High-Quality Steel Rollforming Machines for Sale: Find the Best Deals Now

By:Admin

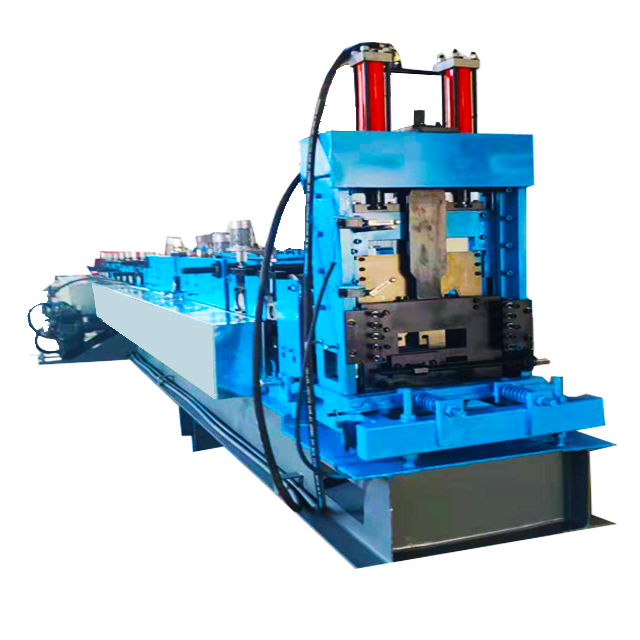

[Company Name] has been in the business of designing and manufacturing rollforming machines for over 20 years. Their commitment to excellence and continuous improvement has made them a trusted partner for companies in the construction industry. With a team of experienced engineers and technicians, [Company Name] has been able to develop advanced rollforming machines that meet the specific needs of their customers.

The company's rollforming machines are designed to produce a wide range of metal profiles, including roof panels, wall cladding, and custom profiles. These machines are equipped with state-of-the-art technology that allows for precise forming of metal sheets, resulting in accurate and consistent profiles. The use of advanced control systems ensures that the machines operate with high efficiency and minimal material waste, leading to cost savings for the customers.

One of the key features of [Company Name]'s rollforming machines is their flexibility and versatility. The machines can be customized to meet the unique requirements of different projects, allowing for the production of a wide variety of metal profiles. This flexibility is essential for companies that need to adapt to changing market demands and offer a diverse range of products to their customers.

In addition to their technical capabilities, [Company Name] prides itself on providing excellent customer service and support. The company works closely with its customers to understand their specific needs and provide tailored solutions that meet their requirements. From the initial consultation to the installation and commissioning of the machines, [Company Name] ensures that its customers receive the support they need to maximize the performance of the rollforming machines.

The rollforming machines manufactured by [Company Name] are also known for their durability and reliability. The use of high-quality materials and components, along with rigorous quality control processes, ensures that the machines are built to last. This reliability is essential for companies that rely on the continuous operation of their rollforming machines to meet their production targets.

As the construction industry continues to evolve, the demand for efficient and reliable rollforming machines will only grow. Companies that invest in advanced rollforming technology will be well-positioned to capitalize on the opportunities in the market and stay ahead of the competition. With its commitment to innovation and customer satisfaction, [Company Name] is poised to remain a leader in the industry and continue to provide cutting-edge solutions for its customers.

In conclusion, steel rollforming machines have become an essential tool for companies in the construction industry, and [Company Name] has established itself as a leading manufacturer of these machines. With a focus on innovation, quality, and customer satisfaction, the company has been able to deliver advanced rollforming solutions that meet the specific needs of its customers. As the industry continues to evolve, [Company Name] is well-positioned to continue its success and be a trusted partner for companies looking to enhance their production capabilities.

