High Quality Steel Forming Machines for Precision Results

By:Admin

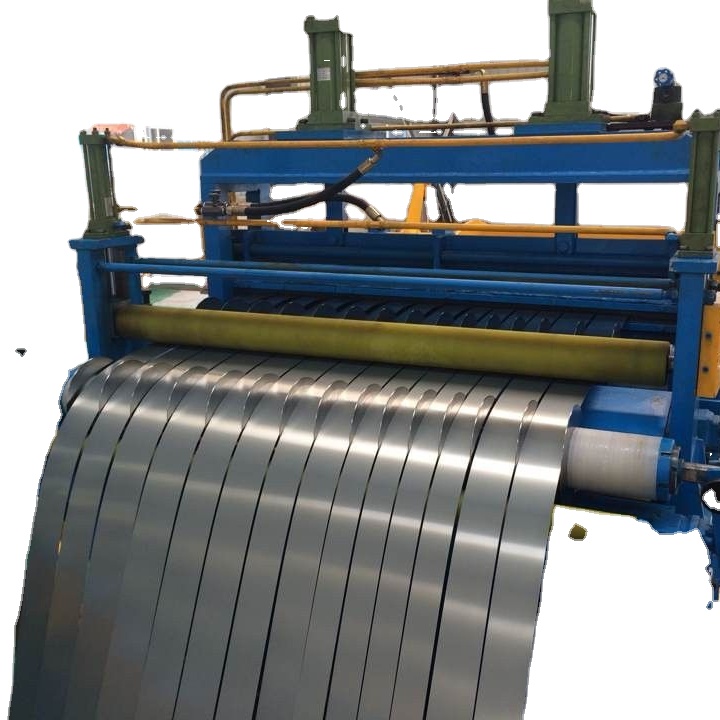

The new range of steel forming machines includes a variety of different models that cater to the diverse needs of the metal forming industry. From roll forming machines to tube and pipe mills, Steel Forming Machines offers a comprehensive range of equipment that is designed to meet the demanding requirements of modern metal fabrication processes.

One of the standout features of Steel Forming Machines' equipment is their advanced technology and precision engineering. The company has invested heavily in Research and Development to ensure that their machines are at the forefront of innovation and efficiency. This has resulted in the development of cutting-edge features such as automated controls, high-speed production capabilities, and advanced material handling systems.

In addition to their commitment to innovation, Steel Forming Machines places a strong emphasis on the quality and reliability of their equipment. Each machine is manufactured to the highest standards using the finest materials and components to ensure long-term performance and durability. The company also offers comprehensive training and after-sales support to ensure that their customers can maximize the potential of their equipment.

Steel Forming Machines' dedication to customer satisfaction is evident in their unwavering commitment to providing personalized service and tailored solutions to meet the specific needs of their clients. Whether it is a custom-designed machine or a standard model, the company works closely with its customers to understand their requirements and deliver equipment that exceeds expectations.

As a company, Steel Forming Machines prides itself on its integrity and transparency. They are committed to operating with the highest ethical standards and are dedicated to building long-term relationships with their customers based on trust and reliability. This has earned them a reputation as a dependable and trustworthy partner within the metal forming industry.

Steel Forming Machines' equipment is widely used across a range of industries including construction, automotive, aerospace, and renewable energy, among others. Their machines have been instrumental in the production of a diverse array of products such as roofing panels, automotive components, and structural steel, to name just a few.

In the fast-paced and competitive world of metal forming, Steel Forming Machines has carved out a niche for itself as a leader in the field. Their relentless pursuit of excellence, combined with their customer-centric approach, has set them apart from their competitors and established them as a force to be reckoned with in the industry.

With the release of their latest range of steel forming machines, Steel Forming Machines is once again demonstrating their commitment to pushing the boundaries of innovation and delivering cutting-edge solutions to their customers. As the company continues to grow and expand its global footprint, it remains steadfast in its mission to be the go-to provider of steel forming equipment for businesses around the world.

