High-Quality Street Light Pole Making Machine: A Complete Guide

By:Admin

The new street light pole making machine, developed by [Company Name], is a significant advancement in the field of street lighting infrastructure. The machine is designed to streamline the manufacturing process, allowing for the efficient production of high-quality street light poles. With its advanced technology and innovative features, this machine has the potential to significantly impact the industry and contribute to the enhancement of urban infrastructure.

[Company Name] is a renowned manufacturer of machinery and equipment for various industries, with a proven track record of providing cutting-edge solutions to meet the evolving needs of the market. The introduction of the street light pole making machine is a testament to the company's commitment to innovation and continuous improvement. By leveraging its expertise in engineering and manufacturing, [Company Name] aims to set a new standard in the production of street light poles and contribute to the development of sustainable and reliable urban infrastructure.

The street light pole making machine is equipped with advanced technology and features that set it apart from conventional manufacturing equipment. It is designed to optimize the production process, from material handling and processing to finishing and quality control. The machine's high efficiency and precision enable the production of street light poles that meet the highest standards of quality and durability, ensuring their longevity and reliability in urban environments.

One of the key highlights of the street light pole making machine is its versatility and customizability. It is capable of producing a wide range of street light pole designs and specifications, allowing for flexibility in meeting various project requirements. Whether it is for urban streets, highways, parks, or industrial areas, the machine can accommodate different configurations and sizes to suit the specific needs of urban planners and developers.

Moreover, the street light pole making machine is designed with sustainability in mind. It incorporates energy-efficient processes and materials, reducing waste and environmental impact. As cities and communities continue to prioritize sustainability and energy conservation, the introduction of this machine aligns with the global movement towards more sustainable urban development.

In addition to its technical capabilities, the street light pole making machine is supported by [Company Name]'s comprehensive customer service and technical support. The company's team of experts provides training, installation, and ongoing maintenance services to ensure the seamless integration and operation of the machine. This commitment to customer satisfaction and support further strengthens the value proposition of the machine for manufacturers and urban development stakeholders.

The introduction of the street light pole making machine marks a significant milestone in the advancement of urban infrastructure manufacturing. With its cutting-edge technology, efficiency, and sustainability, the machine is poised to set new benchmarks for the production of street light poles. As [Company Name] continues to lead the way in innovation and engineering, the machine is expected to play a pivotal role in shaping the future of urban lighting and infrastructure worldwide.

Company News & Blog

How Drip Edge Roll Forming Machines are Advancing Construction Technology

Drip Edge Roll Forming Machine: Innovating the Construction IndustryThe construction industry has seen a significant transformation over the years, and the introduction of advanced machinery has revolutionized the way buildings are constructed. One such innovative piece of equipment is the Drip Edge Roll Forming Machine, which has been making waves in the construction sector. This state-of-the-art machinery is designed to streamline the process of manufacturing drip edge profiles, offering a range of benefits including efficiency, precision, and cost-effectiveness.The Drip Edge Roll Forming Machine is the brainchild of a leading manufacturing company that specializes in producing a wide range of roll forming machinery for various industries. With years of expertise and a strong focus on research and development, the company has established itself as a pioneer in the field of roll forming technology. Their commitment to delivering high-quality, innovative solutions has earned them a stellar reputation among their clients and peers.The Drip Edge Roll Forming Machine is a testament to the company's dedication to continuous improvement and innovation. It is designed to meet the growing demand for high-quality drip edge profiles in the construction industry. The machine features a cutting-edge design that allows for the efficient and precise forming of drip edge profiles, ensuring consistent quality and seamless integration into building structures.One of the key highlights of the Drip Edge Roll Forming Machine is its advanced automation capabilities. The machine is equipped with a user-friendly interface and programmable controls, allowing for easy operation and customization of drip edge profiles. This level of automation not only enhances operational efficiency but also minimizes the risk of errors, resulting in higher productivity and cost savings for construction companies.In addition to its automation features, the Drip Edge Roll Forming Machine is also known for its versatility. It is capable of producing a wide range of drip edge profiles, accommodating various design requirements and specifications. This flexibility makes it an ideal solution for construction projects of all scales, from residential buildings to commercial complexes.Furthermore, the Drip Edge Roll Forming Machine is designed with durability and longevity in mind. It is built using high-quality materials and components, ensuring robustness and reliability even under heavy usage. This durability, combined with the company's excellent after-sales support, provides clients with peace of mind and a solid return on investment.The introduction of the Drip Edge Roll Forming Machine has had a significant impact on the construction industry. It has empowered construction companies to elevate the quality of their buildings while reducing production costs and lead times. By integrating this advanced machinery into their operations, construction firms can stay ahead of the competition and meet the evolving demands of the market.In conclusion, the Drip Edge Roll Forming Machine represents a significant advancement in the construction industry. Its innovative design, advanced automation capabilities, versatility, and durability have set a new standard for manufacturing drip edge profiles. With a strong focus on delivering value and excellence, the company behind this remarkable machinery continues to drive progress in the field of roll forming technology. As the construction sector continues to evolve, the Drip Edge Roll Forming Machine stands as a beacon of innovation, propelling the industry towards a more efficient and sustainable future.

