Steel Glazed Tile Profile Corrugating Machine: Latest News and Updates

By:Admin

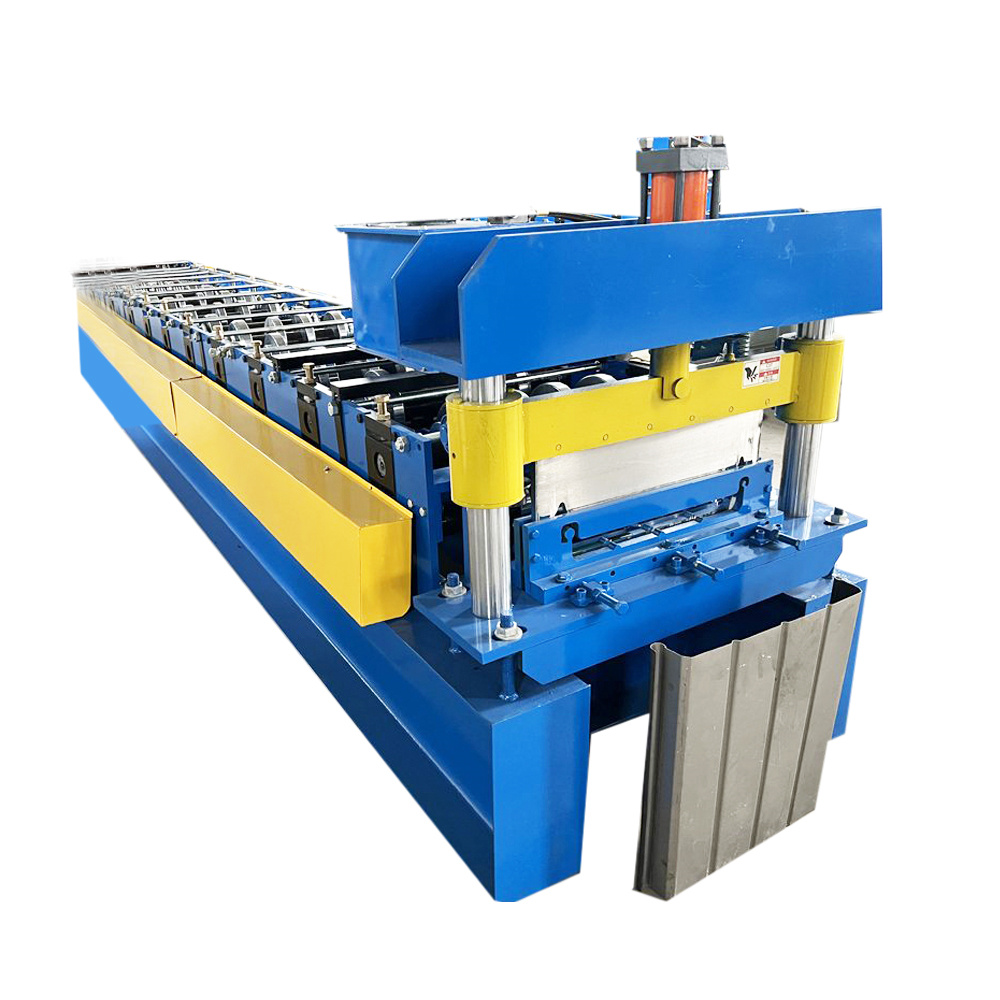

The global leader in the manufacturing of high-quality steel processing equipment has recently introduced its latest innovation, the Color Steel Glazed Tile Profile Corrugating Machine. This cutting-edge machine is designed to meet the growing demand for glazed tile profile corrugated steel sheets within the construction and architectural industry.

With a focus on precision engineering and innovative technology, the company has been at the forefront of the steel processing equipment industry for over two decades. By consistently delivering top-of-the-line machinery and unparalleled customer service, they have established a reputation as a trusted partner for companies in need of reliable and efficient steel processing solutions.

The Color Steel Glazed Tile Profile Corrugating Machine is the latest addition to their extensive portfolio of advanced equipment and is poised to set a new standard for glazed tile profile corrugated steel sheet production. This innovative machine is capable of producing high-quality corrugated steel sheets with a glazed tile profile, offering superior durability and aesthetic appeal for a wide range of architectural and construction applications.