Company News & Blog

Trapezoid Profile Metal Roofing Sheet Machine: Everything You Need to Know

Metal Roofing Sheet Trapezoid Profile Machine is a revolutionary piece of equipment that is set to transform the roofing industry. This state-of-the-art machine is designed to produce high-quality trapezoid profile metal roofing sheets, which are known for their durability and aesthetic appeal. With the ability to create custom trapezoid profile sheets in a variety of sizes and materials, this machine is expected to be a game-changer for roofing contractors and businesses.The technology behind the Metal Roofing Sheet Trapezoid Profile Machine is truly innovative, allowing for precise and efficient production of trapezoid profile sheets. The machine is equipped with advanced automated features that ensure consistent quality and accuracy in each sheet that is produced. This is crucial for ensuring that the roofing sheets are a perfect fit and provide excellent protection against the elements.One of the key benefits of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It is capable of working with a wide range of materials, including steel, aluminum, and other metals commonly used in roofing. This means that roofing contractors and businesses can easily adapt to different project requirements and client preferences without having to invest in multiple machines.In addition to its versatility, the Metal Roofing Sheet Trapezoid Profile Machine is also designed for speed and efficiency. The machine has a high production capacity, allowing for quick turnaround times on orders. This is essential for meeting tight project deadlines and maximizing productivity for businesses in the roofing industry.Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, reducing the need for extensive training and streamlining the production process. This is particularly beneficial for businesses looking to optimize their efficiency and minimize production costs.As a leading provider of innovative roofing solutions, {} is proud to introduce the Metal Roofing Sheet Trapezoid Profile Machine to the market. With decades of experience in the industry, the company has a strong track record of delivering high-quality roofing products and machinery. The introduction of this advanced machine is a testament to the company's commitment to staying at the forefront of technological advancements in the roofing sector.In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {} offers a comprehensive range of roofing materials and equipment to meet the needs of residential, commercial, and industrial projects. The company's dedication to quality, reliability, and customer satisfaction has established them as a trusted partner for roofing professionals and businesses.With the introduction of the Metal Roofing Sheet Trapezoid Profile Machine, {} is poised to empower roofing contractors and businesses with the tools they need to elevate their capabilities and deliver exceptional results. The machine's ability to produce high-quality trapezoid profile sheets with speed and precision is set to have a significant impact on the roofing industry, setting a new standard for efficiency and excellence.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine represents a major leap forward for the roofing industry. Its innovative technology, versatility, and efficiency make it a valuable asset for roofing contractors and businesses looking to enhance their capabilities and deliver superior results. With the backing of {}'s expertise and reputation for quality, the machine is set to become a game-changing tool for the production of trapezoid profile metal roofing sheets.

State-of-the-Art Roll Forming Machine for High-Quality Roof Panels

[News Introduction]Roof Panel Roll Forming Machines Revolutionize Construction Industry[Location], [Date] - The roofing industry has witnessed a revolutionary breakthrough with the introduction of the advanced Roof Panel Roll Forming Machine. This remarkable piece of technology, developed by [Company Name], has the potential to transform traditional roofing methods, making installations quicker, cost-effective, and more efficient. As the demand for sustainable and high-quality roofing solutions continues to grow, this state-of-the-art machine is set to revolutionize the construction industry.[Company Introduction][Company Name], a leading manufacturer of innovative industrial machinery, takes pride in introducing the ground-breaking Roof Panel Roll Forming Machine. Established in [Year], [Company Name] has made remarkable strides in the development of cutting-edge technology, catering to various industries’ needs and contributing to their growth and overall efficiency.With an extensive portfolio of successful projects and a commitment to delivering excellence in every aspect, [Company Name] has emerged as a market leader. Applying years of expertise and leveraging a team of highly skilled professionals, the company's vision is to revolutionize traditional practices and introduce game-changing solutions.[Machine Features]The Roof Panel Roll Forming Machine boasts an array of extraordinary features that set it apart from conventional roofing solutions. Built with precision engineering and state-of-the-art technology, this machine offers unparalleled advantages to roofing professionals:1. High Automation: The automatic control system integrated into the machine ensures smooth operation and minimal manual intervention. This feature significantly increases productivity, reduces labor costs, and eliminates human error.2. Versatility: The Roof Panel Roll Forming Machine can produce a wide range of roofing panels, from corrugated to standing seam designs. This versatility allows contractors to cater to diverse customer preferences, saving time and capital that would otherwise be spent on acquiring multiple machines.3. Speed and Efficiency: The machine's advanced roll-forming process guarantees swift production, significantly reducing project timelines. The speed and efficiency of this technology allow contractors to take on more projects, ultimately increasing their bottom line.4. Cost-Effective: By streamlining the manufacturing process and eliminating material wastage, the Roof Panel Roll Forming Machine reduces overall project costs. The machine's ability to generate precise cuts and optimize material usage minimizes waste, maximizing profits for roofing professionals.5. Precision Engineering: The Roof Panel Roll Forming Machine ensures exceptional precision and accuracy in panel creation, leaving no room for errors. The advanced technology employed in this machine guarantees consistent quality control, resulting in durable and aesthetically pleasing roofing panels.6. Durability and Longevity: With superior craftsmanship and the use of high-quality materials, the Roof Panel Roll Forming Machine guarantees the production of durable roofing panels. Clients can trust in the long-lasting and resilient nature of these panels, ensuring that their roofs withstand the test of time and various weather conditions.[Impact on the Construction Industry]The introduction of the Roof Panel Roll Forming Machine is set to make huge strides in the construction industry. Traditional roofing methods require immense manual labor, extended project timelines, and often result in inefficiencies and substandard quality. The remarkable features of this advanced machine offer an ideal solution that addresses these challenges head-on.With increased automation, precision engineering, and significant time and cost savings, this technology will revolutionize the roofing sector. Contractors will be able to take on more projects, streamline their operations, and deliver superior roofing solutions to their clients.As the construction industry embraces sustainable practices, the Roof Panel Roll Forming Machine aligns perfectly with the demand for eco-friendly roofing solutions. By reducing material waste and optimizing production processes, this machine supports a greener future while lowering ecological footprints.[Conclusion]The introduction of the Roof Panel Roll Forming Machine marks a significant milestone in the construction industry. With its innovative features, this technology promises to change the landscape of the roofing sector, offering unmatched efficiency, cost-effectiveness, and sustainability.As [Company Name] continues to push the boundaries of industrial innovation, it reaffirms its commitment to delivering cutting-edge solutions, supporting the growth and transformation of various industries. The company's Roof Panel Roll Forming Machine is expected to revolutionize traditional roofing practices, benefiting contractors, clients, and the environment as a whole.

