High-quality Pultrusion Machine for FRP Cable Trays

By:Admin

The pultrusion process is a manufacturing method that involves pulling and shaping continuous fiber reinforcements through a liquid resin bath. This process results in a high-strength, lightweight, and corrosion-resistant product that is ideal for a wide range of industrial applications. The FRP Cable Tray Pultrusion Machine utilizes advanced technology to precisely control the pultrusion process, ensuring that the resulting cable trays meet the highest quality standards.

With the growing demand for durable and corrosion-resistant cable management systems, the FRP Cable Tray Pultrusion Machine is poised to revolutionize the industry. The machine is capable of producing a wide range of cable tray profiles, including ladder, perforated, and solid-bottom designs, to accommodate various installation requirements. Additionally, the machine can be customized to produce cable trays in different widths, depths, and load capacities, making it a versatile solution for diverse project specifications.

The company behind the FRP Cable Tray Pultrusion Machine is a renowned industry leader with a proven track record of delivering innovative solutions for the composite manufacturing sector. With years of experience and expertise in pultrusion technology, the company has earned a reputation for producing high-quality machinery that meets the evolving needs of the market.

In addition to the FRP Cable Tray Pultrusion Machine, the company offers a comprehensive range of pultrusion equipment and systems for various applications, including structural profiles, grating, rods, and tubes. The company's commitment to research and development has led to the continual advancement of its pultrusion machinery, ensuring that customers receive state-of-the-art solutions that deliver superior performance and reliability.

The FRP Cable Tray Pultrusion Machine is equipped with advanced features that enhance productivity and efficiency. Its automated control system allows for precise monitoring and adjustment of the pultrusion parameters, ensuring consistent product quality and dimensional accuracy. The machine's robust construction and durable components contribute to its reliability and long-term performance, making it a valuable investment for manufacturers seeking to streamline their production processes.

Moreover, the company provides comprehensive technical support and training services to assist customers in maximizing the potential of the FRP Cable Tray Pultrusion Machine. From installation and commissioning to maintenance and troubleshooting, the company's team of experts is dedicated to ensuring that customers achieve optimal results with their pultrusion equipment.

As the demand for high-performance cable management solutions continues to grow, the FRP Cable Tray Pultrusion Machine is poised to be a valuable asset for manufacturers looking to stay ahead in the market. Its ability to deliver superior quality, flexibility, and efficiency makes it a standout solution for producing FRP cable trays that meet the stringent requirements of modern industrial and commercial projects.

In conclusion, the FRP Cable Tray Pultrusion Machine represents a significant advancement in pultrusion technology, offering manufacturers a competitive edge in producing high-quality and durable cable management systems. With the backing of a leading industry player, this innovative machine is set to make a lasting impact on the composite manufacturing sector, driving efficiency and excellence in cable tray production.

