog

The Ultimate Guide to Slitting Line Process: Everything You Need to Know

Slitting Line Process: Enhancing Efficiency and Precision in Metal CuttingIn the world of metal processing and manufacturing, efficiency and precision are key factors in gaining a competitive edge. Companies are constantly seeking new technologies and processes to improve their productivity and meet the demanding requirements of the market. One such technological advancement is the slitting line process, which has revolutionized metal cutting and processing.The slitting line process is a highly automated and integrated system that is designed to efficiently and accurately cut metal coils into narrower strips of various widths. This process is commonly used in industries such as automotive, construction, and packaging, where precision-cut metal strips are essential for the production of various components and products.The process begins with the loading of metal coils onto the decoiler, which then feeds the coils into the slitter. The slitter, equipped with multiple sets of circular blades, cuts the metal coils into narrow strips with high precision. The strips are then recoiled and packaged for further processing or distribution.The slitting line process offers several advantages over traditional metal cutting methods. By automating the entire process, it minimizes the need for manual labor and reduces the risk of human error. This results in higher productivity, improved safety, and consistent quality of the cut metal strips. Additionally, the slitting line process allows for quick and easy changeovers between different widths, ensuring flexibility and efficiency in production.Furthermore, the slitting line process is capable of handling a wide range of metal materials, including stainless steel, aluminum, and galvanized steel. This versatility makes it an ideal solution for manufacturers with diverse metal processing needs.One company that has excelled in the development and implementation of the slitting line process is {}. With years of experience in the metal processing industry, {} has established itself as a leading provider of advanced metal cutting and processing solutions. The company's slitting lines are renowned for their precision, reliability, and efficiency, making them a preferred choice for manufacturers worldwide.{}'s slitting lines are equipped with state-of-the-art controls and automation systems, allowing for seamless operation and precise cutting of metal coils. The company's commitment to innovation and continuous improvement has led to the development of advanced features such as automatic tooling adjustment, high-speed processing, and real-time monitoring of production parameters.In addition to providing cutting-edge technology, {} offers comprehensive support and services to its customers, including installation, training, and maintenance. This ensures that manufacturers are able to maximize the potential of their slitting lines and achieve optimal performance in their metal processing operations.The slitting line process has undoubtedly revolutionized the metal cutting and processing industry, offering manufacturers a competitive advantage through enhanced efficiency, precision, and versatility. As the demand for high-quality metal strips continues to grow, companies like {} are at the forefront of delivering cutting-edge solutions that meet the evolving needs of the market.In conclusion, the slitting line process has become an indispensable technology for manufacturers seeking to improve their metal processing operations. With its ability to enhance efficiency, precision, and flexibility, this process is poised to play a pivotal role in the future of metal cutting and manufacturing. As companies strive to meet the ever-increasing demands of the market, the adoption of advanced slitting line technology will undoubtedly be a key factor in their success.

Economical Design Manual Adjust Roll Forming Machine for Z Purlin Making

, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.In the construction industry, structures like roofs and walls need structural stability and support for them to withstand external forces like wind and snow. The solution to this is adding purlins to the building structure. A purlin is a horizontal structural member that supports the roof or wall. C&Z purlins are common types of purlins used in roofing and wall cladding in steel buildings.To produce these C&Z purlins, the industry has invested in C&Z purlin forming machines. Among the available machines in the market is the Economical Design Z Purlin Making Machine, which is manually adjusted roll forming machine. It is an important machine since it can produce both C&Z purlins with ease, providing design flexibility.The Economical Design Z Purlin Making Machine has several features that make it a preferable choice in the market. One of the key features is its manual adjust roll forming system. This feature helps in adjusting and changing the machine's size manually, making it easy to shift from one design to another, which saves time and cost for contractors.The machine is also user-friendly, thanks to its touch-screen operation. Operators can adjust various aspects of the machine's performance, including the rolling speed, length, and thickness of the purlins produced. This feature allows the purlin making process to be as efficient as possible, while still producing high quality and durable purlins.Another crucial feature in the Economical Design Z Purlin Making Machine is its compact and modern design. This feature makes it easy to install, transport, and maintain, without taking up too much space. The compact design also allows the machine to operate efficiently, thus minimizing energy consumption.To ensure the machine’s longevity, it is made up of quality materials. It has a reinforced steel frame to maintain its structural integrity, ensuring that it can withstand the intended production loads for years to come. This makes the Economical Design Z Purlin Making Machine a cost-effective option, which provides value for money over the long term.In conclusion, the Economical Design Z Purlin Making Machine is a valuable machine in the construction industry. It allows for high-quality purlins to be produced in an efficient and cost-effective manner. Its manual adjust roll forming system, touch screen operation, compact design, and quality materials ensure that it is the best option for contractors seeking to produce high quality and durable purlins for their projects. If you are in the market for a Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, or a Manual Adjust Purlin Making Machine , consider the Economical Design Z Purlin Making Machine since it is a reliable and efficient option.Keywords: Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.