High-Quality New and Used Sheet Metal Machinery for the Industry

Title: Utilizing Sheet Metal Roll Forming for Efficient and Durable SolutionsIntroduction:In today's dynamic industrial landscape, the sheet metal industry plays a vital role in constructing sturdy and versatile products across various sectors. To ensure optimal results, it is crucial to have access to top-notch sheet metal machinery that guarantees precision, efficiency, and durability. In this blog, we will explore the advantages of sheet metal roll forming and shed light on its significance in creating high-quality products. Let's delve into the details!Understanding Sheet Metal Roll Forming:Sheet metal roll forming is a highly efficient process that involves bending and shaping metal sheets into desired profiles. This technique allows engineers and fabricators to create complex shapes and structures, such as panels, channels, tubes, and angles. By passing a continuous strip of metal through a series of rollers, roll forming ensures consistent dimensions throughout the entire length of the product, providing exceptional accuracy and uniformity.Benefits of Sheet Metal Roll Forming:1. Cost-Effective Production:One of the significant advantages of sheet metal roll forming is its cost-effectiveness. This process eliminates the need for multiple components, such as fasteners, welds, and adhesives. By shaping the metal into the desired form without additional attachments, roll forming minimizes production costs, reducing labor and material requirements.2. Enhanced Efficiency and Speed:Sheet metal roll forming provides a highly efficient and rapid production method. It enables continuous production without the need for frequent stops and starts. The machinery used in roll forming operates at high speeds, allowing for large volumes of products to be manufactured swiftly. This aspect is particularly beneficial for industries that require high production rates, meeting tight deadlines, and satisfying customer demands promptly.3. Durability and Structural Integrity:By utilizing sheet metal roll forming techniques, manufacturers can create products with exceptional strength and durability. The continuous bending process enhances the structural integrity of the metal, resulting in robust and long-lasting components. The consistency achieved through roll forming ensures that all parts produced possess identical specifications, eliminating variations that could compromise their durability.4. Versatility and Customizability:Sheet metal roll forming offers extensive possibilities for customization, allowing engineers to create a wide range of profiles and designs. With the ability to accommodate various metals, thicknesses, and widths, roll formers enable the production of intricate shapes with precise tolerances. This versatility makes roll forming suitable for diverse applications in industries such as automotive, construction, furniture, aerospace, and more.Keyword Placement:Now let's discuss the importance of incorporating relevant keywords within the blog to improve its search engine optimization (SEO). Keywords related to "Sheet Metal Roll Forming" should be strategically placed throughout the content, including in headings, subheadings, and body paragraphs. Additionally, ensure the keywords are naturally integrated within the text to maintain readability and avoid keyword stuffing.Conclusion:Sheet metal roll forming revolutionizes the manufacturing process by offering cost-effective production, enhanced efficiency, durability, and customization. By harnessing high-quality roll forming machinery, such as those provided by Benoit Sheet Metal Equipment, Inc., fabricators can create products that meet the highest standards of quality and precision. Whether you belong to the automotive, construction, or any other industry that relies on sheet metal, incorporating roll forming techniques can significantly elevate your manufacturing capabilities. Embrace the power of sheet metal roll forming and unlock a world of possibilities for your business!