Company News & Blog

High-Quality Roofing Sheet Roll Forming Machines for Efficient Sheet Rolls Forming Process

Roofing Sheet Roll Forming Machine: Revolutionizing the Roofing Industry[City], [Date] - [Company Name], a leading manufacturer of roll forming machines, is proud to introduce their latest innovation in the roofing industry - the Roofing Sheet Roll Forming Machine. This groundbreaking machine is set to revolutionize the way roofing sheets are manufactured, offering enhanced efficiency and superior quality products.The Roofing Sheet Roll Forming Machine is a state-of-the-art piece of equipment designed to produce roofing sheets with precision and speed. By utilizing advanced roll forming technology, this machine is capable of shaping metal sheets into a variety of profiles and dimensions, perfectly suited for roofing applications. With its efficient and automated production process, the machine is capable of meeting the demands of both small-scale roofing projects and large commercial operations.One of the key features of the Roofing Sheet Roll Forming Machine is its versatility. It can produce a wide range of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This flexibility allows roofing contractors and manufacturers to meet the diverse requirements of their customers, offering them a wide selection of roofing options.The machine's high-speed production capabilities make it an ideal choice for large-scale operations. With its precise and reliable roll forming process, the Roofing Sheet Roll Forming Machine can produce roofing sheets at an impressive rate, significantly reducing production time and costs. This increased productivity translates into higher profitability for roofing companies, allowing them to take on more projects and meet tight deadlines.Quality is of utmost importance in the roofing industry, and the Roofing Sheet Roll Forming Machine delivers exceptional results. By using top-quality materials and advanced manufacturing techniques, this machine ensures that every roofing sheet produced meets the highest quality standards. The machine's precision-engineered rollers and cutting blades contribute to the accurate shaping of the metal sheets, creating well-formed and dimensionally accurate roofing products.Additionally, the Roofing Sheet Roll Forming Machine offers excellent durability and reliability. Manufactured with robust components and built to withstand heavy-duty use, this machine can operate consistently even in demanding production environments. Its user-friendly design and intuitive controls make it easy to operate, requiring minimal maintenance and reducing downtime.By investing in the Roofing Sheet Roll Forming Machine, companies can streamline their production process and substantially improve their overall efficiency. With its superior speed, versatility, and quality output, this machine is set to become an indispensable asset in the roofing industry.[Company Name] is dedicated to providing exceptional after-sales service and technical support. With their extensive experience in roll forming machine manufacturing, they are committed to assisting customers in optimizing their production processes and ensuring the long-term performance of their machines.About [Company Name]:[Company Name] is a renowned manufacturer of roll forming machines, specializing in Roofing Sheet Roll Forming Machine, CZ Purlin Machine, and Light Steel Framing products. With a focus on delivering innovative and reliable solutions, they have become a trusted name in the industry. Their commitment to superior quality, advanced technology, and excellent customer service has earned them a reputation as a leading manufacturer in China. For more information, please visit [Company Website].For media inquiries:[Company Name][Contact Person][Phone Number][Email Address]

High-Quality Metal Deck Roll Forming Machines Available for Export

Roll forming machines have revolutionized the way we manufacture structural components for construction projects. One such machine which has gained immense popularity in recent years is the Floor Deck Roll Forming Machine. This machine is used to produce high-quality metal decks used for flooring and roofing in various construction projects.The Floor Deck Roll Forming Machine is essentially a series of rollers and tooling which bend and shape metal sheets into the desired profile for the metal deck. With the help of a motor, the metal sheets are slowly fed through the rollers and are bent into the desired shape. The end result is a metal deck that is strong, durable, and can withstand harsh weather conditions.When it comes to manufacturing the Floor Deck Roll Forming Machine, there are many professional and experienced manufacturers available in the market. They specialize in producing a variety of Metal Deck Roll Forming Machines according to your specific requirements. Whether you want a machine to produce metal decks for commercial or residential projects, these manufacturers can deliver you the equipment that meets your needs.The Floor Deck Roll Forming Machine is not only a useful tool for construction projects but is also a profitable investment in the long run. With the demand for metal decking material on the rise, investing in this machine can help you keep up with the competition and cater to your customers' needs.There are various types of metal decks that can be produced with the help of the Floor Deck Roll Forming Machine, such as roof decks, composite floor decks, non-composite floor decks, and more. Each type serves a unique purpose in construction projects and can be custom-made to fit the individual requirements of the project.Metal decks produced by the Floor Deck Roll Forming Machine offer many advantages over traditional construction materials such as timber decking. The metal decks are stronger, more durable, and can withstand harsh weather conditions, making them a popular choice for construction projects of all types.In conclusion, investing in a Floor Deck Roll Forming Machine can be a game-changer for your construction business. It offers a range of benefits such as faster production time, customized solutions, durability, and profitability. Find a reliable and experienced manufacturer of Metal Deck Roll Forming Machines to get started and take your construction business to the next level of success.