Equipped with state-of-the-art technology, the Color Steel Glazed Tile Profile Corrugating Machine is designed for seamless integration into existing production lines, providing a cost-effective solution for companies looking to enhance their manufacturing capabilities. The machine's advanced features include precision control systems, high-speed processing, and a user-friendly interface, ensuring optimal efficiency and productivity.

Furthermore, the company's commitment to sustainability is evident in the Color Steel Glazed Tile Profile Corrugating Machine, as it is designed to minimize energy consumption and waste generation, aligning with the industry's increasing focus on environmental responsibility.

In addition to its advanced capabilities, the Color Steel Glazed Tile Profile Corrugating Machine is backed by the company's comprehensive support services, including installation, training, and ongoing maintenance, ensuring seamless integration and long-term reliability for its customers.

With its launch, the Color Steel Glazed Tile Profile Corrugating Machine is expected to meet the growing demand for high-quality glazed tile profile corrugated steel sheets in the global market. Its introduction reflects the company's dedication to staying ahead of industry trends and providing cutting-edge solutions that empower its customers to succeed in a competitive market landscape.

In response to the unveiling of the Color Steel Glazed Tile Profile Corrugating Machine, the company's CEO emphasized the importance of innovation and customer-centric solutions, stating, "We are proud to introduce the Color Steel Glazed Tile Profile Corrugating Machine as the latest addition to our lineup of advanced steel processing equipment. This innovative machine is a testament to our ongoing commitment to delivering high-performance solutions that empower our customers to achieve their production goals with precision and efficiency."

As the global construction and architectural industries continue to evolve, the demand for high-quality glazed tile profile corrugated steel sheets is expected to rise. The introduction of the Color Steel Glazed Tile Profile Corrugating Machine positions the company as a driving force in meeting this demand, providing a reliable and efficient solution that addresses the evolving needs of its customers.

With its rich history of innovation and a track record of delivering best-in-class steel processing equipment, the company is well-positioned to set a new industry standard with the Color Steel Glazed Tile Profile Corrugating Machine. As companies seek to enhance their production capabilities and meet the increasing demand for high-quality steel products, this innovative machine is poised to play a pivotal role in shaping the future of the construction and architectural industries.

Company News & Blog

Discover How a Metal Roofing Roller Machine Enhances Efficiency and Precision in Roofing Projects

[Company Name] Revolutionizing the Metal Roofing Industry with the Introduction of the Innovative Roofing Roller Machine[date][City, State] – Metal roofing has long been sought after for its durability and longevity. However, the installation process has traditionally been time-consuming and labor-intensive. In an effort to streamline this process and provide a more efficient solution, [Company Name], a leading manufacturer of roofing solutions, has recently launched their groundbreaking Metal Roofing Roller Machine.[Company Name] has been a driving force in the roofing industry for over three decades, constantly pushing the boundaries of innovation and technology. With a team of expert engineers and designers, the company has built a reputation for delivering high-quality products that not only meet industry standards but also exceed customer expectations.The Metal Roofing Roller Machine is the latest addition to their extensive line of roofing equipment. This state-of-the-art machine is designed to revolutionize the installation process, making it faster, easier, and more cost-effective. It eliminates the need for manual sheet bending and reshaping, thereby significantly reducing labor costs and minimizing the risk of human error.One of the key features of this machine is its ability to handle a wide range of metal roofing materials. Whether it be aluminum, steel, copper, or zinc, the Metal Roofing Roller Machine can effortlessly shape and reshape these materials according to the specifications of any roofing project. This versatility ensures that contractors and roofers can tackle a variety of projects without the need for multiple machines and tools, making it a cost-effective solution for businesses of all sizes.In addition to its versatility, the Metal Roofing Roller Machine is also remarkably user-friendly. Its intuitive interface and easy-to-use controls allow even inexperienced users to operate the machine with confidence. This eliminates the training time traditionally associated with new equipment, allowing contractors to scale their workforce quickly and meet project demands efficiently.Furthermore, the Roller Machine is equipped with advanced safety features to ensure the well-being of workers. An automatic shut-off mechanism is in place to prevent accidents, such as entanglement or injury, during operation. The robust construction of the machine also adds an extra layer of protection, ensuring its durability and longevity even in demanding working conditions.Since its launch, the Metal Roofing Roller Machine has garnered significant attention and praise from industry professionals. Roofers and contractors have lauded its ability to enhance productivity and streamline their operations. The machine's efficiency has enabled businesses to complete projects in record time, opening up new avenues for growth and profitability.[Company Name] understands the importance of sustainability in the roofing industry and has taken steps to reduce the environmental impact of their products. The Metal Roofing Roller Machine is designed to optimize material usage, minimizing waste and reducing carbon emissions. With this innovative machine, businesses can not only improve their efficiency but also contribute to a greener future.In conclusion, [Company Name]'s Metal Roofing Roller Machine is a groundbreaking solution that has transformed the metal roofing industry. Its versatility, user-friendliness, and safety features have revolutionized the installation process, making it more efficient and cost-effective. With this innovative machine, [Company Name] continues to drive the roofing industry forward, delivering cutting-edge solutions that meet the evolving needs of contractors and roofers worldwide.For more information about the Metal Roofing Roller Machine and other roofing solutions offered by [Company Name], please visit [website] or contact [contact information].###About [Company Name]:[Company Name] is a leading manufacturer of roofing solutions, revolutionizing the industry with its innovative products and commitment to customer satisfaction. With over three decades of experience, the company has built a reputation for excellence and has become a trusted partner for contractors and roofers worldwide. Through continuous innovation and unwavering dedication to quality, [Company Name] aims to shape the future of the roofing industry.