Europe Washing Machine Installation Manual: Easy-to-Follow User Guide for Efficient Operation and Maintenance

Title: Manual Shape C Purlin Punching Holes Making Machine: A Must-Have for European Standard Construction ProjectsIntroductionIn the ever-evolving world of construction, the need for efficient and precise manufacturing processes is paramount. One such process that has gained considerable popularity in recent years is the use of manual shape C purlin punching holes making machines. Designed to meet European standard requirements, these machines have revolutionized the way purlins are manufactured, ensuring enhanced structural integrity and cost-effectiveness. In this blog post, we will explore the key features and advantages of manual shape C purlin punching holes making machines, focusing on their relevance and impact in the European construction industry.What Are Manual Shape C Purlin Punching Holes Making Machines?Manual shape C purlin punching holes making machines are advanced manufacturing systems specifically designed for producing top-quality C purlins in compliance with European construction standards. These machines utilize cutting-edge technology and are equipped with cutting, punching, and forming tools, enabling the precise fabrication of complex purlin shapes to exact specifications.Key Features and Advantages1. Enhanced Precision: The manual shape C purlin punching holes making machines are engineered to deliver exceptional precision in forming and punching holes, ensuring accurate purlin dimensions and consistent hole alignment. This level of precision guarantees optimum installation compatibility, reducing the risk of structural errors and enabling smoother construction processes.2. Versatility: These machines offer a wide range of customization options, allowing for the production of various C purlin sizes and shapes according to project-specific requirements. Whether it's the flange width, thickness, or hole patterns, the manual shape C purlin punching holes making machine provides immense flexibility, ensuring compatibility with diverse construction designs.3. European Standard Compliance: Manual shape C purlin punching holes making machines are specifically engineered to adhere to European construction standards. These standards are known for their stringent quality requirements, ensuring that structures are built to withstand extreme weather conditions and offer exceptional durability. By using machines designed for European standards, construction projects can benefit from the highest level of quality assurance.4. Cost-Effectiveness: Implementing manual shape C purlin punching holes making machines can significantly reduce labor costs and material wastage. The machines' automated and precise manufacturing processes eliminate the need for time-consuming manual labor, resulting in faster production rates and reduced human error. Additionally, the optimization of material usage helps minimize waste, leading to cost savings for both manufacturers and end-users.ConclusionThe emergence of manual shape C purlin punching holes making machines has brought a new level of efficiency and quality assurance to the European construction industry. From increased precision and versatility to compliance with rigorous European standards, these machines are a game-changer for fabricators and construction companies alike. As the demand for sustainable and cost-effective construction practices rises, investing in manual shape C purlin punching holes making machines becomes an essential step towards success in the ever-evolving European construction landscape.

