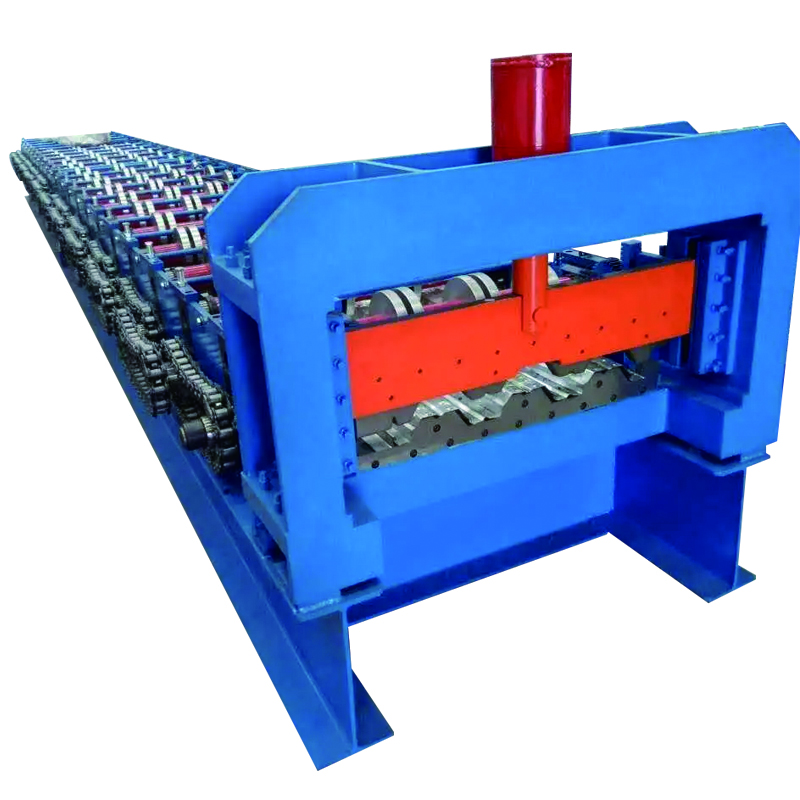

Top Corrugated Roll Former for Efficient Production Lines

By:Admin

The Corrugated Roll Former from [Your Company Name] is capable of producing a wide range of corrugated metal profiles, catering to the diverse needs of the construction, roofing, and architectural industries. With its advanced technology and innovative features, this machine offers unmatched efficiency and reliability, ensuring consistent and accurate production of corrugated metal sheets.

One of the key highlights of the Corrugated Roll Former is its versatility, allowing for the seamless production of various types of corrugated profiles, including sinusoidal, trapezoidal, and custom-designed shapes. This flexibility makes it a highly adaptable solution for metal forming operations of all sizes and requirements.

In addition to its impressive capabilities, the Corrugated Roll Former is engineered for ease of use and maintenance. The machine is equipped with intuitive controls and user-friendly features, allowing operators to set up and operate the system with minimal training. Furthermore, it is designed for durability and longevity, minimizing downtime and maximizing productivity for the end user.

With its robust construction and precision engineering, the Corrugated Roll Former from [Your Company Name] delivers superior quality and accuracy in the production of corrugated metal sheets. The machine is built to meet the highest industry standards, ensuring consistent and reliable performance in demanding manufacturing environments.

Furthermore, [Your Company Name] prides itself on delivering exceptional customer service and support. The company offers comprehensive training programs, technical assistance, and after-sales services to ensure that customers can maximize the potential of their investment in the Corrugated Roll Former. This commitment to customer satisfaction sets [Your Company Name] apart as a trusted partner in the metal forming industry.

The introduction of the Corrugated Roll Former represents [Your Company Name]'s dedication to innovation and excellence in the manufacturing sector. With a focus on cutting-edge technology, superior quality, and customer value, the company continues to be at the forefront of delivering advanced solutions for metal forming and fabrication.

As a leading manufacturer of industrial machinery, [Your Company Name] is committed to providing a comprehensive range of solutions for metal forming, including roll forming machines, slitting lines, and other custom-engineered systems. With a strong emphasis on research and development, the company continually pushes the boundaries of innovation to meet the evolving needs of the industry.