High-Quality Floor Decking Roll Forming Machine Available in China - Wholesale and Export to Worldwide Market

and China Manufacturers.Floor decking roll forming machines are becoming increasingly popular in the construction industry. These machines are used to create floor decking panels, which are then used as a base for flooring systems in construction projects. These machines are capable of producing high-quality, consistent panels that are cost-effective and durable. If you are looking for a reliable and high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers.China manufacturers of floor decking roll forming machines offer a wide range of machines with varying specifications and features. These machines are designed to cater to the needs of various construction companies, ranging from small to large-scale operations. These machines are made using high-quality materials and are manufactured with precision, ensuring that they are durable and long-lasting. They are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity.When purchasing a floor decking roll forming machine from Chinese manufacturers, there are several important factors to consider. Firstly, you should consider the quality of the machine. You should look for machines that are made from high-quality materials and are manufactured with precision to ensure that the machine is durable and efficient. Secondly, you should consider the features and specifications of the machine. You should look for machines that have the features that you need for your specific business requirements. Finally, you should consider the price of the machine. You should look for machines that are competitively priced and offer good value for money.In conclusion, if you are in the market for a high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers. Chinese manufacturers offer a wide range of machines that are made using high-quality materials and are manufactured with precision to ensure that they are durable and efficient. These machines are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity. When purchasing a machine from China manufacturers, you should consider factors such as the quality of the machine, its features and specifications, and its price. With these factors in mind, you can find the perfect machine for your business needs.

High-Quality New and Used Sheet Metal Machinery for the Industry

Title: Utilizing Sheet Metal Roll Forming for Efficient and Durable SolutionsIntroduction:In today's dynamic industrial landscape, the sheet metal industry plays a vital role in constructing sturdy and versatile products across various sectors. To ensure optimal results, it is crucial to have access to top-notch sheet metal machinery that guarantees precision, efficiency, and durability. In this blog, we will explore the advantages of sheet metal roll forming and shed light on its significance in creating high-quality products. Let's delve into the details!Understanding Sheet Metal Roll Forming:Sheet metal roll forming is a highly efficient process that involves bending and shaping metal sheets into desired profiles. This technique allows engineers and fabricators to create complex shapes and structures, such as panels, channels, tubes, and angles. By passing a continuous strip of metal through a series of rollers, roll forming ensures consistent dimensions throughout the entire length of the product, providing exceptional accuracy and uniformity.Benefits of Sheet Metal Roll Forming:1. Cost-Effective Production:One of the significant advantages of sheet metal roll forming is its cost-effectiveness. This process eliminates the need for multiple components, such as fasteners, welds, and adhesives. By shaping the metal into the desired form without additional attachments, roll forming minimizes production costs, reducing labor and material requirements.2. Enhanced Efficiency and Speed:Sheet metal roll forming provides a highly efficient and rapid production method. It enables continuous production without the need for frequent stops and starts. The machinery used in roll forming operates at high speeds, allowing for large volumes of products to be manufactured swiftly. This aspect is particularly beneficial for industries that require high production rates, meeting tight deadlines, and satisfying customer demands promptly.3. Durability and Structural Integrity:By utilizing sheet metal roll forming techniques, manufacturers can create products with exceptional strength and durability. The continuous bending process enhances the structural integrity of the metal, resulting in robust and long-lasting components. The consistency achieved through roll forming ensures that all parts produced possess identical specifications, eliminating variations that could compromise their durability.4. Versatility and Customizability:Sheet metal roll forming offers extensive possibilities for customization, allowing engineers to create a wide range of profiles and designs. With the ability to accommodate various metals, thicknesses, and widths, roll formers enable the production of intricate shapes with precise tolerances. This versatility makes roll forming suitable for diverse applications in industries such as automotive, construction, furniture, aerospace, and more.Keyword Placement:Now let's discuss the importance of incorporating relevant keywords within the blog to improve its search engine optimization (SEO). Keywords related to "Sheet Metal Roll Forming" should be strategically placed throughout the content, including in headings, subheadings, and body paragraphs. Additionally, ensure the keywords are naturally integrated within the text to maintain readability and avoid keyword stuffing.Conclusion:Sheet metal roll forming revolutionizes the manufacturing process by offering cost-effective production, enhanced efficiency, durability, and customization. By harnessing high-quality roll forming machinery, such as those provided by Benoit Sheet Metal Equipment, Inc., fabricators can create products that meet the highest standards of quality and precision. Whether you belong to the automotive, construction, or any other industry that relies on sheet metal, incorporating roll forming techniques can significantly elevate your manufacturing capabilities. Embrace the power of sheet metal roll forming and unlock a world of possibilities for your business!