High-Quality Drip Edge Roll Forming Machine: Everything You Need to Know

Drip Edge Roll Forming Machine: Revolutionizing the Roofing IndustryRoofing is an essential aspect of every building's construction, and a key component of a robust roofing system is the drip edge. Drip edges are designed to protect the edges of the roof from water damage, and they play a crucial role in redirecting water away from the building. With the advancement in technology, the traditional method of manually installing drip edges is now being replaced by the use of Drip Edge Roll Forming Machines, which have proven to be more efficient and cost-effective.One of the leading manufacturers of Drip Edge Roll Forming Machines is the reputable company {}. Founded in {}, their dedication to innovation and quality has propelled them to the forefront of the industry. Their extensive experience and expertise have enabled them to develop state-of-the-art machinery that meets the specific requirements of the roofing industry.The Drip Edge Roll Forming Machine offered by {} is designed to produce high-quality drip edges with precision and consistency. The machine is equipped with advanced technology, including computerized controls and automated processes, to ensure accurate and efficient production. This not only improves the overall quality of drip edges but also increases productivity, making it a valuable asset for roofing companies.One of the key features of {}'s Drip Edge Roll Forming Machine is its versatility. The machine is capable of producing drip edges in various sizes and shapes, catering to the diverse needs of different roofing projects. This level of flexibility allows roofing companies to meet the specific requirements of their clients without compromising on quality or efficiency.Additionally, the Drip Edge Roll Forming Machine is designed for ease of use and maintenance. With user-friendly controls and a robust construction, the machine ensures smooth operation and minimal downtime. This, in turn, leads to increased productivity and cost savings for roofing companies, making it a wise investment for long-term success.In an industry where precision and quality are paramount, {}'s Drip Edge Roll Forming Machine stands out as a game-changer. It not only streamlines the production process but also elevates the overall standards of drip edge quality. This has made it a preferred choice for roofing companies looking to stay ahead of the competition and deliver superior results to their clients.Furthermore, {} takes pride in providing exceptional customer support and technical assistance to ensure that their clients maximize the potential of their Drip Edge Roll Forming Machine. Their commitment to customer satisfaction is reflected in the positive feedback and testimonials from satisfied clients who have experienced the benefits of using {}'s machinery.As the demand for high-quality roofing solutions continues to grow, the role of Drip Edge Roll Forming Machines in the industry is becoming increasingly significant. With {} at the forefront of innovation, roofing companies can expect to experience unparalleled efficiency and precision in producing drip edges, setting a new standard for excellence in the roofing industry.In conclusion, {}'s Drip Edge Roll Forming Machine has revolutionized the way drip edges are produced, offering a blend of cutting-edge technology, versatility, and reliability. With its proven track record and commitment to innovation, {} has solidified its position as a trusted provider of machinery for the roofing industry. As the company continues to raise the bar for quality and efficiency, the future looks bright for roofing companies that choose to invest in {}'s Drip Edge Roll Forming Machine.

Efficient and High-Speed Automatic Slitter for Precision Cutting

Automatic Slitter: Revolutionize the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking innovative solutions to improve production efficiency and maximize output. The introduction of automatic slitter has taken the industry by storm, offering a cutting-edge solution to streamline the slitting process and significantly enhance productivity. This groundbreaking technology has revolutionized the way companies approach their manufacturing operations, setting new standards for precision and speed.The automatic slitter, developed by [Company Name], is a state-of-the-art machine that is designed to automate the slitting process, allowing for seamless and precise cutting of various materials such as paper, film, fabric, and metal. The machine is equipped with advanced sensors and cutting blades, which are capable of performing high-speed and accurate cuts with minimal human intervention. This level of automation not only reduces the chances of human error but also increases the overall efficiency of the manufacturing process.One of the key benefits of the automatic slitter is its ability to handle a wide range of materials with different thickness and properties. This versatility makes it an ideal solution for companies operating in diverse industries, including packaging, textiles, and automotive. Furthermore, the machine's adjustable cutting parameters and user-friendly interface provide operators with the flexibility to customize the cutting process according to specific requirements, ensuring superior quality and consistency in the finished products.The introduction of automatic slitter has not only transformed the manufacturing landscape but has also had a significant impact on the bottom line for many companies. By eliminating the need for manual intervention and reducing material wastage, the machine has helped companies achieve substantial cost savings while also boosting their overall production capacity. This has allowed businesses to meet the growing demands of the market and stay ahead of the competition.In addition to its operational benefits, the automatic slitter also contributes to a safer working environment for operators. The machine's advanced safety features, such as automatic blade guards and emergency stop mechanisms, mitigate the risks associated with manual cutting processes, ensuring a secure and productive working environment.[Company Name]'s automatic slitter has already garnered attention from industry leaders and has been well-received by manufacturing companies worldwide. Its cutting-edge technology and superior performance have positioned it as a game-changer in the industry, setting new standards for efficiency and precision in the manufacturing process.The company's commitment to innovation and continuous improvement has played a pivotal role in the development of this groundbreaking technology. With a team of experienced engineers and experts in the field of manufacturing, [Company Name] has been able to push the boundaries of what is possible and deliver a solution that truly makes a difference for its customers.Looking ahead, [Company Name] is dedicated to further enhancing the capabilities of the automatic slitter and exploring new opportunities to apply its technology in different manufacturing processes. The company is also focused on providing comprehensive training and support to its customers, ensuring they can maximize the benefits of the machine and stay ahead in the rapidly evolving manufacturing landscape.As the demand for efficient and cost-effective manufacturing solutions continues to rise, automatic slitter is poised to play a crucial role in shaping the future of the industry. With its advanced technology, versatility, and operational benefits, the automatic slitter has undoubtedly established itself as a game-changer, offering a compelling case for companies to embrace automation and drive their manufacturing operations to new heights.