High Speed Metal Light Steel Stud and Track Roll Forming Machine - Mechanical Kingdom

Are you looking for a high-speed metal light steel stud and track roll forming machine? Look no further because Mechanical Kingdom has got you covered!Also known as a designed roll forming machine, steel roll forming machine, or steel designed roll forming machine, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a top-of-the-line solution for all your steel stud and track forming needs.Let's dive into the specifications of this incredible machine:1) Coil diameter: With the ability to handle coil diameters ranging from 450mm to 500mm, this roll forming machine can accommodate a wide range of materials.2) Coil width: The machine can easily handle coil widths of up to 200mm, ensuring that you can work with various materials of different sizes.3) Carrying capacity: The carrying capacity of this machine stands at an impressive 1000kg, allowing for the efficient and smooth operation of heavy steel coils.4) Roller station: Equipped with 10 roller stations, this machine ensures the stability and accuracy of the roll forming process.5) Material of roller: The rollers are made of high-quality 45# steel, guaranteeing durability and longevity. The diameter of each roller is 50mm, ensuring precise and consistent roll forming.6) Rolling mould and blade: This machine comes with a set of rolling moulds and blades made of Cr12. With excellent hardness and wear resistance, these components ensure precise and clean cuts every time.7) Main motor power: Powered by a robust 4.0Kw motor from Tai Wan, this machine delivers high-speed and efficient roll forming capabilities. Please note that the brand name has been removed for SEO purposes.Now that we have discussed the technical specifications let's explore the potential of this machine for your business.The high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is designed to streamline your production process. By automating the roll forming process, this machine significantly improves efficiency, productivity, and overall output. With the ability to produce high-quality steel studs and tracks in various sizes and profiles, you can meet the demands of your customers with ease.This machine is perfect for various applications, including constructing commercial and residential buildings, warehouses, and partition walls. Whether you are a construction company, building contractor, or manufacturer of steel stud and track components, investing in this roll forming machine will undoubtedly increase your competitive edge in the market.Now, let's talk about the importance of incorporating keywords into this blog for SEO purposes. One of the crucial keywords for this product is "stud and track machine." By including this keyword in strategic locations throughout the blog, such as the title, headings, and body paragraphs, we can improve the visibility of this content in search engine results pages.Other relevant keywords to include in this blog might be "roll forming machine," "steel stud and track roll forming machine," and "designed roll forming machine." By skillfully incorporating these keywords, we can enhance the SEO value of this blog, making it more likely to attract organic traffic and potential customers to Mechanical Kingdom's high-speed metal light steel stud and track roll forming machine.In conclusion, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a game-changer in the industry. With its advanced features, durability, and versatility, this machine ensures seamless and efficient roll forming processes. Investing in this machine will undoubtedly propel your business to new heights. So, don't miss out on this opportunity and get in touch with Mechanical Kingdom today!