Company News & Blog

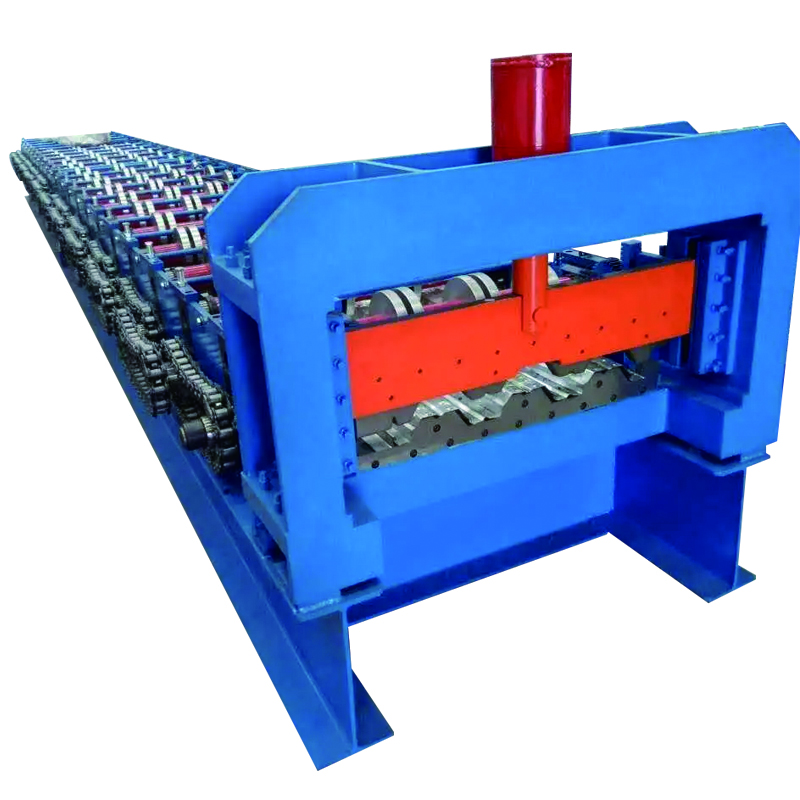

Roll Forming Machine Manufacturers For Sale in China - Superior Quality

Roll Forming Machine Manufacturers in China are Dedicated to Providing High-Quality MachinesIn today's world, the demand for roll forming machines has drastically increased. Roll forming machines are used by manufacturers in diverse industries to create uniform shapes of metal sheets. These machines are highly efficient and produce high-quality products in a short time. There are many roll forming machine manufacturers in China, and RISHBIN is committed to providing customers with the best quality roll forming machines.Founded in 1998, RISHBIN is a sheet metal roll forming machine manufacturer that offers a comprehensive range of roll forming machines for different applications. Over the years, the company has built a reputation for producing high-quality machines that are reliable, efficient, and durable. RISHBIN roll forming machines are used in the construction, automobile, HVAC, and packaging industries.The company prides itself on providing customized solutions to meet the specific needs of their customers. This is possible because RISHBIN has a team of experienced engineers who develop unique designs for their customers. The engineers use modern software to design and simulate the machines before production to ensure that the final product meets the customer's specifications.RISHBIN roll forming machines are designed to be highly efficient in terms of speed and accuracy. The machines are manufactured using the latest technology and high-quality materials to ensure they last longer and require minimal maintenance. The company uses top-quality components such as Mitsubishi, Siemens, and Schneider for the electrical parts, and SKF, NSK, and Timken for the bearings to ensure the machines' high stability and reliability.The company's roll forming machines are available in different models, including simple manual machines, hydraulic machines, and fully automated roll forming machines. This range of machinery allows customers to choose a product that suits their production needs and budget.RISHBIN is also committed to providing excellent customer service. The company has a team of trained and experienced customer service representatives who are available 24/7 to provide support and answer customer questions. This ensures that customers can have peace of mind knowing that they will receive prompt and efficient after-sales service.In conclusion, RISHBIN is committed to providing customers with the best quality roll forming machines. The company's commitment to quality, efficiency, and customer service has earned it a reputation as one of the leading roll forming machine manufacturers in China. By working with RISHBIN, customers can be assured of getting customized products that meet their specific requirements and budgets.