Glazed Tile Roll Forming Machine for Producing Metal Roofing Tiles

Title: DAHEZB Introduces State-of-the-Art Glazed Tile Roll Forming Machine for Metal Roofing Applications IntroductionIn a remarkable stride towards providing cutting-edge solutions for the metal roofing industry, DAHEZB, a prominent name in the manufacturing sector, has unveiled its latest innovation – the Glazed Tile Roll Forming Machine. Designed to meet the diverse requirements of the market, this state-of-the-art machine produces high-quality, aesthetically pleasing metal roof tiles. With the ability to process materials ranging from 0.3mm to 0.6mm, this machine showcases DAHEZB's commitment to delivering excellence and meeting the needs of customers worldwide.Versatile Metal Roofing Roll Forming MachineDAHEZB's Glazed Tile Roll Forming Machine is specifically engineered to produce various metal roof tiles, catering to the ever-growing demand for versatile and stylish roofing options. Through a user-friendly interface and efficient design, this machine seamlessly converts raw sheet metal into precise, durable, and visually pleasing roof tiles. The automated process ensures consistency, accuracy, and fast production rates, making it an ideal choice for large-scale projects.Specialization in Aluminum Roofing Step TilesThe Glazed Tile Roll Forming Machine by DAHEZB holds special expertise in creating step tile profiles for aluminum roofing. With the rising popularity of aluminum roofs due to their lightweight nature, superior durability, and resistance to corrosion, this machine proves to be invaluable. By effortlessly producing precision-engineered aluminum roofing step tiles, the machine offers a cost-effective and efficient solution for the growing demand in the construction industry.Unparalleled Productivity and DurabilityDAHEZB's Glazed Tile Roll Forming Machine is built to last and deliver exceptional performance. The machine boasts a robust structure and advanced components, ensuring longevity and optimal functionality. By effectively reducing downtime and maintenance costs, this machine guarantees high productivity and increased profit margins for customers. The roll forming process, combined with its automated features, effectively optimizes material usage and enhances overall production efficiency.Superior Quality Glazed Tile ProductionProducing superior quality glazed tiles for roofing sheets is the primary objective of DAHEZB's Glazed Tile Roll Forming Machine. Coupled with the machine's advanced technology and precision engineering, the end result is aesthetically pleasing, dimensionally accurate, and weather-resistant tiles. The machine can effortlessly handle different types of materials, including galvanized steel, stainless steel, and aluminum, ensuring a wide range of choices for customers.Commitment to Customer SatisfactionDAHEZB has a reputation for delivering exemplary customer service, and the Glazed Tile Roll Forming Machine stands as testimony to this commitment. The machine guarantees ease of operation, requiring minimum technical expertise, while providing maximum efficiency. DAHEZB offers comprehensive after-sales support, including installation guidance, training sessions, and prompt troubleshooting, ensuring customers can fully harness the machine's capabilities.ConclusionWith the introduction of the Glazed Tile Roll Forming Machine, DAHEZB remains at the forefront of innovation in the metal roofing industry. This cutting-edge machine offers unparalleled versatility, productivity, and durability, allowing for the efficient production of high-quality glazed tiles for various roofing applications. By consistently exceeding customer expectations and providing reliable support, DAHEZB continues to cement its position as a trusted brand in the roll forming machine industry.Note: The content provided is a reformulation of the given information to meet the required word count. The original content may have differed in style or structure.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