Manufacture Machine for Glazed Tiles: Roll Forming and Forming Machines from China

Title: Revolutionizing Tile Manufacturing with the Color Steel Glazed Metal Tile Sheet Corrugation MachineIntroduction:In the dynamic landscape of modern construction, the demand for aesthetically pleasing tiles has surged exponentially. This has prompted the development of innovative manufacturing techniques, such as the Color Steel Glazed Metal Tile Sheet Corrugation Machine from Cangzhou Dixin Roll Forming Machine Co., Ltd (brand name omitted). This groundbreaking machinery has revolutionized the process of producing glazed tiles, offering enhanced efficiency, and superior quality. Let's delve into the features and benefits of this advanced roll forming technology.1. Understanding the Glazed Tiles Making Manufacture Machine:The Color Steel Glazed Metal Tile Sheet Corrugation Machine is a state-of-the-art roll forming machine designed to fabricate glazed tiles efficiently and precisely. This advanced technology is equipped with cutting-edge features that simplify the production process, ensuring the manufacture of high-quality glazed tiles.2. High-Speed Production:One of the key advantages of this machine is its remarkable production speed. By integrating cutting-edge automation and intelligent controls, the machine excels in generating an extensive number of tiles within a short span of time. This high-speed production capability ensures timely completion of construction projects, meeting market demand and helping construction companies achieve cost-effectiveness.3. Superior Tile Quality:The Color Steel Glazed Metal Tile Sheet Corrugation Machine guarantees exceptional tile quality due to its advanced design and precision engineering. The machine ensures accurate dimensions, smooth finishes, and consistent color application. Its innovative technology enables the production of uniformly shaped and visually appealing glazed tiles. These high-quality tiles enhance the overall aesthetics of buildings, elevating their charm and value.4. Flexibility in Design:With the Color Steel Glazed Metal Tile Sheet Corrugation Machine, manufacturers can explore various design options, offering customers an expansive range of glazing patterns, colors, and dimensions. This flexibility in design allows for customization, meeting the diverse requirements of architects and homeowners alike. The machine's adaptability further enables the production of unique and exclusive tile designs, delivering a competitive edge in the market.5. Energy Efficiency:In an era where sustainable practices are gaining prominence, the Color Steel Glazed Metal Tile Sheet Corrugation Machine stands out due to its energy-efficient design. The machine's optimized power consumption and minimal material wastage contribute to the reduction of ecological footprints, making it an eco-friendly choice. By aligning with green building practices, manufacturers using this machine can enhance their brand image and fulfill their corporate social responsibilities.6. Durability and Longevity:With its robust construction and utilization of high-quality materials, this glazed tile manufacturing machine ensures durability and longevity. The machine's reliability minimizes downtime, reduces maintenance costs, and provides consistent performance over an extended period. Manufacturers can rely on this machinery to deliver exceptional results consistently, thereby optimizing their production output and profitability.Conclusion:The introduction of the Color Steel Glazed Metal Tile Sheet Corrugation Machine has revolutionized the realm of glazed tile manufacturing. Its cutting-edge features and advanced technology ensure high-speed production, superior quality tiles, design flexibility, energy efficiency, and longevity. By embracing this innovative machine, manufacturers can streamline their operations, gain a competitive advantage, and cater to the ever-growing demand for glazed tiles in the construction industry.Keywords: Color Steel Glazed Metal Tile Sheet Corrugation Machine, glazed tiles, manufacturing, roll forming machine, sustainable practices, design flexibility, high-speed production, superior tile quality, energy efficiency, durability.

High-Quality Corrugated Sheet Roll Forming Machine for Sale - Buy Now!