High-Quality Portable Roll Forming Machine for Sale

Portable Roll Forming Machine Provides Efficient Solution for On-site Metal Fabrication[Company Name], a leading provider of innovative metal forming solutions, has introduced a state-of-the-art portable roll forming machine that is designed to revolutionize on-site metal fabrication processes. This cutting-edge machine offers unparalleled flexibility and efficiency, allowing contractors and builders to streamline their operations and achieve superior results in metal roofing, siding, and other construction applications.The portable roll forming machine is the latest addition to [Company Name]'s comprehensive lineup of metal forming equipment, and it is set to redefine the way metal products are fabricated in the field. With its advanced technology and user-friendly design, this machine enables operators to produce custom metal profiles directly at the job site, eliminating the need for transportation and reducing material waste. This not only saves time and money, but also minimizes the environmental impact of metal fabrication processes.One of the key advantages of the portable roll forming machine is its ability to handle a wide variety of metal materials, including steel, aluminum, and copper. This versatility allows contractors to take on a diverse range of projects without the need for multiple machines, making it an invaluable asset for construction firms of all sizes. In addition, the machine's compact size and lightweight construction make it easy to transport and set up, further enhancing its appeal for on-site fabrication applications.In terms of performance, the portable roll forming machine is engineered to deliver exceptional accuracy and consistency in metal profiling. Its precision roller system and automated controls ensure that each profile meets the exact specifications, resulting in high-quality finished products that meet or exceed industry standards. Furthermore, the machine's adjustable speed and feed settings enable operators to optimize production efficiency and adapt to different material thicknesses with ease.To support users in maximizing the capabilities of the portable roll forming machine, [Company Name] provides comprehensive training and technical support services. Their team of experienced metal forming specialists is on hand to offer guidance on machine setup, operation, and maintenance, ensuring that customers can make the most of their investment and achieve superior results in their metal fabrication projects. This commitment to customer satisfaction is a cornerstone of [Company Name]'s business philosophy, and it has helped them build a reputation as a trusted partner in the metal forming industry."We are thrilled to introduce our portable roll forming machine to the market, as we believe it represents a major breakthrough in on-site metal fabrication technology," said [Spokesperson Name], the CEO of [Company Name]. "This machine is the result of years of research and development, and we are confident that it will empower our customers to take their metal forming capabilities to the next level. From its portable design to its advanced performance features, every aspect of this machine has been engineered with the needs of on-site fabricators in mind."With the introduction of the portable roll forming machine, [Company Name] is poised to set a new standard for on-site metal fabrication efficiency and quality. As construction and renovation projects continue to demand faster turnaround times and superior craftsmanship, this innovative machine is expected to become an indispensable tool for contractors, builders, and metal fabricators seeking to stay ahead of the curve in the industry. [Company Name] remains committed to driving the advancement of metal forming technology, and their portable roll forming machine is a testament to their dedication to innovation and excellence.

High-Quality Steel Sheet Making Machine for Efficient Production

The Steel Sheet Making Machine is a revolutionary piece of equipment that has the ability to transform raw materials into high-quality steel sheets with precision and efficiency. With its advanced technology and innovative design, the machine is set to revolutionize the steel manufacturing industry.The machine, developed by the leading steel manufacturing company, is the result of years of research and development. It incorporates the latest advancements in steel production technology, enabling it to produce steel sheets of superior quality at a faster rate than traditional methods.One of the key features of the Steel Sheet Making Machine is its automation capabilities. The machine is equipped with advanced robotics and control systems that allow it to operate seamlessly and with minimal human intervention. This not only improves production efficiency but also ensures consistent quality in every sheet produced.Furthermore, the machine is designed to be highly customizable, allowing for a wide range of steel sheet specifications to be produced. This versatility makes it an ideal solution for a variety of applications, from construction and automotive manufacturing to consumer goods production.In addition to its technological advancements, the machine also boasts enhanced safety features. With built-in sensors and safety mechanisms, the machine can detect and respond to potential hazards, ensuring a safe working environment for the operators.The company behind the Steel Sheet Making Machine has a long-standing reputation for innovation and excellence in the steel manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in steel production, leading to the development of the highly advanced machine.In addition to its technical expertise, the company also places a strong emphasis on sustainability and environmental responsibility. The Steel Sheet Making Machine is designed to minimize waste and energy consumption, making it a more eco-friendly option compared to traditional steel manufacturing methods.Moreover, the company is committed to providing comprehensive support and maintenance services for the machine, ensuring that it continues to operate at its full potential throughout its lifespan.The introduction of the Steel Sheet Making Machine marks a significant advancement in the steel manufacturing industry. With its cutting-edge technology, high efficiency, and commitment to sustainability, the machine is set to redefine the way steel sheets are produced.As the demand for steel continues to grow across various industries, the Steel Sheet Making Machine offers a solution that is not only capable of meeting this demand but also of doing so in a way that is more efficient, reliable, and sustainable.The company is confident that the machine will have a significant impact on the steel manufacturing industry, providing manufacturers with a competitive edge in the market. With its advanced capabilities and commitment to excellence, the Steel Sheet Making Machine is poised to become a game-changer in the industry, setting new standards for quality and efficiency in steel production.In conclusion, the Steel Sheet Making Machine represents a major step forward in the steel manufacturing industry. With its advanced technology, customizable capabilities, and commitment to sustainability, the machine is poised to revolutionize the way steel sheets are produced, setting new benchmarks for quality, efficiency, and environmental responsibility. The company's dedication to innovation and excellence has culminated in the development of a truly groundbreaking machine that is set to shape the future of steel manufacturing.