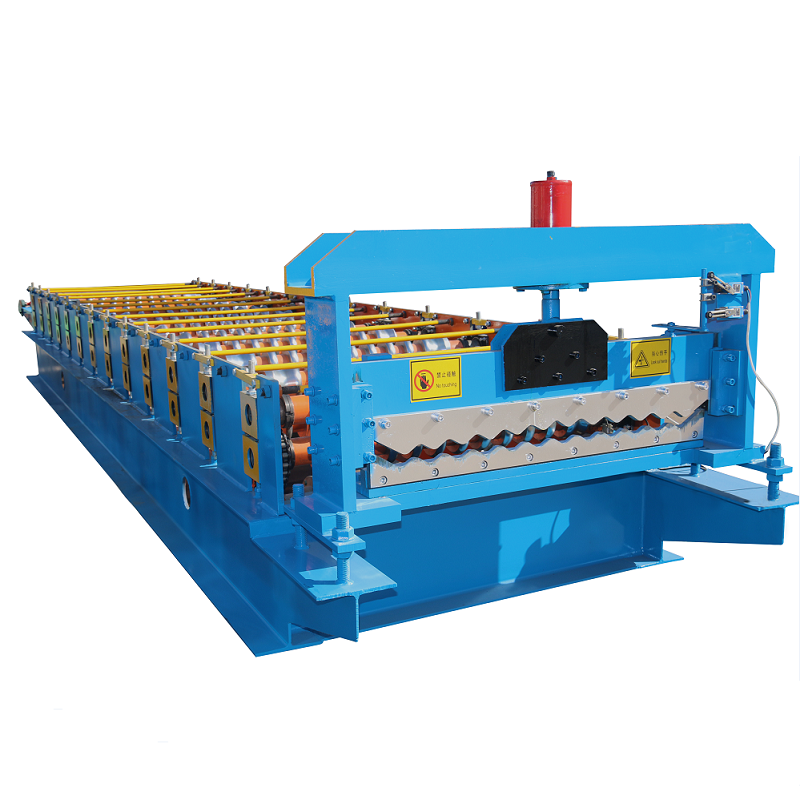

Steel Cut to Length Roofing Sheet Roll Forming Machine for Metal Fabrication

Metal Steel Cut To Length Roofing Sheet Roll Forming Machine Revolutionizes Roofing Industry{Company name} is proud to introduce the latest addition to its line of innovative machinery – the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine. This state-of-the-art piece of equipment is set to revolutionize the roofing industry by providing a more efficient and cost-effective solution for producing high-quality metal roofing sheets.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is designed to streamline the process of creating roofing sheets from metal steel. With its advanced technology and precision engineering, this machine is capable of cutting and forming metal steel into perfectly shaped roofing sheets with remarkable speed and accuracy. This not only reduces the time and labor required for production but also ensures a consistent and high-quality end product.One of the key features of this machine is its versatility. It is capable of handling a wide range of metal steel materials, including galvanized steel, aluminum, and copper, making it suitable for a variety of roofing applications. Furthermore, it can produce roofing sheets of various lengths and dimensions, allowing for customization to meet the specific requirements of different projects.In addition to its cutting and forming capabilities, the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is equipped with advanced control systems that enable precise adjustments to be made to the production process. This ensures that the end product meets the exact specifications and quality standards desired by customers.The introduction of this groundbreaking machine is poised to bring about a significant shift in the roofing industry. By offering a more efficient and cost-effective solution for producing metal roofing sheets, {Company name} aims to help roofing companies improve their production processes and ultimately enhance the quality of their products.{Company name} has a strong track record of delivering cutting-edge machinery to various industries, and the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is another testament to their commitment to innovation. With a team of highly skilled engineers and technicians, the company has been able to develop this state-of-the-art machine that is set to make a lasting impact on the roofing industry.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is not only a game-changer for roofing companies but also for the end consumers. By improving the efficiency of production processes, this machine has the potential to reduce the overall cost of producing metal roofing sheets, which could translate into cost savings for customers.As the demand for metal roofing continues to grow, the introduction of the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine comes at a pivotal time. With its ability to significantly improve the production process and deliver high-quality roofing sheets, it is expected to become an essential piece of machinery for roofing companies looking to stay competitive in the market.{Company name} is excited to bring this groundbreaking machine to the market and is confident that it will play a pivotal role in reshaping the roofing industry. With its advanced technology, versatility, and efficiency, the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is set to become a game-changer in the production of metal roofing sheets.