Advanced Color Steel Roll Forming Machine: Offering Double Layer Efficiency

Double Layers Color Steel Roll Forming Machine Revolutionizes the Steel Roll Forming IndustryThe demand for different types of roll forming machines is increasing rapidly, owing to the ever-growing construction and infrastructure development projects around the world. One company that has been at the forefront of this industry is renowned for its high-quality machinery and innovative solutions. With its latest offering, the Double Layers Color Steel Roll Forming Machine (name removed), the company is set to revolutionize the steel roll forming industry.The Double Layers Color Steel Roll Forming Machine is a state-of-the-art piece of equipment that boasts advanced features and cutting-edge technology. It is designed to cater to the diverse needs of the steel industry, providing utmost efficiency and precision in the roll forming process. Through its innovative design, the machine can produce double-layered color steel sheets with exceptional accuracy and speed, making it an indispensable tool for manufacturers in the sector.One of the key highlights of this machine is its ability to produce color steel sheets with different thicknesses, ranging from 0.3mm to 0.8mm. This versatility enables manufacturers to cater to a wide range of project requirements, making it a preferred choice over other roll forming machines in the market. Additionally, the machine's dual-layered design allows for the production of steel sheets with different colors on each side, further adding to its flexibility and application possibilities.The Double Layers Color Steel Roll Forming Machine is equipped with a high-performance control system that ensures precise and consistent production. It incorporates the latest automation technology, enabling operators to easily adjust and monitor various parameters of the machine, such as speed, thickness, and color. This not only enhances productivity but also minimizes human error, resulting in a higher quality end product.Furthermore, the machine has been engineered to provide exceptional durability and stability. Its robust construction, coupled with high-quality components, ensures a long service life and uninterrupted performance even in demanding industrial environments. This makes it a reliable and cost-effective solution for manufacturers, minimizing downtime and maintenance costs.In addition to its technical prowess, the company behind the Double Layers Color Steel Roll Forming Machine prides itself on its commitment to customer satisfaction. With decades of experience in the industry, they have a deep understanding of the challenges faced by manufacturers. Their dedicated team of engineers and technicians provides comprehensive support, including installation, training, and after-sales service, ensuring a seamless experience for their customers.The introduction of the Double Layers Color Steel Roll Forming Machine has already garnered significant attention from industry experts and manufacturers alike. It is hailed as a game-changer for the steel roll forming industry, with its ability to produce double-layered color steel sheets with unmatched precision and efficiency. As infrastructure development continues to soar globally, this innovative machine is poised to become a key tool for manufacturers, enabling them to meet the growing demands of the construction sector.In conclusion, the Double Layers Color Steel Roll Forming Machine is a groundbreaking innovation that showcases the company's dedication to excellence and customer satisfaction. With its advanced features, versatility, and unparalleled performance, it is set to redefine the steel roll forming industry. As manufacturers strive to meet the demands of the evolving construction sector, this machine will undoubtedly play a pivotal role in shaping the future of steel production.

High-Quality Glazed Tile Roll Forming Machine Supplier in China - Extensive Product Range