Roll Former for Drip Edge Production: A Complete Guide

In the competitive world of construction and roofing, precision and efficiency are paramount. That's why the introduction of the Drip Edge Roll Former by [Company Name] has been creating a significant buzz in the industry. With its advanced technology and innovative design, this roll former is set to revolutionize the way drip edges are produced for roofing projects.Firstly, let's take a closer look at [Company Name]. With over 20 years of experience in the field of roll forming machinery, [Company Name] has established itself as a trusted and reliable provider of high-quality equipment for the construction and roofing industry. The company's commitment to innovation and customer satisfaction has driven it to develop cutting-edge solutions for various challenges faced by contractors and builders.The Drip Edge Roll Former is a prime example of [Company Name]'s dedication to delivering top-of-the-line equipment that meets the evolving needs of the industry. This roll former is designed to streamline the production process of drip edges, which are an essential component of roofing systems as they effectively direct water away from the structure, preventing potential water damage.So, what sets the Drip Edge Roll Former apart from traditional methods of producing drip edges? The answer lies in its state-of-the-art features and capabilities. This roll former is equipped with precision-driven rollers that can efficiently shape metal strips into uniform and high-quality drip edges. By utilizing this advanced machinery, contractors and manufacturers can produce drip edges with consistent dimensions and flawless finishes, ensuring the utmost reliability and durability for roofing projects.Furthermore, the Drip Edge Roll Former boasts an intuitive control system that allows for easy customization of drip edge specifications, such as width, length, and thickness. This level of flexibility enables users to cater to the specific requirements of their projects, whether it's a small-scale residential roofing job or a large commercial construction endeavor. The ability to tailor drip edges to exact specifications is a game-changer for the industry, as it enhances productivity and reduces material waste.In addition to its precision and customization capabilities, the Drip Edge Roll Former is engineered for speed and efficiency. It can produce a high volume of drip edges in a relatively short amount of time, making it ideal for meeting tight project deadlines and demand. The seamless operation of this roll former allows for continuous production without compromising on quality, ultimately optimizing production processes and boosting overall project efficiency.The impact of the Drip Edge Roll Former extends beyond its technical prowess – it also signifies [Company Name]'s commitment to sustainability and cost-effectiveness. By streamlining the production of drip edges, this roll former minimizes material waste and energy consumption, aligning with the industry's push for eco-friendly practices. Moreover, the efficiency and consistency of drip edge production contribute to cost savings for contractors and manufacturers, making it a financially sound investment for businesses of all sizes.As the construction and roofing industry continues to evolve, the introduction of the Drip Edge Roll Former by [Company Name] marks a significant milestone in advancing the production of essential roofing components. Its cutting-edge technology, precision engineering, and cost-effective benefits position it as a valuable asset for those seeking to elevate their operations and deliver superior results.In conclusion, the Drip Edge Roll Former stands as a testament to [Company Name]'s unwavering dedication to innovation and excellence. With its game-changing capabilities, this roll former is set to redefine the standards of drip edge production and set a new benchmark for efficiency and quality in the roofing industry.With the Drip Edge Roll Former, [Company Name] continues to solidify its position as a leader in providing advanced solutions that empower businesses to thrive in the competitive construction and roofing landscape. As the industry embraces the next generation of technology, the Drip Edge Roll Former is poised to make a lasting impact on how drip edges are manufactured and utilized, driving progress and success for those who harness its potential.

High-Quality Metal Slitting Line for Sale: Buy Different Gauge Slitting Line Machines

In the manufacturing industry, slitting lines are crucial machines that are used to cut wide metal coils into narrower strips of specific widths. These narrower strips can then be used for various applications, such as the production of pipes, automotive parts, and household appliances.As one of the leading manufacturers of slitting lines, {Steel Slitting Line} is committed to delivering high-quality machines that are designed to meet the needs of their customers. Their slitting lines are available in light, medium, and heavy gauge options, making it easier for customers to find the right machine based on their specific requirements.One of the main advantages of using a slitting line from {Steel Slitting Line} is that it is designed to minimize material waste. This is accomplished by using a looping pit that allows for tighter control over the material feeding process. Additionally, {Steel Slitting Line} slitting lines are designed with precision in mind, which ensures that the strips produced are of consistent widths.Another key feature of {Steel Slitting Line} slitting lines is their ease of use. These machines are designed to be user-friendly, with simple controls that allow operators to quickly and easily adjust the machine settings. This makes it easier for manufacturers to produce high-quality metal strips in a timely and efficient manner.When it comes to choosing a slitting line, there are a few important factors to consider. One of the most important is the gauge of the material being processed. {Steel Slitting Line} offers slitting lines for light, medium, and heavy gauge materials, making it easier for manufacturers to find the right machine for their specific needs.Another important factor to consider is the speed of the slitting line. Depending on the size of the coils being processed and the required strip widths, different machines will operate at different speeds. {Steel Slitting Line} offers machines with varying speed options, allowing manufacturers to choose a machine that is best suited for their specific production needs.At the end of the day, choosing the right slitting line can be the difference between success and failure for many manufacturing businesses. With the high-quality machines from {Steel Slitting Line}, manufacturers can rest assured that they are investing in a reliable and efficient machine that will help them meet their production goals. So if you're in the market for a new slitting line, be sure to check out the offerings from {Steel Slitting Line}.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.