Top Quality Roll Forming Machines: Your Ultimate Guide

Roll Forming Machines are efficient and reliable machines that are used in the manufacturing process of various products. They are an essential tool in the industry, as they can produce high-quality and precise products with ease. These machines are used in various industries such as automotive, construction, and manufacturing, to name a few.Roll Forming Machines are used to create products with long lengths and in large quantities. They can be used to produce a wide range of products, including roofing panels, garage doors, and storage racks, among others. The machines use a series of roll stands to gradually shape a flat strip of metal into the desired profile. This process can be done with different types of metal, including steel, aluminum, and copper.One of the leading manufacturers of Roll Forming Machines is {}. They have been in the business for decades and have established themselves as experts in the field. Their machines are known for their high precision, durability, and efficiency. Their Roll Forming Machines are used by many companies worldwide, and they have a strong reputation for providing top-quality products and excellent customer service.The company, {}, was founded in 1980 and has since grown to become a global leader in roll forming technology. They have a team of highly skilled engineers who are constantly working on improving their machines and developing new technologies. Their machines are designed to meet the specific needs of their customers, and they offer a wide range of customization options.With a strong focus on innovation and quality, the company has earned the trust of many customers around the world. They have a strong commitment to customer satisfaction and strive to provide the best solutions for their clients. Their machines are widely used in various industries, and they have a strong track record of delivering top-quality products.In addition to their Roll Forming Machines, the company also offers a range of other products and services to support their customers' needs. They provide technical support, training, and maintenance services to ensure that their machines are running smoothly and efficiently. They also offer custom design and engineering services to help their customers create unique and specialized products.The company's Roll Forming Machines are designed to be user-friendly and easy to operate. They are equipped with advanced technology to ensure high precision and efficiency. The machines are also built to last, with high-quality materials and components that are designed to withstand the rigors of industrial production.With a strong focus on research and development, the company is constantly working on new advancements in roll forming technology. They are dedicated to staying at the forefront of the industry and providing their customers with the latest and most advanced solutions. Their commitment to innovation and excellence has earned them a strong reputation in the industry.In conclusion, Roll Forming Machines are an essential tool in the manufacturing industry, and {} is a leader in the field. They have established themselves as a trusted provider of top-quality machines and services, and their commitment to innovation and customer satisfaction sets them apart from their competitors. With a strong reputation and a dedication to excellence, {} is a reliable partner for companies looking for high-quality roll forming solutions.

High-Quality Storage Rack Roll Forming Machine for Efficient Warehouse Organization