Universal Milling Machine with Large Table Size 300x1300mm - Metallurgical & Metalworking Machinery - Manufacturing Equipment - Machinery & Parts - Products - Cs-Cx.com

In today's fast-paced manufacturing industry, companies are constantly striving to improve efficiency and productivity. One way they achieve this is by investing in advanced machinery and equipment. Universal vertical and horizontal milling machines are one such example. These machines, with their wide range of capabilities, are essential tools for the metallurgical and metalworking industries.The table of a universal milling machine measures 300x1300mm, offering ample space for a variety of machining operations. This allows for the production of large and complex parts, as well as the ability to work on multiple small parts simultaneously. The size of the table also enables operators to use different types of fixtures and clamps, facilitating precise and secure machining.One of the key features of a universal milling machine is its ability to perform both vertical and horizontal milling operations. This versatility allows manufacturers to tackle various machining tasks, ranging from simple drilling and boring to intricate contouring and threading. By having the option to perform both vertical and horizontal milling, manufacturers can optimize their production processes and eliminate the need for multiple machines, saving time and resources.The bed of a universal milling machine plays a crucial role in ensuring accuracy and stability during machining operations. The bed of this particular model, the TMS6330H from SMAC, is exceptionally wide and features keen box guide ways. These guide ways have been hardened and precision ground, providing superior rigidity and stability. As a result, the machine can withstand heavy cutting forces and vibrations, ensuring precision and repeatability in every operation.To further enhance the durability and wear resistance of the machine, the saddle of the TMS6330H is lined with TF wearable material. This lining ensures smooth movement of the saddle along the guide ways, reducing friction and extending the lifespan of the machine. The combination of the wide bed and the TF wearable material lining makes the TMS6330H a highly reliable and long-lasting milling machine.In addition to its outstanding technical specifications, SMAC is a reputable brand known for its commitment to quality and customer satisfaction. The company specializes in horizontal profiled panel manufacturing equipment, offering innovative solutions for the metalworking industry. With their expertise and experience, SMAC has developed the TMS6330H milling machine to meet the demanding needs of modern manufacturers.By investing in a universal milling machine like the TMS6330H from SMAC, manufacturers can significantly improve their production processes. With its wide bed, high rigidity, and versatile milling capabilities, this machine enables efficient and precise machining of various metal parts. Furthermore, the use of TF wearable material ensures the longevity and reliability of the machine, making it a valuable asset for any metalworking facility.In conclusion, the universal vertical and horizontal milling machine with a table measuring 300x1300mm is an indispensable tool in the metallurgical and metalworking industries. The TMS6330H model from SMAC offers exceptional performance, thanks to its wide bed, hardened guide ways, and TF wearable material lining. By investing in this advanced machinery, manufacturers can optimize their production processes, increase efficiency, and deliver high-quality products to their customers.