In conclusion, the introduction of the Corrugated Roll Former from [Your Company Name] is set to make a significant impact on the metal forming industry. With its advanced technology, versatility, and reliability, this machine offers a comprehensive solution for the production of high-quality corrugated metal sheets. Coupled with [Your Company Name]'s commitment to customer service and support, the Corrugated Roll Former is poised to be a game-changer for manufacturers seeking to enhance their metal forming capabilities.

Company News & Blog

Highly Efficient Rolling Forming Machine for Profile Manufacturing

Profile Rolling Forming Machine Revolutionizes the Manufacturing IndustryIn today's fast-paced industrial landscape, the need for efficient and reliable machinery has never been more critical. Companies across various sectors are constantly seeking innovative solutions that not only enhance productivity but also ensure top-notch quality. One such groundbreaking development comes in the form of the Profile Rolling Forming Machine, a technology that has taken the manufacturing industry by storm.Profile Rolling Forming Machine utilizes state-of-the-art techniques to produce high-precision profiles in a cost-effective manner. By employing a unique rolling process, this cutting-edge machine enables the creation of complex profiles from a wide range of materials, including metal, plastic, and composite materials. This revolutionary technology has garnered significant attention and is set to have a major impact on multiple industries.One key advantage of the Profile Rolling Forming Machine lies in its ability to produce profiles with exceptional accuracy and uniformity. Traditionally, manufacturing complex profiles involves various time-consuming and labor-intensive processes, such as casting, cutting, and shaping. However, with the advent of this new technology, these conventional methods are being replaced by a streamlined process that guarantees superior precision.The Profile Rolling Forming Machine's rolling process starts with a specially designed set of rolls that gradually shape the material into the desired profile. This continuous bending and rolling operation not only ensures an impeccable finish but also eliminates the need for excessive material wastage. The precision and efficiency of this process significantly reduce production costs and enhance overall productivity.Additionally, the Profile Rolling Forming Machine offers immense flexibility in terms of profile customization. With its advanced computer-controlled system, users can easily program the machine to produce profiles of various shapes and dimensions, catering to unique design requirements. This versatility has opened up several opportunities for manufacturers, enabling them to manufacture highly intricate profiles that were previously deemed unachievable.Furthermore, this groundbreaking technology excels in both small-scale and large-scale production. The Profile Rolling Forming Machine can efficiently handle both small batches and high-volume production, making it suitable for a wide range of applications. From automotive components to architectural elements, this innovation has the potential to revolutionize numerous industries that rely heavily on complex profile production.Moreover, the Profile Rolling Forming Machine offers enhanced productivity by minimizing downtime and maintenance requirements. The robust design of this machine ensures prolonged usage without compromising on performance. Advanced sensors integrated into the machinery provide real-time data about the process, enabling operators to detect any issues promptly and take corrective measures, thereby reducing production delays.In conclusion, the Profile Rolling Forming Machine represents an exciting breakthrough in the manufacturing industry. With its unmatched precision, flexibility, and scalability, this innovative technology has the power to revolutionize the way complex profiles are produced. As industries strive for greater efficiency and productivity, the Profile Rolling Forming Machine emerges as a game-changer, providing manufacturers with the means to achieve exceptional quality while optimizing costs. Embracing this technology will undoubtedly propel businesses to the forefront of their respective industries, opening new avenues for growth and advancement.

Discover How a Metal Roofing Roller Machine Enhances Efficiency and Precision in Roofing Projects