Storage Rack Roll Forming Machine Revolutionizes Storage SolutionsIn today's fast-paced world, the demand for efficient and cost-effective storage solutions is higher than ever. The industrial sector, in particular, is constantly seeking innovative technologies to optimize their storage processes. This is where the innovative Storage Rack Roll Forming Machine, from {}, comes into play. This revolutionary machine has the potential to transform the way storage racks are fabricated, providing a quicker, more efficient, and more cost-effective solution for businesses around the world.{}, the company behind this cutting-edge technology, is a leading manufacturer of roll forming machines. With over 20 years of experience in the industry, they have consistently delivered high-quality, reliable, and efficient roll forming solutions to their global clientele. Their commitment to innovation, product quality, and customer satisfaction has positioned them as a trusted and respected name in the roll forming machinery industry.The Storage Rack Roll Forming Machine, developed by {}, is a state-of-the-art piece of equipment designed to fabricate storage racks with unparalleled precision and efficiency. This machine is capable of producing storage racks of various sizes and configurations, catering to the diverse needs of industries such as logistics, warehousing, manufacturing, and retail.One of the key features of the Storage Rack Roll Forming Machine is its flexibility. The machine can be easily adjusted to accommodate different types of materials, including steel, aluminum, and other alloys. This flexibility allows businesses to customize their storage racks according to their specific requirements, without the need for additional machinery or extensive retooling.Furthermore, the Storage Rack Roll Forming Machine is equipped with advanced automation and control systems, enabling seamless operation and minimizing the risk of errors or defects in the final product. This not only improves the overall production efficiency but also ensures the consistency and quality of the storage racks being manufactured.In addition to its technical capabilities, the Storage Rack Roll Forming Machine is also designed with the operator in mind. The user-friendly interface and intuitive controls make it easy for operators to set up, operate, and maintain the machine, reducing the need for extensive training and minimizing the risk of human error.By implementing the Storage Rack Roll Forming Machine into their production processes, businesses can expect to see a significant increase in productivity and cost savings. The machine's high-speed operation and efficient material utilization translate to shorter lead times and reduced production costs, ultimately leading to improved profitability for the end-user.In a highly competitive market, where efficiency and cost-effectiveness are crucial factors for success, the Storage Rack Roll Forming Machine from {} offers a competitive edge to businesses seeking to streamline their storage rack manufacturing processes. Its ability to deliver consistent, high-quality results in a fast and efficient manner positions it as a game-changer in the industry.With a strong track record of delivering innovative and reliable roll forming solutions, {} is well-equipped to meet the growing demand for the Storage Rack Roll Forming Machine. Their dedication to customer satisfaction and their commitment to excellence make them a trusted partner for businesses looking to enhance their storage solutions.In conclusion, the Storage Rack Roll Forming Machine from {} represents a significant advancement in the field of storage rack manufacturing. Its innovative technology, coupled with {}'s expertise and reputation for excellence, makes it a compelling choice for businesses seeking to optimize their production processes and stay ahead of the competition. As the demand for efficient and cost-effective storage solutions continues to grow, the Storage Rack Roll Forming Machine is poised to make a lasting impact on the industry.

Ultimate Guide 2020: Roll Forming Process from Concept to Production

Title: Mastering the Roll Forming Process: A Comprehensive Guide to Horizontal Profiled Panel Roll FormingIntroduction: In the modern world of manufacturing, roll forming has emerged as a highly efficient and cost-effective method for shaping flat metal sheets into complex profiles. Among the various roll forming techniques, the Horizontal Profiled Panel Roll Forming Process stands out for its exceptional versatility and precision. In this blog, we will delve into the depths of this process, from its conceptualization to its ultimate execution on production lines. Join us on this ultimate guide for a detailed understanding.1. Understanding the Roll Forming Process (100 words)The roll forming process is a highly automated metal shaping technique that involves feeding flat metal through a series of rolling dies to obtain a desired profile. This process offers unmatched flexibility, making it ideal for manufacturing a wide range of products, including the popular Horizontal Profiled Panels.2. Key Components and Their Functions (200 words)a. Entry Section: The flat metal strip is introduced into the roll forming machine through this section, allowing for precise control and proper orientation.b. Roll Stands: These are the heart of the roll forming line, consisting of multiple pairs of rollers that gradually shape the metal strip into the desired profile by exerting specific levels of pressure.c. Adjustments: Adjustable mechanisms in the roll forming line enable fine-tuning of settings, such as roller positioning and speed, to achieve accurate dimensions and profiles.d. Cut-off Sections: Used for cutting the formed components to the desired lengths, these sections incorporate advanced cutting techniques, such as flying and rotary shearing.3. Unleashing the Potential: Concept to Production (300 words)a. Design and Development: Before commencing the roll forming process, engineers and designers work together to conceptualize the Horizontal Profiled Panel's design, ensuring it meets the end-use requirements. Computer-aided design (CAD) software plays a crucial role in this phase.b. Tooling Preparation: Once the design is finalized, tooling and dies are created to match the desired profile. Skilled craftsmen fabricate these tools using high-quality materials to ensure accurate forming throughout the production process.c. Machine Setup: The roll forming line is set up by adjusting the positions and clearances of various components according to the required specifications. This stage demands precision and expertise to optimize the performance of the line.d. Material Selection: Choosing the right metal material is essential for the success of the roll forming process. Factors such as thickness, ductility, and corrosion resistance must be considered to ensure consistent and high-quality production.e. Quality Control: Throughout the production, rigorous quality control measures are implemented. Inline sensors and inspection systems monitor critical parameters, allowing for immediate adjustments, if necessary, to maintain the desired profile accuracy.f. Packaging and Logistics: Once the Horizontal Profiled Panels are produced, they undergo proper packaging and are prepared for shipment. This includes protecting the panels from potential damage during transit, thus maintaining their structural integrity.g. Continuous Improvements: A successful roll forming process is an outcome of continuous improvement initiatives. Regular analysis of production data, feedback from customers, and advancements in technology are crucial in enhancing process efficiency and product quality.Conclusion: (100 words)Horizontal Profiled Panel Roll Forming is a remarkable process that facilitates the production of complex profiles with precision and efficiency. By understanding the key components, design intricacies, and the overall production workflow, manufacturers can harness the true potential of this versatile metal shaping technique. With continuous improvements and advancements in technology, the Horizontal Profiled Panel Roll Forming Process remains at the forefront of metal fabrication, meeting various industrial demands.