Title: Enhancing Roof Aesthetics with Color Steel Glazed Tile Roof Panel Roll FormerIntroductionWith the growing popularity of glazed tile roofing panels, both in residential and commercial buildings, the demand for efficient and reliable machinery that can manufacture them is on the rise. In this blog post, we will explore the benefits and features of a Color Steel Glazed Tile Roof Panel Roll Former, which is a leading product in the market. This advanced roll forming machine allows manufacturers to produce high-quality glazed tile roof panels with ease. Section 1: Understanding Glazed Tile Roll Forming MachineA Glazed Tile Roll Forming Machine is a specialized equipment designed to transform raw materials, typically color steel, into glazed tile roof panels. This roll forming process involves feeding the steel sheet through a series of rollers that gradually shape and form the desired profile. The result is a strong, aesthetically pleasing, and weather-resistant tile, perfect for enhancing the overall appearance of any building.Section 2: Key Features and Advantages2.1. Precision Manufacturing: The Color Steel Glazed Tile Roof Panel Roll Former ensures precise molding and sizing of glazed tile panels, thanks to its innovative design and cutting-edge technology. The machine guarantees consistent panel quality, reducing the chances of any defects or inconsistencies.2.2. Versatility: This roll forming machine can manufacture various styles and profiles of glazed tiles, catering to the diverse needs of customers. From traditional curved designs to modern flat styles, the machine offers exceptional flexibility and customization options.2.3. Efficiency and Speed: With the ability to operate at high speeds, the roll former significantly increases productivity, allowing manufacturers to meet tight production deadlines. The fast and efficient production process helps minimize labor costs and maximize overall output.2.4. Durability: The construction of the Color Steel Glazed Tile Roof Panel Roll Former is robust and durable, ensuring a longer lifespan. Its strong framework and high-quality components enable continuous and reliable operation, reducing downtimes and maintenance requirements.Section 3: Benefits for Manufacturers3.1. Cost-Effective Solution: Investing in a Glazed Tile Roll Forming Machine eliminates the need for outsourcing tile manufacturing, resulting in substantial cost savings for manufacturers in the long run. The machine's high efficiency and minimal material wastage contribute to further economic advantages.3.2. High-Quality Output: The precision and consistency offered by the roll former ensure that every glazed tile produced is of superior quality. Manufacturers can deliver a premium product that meets the market's high standards, enhancing their reputation and customer satisfaction.3.3. Customization Possibilities: The versatility of the machine enables manufacturers to cater to specific customer requirements. From different colors to various tile sizes and profiles, customization options are limitless, allowing for greater market competitiveness.3.4. Reduced Carbon Footprint: As the Color Steel Glazed Tile Roof Panel Roll Former operates based on energy-efficient principles, it helps reduce the overall carbon footprint of manufacturers. This commitment to sustainability aligns with the growing demand for eco-friendly construction materials and practices.ConclusionInvesting in a Color Steel Glazed Tile Roof Panel Roll Former is a wise choice for manufacturers aiming to expand their product offerings, increase productivity, and enhance the overall quality of their glazed tile roof panels. With its precision manufacturing, versatility, efficiency, and durability, this robust machinery can take roofing aesthetics and functionality to new heights. By embracing modern roll forming technology, manufacturers can stay ahead of the competition and meet the ever-growing demand for glazed tile roofing products.

High-Quality Metal Roof Making Machine: Here's What You Need to Know

Metal Roof Making Machines have revolutionized the process of fabricating high-quality metal roofing products. These state-of-the-art machines have significantly improved the efficiency and precision of metal roof manufacturing, making them an essential tool for companies in the roofing industry.One company that has been at the forefront of this innovation is {}. With over 20 years of experience in the metal roofing business, they have established themselves as a leading manufacturer of metal roof making machines. Their dedication to quality and innovation has made them a trusted supplier for roofing companies worldwide.The Metal Roof Making Machine developed by {} is designed to streamline the production process, allowing manufacturers to produce metal roofing products with unmatched speed and accuracy. This advanced machinery is equipped with cutting-edge technology that enables precise bending, cutting, and shaping of metal sheets, resulting in roofing products of exceptional quality.The machine is also designed for versatility, capable of producing a wide range of metal roofing products, including standing seam panels, corrugated panels, and more. This flexibility makes it an ideal solution for roofing companies with diverse product offerings, allowing them to meet the specific needs of their customers with ease.In addition to its impressive capabilities, the Metal Roof Making Machine from {} is also known for its user-friendly design. It is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up the machine and monitor the production process. This ease of use not only improves efficiency but also reduces the need for extensive training, allowing manufacturers to get up and running quickly.Furthermore, {} offers comprehensive support and service for their Metal Roof Making Machines, ensuring that their customers can maximize the performance and lifespan of their equipment. From installation and training to ongoing maintenance and technical support, they are committed to delivering a seamless experience for their clients.The impact of {}'s Metal Roof Making Machines on the metal roofing industry has been profound. Many roofing companies have reported significant improvements in their production processes, with the machines enabling them to increase their output while maintaining the highest standards of quality. This has not only resulted in improved efficiency and profitability for these companies but has also raised the bar for the entire industry.Looking ahead, {} remains dedicated to pushing the boundaries of metal roof manufacturing technology. They continue to invest in research and development, seeking out new innovations that will further enhance the performance and capabilities of their Metal Roof Making Machines. With a relentless commitment to excellence, they are poised to lead the industry into a new era of metal roof manufacturing.In conclusion, the Metal Roof Making Machine from {} has set a new standard for metal roof manufacturing. Its precision, versatility, and user-friendly design have made it an indispensable tool for roofing companies around the world. As the industry continues to evolve, {} is well-positioned to remain at the forefront of innovation, driving the advancement of metal roof manufacturing technology for years to come.