[Company Name] Revolutionizing the Metal Roofing Industry with the Introduction of the Innovative Roofing Roller Machine[date][City, State] – Metal roofing has long been sought after for its durability and longevity. However, the installation process has traditionally been time-consuming and labor-intensive. In an effort to streamline this process and provide a more efficient solution, [Company Name], a leading manufacturer of roofing solutions, has recently launched their groundbreaking Metal Roofing Roller Machine.[Company Name] has been a driving force in the roofing industry for over three decades, constantly pushing the boundaries of innovation and technology. With a team of expert engineers and designers, the company has built a reputation for delivering high-quality products that not only meet industry standards but also exceed customer expectations.The Metal Roofing Roller Machine is the latest addition to their extensive line of roofing equipment. This state-of-the-art machine is designed to revolutionize the installation process, making it faster, easier, and more cost-effective. It eliminates the need for manual sheet bending and reshaping, thereby significantly reducing labor costs and minimizing the risk of human error.One of the key features of this machine is its ability to handle a wide range of metal roofing materials. Whether it be aluminum, steel, copper, or zinc, the Metal Roofing Roller Machine can effortlessly shape and reshape these materials according to the specifications of any roofing project. This versatility ensures that contractors and roofers can tackle a variety of projects without the need for multiple machines and tools, making it a cost-effective solution for businesses of all sizes.In addition to its versatility, the Metal Roofing Roller Machine is also remarkably user-friendly. Its intuitive interface and easy-to-use controls allow even inexperienced users to operate the machine with confidence. This eliminates the training time traditionally associated with new equipment, allowing contractors to scale their workforce quickly and meet project demands efficiently.Furthermore, the Roller Machine is equipped with advanced safety features to ensure the well-being of workers. An automatic shut-off mechanism is in place to prevent accidents, such as entanglement or injury, during operation. The robust construction of the machine also adds an extra layer of protection, ensuring its durability and longevity even in demanding working conditions.Since its launch, the Metal Roofing Roller Machine has garnered significant attention and praise from industry professionals. Roofers and contractors have lauded its ability to enhance productivity and streamline their operations. The machine's efficiency has enabled businesses to complete projects in record time, opening up new avenues for growth and profitability.[Company Name] understands the importance of sustainability in the roofing industry and has taken steps to reduce the environmental impact of their products. The Metal Roofing Roller Machine is designed to optimize material usage, minimizing waste and reducing carbon emissions. With this innovative machine, businesses can not only improve their efficiency but also contribute to a greener future.In conclusion, [Company Name]'s Metal Roofing Roller Machine is a groundbreaking solution that has transformed the metal roofing industry. Its versatility, user-friendliness, and safety features have revolutionized the installation process, making it more efficient and cost-effective. With this innovative machine, [Company Name] continues to drive the roofing industry forward, delivering cutting-edge solutions that meet the evolving needs of contractors and roofers worldwide.For more information about the Metal Roofing Roller Machine and other roofing solutions offered by [Company Name], please visit [website] or contact [contact information].###About [Company Name]:[Company Name] is a leading manufacturer of roofing solutions, revolutionizing the industry with its innovative products and commitment to customer satisfaction. With over three decades of experience, the company has built a reputation for excellence and has become a trusted partner for contractors and roofers worldwide. Through continuous innovation and unwavering dedication to quality, [Company Name] aims to shape the future of the roofing industry.

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.

Steel Coil Slitting Line: Streamlining Precision Cutting and Efficiency in the Manufacturing Industry

Steel Coil Slitting Line is one of the most important machines for the steel industry. It is a machine that is used to cut large coils of steel into smaller strips of the required width. This process is necessary for various applications, such as manufacturing of pipes, tubes, metal sheets, and so on. In this regard, machine suppliers, including {brand name removed}, are vital for the steel industry.{Supplier name removed} is a leading supplier of steel processing machines that includes Steel Coil Slitting Line. The company is a prominent entity in the industry and has carved a niche for itself in the international market. It has established a reputation for quality, durability, and reliability, which has made the company a preferred choice for organizations that deal in the manufacture of steel products.The Steel Coil Slitting Line from {supplier name removed} is built to cater to the diverse needs of customers worldwide. It is designed with cutting-edge technology and equipment that makes it highly productive, efficient, and accurate. This machine is easy to operate and requires minimal maintenance, which further enhances its reliability and durability.Furthermore, this Steel Coil Slitting Line is versatile and capable of handling different types of steel coils. It can process various types of steel materials and thicknesses with ease. Its high precision and accuracy ensure that customers are provided with consistent cuts, which is crucial for the successful production of quality steel products.{Supplier name removed} understands the significance of customer satisfaction and strives to provide top-notch products and exceptional after-sales support to its customers. They have a team of experts who are always available to assist their clients, ranging from machine installation, training, maintenance, and upgrades.Steel Coil Slitting Line has numerous benefits that make it a necessary machine for the steel industry. Firstly, it allows for efficient utilization of steel coils, which reduces the cost of production and waste. Secondly, it is flexible and can accommodate different widths and thicknesses of coils, which offers flexibility in production processes. Thirdly, its high precision and accuracy ensure that customers receive products with consistent quality.In conclusion, Steel Coil Slitting Line is a vital machine for the steel industry. It facilitates efficient and consistent production processes, reduces waste, and enhances the overall quality of steel products. {Supplier name removed} is a renowned supplier of high-quality steel processing machines, and their Steel Coil Slitting Line is one of the best in the market. The company's commitment to excellence, reliability, and customer satisfaction makes them a preferred choice for organizations that require the best steel processing machines in the industry. With {supplier name removed}, customers can count on getting the best value for their investment in steel processing machines.