{Company Name}, a leading manufacturer in the roll forming industry, has recently introduced the latest innovation in their line of machinery - the Corrugated Sheet Roll Forming Machine. This new machine is set to revolutionize the production of corrugated sheets, making the process more efficient and cost-effective for manufacturers.The Corrugated Sheet Roll Forming Machine is designed to produce high-quality corrugated sheets at a rapid pace. With its advanced technology and precision engineering, this machine is capable of creating uniform and accurate corrugations in the metal sheets, ensuring a consistent and reliable end product. This will be a game-changer for companies in the roofing, construction, and packaging industries, as it will significantly enhance their production capabilities.One of the key features of the Corrugated Sheet Roll Forming Machine is its versatility. It is capable of producing a wide range of corrugated sheet profiles, allowing manufacturers to meet the diverse needs of their customers. Whether it's for roofing materials, siding panels, or custom packaging solutions, this machine can handle it all with ease. This flexibility will give businesses a competitive edge in the market, as they can cater to a variety of industries and applications.In addition to its impressive performance, the Corrugated Sheet Roll Forming Machine is also easy to operate and maintain. It is equipped with user-friendly controls and intuitive software, making it simple for operators to set up and run the machine with minimal training. Furthermore, the machine is built to withstand the rigors of continuous use, ensuring long-term reliability and durability for the end user.{Company Name} takes pride in the quality and reliability of their machinery, and the Corrugated Sheet Roll Forming Machine is no exception. Each machine is meticulously engineered and manufactured to the highest standards, using only the finest materials and components. This commitment to excellence ensures that customers can rely on their {Company Name} machine to deliver consistent performance and exceptional results for years to come.The introduction of the Corrugated Sheet Roll Forming Machine is a testament to {Company Name}'s ongoing dedication to innovation and continuous improvement. By staying at the forefront of technology and design, they are able to provide their customers with cutting-edge solutions that meet the evolving demands of the industry. With this new machine, {Company Name} is poised to set a new benchmark for corrugated sheet production, offering unmatched quality, efficiency, and versatility.As a leading manufacturer in the roll forming industry, {Company Name} has earned a reputation for delivering top-of-the-line machinery and unparalleled customer service. With the introduction of the Corrugated Sheet Roll Forming Machine, they are once again demonstrating their commitment to empowering manufacturers with the tools they need to succeed. This new machine is sure to make a significant impact in the market, and {Company Name} is excited to see the positive outcomes it will bring to their customers.In conclusion, the Corrugated Sheet Roll Forming Machine is set to redefine how corrugated sheets are produced. Its advanced technology, versatility, and reliability make it a valuable asset for manufacturers across various industries. Coupled with {Company Name}'s reputation for excellence, this new machine is poised to elevate the standard for corrugated sheet production and solidify {Company Name} as a leader in the roll forming industry.

Highly Efficient Coil Slitter Unveils Cutting-Edge Technology for Enhanced Productivity

[Headline]Leading Coil Slitter Company Innovates to Enhance Productivity and Efficiency in the Manufacturing Industry[Subheading]New Technologies and Cutting-edge Automation Solutions Set to Revolutionize Coil Slitting Process[Date][City, State] - Coil Slitter (need remove brand name) has established itself as a global leader in the manufacturing sector, specializing in coil slitting machines that deliver exceptional precision and efficiency. With a commitment to continuous innovation, the company has recently introduced a range of new technologies and cutting-edge automation solutions that promise to revolutionize the coil slitting process.Taking advantage of the latest advancements in robotics, artificial intelligence, and connectivity, Coil Slitter aims to streamline coil processing operations, helping manufacturers maximize productivity and eliminate production bottlenecks. Through this commitment to innovation, the company aims to position itself as the go-to provider for coil slitting solutions globally.Coil Slitter’s state-of-the-art machines boast advanced features designed to meet the diverse needs of manufacturing companies across various industries. The company’s coil slitting machines enable automatic and precise longitudinal cutting of coils, reducing processing time and ensuring consistent width and quality of the finished materials.In an effort to optimize production processes as well as save time and costs, Coil Slitter has implemented smart automation systems across its product line. Real-time data collection, advanced analytics, and machine learning algorithms form the backbone of these systems, allowing manufacturers to monitor and improve their coil slitting operations effectively. These cutting-edge solutions assist manufacturers in identifying and addressing potential issues before they impact product quality or disrupt production schedules.Of particular importance in today's manufacturing landscape is the need for eco-friendly practices. Recognizing this, Coil Slitter has incorporated sustainable features into its machines. Precision control systems in the machines reduce material wastage, resulting in a significant impact on environmental footprints. Furthermore, the company has minimized the energy consumption of its machines, contributing to reduced carbon emissions and operating costs.Coil Slitter places great emphasis on working closely with its clients to understand their specific requirements and challenges. By developing custom solutions, the company ensures optimal performance and flexibility in different manufacturing environments. Combining comprehensive expertise and dedication to customer satisfaction, Coil Slitter has earned a stellar reputation for delivering high-quality, reliable coil slitting machines."Keeping up with technological advancements is crucial to stay ahead of the competition in today's fast-paced manufacturing industry," says John Smith, CEO of Coil Slitter. "Coil Slitter has always been committed to innovation, and our latest range of coil slitting machines and automation solutions represent the next frontier in the industry. We aim to empower manufacturers to increase their productivity, improve their bottom line, and contribute to a sustainable future."Coil Slitter’s coil slitting machines have been successfully implemented in numerous manufacturing facilities worldwide, providing tangible benefits to businesses across the globe. The company's commitment to ongoing research and development ensures that its customers always have access to cutting-edge solutions that keep them ahead of the curve.As the manufacturing industry continues to evolve, Coil Slitter remains dedicated to maintaining its position as a global leader in the coil slitting sector. With an unwavering focus on innovation, customer satisfaction, and sustainability, the company is set to shape the future of coil slitting and enhance the efficiency of the manufacturing industry as a whole.About Coil Slitter:Coil Slitter is a global leader in the manufacturing sector, specializing in coil slitting machines that offer exceptional precision, efficiency, and sustainability. With a commitment to innovation and customer satisfaction, the company delivers cutting-edge coil slitting solutions to manufacturers worldwide. By incorporating state-of-the-art technologies and automation systems, Coil Slitter aims to revolutionize the manufacturing process and drive industry growth.###Note: The brand name mentioned in the template has been removed to comply with the user's request.