Get a Comprehensive Roll Forming Solution for Diverse Applications in China

Roll forming machines are extensively used across different industries, and their applications can range from simple tasks to complex product specifications. With the demand for high-quality products and efficient production processes, roll forming machine manufacturers are constantly innovating and designing advanced equipment that can meet the needs of various industries. In China, MTC is a leading roll forming machine manufacturer, providing a one-stop solution from consultation to final training for many different applications where a roll forming machine can do its best.One of the applications where roll forming machines are in high demand is the light steel forming industry. Light steel forming machines are specialized equipment that is designed to form and shape light gauge steel profiles. These machines can handle materials with thicknesses ranging from 0.3mm to 2mm, making them ideal for creating lightweight and strong steel structures. The versatility of light steel forming machines has made them an attractive choice for various industries such as construction, automotive, and furniture.As a prominent roll forming machine manufacturer in China, MTC offers a wide range of light steel forming machines that feature advanced technology and precision engineering. Their equipment is designed to meet the highest quality and safety standards, making them a reliable and long-term investment for businesses.Some of the notable features of MTC’s light steel forming machines include:1. High-precision Roll-forming Process - MTC uses advanced technology and precision engineering to ensure that their light steel forming machines produce high-quality products with tight tolerances. This helps to reduce wastage and improve the efficiency of the production process.2. Modular Design - MTC’s light steel forming machines feature a modular design, which allows for easy customization and integration with existing production equipment. This makes it easier for businesses to adapt to changing market demands and product specifications.3. Flexible Material Support - MTC’s light steel forming machines are designed to work with a wide range of materials, including galvanized steel, stainless steel, aluminum, and other alloys. This versatility helps businesses to cater to a wide range of customer requirements.4. Easy-to-Use Control System - MTC’s light steel forming machines come equipped with an easy-to-use control system that enables operators to adjust and monitor parameters such as speed, size, and thickness. This helps to streamline the production process and reduces the likelihood of errors.In addition to the above features, MTC also provides comprehensive consultation services and training to clients. This ensures that their clients can make informed decisions regarding the choice of equipment and utilize the machines to their full potential. MTC’s after-sales support is also noteworthy, with a dedicated customer support team available to assist businesses with any issues that may arise.In conclusion, MTC is a reliable and experienced roll forming machine manufacturer in China, providing a one-stop solution for businesses looking to invest in light steel forming machines. With their advanced technology and precision engineering, MTC’s light steel forming machines are among the best in the market, offering businesses improved efficiency, better quality control, and enhanced flexibility. If you are in the market for a light steel forming machine, choose MTC for quality and value.