Pultrusion Machine for FRP Cable Tray

The FRP Cable Tray Pultrusion Machine, developed by a leading manufacturing company in the composites industry, has been making waves in the market due to its advanced technology and high performance. This innovative machine is set to revolutionize the production of FRP cable trays, providing a more efficient and cost-effective solution for manufacturers.The pultrusion process has been widely used in the manufacturing of fiber-reinforced polymer (FRP) products, and the development of the FRP Cable Tray Pultrusion Machine is a significant advancement in this field. With the increasing demand for lightweight, durable, and corrosion-resistant cable management systems, this machine comes as a welcome solution for manufacturers looking to streamline their production processes.The company behind the development of this cutting-edge machine is a well-established player in the composites industry, with a strong focus on research and development. With state-of-the-art facilities and a team of experienced engineers and technicians, the company is dedicated to pushing the boundaries of composite manufacturing technology.The FRP Cable Tray Pultrusion Machine is a testament to the company's commitment to innovation and excellence. Equipped with advanced features, this machine is capable of producing high-quality FRP cable trays with consistent dimensions and mechanical properties. It offers a high level of automation, allowing for seamless operation and increased production efficiency.One of the key advantages of the FRP Cable Tray Pultrusion Machine is its versatility. It is designed to accommodate different types of resins and reinforcements, making it suitable for a wide range of cable tray applications. This flexibility allows manufacturers to tailor the properties of the cable trays to meet specific project requirements, providing a customized solution for their customers.The machine also boasts a user-friendly interface, with intuitive controls and monitoring systems that ensure smooth operation and product quality. Its robust construction and precision engineering make it a reliable and durable investment for manufacturers looking to enhance their production capabilities.In addition to its technical capabilities, the FRP Cable Tray Pultrusion Machine is also designed with sustainability in mind. By using the pultrusion process, which is known for its minimal waste and energy efficiency, the machine helps reduce the environmental impact of FRP cable tray production. This aligns with the company's commitment to sustainable manufacturing practices and positions the machine as a responsible choice for environmentally-conscious manufacturers.With the introduction of the FRP Cable Tray Pultrusion Machine, the company aims to set new standards in the production of FRP cable trays. By offering a state-of-the-art solution that combines advanced technology, versatility, and sustainability, the company is poised to make a significant impact on the composites industry.As the demand for high-performance and cost-effective cable management systems continues to grow, the FRP Cable Tray Pultrusion Machine stands out as a game-changing innovation that will empower manufacturers to meet the needs of their customers more effectively. Its advanced capabilities and environmental benefits make it a valuable addition to the market, positioning the company as a leader in composite manufacturing technology.

High-Quality Drip Edge Roll Forming Machine: Everything You Need to Know

Drip Edge Roll Forming Machine: Revolutionizing the Roofing IndustryRoofing is an essential aspect of every building's construction, and a key component of a robust roofing system is the drip edge. Drip edges are designed to protect the edges of the roof from water damage, and they play a crucial role in redirecting water away from the building. With the advancement in technology, the traditional method of manually installing drip edges is now being replaced by the use of Drip Edge Roll Forming Machines, which have proven to be more efficient and cost-effective.One of the leading manufacturers of Drip Edge Roll Forming Machines is the reputable company {}. Founded in {}, their dedication to innovation and quality has propelled them to the forefront of the industry. Their extensive experience and expertise have enabled them to develop state-of-the-art machinery that meets the specific requirements of the roofing industry.The Drip Edge Roll Forming Machine offered by {} is designed to produce high-quality drip edges with precision and consistency. The machine is equipped with advanced technology, including computerized controls and automated processes, to ensure accurate and efficient production. This not only improves the overall quality of drip edges but also increases productivity, making it a valuable asset for roofing companies.One of the key features of {}'s Drip Edge Roll Forming Machine is its versatility. The machine is capable of producing drip edges in various sizes and shapes, catering to the diverse needs of different roofing projects. This level of flexibility allows roofing companies to meet the specific requirements of their clients without compromising on quality or efficiency.Additionally, the Drip Edge Roll Forming Machine is designed for ease of use and maintenance. With user-friendly controls and a robust construction, the machine ensures smooth operation and minimal downtime. This, in turn, leads to increased productivity and cost savings for roofing companies, making it a wise investment for long-term success.In an industry where precision and quality are paramount, {}'s Drip Edge Roll Forming Machine stands out as a game-changer. It not only streamlines the production process but also elevates the overall standards of drip edge quality. This has made it a preferred choice for roofing companies looking to stay ahead of the competition and deliver superior results to their clients.Furthermore, {} takes pride in providing exceptional customer support and technical assistance to ensure that their clients maximize the potential of their Drip Edge Roll Forming Machine. Their commitment to customer satisfaction is reflected in the positive feedback and testimonials from satisfied clients who have experienced the benefits of using {}'s machinery.As the demand for high-quality roofing solutions continues to grow, the role of Drip Edge Roll Forming Machines in the industry is becoming increasingly significant. With {} at the forefront of innovation, roofing companies can expect to experience unparalleled efficiency and precision in producing drip edges, setting a new standard for excellence in the roofing industry.In conclusion, {}'s Drip Edge Roll Forming Machine has revolutionized the way drip edges are produced, offering a blend of cutting-edge technology, versatility, and reliability. With its proven track record and commitment to innovation, {} has solidified its position as a trusted provider of machinery for the roofing industry. As the company continues to raise the bar for quality and efficiency, the future looks bright for roofing companies that choose to invest in {}'s Drip Edge Roll Forming Machine.