High-Strength Multi-Heads Rotary Woodworking CNC Machine for Efficient Wood Processing

Title: Multi-Head Rotary Woodworking CNC Machine: Advancing Efficiency in Residential and Commercial Woodwork ProjectsIntroductionIn the world of woodworking, the demand for precision and efficiency is paramount. With advancements in technology, the introduction of Multi-Head Rotary Woodworking CNC Machines has revolutionized the industry. HBHongchen.com proudly presents a woodworking CNC router that is designed to meet the diverse needs of both residential and commercial projects, offering a range of advantages that make it an essential tool for anyone involved in the woodworking field.High-Strength Design and Enhanced SpeedOne of the key advantages of the woodworking CNC router is its high-strength body design. Equipped with double driving motors on the Y-axis, the machine operates with more remarkable precision and efficiency than ever before. The more reasonable and advanced design ensures fast processing speeds, reducing project completion times significantly. This improved speed is a boon for both large-scale commercial projects and intricate residential woodworking endeavors.Easy Operation and Low MaintenanceThe woodworking CNC router prides itself on its user-friendly interface, making it easily operable even by novices in the woodworking field. The machine's design incorporates simplicity, allowing operators to quickly grasp its functionalities and navigate through its various features effortlessly. Additionally, the easy-operated maintenance feature allows users to perform routine checks and troubleshoot efficiently, minimizing downtime and optimizing productivity.Reduced Fault Rate for Increased ReliabilityWoodworking projects can often be time-consuming, and any unanticipated faults in the machinery can result in costly delays. However, the woodworking CNC router boasts an exceptionally low fault rate, ensuring reliability throughout the production process. This unwavering performance provides peace of mind for both individual craftsmen and commercial manufacturers, allowing them to focus on their core woodworking tasks without unnecessary interruptions.Premium Drivers and MotorsA key component of the woodworking CNC router's efficiency lies in the integration of famous brand drivers and motors. It is important to note that specific brand names have been omitted for this content. However, the woodworking CNC machine incorporates renowned components that meet and exceed industry standards. These premium drivers and motors ensure smooth and precise operations, providing consistent results regardless of the scale or complexity of the project.Synergy with C Z Purlin Multi-Size Purlin Making MachineHBHongchen.com has also established itself as a leading provider of the C Z Purlin Multi-Size Purlin Making Machine. This innovative equipment enables the efficient production of C and Z-shaped steel purlins, commonly used in residential and commercial building construction. By combining the woodworking CNC router with the C Z Purlin Making Machine, manufacturers can seamlessly transition between woodworking and metalworking, streamlining their production processes and maximizing productivity.ConclusionThe Multi-Head Rotary Woodworking CNC Machine provided by HBHongchen.com offers a range of advantages that elevate its performance in residential and commercial woodworking projects. With its high-strength body design, fast processing speeds, easy operation, low maintenance requirements, and premium quality drivers and motors, this woodworking CNC router redefines efficiency and reliability in the woodworking industry.Furthermore, by integrating it with the C Z Purlin Multi-Size Purlin Making Machine, manufacturers can seamlessly achieve a smoother transition between woodworking and metalworking processes. For professionals in the woodworking field, investing in this state-of-the-art machinery ensures optimal performance, increased productivity, and cost-effective woodworking solutions. HBHongchen.com leaves no stone unturned in providing woodworking enthusiasts and professionals with the best tools to realize their creative visions while optimally meeting the demands of the industry.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.