High-quality Cold Roller Former for Efficient Metal Processing

Cold Roller Former, a cutting-edge technology developed by a leading manufacturing company, is making waves in the industry with its innovative and efficient cold rolling process. This revolutionary machine is designed to shape metallic materials into various components, providing a cost-effective and high-quality solution for a wide range of applications.The cold rolling process is a critical step in metal forming, as it helps to improve the surface finish and mechanical properties of the material. Unlike traditional hot rolling, cold rolling occurs at room temperature, which results in a smoother and more precise finish. This method is particularly important for industries such as automotive, aerospace, and construction, where the quality and integrity of the metal components are paramount.With the introduction of Cold Roller Former, manufacturers can now benefit from a streamlined and advanced cold rolling process. This machine is equipped with state-of-the-art technology, including precision control systems and high-speed capabilities, allowing for the efficient production of complex and high-quality components. Additionally, its modular design and customizable features make it adaptable to various production needs, providing flexibility and versatility to manufacturers.One of the key advantages of Cold Roller Former is its ability to produce parts with tighter tolerances and improved surface finish, resulting in higher precision and quality. This is particularly beneficial for industries that require components with intricate geometries and superior mechanical properties. With Cold Roller Former, manufacturers can achieve a level of consistency and accuracy that is not possible with traditional cold rolling methods, leading to enhanced product performance and reliability.Furthermore, Cold Roller Former is designed with efficiency in mind, offering a significant increase in productivity and cost savings for manufacturers. Its high-speed capabilities and advanced control systems enable faster production cycles and reduced material waste, resulting in a more streamlined and economical manufacturing process. This not only helps to improve the overall competitiveness of manufacturers but also contributes to a more sustainable and environmentally friendly production environment.In addition to its technological advancements, Cold Roller Former is backed by a dedicated team of experts who provide comprehensive support and expertise to ensure the successful implementation and operation of the machine. From initial consultation to ongoing maintenance and training, the company's commitment to customer satisfaction and knowledge sharing sets a new standard for excellence in the industry.As a testament to its success, Cold Roller Former has already made significant strides in the market, garnering attention and accolades from industry experts and customers alike. Its proven track record of delivering superior performance, cost-effectiveness, and reliability has positioned it as the go-to solution for manufacturers seeking to elevate their cold rolling capabilities.Looking ahead, the company is committed to further advancing and enhancing Cold Roller Former to meet the evolving needs of the industry. With ongoing research and development efforts, the company is dedicated to pushing the boundaries of cold rolling technology, ultimately redefining the standards of excellence and innovation in metal forming.In conclusion, Cold Roller Former represents a significant breakthrough in cold rolling technology, offering a game-changing solution for the manufacturing industry. With its advanced capabilities, efficiency, and reliability, this revolutionary machine is poised to shape the future of cold rolling and set a new benchmark for excellence in metal forming.

9ct Rose Gold Cubic Zirconia Full Eternity Stacker Ring with Round Brilliant Cut Channel Set