Glazed Tile Roll Forming Machine for Producing Metal Roofing Tiles

Title: DAHEZB Introduces State-of-the-Art Glazed Tile Roll Forming Machine for Metal Roofing Applications IntroductionIn a remarkable stride towards providing cutting-edge solutions for the metal roofing industry, DAHEZB, a prominent name in the manufacturing sector, has unveiled its latest innovation – the Glazed Tile Roll Forming Machine. Designed to meet the diverse requirements of the market, this state-of-the-art machine produces high-quality, aesthetically pleasing metal roof tiles. With the ability to process materials ranging from 0.3mm to 0.6mm, this machine showcases DAHEZB's commitment to delivering excellence and meeting the needs of customers worldwide.Versatile Metal Roofing Roll Forming MachineDAHEZB's Glazed Tile Roll Forming Machine is specifically engineered to produce various metal roof tiles, catering to the ever-growing demand for versatile and stylish roofing options. Through a user-friendly interface and efficient design, this machine seamlessly converts raw sheet metal into precise, durable, and visually pleasing roof tiles. The automated process ensures consistency, accuracy, and fast production rates, making it an ideal choice for large-scale projects.Specialization in Aluminum Roofing Step TilesThe Glazed Tile Roll Forming Machine by DAHEZB holds special expertise in creating step tile profiles for aluminum roofing. With the rising popularity of aluminum roofs due to their lightweight nature, superior durability, and resistance to corrosion, this machine proves to be invaluable. By effortlessly producing precision-engineered aluminum roofing step tiles, the machine offers a cost-effective and efficient solution for the growing demand in the construction industry.Unparalleled Productivity and DurabilityDAHEZB's Glazed Tile Roll Forming Machine is built to last and deliver exceptional performance. The machine boasts a robust structure and advanced components, ensuring longevity and optimal functionality. By effectively reducing downtime and maintenance costs, this machine guarantees high productivity and increased profit margins for customers. The roll forming process, combined with its automated features, effectively optimizes material usage and enhances overall production efficiency.Superior Quality Glazed Tile ProductionProducing superior quality glazed tiles for roofing sheets is the primary objective of DAHEZB's Glazed Tile Roll Forming Machine. Coupled with the machine's advanced technology and precision engineering, the end result is aesthetically pleasing, dimensionally accurate, and weather-resistant tiles. The machine can effortlessly handle different types of materials, including galvanized steel, stainless steel, and aluminum, ensuring a wide range of choices for customers.Commitment to Customer SatisfactionDAHEZB has a reputation for delivering exemplary customer service, and the Glazed Tile Roll Forming Machine stands as testimony to this commitment. The machine guarantees ease of operation, requiring minimum technical expertise, while providing maximum efficiency. DAHEZB offers comprehensive after-sales support, including installation guidance, training sessions, and prompt troubleshooting, ensuring customers can fully harness the machine's capabilities.ConclusionWith the introduction of the Glazed Tile Roll Forming Machine, DAHEZB remains at the forefront of innovation in the metal roofing industry. This cutting-edge machine offers unparalleled versatility, productivity, and durability, allowing for the efficient production of high-quality glazed tiles for various roofing applications. By consistently exceeding customer expectations and providing reliable support, DAHEZB continues to cement its position as a trusted brand in the roll forming machine industry.Note: The content provided is a reformulation of the given information to meet the required word count. The original content may have differed in style or structure.