High-Quality Roll Making Machine for Efficient Production

Roll Making Machine upgrades to provide enhanced efficiency and precision for the manufacturing industry. The new and improved roll making machine has been developed by a leading company in the manufacturing industry. With advanced technology and state-of-the-art engineering, the machine is designed to meet the growing demands of the industry for higher productivity and product quality.The roll making machine is an essential tool for various manufacturing processes, including paper, plastic, metal, and textile production. It is used to fabricate rolls of different sizes and specifications, which are then integrated into various production lines to facilitate the manufacturing process. The quality and precision of the rolls produced by the machine directly impact the overall efficiency and output of the manufacturing operation.The upgraded roll making machine features advanced automation and control systems, which allow for greater precision and efficiency in roll production. The machine is equipped with high-precision cutting and shaping tools, as well as enhanced material handling and feeding mechanisms, which ensure consistent and accurate roll fabrication. The new technology also enables faster setup and changeover times, reducing downtime and increasing overall productivity.In addition to the technological upgrades, the company has also focused on enhancing the durability and reliability of the roll making machine. The machine is built with high-quality materials and components to ensure long-term performance and minimal maintenance requirements. The robust design and construction of the machine make it suitable for continuous operation in demanding manufacturing environments.Furthermore, the roll making machine is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user interface that provides real-time monitoring and control of the production process, allowing operators to make adjustments and corrections as needed. This not only improves the overall efficiency of the machine but also reduces the potential for errors in roll fabrication.The company behind the development of the roll making machine is a leading manufacturer of industrial machinery and equipment. With decades of experience in the industry, the company has established a reputation for delivering high-quality and innovative solutions to meet the evolving needs of the manufacturing sector. The company's commitment to research and development has led to the continuous improvement of its products, ensuring that they remain at the forefront of technological advancements.The roll making machine is the latest addition to the company's portfolio of manufacturing solutions. By leveraging its expertise in engineering and manufacturing, the company has been able to develop a machine that not only meets the current requirements of the industry but also anticipates future demands. The company's dedication to innovation and quality has positioned it as a trusted partner for manufacturing businesses seeking to enhance their production capabilities.In conclusion, the upgraded roll making machine represents a significant advancement in roll production technology. With its advanced automation, precision, and durability, the machine is poised to have a positive impact on the manufacturing industry, enabling businesses to achieve higher efficiency and product quality. As a leading company in the manufacturing sector, the company's continuous commitment to innovation underscores its role as a key contributor to the advancement of the industry.

High-Quality Steel Coil Slitting Machines for Efficient Metal Sheet Cutting and Stainless Steel Strips

Stainless Steel Strip Slitting Machine: A Revolutionary Solution for Cutting and Slitting Metal SheetsWhen it comes to metalworking, precision and accuracy are critical factors in achieving quality results. One such process is slitting, which involves cutting a wide metal sheet into narrower strips to meet specific requirements. This process is necessary for industries that require smaller widths for their product manufacturing, such as automotive, electronics, and construction.To achieve this, manufacturers use a slitting machine, a unique piece of equipment that cuts and converts metal coils into narrower strips. One type of slitting machine that has gained popularity in recent years is the stainless steel strip slitting machine, which provides greater precision and efficiency in metal sheet cutting.What is a Stainless Steel Strip Slitting Machine?A stainless steel strip slitting machine is a piece of equipment specifically designed for cutting and slitting metal sheets, mainly made of stainless steel. This machine is equipped with a set of blades or knives that sever the material in smaller strips with the desired width. The blades or knives can be adjusted to achieve the desired cut and width of the strips, making it highly customizable.Uses of Stainless Steel Strip Slitting MachineStainless Steel Strip Slitting Machine is widely used in many industries that utilize metal sheets in their manufacturing processes. These include the automotive, aerospace, and construction industries. It is also useful for electronics, textile, and paper industries for creating smaller electronic components and packaging materials.Advantages of Stainless Steel Strip Slitting Machine1.Precision CuttingOne of the primary advantages of using a stainless steel strip slitting machine is its ability to produce precise cuts and meet the required specifications. The machine can cut narrow strips with the desired width and high accuracy, reducing material waste and saving production time.2. High ProductivityStainless Steel Strip Slitting Machine can work continuously, producing strips of varying widths with minimal operator intervention. This leads to increased productivity and output while ensuring consistent quality in products.3. CustomizationThe Stainless Steel Strip Slitting Machine can be customized to meet specific requirements, such as cutting thickness, strip widths, and number of pieces produced per roll.4. DurabilityAs the name suggests, the machine is made of stainless steel, making it resistant to corrosion and ensuring durability. The blades are also made of high-quality materials that can withstand the stress of cutting metal sheets for extended periods.ConclusionIn conclusion, the Stainless Steel Strip Slitting Machine is a revolutionary technology that has changed the game in metal sheet cutting and slitting. It offers high precision, customization, efficiency, and durability in metalworking, making it an excellent investment for industries that rely on metal sheets. With its versatile applications and advantages, it is no wonder why it has become popular among manufacturers. Keywords: Stainless Steel Strip Slitting Machine, Metal Sheet Cutting Machine, Steel Strip Slitting Machine.