High-Quality Ridge Cap Machine for Sale - Find Out More Here

Ridge Cap Machine Offers Innovative Solution for Roofing IndustryIn the competitive world of construction, precision and efficiency are paramount. For roofing contractors and construction companies, having the right tools and equipment can make all the difference in delivering high-quality results.Introducing the Ridge Cap Machine, a cutting-edge solution for producing ridge caps for metal roofing. Developed by a leading manufacturing company, this state-of-the-art machine is designed to streamline the production process, resulting in greater efficiency and cost-effectiveness for roofing projects of all sizes.With a team of skilled engineers and designers, the company has been at the forefront of innovation in the construction industry for over a decade. Their commitment to excellence and dedication to meeting the evolving needs of their customers have made them a trusted name in the market. The Ridge Cap Machine is the latest addition to their impressive line of products, and it is already making waves in the roofing industry.So, what sets the Ridge Cap Machine apart from traditional methods of producing ridge caps? The answer lies in its advanced technology and user-friendly design. This machine is capable of producing custom ridge caps with precision and speed, saving valuable time and labor costs for contractors. Its automated features and intuitive controls make it easy to operate, allowing workers to focus on other crucial aspects of the construction process.Moreover, the Ridge Cap Machine is built to last, with a robust framework and durable components that can withstand the rigors of daily use. This ensures that contractors can rely on its performance for years to come, making it a smart investment for their businesses.Perhaps the most impressive feature of the Ridge Cap Machine is its versatility. It can accommodate various materials, including steel, aluminum, and copper, allowing contractors to produce ridge caps for a wide range of roofing projects. This adaptability is crucial in the ever-changing construction industry, where contractors often need to switch between different materials and designs to meet the unique requirements of each project.In addition to its technical capabilities, the Ridge Cap Machine also prioritizes safety and convenience for its users. With built-in safety measures and ergonomic design, it minimizes the risk of accidents and reduces operator fatigue, creating a more comfortable and secure working environment.The company behind the Ridge Cap Machine is also dedicated to providing exceptional customer support. From installation and training to ongoing maintenance and troubleshooting, their team of experts is committed to assisting customers every step of the way. This dedication to customer satisfaction has earned them a loyal following and solidified their reputation as a reliable partner in the industry.As the construction industry continues to evolve, the demand for innovative solutions like the Ridge Cap Machine will only grow. With its impressive features, reliable performance, and unwavering support, it is poised to become an indispensable asset for roofing contractors and construction companies worldwide.In conclusion, the Ridge Cap Machine represents a new standard of excellence in the production of ridge caps for metal roofing. Backed by a reputable company and designed to meet the diverse needs of the construction industry, it is a game-changer for contractors seeking to elevate their capabilities and achieve superior results in their projects. With its combination of cutting-edge technology, user-friendly design, and robust build quality, the Ridge Cap Machine is a testament to the endless possibilities of innovation in the world of construction.