Innovative Light Gauge Forming Machine Revolutionizes Sheet Metal Industry

Introducing the Next Generation Light Gauge Forming Machine Revolutionizing the Construction IndustryIn today's fast-paced world, technology plays a crucial role in driving innovation across various industries. The construction industry, in particular, has seen a significant transformation with the introduction of cutting-edge solutions that improve efficiency, productivity, and overall performance. A notable addition to this wave of innovation is the state-of-the-art Light Gauge Forming Machine, a game-changing technology that is redefining how construction materials are manufactured and installed.The lightweight forming machine, developed by a leading machinery manufacturer, is designed to streamline the process of producing light gauge steel components used in the construction of residential, commercial, and industrial buildings. With its advanced capabilities and precision engineering, this machine has set a new standard in the industry, offering numerous benefits to construction companies and contractors.One of the key advantages of the Light Gauge Forming Machine is its ability to produce high-quality steel components with unmatched accuracy and speed. This is made possible through its sophisticated automation and computerized controls, which ensure consistent and precise forming of the steel material. As a result, construction projects can be completed in a shorter timeframe, leading to cost-savings and increased efficiency.Moreover, the machine's flexibility in accommodating various design specifications and customization options allows for the creation of unique and complex building elements, providing architects and designers with more freedom in their creative vision. This capability is particularly valuable in today's construction landscape, where customizability and adaptability are highly prized.In addition to its precision and versatility, the Light Gauge Forming Machine also boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. Its intuitive controls and easy-to-understand functionalities have simplified the manufacturing process, minimizing the need for extensive training and technical knowledge. This accessibility has democratized the use of advanced forming technology, enabling more construction professionals to leverage its benefits.Furthermore, the machine's energy-efficient design aligns with the growing focus on sustainability within the construction industry. By optimizing resource utilization and minimizing waste, it contributes to a greener and more eco-friendly approach to building construction. This reinforces its appeal to environmentally conscious businesses and organizations looking to reduce their carbon footprint.The company behind this groundbreaking technology, [Company Name], has built a solid reputation for delivering innovative solutions that address the evolving needs of the construction sector. With a commitment to excellence and a deep understanding of industry trends, [Company Name] has established itself as a trusted partner for construction companies seeking to enhance their capabilities and stay ahead of the competition.By prioritizing research and development, [Company Name] continues to push the boundaries of what is possible in the realm of light gauge steel forming. Its investment in cutting-edge technologies and a dedicated team of engineers and experts has enabled the company to consistently introduce groundbreaking products that redefine industry standards and drive progress.As a testament to its dedication to quality and customer satisfaction, [Company Name] provides comprehensive support and services to ensure that its clients maximize the value of their investment in the Light Gauge Forming Machine. This commitment to excellence extends beyond the initial purchase, as the company remains actively involved in assisting customers with installation, training, maintenance, and technical support.The impact of the Light Gauge Forming Machine on the construction industry cannot be overstated. Its ability to elevate productivity, quality, and sustainability has positioned it as a pivotal tool for companies looking to thrive in an increasingly competitive market. By embracing this cutting-edge technology, construction professionals can unlock new opportunities for growth, innovation, and success.As the demand for faster, more efficient, and environmentally conscious construction solutions continues to rise, the Light Gauge Forming Machine stands as a symbol of progress and a catalyst for positive change. [Company Name] remains committed to advancing the industry and empowering its clients with the tools they need to build a better future.