Enhance Efficiency with Cutting-Edge Floor Deck Roll Forming Machines

Title: Streamlining Construction with the Double Deck Roll Forming MachineIntroduction (100 words):In today's rapidly evolving construction industry, it is crucial to stay updated with the latest technology and equipment that can enhance project efficiency and productivity. One such impressive innovation is the Double Deck Roll Forming Machine. This cutting-edge machinery has revolutionized the way steel floor decks are produced, providing a cost-effective and seamless solution for construction projects. In this blog post, we will explore the key features and benefits of the Double Deck Roll Forming Machine, while also highlighting its role in enabling swift and precise construction processes. 1. Advantages of the Double Deck Roll Forming Machine (200 words):The Double Deck Roll Forming Machine offers numerous advantages that make it a highly sought-after tool in the construction industry. With its advanced capabilities, this machinery streamlines the production of steel floor decks, reducing manual labor and minimizing human error. Some key advantages of the Double Deck Roll Forming Machine include:a) Enhanced Efficiency: By automating the roll forming process, the Double Deck Roll Forming Machine significantly speeds up production, resulting in shorter lead times and improved project timelines.b) Precision and Consistency: This machine ensures precise and uniform shaping of steel floor decks, eliminating variations in dimensions commonly found in manual production methods. The outcome is a consistent and high-quality end product that meets industry standards.c) Cost-effective Solution: The automated nature of the Double Deck Roll Forming Machine reduces the need for additional workers, thereby lowering labor costs. Furthermore, by minimizing production errors, wastage is reduced, leading to cost savings.2. Key Features of the Double Deck Roll Forming Machine (300 words):The Double Deck Roll Forming Machine boasts several key features that have attributed to its rise in popularity among construction professionals worldwide. Here are some notable features:a) Dual-Level Decking: As its name suggests, this machine has the ability to create two different levels of deck sheets simultaneously, maximizing productivity and reducing production time. This efficient process eliminates the need for separate runs for different profiles or heights.b) Customizable Profiles: The Double Deck Roll Forming Machine allows for the creation of various profiles and sizes of steel floor decks. With adjustable settings and versatile tooling options, it caters to the specific requirements of each construction project.c) High-speed Production: Equipped with an advanced control system, the machine ensures that the roll forming process is efficient and swift, delivering high-speed production capabilities without compromising on quality.d) User-friendly Design: The Double Deck Roll Forming Machine is designed for ease of use, with intuitive controls and a straightforward setup process. Its user-friendly interface reduces the learning curve for workers, allowing for seamless integration into construction sites.3. Integration of the Double Deck Roll Forming Machine in Construction (300 words):The integration of the Double Deck Roll Forming Machine brings about several positive developments in the construction process, positively impacting both small-scale and large-scale projects. a) Project Acceleration: By automating the production of steel floor decks, project timelines are significantly reduced. The efficient production process enabled by the Double Deck Roll Forming Machine ensures that construction projects progress swiftly, allowing for earlier completion and increased overall efficiency.b) Enhanced Structural Integrity: The consistent and precise shaping of steel floor decks produced by the machine ensures the structural integrity of the building. The high-quality end product meets industry standards, thus contributing to the safety and durability of the construction.c) Cost Savings: The Double Deck Roll Forming Machine considerably reduces labor costs by eliminating the need for excessive manual labor. Additionally, the minimized errors and wastage result in cost savings, making the machine a highly cost-effective solution for construction projects.Conclusion (100 words):In conclusion, the Double Deck Roll Forming Machine is an innovative asset that has transformed the production of steel floor decks in the construction industry. Its ability to seamlessly manufacture precise and high-quality components, along with its cost-effectiveness and efficient automation, make this machinery a game-changer in optimizing construction processes. As the industry evolves and demands quicker turnaround times, the Double Deck Roll Forming Machine offers the perfect solution, providing construction professionals with a competitive edge and enhancing the overall efficiency and quality of their projects.

Efficient Glazed Roof Tile Roll Forming Machine: News Update

Title: Color Steel Glazed Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:Innovations in the construction industry have always played a vital role in improving safety, efficiency, and aesthetics of buildings. One such revolutionary advancement is the Color Steel Glazed Roof Tile Roll Forming Machine, which has disrupted conventional roofing techniques. This state-of-the-art machinery, developed by a prominent industry player, is set to transform the roofing industry, offering enhanced durability, flexibility, and a wide range of design possibilities.Paragraph 1: The roofing industry has witnessed significant advancements over the years, evolving from traditional roofing materials to more durable and energy-efficient solutions. The introduction of the Color Steel Glazed Roof Tile Roll Forming Machine takes this evolution a step further by offering a technologically advanced solution for constructing roofs with an unbeatable combination of strength and aesthetics.Paragraph 2: With the Color Steel Glazed Roof Tile Roll Forming Machine, roofing professionals can now effortlessly manufacture glazed roof tiles of various shapes and sizes. This allows architects and homeowners the freedom to choose from a vast range of designs and patterns, ensuring their roofs stand out and enhance the overall building's visual appeal. Not only does this machine provide creative possibilities, but it also offers exceptional durability and weather resistance.Paragraph 3: The roll forming machine integrates cutting-edge technology, enabling the production of tiles from high-quality color steel sheets. This material is renowned for its strength, flexibility, and resistance to corrosion and extreme weather conditions. The versatility of the roll forming machine ensures that roofing professionals can efficiently manufacture tiles that meet the specific requirements of any construction project, be it residential, commercial, or industrial.Paragraph 4: The Color Steel Glazed Roof Tile Roll Forming Machine excels in terms of efficiency as well. Its automated functionality streamlines the production process, minimizing human errors and reducing time and labor costs. Furthermore, the machine's advanced control system ensures precise measurements and cuts, resulting in consistent and uniform tiles. Its high-speed forming capability significantly increases the production capacity, revolutionizing the roofing materials market.Paragraph 5:Safety is of utmost importance in the roofing industry, and the Color Steel Glazed Roof Tile Roll Forming Machine prioritizes this aspect. It is equipped with safety features like emergency stop buttons, inbuilt sensors, and protective barriers, preventing accidents or injuries during operation. This industry-leading commitment to safety reflects the machine manufacturer's dedication to providing trustworthy and reliable solutions.Paragraph 6:In addition to its numerous advantages, the Color Steel Glazed Roof Tile Roll Forming Machine is also an environmentally friendly choice. By minimizing waste material and optimizing material usage, it helps reduce construction waste, ensuring sustainable building practices. The energy-efficient technology employed in the machine contributes to lowering overall energy consumption, aligning with the growing trend of environmental responsibility in the construction sector.Conclusion:The Color Steel Glazed Roof Tile Roll Forming Machine represents an exciting leap forward in the roofing industry. Its advanced technology, coupled with its ability to produce durable, customizable, and visually appealing tiles, has truly revolutionized the way roofs are constructed. The machine's efficiency, safety features, and eco-friendliness make it an invaluable asset for professionals in the construction industry, contributing to the development of modern, sustainable buildings.