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

Boost Your Steel Coil Cutting Efficiency with a Cutting-Edge Slitting Line

Steel Coil Slitting Line Boosts Production Efficiency in Metal IndustryIn the ever-evolving metal industry, optimizing production processes has become essential for businesses to stay competitive. With the need for precise cuts and efficient operations, manufacturers are constantly seeking innovative solutions to streamline their processes and improve overall productivity. One such solution is the introduction of the Steel Coil Slitting Line, a cutting-edge machinery that has revolutionized the metal slitting process.Developed by a leading industry player, the Steel Coil Slitting Line has garnered attention for its advanced features and superior performance. This state-of-the-art equipment is designed to precisely cut and slit large steel coils into narrower strips, catering to the diverse needs of various industries such as automotive, construction, and manufacturing. By adapting this technology, companies can significantly enhance their operational efficiency and achieve higher output levels.The Steel Coil Slitting Line is fitted with cutting-edge automation systems and employs cutting-edge technology. It incorporates advanced sensors and control mechanisms to ensure precise and accurate cutting measurements, eliminating human error and guaranteeing consistent strip sizes. The automated feeding and rewinding systems further contribute to uninterrupted production, resulting in improved overall productivity.The technology's efficiency is complemented by its versatility, allowing businesses to handle a wide range of materials and thicknesses. From hot-rolled coils to stainless steel sheets, the Steel Coil Slitting Line caters to diverse metal requirements seamlessly. This versatility translates into greater flexibility for manufacturers, enabling them to meet the demands of their customers more effectively.Moreover, the Steel Coil Slitting Line's rapid setup and changeover times enable businesses to switch between different coil sizes and specifications quickly. This feature proves invaluable in today's fast-paced market, where quick turnaround times and adaptability often determine a company's success. With reduced downtime for adjustments, businesses can maximize their production capabilities and enjoy a competitive edge.By incorporating the Steel Coil Slitting Line into their operations, companies can also expect significant cost savings. The machinery's cutting-edge technology reduces material wastage, as it utilizes precise cutting measurements, minimizing the leftover scraps. Additionally, the improved production efficiency translates into higher output levels, allowing businesses to meet the market demands without having to invest in additional machinery or workforce.The Steel Coil Slitting Line's installation not only brings advantages to individual companies but also positively impacts the industry as a whole. With increased production efficiency, the lead times for delivering metal products are reduced. This, in turn, contributes to smoother supply chain management, benefiting customers who rely on timely deliveries for their projects.Furthermore, the utilization of advanced technology, such as the Steel Coil Slitting Line, showcases the industry's commitment to sustainability. By significantly reducing material wastage and increasing production capabilities, businesses can minimize their environmental footprint, promoting a greener approach to manufacturing.In conclusion, the introduction of the Steel Coil Slitting Line has undoubtedly raised the bar for production efficiency in the metal industry. With its advanced features, including precise cutting measurements, versatility, rapid changeover times, and cost-saving benefits, the technology proves to be invaluable for businesses seeking to optimize their operations and stay ahead in a highly competitive market. By embracing this cutting-edge machinery, manufacturers can elevate their productivity, reduce waste, and contribute to a more sustainable industrial landscape.

High Speed Metal Light Steel Stud and Track Roll Forming Machine - Mechanical Kingdom