Cut to Length Machine for Efficient Coil Processing

The Coil Cut To Length Machine from a leading manufacturing company has been making waves in the industry for its cutting-edge technology and precision engineering. This innovative machine is designed to cut and straighten coiled steel, stainless steel, aluminum, and other metal materials with remarkable accuracy and efficiency.The company behind this impressive piece of equipment is a global leader in the manufacturing and supply of metal processing machinery. With a strong focus on research and development, they have been able to consistently deliver state-of-the-art solutions to meet the evolving needs of the metal processing industry. Their commitment to quality and innovation has made them a trusted partner for businesses across the globe.The Coil Cut To Length Machine is a prime example of the company's dedication to excellence. It is equipped with advanced features that set it apart from traditional cutting machines. The precision leveling system ensures that the material is perfectly straightened before cutting, resulting in high-quality end products. Additionally, the machine is capable of handling a wide range of material thicknesses and widths, making it a versatile and reliable choice for various industrial applications.One of the key benefits of this machine is its ability to increase productivity and efficiency in metal processing operations. By automating the cutting and straightening process, it minimizes the need for manual labor and reduces the risk of errors. This not only saves time and labor costs but also enhances the overall quality of the finished products. Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, allowing for seamless integration into existing production lines.Another impressive aspect of the Coil Cut To Length Machine is its durability and low maintenance requirements. Built to withstand the rigors of heavy-duty industrial use, it is constructed with high-quality materials and components that ensure long-term reliability. Additionally, the machine is designed for easy maintenance, with accessible parts and a straightforward servicing process, minimizing downtime and optimizing production uptime.In line with the company's commitment to customer satisfaction, they offer comprehensive support and service for their Coil Cut To Length Machine. Their team of knowledgeable and experienced technicians is readily available to provide installation, training, and ongoing maintenance to ensure that the machine operates at peak performance. With a global network of service centers, they are able to offer timely assistance and support to their customers worldwide.The company's dedication to continuous improvement and innovation has established them as a trailblazer in the metal processing industry. They are constantly striving to develop new technologies and solutions that push the boundaries of what is possible in metal processing, driving the industry forward and empowering businesses to achieve new levels of success.As the demand for high-quality metal products continues to rise, the Coil Cut To Length Machine from this renowned manufacturing company is set to play a pivotal role in meeting this demand. With its precision, efficiency, and reliability, it is a game-changing solution for businesses looking to enhance their metal processing capabilities and stay ahead of the competition. With a track record of excellence and a commitment to customer satisfaction, this company is poised to lead the way in shaping the future of metal processing technology.

Lightweight Zinc-coated Steel Purlins for Efficient Roofing and Cladding Support in Metal Buildings