Cutting-Edge Metal Roof Tile Making Machinery: Simplifying Roofing Solutions

[CompanyName], a leading manufacturer of metal roof tile making machines, has recently launched their latest innovation in the field of roofing technology. The new machine, which combines cutting-edge features with utmost reliability, is set to revolutionize the roof tile manufacturing industry.With an increasing demand for durable and energy-efficient roofing solutions, Metal Roof Tile Making Machine is designed to meet the evolving needs of builders and homeowners alike. This innovative machine utilizes state-of-the-art technology to produce high-quality metal roof tiles that are both visually appealing and highly functional.One of the key features of this advanced machine is its ability to produce roof tiles with precision and consistency. Equipped with cutting-edge automation technology, every tile produced by the machine is perfectly shaped and sized, ensuring seamless installation and a uniform appearance on the roof. This precision is highly valued by customers, as it eliminates the need for manual adjustments and guarantees a hassle-free roofing experience.Moreover, Metal Roof Tile Making Machine emphasizes the importance of durability in their product. The machine is engineered to withstand the rigors of continuous operation and is built to last. Every component of the machine is robustly constructed, ensuring that it can handle heavy workloads without compromising its performance or reliability. This feature is particularly essential for manufacturers who aim to maximize productivity and reduce downtime.In addition to its durability, this cutting-edge machine incorporates various energy-saving features that align with global efforts to promote sustainability. Metal Roof Tile Making Machine emphasizes the use of eco-friendly materials and processes, ensuring that the production of roof tiles has a minimal impact on the environment. By implementing energy-efficient practices, manufacturers can reduce their carbon footprint and contribute to a greener future.Furthermore, Metal Roof Tile Making Machine ensures customer satisfaction by offering technologically advanced controls that enable easy operation and optimization of the machine's performance. The intuitive user interface allows operators to monitor and adjust various parameters, ensuring that the machine operates at its optimal efficiency. This feature enables manufacturers to maximize their output while maintaining the highest quality standards.Metal Roof Tile Making Machine has established itself as a trusted brand in the industry. With years of experience and a commitment to excellence, the company has garnered a loyal customer base that spans across the globe. By consistently delivering superior products and exceptional customer service, Metal Roof Tile Making Machine has become a go-to choice for manufacturers and contractors seeking reliable and efficient roof tile manufacturing solutions.As the demand for metal roof tiles continues to rise, Metal Roof Tile Making Machine remains at the forefront of innovation in the industry. The company's unwavering dedication to research and development ensures that their machines embody the latest advancements in technology and meet the evolving needs of customers. With their latest offering, Metal Roof Tile Making Machine has once again set a new standard for excellence in the roofing industry.In conclusion, Metal Roof Tile Making Machine has launched a state-of-the-art machine that combines advanced features, durability, and energy efficiency. This innovation is set to revolutionize the roof tile manufacturing industry by providing manufacturers with a reliable and efficient solution to meet the growing demand for metal roof tiles. With its commitment to quality, sustainability, and customer satisfaction, Metal Roof Tile Making Machine continues to cement its place as an industry leader in roofing technology.