Are you looking for a high-speed metal light steel stud and track roll forming machine? Look no further because Mechanical Kingdom has got you covered!Also known as a designed roll forming machine, steel roll forming machine, or steel designed roll forming machine, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a top-of-the-line solution for all your steel stud and track forming needs.Let's dive into the specifications of this incredible machine:1) Coil diameter: With the ability to handle coil diameters ranging from 450mm to 500mm, this roll forming machine can accommodate a wide range of materials.2) Coil width: The machine can easily handle coil widths of up to 200mm, ensuring that you can work with various materials of different sizes.3) Carrying capacity: The carrying capacity of this machine stands at an impressive 1000kg, allowing for the efficient and smooth operation of heavy steel coils.4) Roller station: Equipped with 10 roller stations, this machine ensures the stability and accuracy of the roll forming process.5) Material of roller: The rollers are made of high-quality 45# steel, guaranteeing durability and longevity. The diameter of each roller is 50mm, ensuring precise and consistent roll forming.6) Rolling mould and blade: This machine comes with a set of rolling moulds and blades made of Cr12. With excellent hardness and wear resistance, these components ensure precise and clean cuts every time.7) Main motor power: Powered by a robust 4.0Kw motor from Tai Wan, this machine delivers high-speed and efficient roll forming capabilities. Please note that the brand name has been removed for SEO purposes.Now that we have discussed the technical specifications let's explore the potential of this machine for your business.The high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is designed to streamline your production process. By automating the roll forming process, this machine significantly improves efficiency, productivity, and overall output. With the ability to produce high-quality steel studs and tracks in various sizes and profiles, you can meet the demands of your customers with ease.This machine is perfect for various applications, including constructing commercial and residential buildings, warehouses, and partition walls. Whether you are a construction company, building contractor, or manufacturer of steel stud and track components, investing in this roll forming machine will undoubtedly increase your competitive edge in the market.Now, let's talk about the importance of incorporating keywords into this blog for SEO purposes. One of the crucial keywords for this product is "stud and track machine." By including this keyword in strategic locations throughout the blog, such as the title, headings, and body paragraphs, we can improve the visibility of this content in search engine results pages.Other relevant keywords to include in this blog might be "roll forming machine," "steel stud and track roll forming machine," and "designed roll forming machine." By skillfully incorporating these keywords, we can enhance the SEO value of this blog, making it more likely to attract organic traffic and potential customers to Mechanical Kingdom's high-speed metal light steel stud and track roll forming machine.In conclusion, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a game-changer in the industry. With its advanced features, durability, and versatility, this machine ensures seamless and efficient roll forming processes. Investing in this machine will undoubtedly propel your business to new heights. So, don't miss out on this opportunity and get in touch with Mechanical Kingdom today!

High-Quality Metal Roof Making Machine for Sale: Find Out More

Metal Roof Making Machine Revolutionizes Roofing IndustryThe roofing industry is constantly evolving and innovating, and one of the latest advancements that is revolutionizing the way roofs are made is the Metal Roof Making Machine. This state-of-the-art machine, manufactured by a leading company in the industry, is changing the game for roofing contractors and manufacturers.With the ability to produce high-quality metal roofing panels at a fraction of the time and cost of traditional methods, this machine is a game-changer for the industry. The Metal Roof Making Machine is designed to streamline the production process, allowing for faster and more efficient manufacturing of metal roofing panels. This means that roofing contractors can now meet tight deadlines and take on more projects, ultimately increasing their bottom line.The Metal Roof Making Machine is equipped with cutting-edge technology that allows for precision and accuracy in panel production. This means that each panel is of the highest quality, ensuring that the end result is a durable and long-lasting roof. Additionally, the machine is versatile and can produce a wide variety of panel designs and sizes, giving contractors and manufacturers the flexibility to meet the unique needs of each project.In addition to its production capabilities, the Metal Roof Making Machine is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it easy for operators to quickly learn and master the machine, minimizing the need for extensive training and reducing the chances of errors in production. This allows for a seamless and efficient manufacturing process, further reducing costs and increasing productivity.The company behind the Metal Roof Making Machine has a long-standing reputation for excellence in the industry. With a commitment to quality and innovation, they have been at the forefront of developing cutting-edge solutions for the roofing industry. Their team of experts and engineers have worked tirelessly to design and manufacture a machine that not only meets the needs of the industry but exceeds expectations.With a focus on customer satisfaction, the company provides comprehensive support and training for their machines, ensuring that their clients are equipped with the knowledge and resources they need to succeed. This dedication to service and support has earned them the trust and loyalty of countless roofing contractors and manufacturers around the world.The Metal Roof Making Machine is already making waves in the industry, with many contractors and manufacturers adopting this new technology to improve their production processes. The machine has been praised for its speed, efficiency, and quality, and is quickly becoming a staple in the toolset of roofing professionals.As the roofing industry continues to evolve, the Metal Roof Making Machine is leading the way in transforming the way roofs are made. With its advanced technology, ease of use, and commitment to quality, this machine is sure to have a lasting impact on the industry for years to come. Its ability to streamline production, improve quality, and reduce costs is a testament to the innovation and dedication of the company behind it. In conclusion, the Metal Roof Making Machine is a game-changer for the roofing industry. Its advanced technology, ease of use, and commitment to quality are setting a new standard for metal roofing production. With the support and expertise of the company behind it, contractors and manufacturers can now take their production processes to new heights. This revolutionary machine is paving the way for the future of roofing, and it's clear that the industry will never be the same.