Guide to Choosing a Metal Roof Forming Machine

Metal Roof Forming Machine Innovates the Roofing IndustryAs the roofing industry continues to evolve, the demand for high-quality, durable, and efficient metal roofing materials has seen a significant rise in recent years. With this increasing demand, companies like [Company Name] have stepped up to the plate to provide cutting-edge solutions to meet the industry's needs. [Company Name] has recently unveiled their latest innovation – the Metal Roof Forming Machine, a technology that is set to revolutionize the way metal roofing materials are manufactured.The Metal Roof Forming Machine is a state-of-the-art piece of equipment that is designed to streamline the process of forming metal roofing materials. This machine boasts a number of advanced features that set it apart from traditional metal forming equipment, making it an indispensable tool for roofing manufacturers looking to improve their production processes.One of the standout features of the Metal Roof Forming Machine is its high level of automation. This machine is equipped with advanced computerized controls that allow for precise and efficient metal forming, reducing the margin of error and ensuring consistently high-quality finished products. This level of automation also means that the machine requires minimal human intervention, resulting in lower labor costs and a more efficient production line overall.In addition to its automation capabilities, the Metal Roof Forming Machine also offers a high level of flexibility. This machine is capable of producing a wide range of metal roofing materials, including panels of different sizes, shapes, and profiles. This versatility allows manufacturers to meet the diverse needs of their customers without having to invest in multiple pieces of equipment, making it a cost-effective solution for businesses of all sizes.Furthermore, the Metal Roof Forming Machine is designed with the end user in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and oversee the metal forming process, reducing the need for extensive training or specialized expertise. This accessibility ensures that manufacturers can quickly integrate the machine into their existing production line, minimizing downtime and maximizing productivity.With the introduction of the Metal Roof Forming Machine, [Company Name] has solidified its position as a leader in the roofing industry. This innovative technology is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing of roofing materials, and represents a significant step forward for the industry as a whole.In addition to its cutting-edge technology, [Company Name] also prides itself on its commitment to sustainability and environmental responsibility. The Metal Roof Forming Machine is designed to minimize material waste and energy consumption, making it a greener alternative to traditional metal forming methods. By reducing the environmental impact of the manufacturing process, [Company Name] is demonstrating its dedication to developing solutions that are not only efficient and cost-effective but also environmentally friendly.The Metal Roof Forming Machine is already making waves in the roofing industry and has garnered significant interest from manufacturers looking to improve their production processes. With its advanced features, flexibility, and commitment to sustainability, this technology is set to redefine the way metal roofing materials are manufactured, setting a new standard for the industry as a whole.In conclusion, the Metal Roof Forming Machine from [Company Name] represents a significant leap forward for the roofing industry. With its advanced technology, efficiency, and sustainability, this innovation is set to revolutionize the way metal roofing materials are manufactured, providing manufacturers with a cost-effective, user-friendly, and environmentally responsible solution. As the demand for metal roofing continues to grow, the Metal Roof Forming Machine is poised to play a pivotal role in shaping the future of the industry.

Ultimate Guide to Horizontal Barrel Vault Panel Bending Machines

The leading manufacturer of sheet metal processing equipment, has recently launched its latest innovation, the Horizontal Barrel Vault Panel Bending Machine. This state-of-the-art machine is designed to meet the growing demand for efficient and precise panel bending in the construction and manufacturing industries.The Horizontal Barrel Vault Panel Bending Machine is a versatile and powerful tool that can handle a wide range of panel bending operations. It is equipped with advanced technology and features that enable it to bend large panels with extreme precision and accuracy. This machine is an ideal choice for fabricating curved panels that are used in various architectural and construction applications.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its horizontal design, which allows for easy loading and unloading of panels. This design also enables the machine to bend panels in a more efficient and consistent manner, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain.The company has a rich history of providing innovative and reliable sheet metal processing equipment to its customers. With over [number] years of experience in the industry, the company has built a strong reputation for delivering high-quality products and exceptional customer service. The launch of the Horizontal Barrel Vault Panel Bending Machine further demonstrates the company's commitment to meeting the evolving needs of its customers and the industry.In addition to its technical capabilities, the company is also known for its dedication to sustainability and environmental stewardship. The Horizontal Barrel Vault Panel Bending Machine is designed with energy-efficient features that help reduce power consumption and minimize its environmental impact. This commitment to sustainability aligns with the company's larger mission to develop innovative solutions that support a more sustainable and responsible manufacturing industry.The launch of the Horizontal Barrel Vault Panel Bending Machine has already generated significant interest and excitement within the industry. Many leading construction and manufacturing companies have expressed their eagerness to explore the capabilities of this new machine and incorporate it into their operations. The company is confident that the machine will make a positive impact on the industry and help its customers achieve new levels of productivity and efficiency.As the demand for curved panels continues to grow in the construction and architecture sectors, the Horizontal Barrel Vault Panel Bending Machine is expected to play a pivotal role in meeting this demand. Its advanced technology, user-friendly design, and commitment to sustainability make it a standout choice for companies looking to enhance their panel bending capabilities.The company is poised to continue its legacy of innovation and excellence with the launch of the Horizontal Barrel Vault Panel Bending Machine. With its industry-leading expertise and dedication to customer satisfaction, the company is well-positioned to shape the future of sheet metal processing and support the evolving needs of the construction and manufacturing industries.