Highly Efficient and Advanced Roll Forming Machine for Light Gauge Steel Keels

Light Gauge Steel Keel Roll Forming Machine – Revolutionizing the Construction Industry{Company Introduction}The construction industry has seen significant advancement in recent years with the introduction of new technologies and equipment. One such innovation that has gained tremendous popularity is the light gauge steel keel roll forming machine. These machines are used to produce steel keels that are widely used in construction projects.As the name suggests, light gauge steel keel roll forming machines are designed to produce lightweight steel keels that are used for various purposes in construction projects, such as drywall partitioning, suspended ceilings, and wall framing. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy.The Advantages of Light Gauge Steel Keel Roll Forming MachinesOne of the biggest advantages of light gauge steel keel roll forming machines is their ability to produce steel keels of various sizes and shapes. This means that these machines can produce steel keels that are tailor-made to suit specific construction needs. The use of steel keels produced by these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects.Another significant advantage of light gauge steel keel roll forming machines is their efficiency. These machines are designed to operate at high speeds, which results in a higher production rate and reduced labor costs. Additionally, the use of these machines reduces the need for on-site welding, which not only saves time but also results in higher quality work. Furthermore, these machines can produce steel keels continuously, which means that the production process is faster, more efficient, and more streamlined.Light gauge steel keel roll forming machines are also highly versatile. These machines can produce steel keels of different thicknesses, lengths, and shapes, which means that they can be used in a wide range of construction projects. Moreover, these machines are easy to set up, operate, and maintain, which ensures that they can be used by both large-scale and small-scale construction companies.The Future of Light Gauge Steel Keel Roll Forming MachinesThe demand for light gauge steel keel roll forming machines has been steadily increasing in recent years. This trend is expected to continue in the future as more construction companies realize the benefits of using these machines. The rapid urbanization and industrialization of many countries have also contributed to the growing demand for these machines as they can produce high-quality steel keels that are essential for modern construction.Given these factors, it is safe to say that the future of light gauge steel keel roll forming machines looks bright. Advances in technology are expected to make these machines even more efficient, versatile, and user-friendly than they already are. As a result, more construction companies are expected to adopt these machines, leading to increased productivity, reduced labor costs, and improved quality of work.ConclusionThe light gauge steel keel roll forming machine has revolutionized the construction industry by making the production of steel keels more efficient, versatile, and cost-effective. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy, making them ideal for a wide range of construction projects. Additionally, the use of these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects. With the growing demand for these machines, it is safe to say that they will continue to play a major role in the construction industry for years to come.

Cold Rolling Forming Machines for Automated Production of Various Roofing Sheets

and IBR sheet making machine.Roof Sheet Making Machines - An OverviewRoof sheet making machines are modern-day machines that utilize the cold roll forming principle to produce roofing sheets in bulk. These machines are also known as IBR sheet making machines or color steel roll forming machines. They are fully automatic and designed to produce sheets in a variety of designs and dimensions. They are robust, reliable, and highly efficient, capable of producing high-quality roofing sheets that can be used for AD boards, wall panels, and other applications.The Working Principle of Roof Sheet Making MachinesRoof sheet making machines use a series of rollers to form different shapes and designs on flat metal sheets. The process begins when the metal sheet passes through the first set of rollers, which bend it into a curve. The sheet then moves through several sets of rollers, each producing a different shape and size until the final product is produced. The rollers on these machines are designed to be adjustable, allowing operators to create different designs, dimensions, and shapes.Advantages of Roof Sheet Making MachinesRoof sheet making machines offer several benefits, including:1. High efficiency - Roof sheet making machines are fully automatic and can produce large quantities of roofing sheets in a short period. This makes them ideal for mass production.2. Customization - With the adjustable rollers, roof sheet making machines make it possible to create unique designs and shapes that meet specific customer requirements.3. Low maintenance - These machines are designed to be low maintenance, reducing the overall cost of operation.4. High-quality output - Roof sheet making machines produce high-quality roofing sheets that are durable, robust, and weather-resistant.Applications of Roof Sheet Making MachinesRoof sheet making machines find broad applications in the construction industry, particularly in roofing. The roofing sheets produced by these machines are used for:1. Residential roofing - The roofing sheets are used to create attractive, durable, and weather-resistant roofs for homes.2. Commercial roofing - Roof sheet making machines produce roofing sheets that are ideal for commercial buildings such as warehouses, factories, and workshops.3. Agricultural roofing - The roofing sheets are ideal for agricultural use since they are weather-resistant, durable, and low maintenance.ConclusionRoof sheet making machines are versatile, efficient, and affordable pieces of equipment that make the production of high-quality roofing sheets possible. They offer several benefits over other manufacturing methods, including low maintenance, high output, and customization options. With ongoing technological advancements, the market for roof sheet making machines is expected to grow, driving innovation and leading to even greater efficiency and customization options.