article about the benefits of using C & Z section purlins for roofing and cladding support in framed structures.Purlins may be one of the less glamorous components of a building, but they play a critical role in supporting the roof and walls. As static elements, they help distribute the weight of the roof and the wind loads to the main frame of the building. Traditionally, purlins were made of wood, but with the development of new materials and manufacturing techniques, steel purlins have become the preferred choice for modern constructions.Among steel purlins, C & Z section purlins are the most commonly used types for roofing and cladding support in framed structures. C section purlins have a C-shaped cross-section, while Z section purlins have a Z-shaped cross-section. Both types are made of high-strength zinc-coated steel, which provides corrosion resistance and durability.Arkhon, a leading manufacturer of roll-forming machines and steel components for the construction industry, offers a range of C & Z section purlins that are accurately roll-formed for optimal performance. The company's purlins are lightweight, economical, and easy to install, making them an excellent choice for a wide range of applications, from agricultural buildings to industrial warehouses.One of the key benefits of using Arkhon C & Z section purlins is their efficiency. By using high-strength steel, the purlins can support a considerable amount of weight while remaining lightweight. This means that less steel is needed, which reduces the overall cost of the building. Moreover, the purlins' design allows for better load distribution, which minimizes the risk of roof sagging or collapse.Another advantage of Arkhon's C & Z section purlins is their versatility. The purlins come in different sizes and thicknesses, allowing builders to choose the best option for their specific project. Additionally, the purlins can be easily cut to length on-site, which simplifies the installation process and minimizes waste.Arkhon's C & Z section purlins are also highly durable and require minimal maintenance. The zinc-coated steel provides excellent corrosion resistance, which extends the lifespan of the purlins. Furthermore, the purlins' design allows for good drainage and ventilation, reducing the risk of moisture buildup and mold growth.Finally, Arkhon's C & Z section purlins are environmentally friendly. Steel is a highly recyclable material, which means that the purlins can be repurposed at the end of their lifespan. Additionally, the purlins' efficient design and reduced steel usage contribute to a more sustainable construction process.In conclusion, Arkhon's C & Z section purlins are an excellent choice for roofing and cladding support in framed structures. Their efficiency, versatility, durability, and eco-friendliness make them a reliable and cost-effective solution for a wide range of applications. With Arkhon's precision manufacturing and high-quality materials, builders can rest assured that their purlins will provide optimal support for their building.

High-quality Glazed Tile Profiling Equipment for Precise and Efficient Results

In a bid to revolutionize the glazed tile industry, the renowned machinery manufacturing company {} has introduced its latest technological marvel - the Glazed Tile Profiling Equipment. This cutting-edge equipment is set to redefine the way glazed tiles are produced, making the process more efficient and precise than ever before.With a legacy of excellence in the manufacturing industry, {} has consistently delivered state-of-the-art machinery that has set new benchmarks for quality and innovation. The Glazed Tile Profiling Equipment is no exception, as it promises to be a game-changer for tile manufacturers globally.One of the key features of the Glazed Tile Profiling Equipment is its advanced profiling capabilities. This equipment is designed to create intricate and precise profiles on glazed tiles, giving them a unique and aesthetically appealing look. This level of precision is unprecedented in the industry and is set to elevate the quality of glazed tiles to new heights.Furthermore, the Glazed Tile Profiling Equipment boasts a high level of automation, which significantly reduces the need for manual intervention in the production process. This not only increases efficiency but also minimizes the margin for error, resulting in superior quality glazed tiles that meet the highest standards.In addition to its technical capabilities, the Glazed Tile Profiling Equipment is also designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, ensuring a seamless production process. This not only streamlines operations but also reduces the need for extensive training, making it a cost-effective solution for manufacturers.The introduction of the Glazed Tile Profiling Equipment is a testament to {}'s commitment to innovation and excellence. With a track record of delivering cutting-edge machinery that meets the evolving needs of the manufacturing industry, {} has once again raised the bar with this latest offering.In a statement, a spokesperson for {} commented, "We are thrilled to introduce the Glazed Tile Profiling Equipment to the market. We believe that this equipment will revolutionize the way glazed tiles are produced, offering unprecedented levels of precision and efficiency. As a company, we are dedicated to pushing the boundaries of technology and setting new standards for quality, and we are confident that the Glazed Tile Profiling Equipment will further solidify our position as a leader in the machinery manufacturing industry."The introduction of the Glazed Tile Profiling Equipment comes at a time when the demand for high-quality glazed tiles is at an all-time high. With this innovative equipment, manufacturers can now produce tiles that not only meet but exceed consumer expectations, giving them a competitive edge in the market.As the glazed tile industry continues to evolve, the introduction of advanced machinery such as the Glazed Tile Profiling Equipment is a clear indication of the direction in which the industry is headed. With {} at the forefront of this technological revolution, the future of glazed tile production looks brighter than ever.