Highly Efficient and Versatile Corrugated Roll Making Machine Unveiled in Recent News

Title: Corrugated Roll Making Machine Revolutionizes Packaging IndustryIntroduction:The packaging industry is witnessing a remarkable technological advancement with the introduction of the state-of-the-art Corrugated Roll Making Machine. This innovative machinery is set to revolutionize the production process of corrugated rolls, boosting efficiency and meeting the ever-increasing demand for sustainable packaging solutions. Developed by an industry-leading company, the machine serves as a game-changer by enhancing productivity, reducing material wastage, and providing cost-effective solutions.Increased Efficiency and Productivity:The Corrugated Roll Making Machine offers exceptional speed and accuracy, ensuring a significant increase in productivity compared to conventional methods. By automating the process, it reduces labor costs and minimizes human error. The machine can handle large volumes of corrugated rolls, making it ideal for industries dealing with high-demand packaging requirements. With its high-speed production capabilities, businesses can meet tight deadlines without compromising on quality.Advanced Design and Customization:The cutting-edge technology integrated into the Corrugated Roll Making Machine enables it to produce corrugated rolls in various sizes and designs. The machine features adjustable settings, allowing businesses to cater to their specific packaging needs. Whether it is producing rolls for fragile electronics or heavy-duty products, this versatile machinery adapts effortlessly, providing tailor-made solutions to a diverse range of industries.Precision and Durability:Precision is a fundamental requirement in the packaging industry, and the Corrugated Roll Making Machine ensures exceptional accuracy throughout the production process. The machine's robust construction and premium quality components guarantee durability and longevity, resulting in continuous high-performance. Businesses can rely on this machine to consistently deliver superior quality corrugated rolls, meeting the stringent standards of packaging regulations.Sustainability and Cost-effectiveness:In today's environmentally conscious world, sustainable packaging solutions are in high demand. The Corrugated Roll Making Machine addresses this need by reducing material wastage to a minimum. Its efficient design optimizes the usage of raw materials, minimizing both costs and environmental impact. The machine also offers recyclable options, contributing to a circular economy and meeting the demands of eco-friendly packaging practices.Integration of IoT and Smart Technology:The Corrugated Roll Making Machine incorporates internet of things (IoT) and smart technology capabilities. This integration enables real-time monitoring of the production process, ensuring maximum efficiency and minimizing downtime. The machine can detect any issues and send instant notifications, allowing operators to quickly address them. The incorporation of smart technology streamlines operations and enhances the overall production cycle.Future Prospects and Market Impact:The introduction of the Corrugated Roll Making Machine is poised to have a significant impact on the packaging industry. As businesses strive for higher productivity and sustainability, this advanced machinery provides a competitive edge. With its ability to meet diverse packaging requirements and reduce operational costs, this innovation promises increased efficiency and profitability for manufacturers. Additionally, its adherence to sustainability practices will appeal to environmentally conscious businesses and consumers alike.Conclusion:The Corrugated Roll Making Machine represents a breakthrough in the packaging industry. Combining speed, precision, sustainability, and smart technology, this state-of-the-art machinery stands at the forefront of packaging solution advancements. With its ability to boost productivity, reduce material wastage, and provide tailored packaging options, it has the potential to reshape how businesses approach packaging manufacturing. Embracing this innovation will undoubtedly lead to increased profitability, meeting market demands, and ensuring sustainable practices in the packaging industry.