Title: The Allure of the Stacker for the CZ Purline Machine: Enhancing Your Jewelry CollectionIntroduction: Welcome to our blog on the fascinating world of high-quality jewelry. Today, we will be exploring the captivating style and craftsmanship of the Stacker for the CZ Purline Machine. Specifically, we will delve into the stunning 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring and its timeless appeal that resonates with jewelry enthusiasts around the world. Let's dive into this exceptional piece and discover how it can enhance your personal collection.1. Embracing the Stackable Trend:Stackable rings are a growing phenomenon in the world of fashion jewelry. The versatility of these pieces allows wearers to mix and match, creating unique and personalized combinations. The CZ Purline Machine's Stacker Ring is no exception. Its minimalist design flawlessly harmonizes with other rings, making it an ideal choice for those looking to make a statement.2. The Allure of Rose Gold:Rose gold has experienced a significant resurgence in popularity in recent years, captivating the hearts of fashion-forward individuals everywhere. The warm, rosy hue complements a variety of skin tones, adding a touch of elegance and sophistication to any outfit. With its 9ct composition, the Stacker Ring possesses a delicate balance of durability and subtlety.3. The Timeless Brilliance of Cubic Zirconia:Cubic Zirconia (CZ) is renowned for its remarkable similarity to diamonds, boasting an exceptional brilliance and clarity that make it an affordable alternative. The round brilliant-cut CZ stones in the Stacker Ring are meticulously set using the channel setting technique, ensuring maximum light reflection and an intense sparkle that catches the eye.4. Unmatched Elegance of the Full Eternity Design:The full eternity design of the Stacker Ring is nothing short of breathtaking. The channel-set CZ stones encircle the entirety of the band, symbolizing an everlasting bond and adding a touch of luxury. This timeless design is not only visually stunning but also holds significant sentimental value, making it an excellent choice for special occasions, anniversaries, or as a heartfelt gift.5. Crafting Excellence with CZ Purline Machine:The CZ Purline Machine revolutionizes the world of cubic zirconia jewelry, ensuring precise stone placement and meticulous craftsmanship. By utilizing advanced technology, the Stacker Ring is a testament to the manufacturer's dedication to excellence, resulting in a flawlessly executed piece that is sure to turn heads.Conclusion:In conclusion, the 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring is an exceptional addition to any jewelry collection. Its stackable nature allows for endless customization and versatility, while the rose gold and sparkling CZ stones offer timeless appeal. The craftsmanship and attention to detail, facilitated by the CZ Purline Machine, make this ring a true masterpiece. Elevate your style and leave a lasting impression with this stunning piece of jewelry.

Cutting-Edge Technology Unveiled: Revolutionary Glazed Tile Sheet Forming and Corrugating Machine Takes Industry by Storm

article:Glazed Tile Sheet Forming And Corrugating Machine Making Waves in Manufacturing IndustryThe new generation of Glazed Tile Sheet Forming And Corrugating Machine by a well-known Chinese-based manufacturing company has taken the industry by storm. The state-of-the-art machine is revolutionizing the manufacturing process of glazed tile sheets, enabling manufacturers to produce high-quality products in less time and at low production costs.The economically designed Glazed Tile Sheet Forming And Corrugating Machine is ideal for obtaining glazed sheets of different dimensions and shapes that are used in various roofing and cladding applications. The machine is composed of a steel base, a corrugated roll former, a hydraulic punching and forming device, an automatic cutting system, an electrical control system, and a product stacking device. These components not only ensure the efficiency and functionality of the machine but also provide the much-needed precision and accuracy while producing the glazed sheets.According to the company's press release, the Glazed Tile Sheet Forming And Corrugating Machine boasts several features that differentiates it from conventional machines in the market. First, the hydraulic punching and forming device can form an array of patterns that greatly improves the aesthetic appeal of the final product. Second, the exclusive rolling mechanism produces a high-quality surface finish that resists corrosion, abrasion, and scratching. Third, the machine can produce over 10 meters of glazed tiles per minute, which translates to over 300 pieces per hour.The Glazed Tile Sheet Forming And Corrugating Machine also has a user-friendly interface that simplifies the operation and maintenance process. With only a few button clicks, users can load and unload raw materials, adjust the machine's speed, and troubleshoot common problems. The machine is also equipped with an automatic lubricant system that reduces wear and tear, prolongs the machine's lifespan, and reduces maintenance costs.The company behind the Glazed Tile Sheet Forming And Corrugating Machine has been at the forefront of producing innovative, high-quality, and affordable machinery for various industries globally. The company, which has over 20 years of experience in the manufacturing industry, has invested heavily in research and development, production, and quality control which has earned them an undisputed reputation in the industry.Their Glazed Tile Sheet Forming And Corrugating Machine have been popular among small, medium, and large-scale manufacturers worldwide, as it provides a cost-effective solution for producing high-quality glazed tile sheets without compromising on quality. Furthermore, the machine is suitable for a wide range of materials, including zinc, galvanized steel, and color-coated steel, giving manufacturers an extensive range of options to choose from.The company's commitment to providing superior customer service also stands out, with a team of dedicated customer service representatives who offer after-sales service, technical assistance, and training to ensure customers get the most out of their machines. Additionally, the company's technical team ensures the machines are regularly updated and upgraded with the latest technology to guarantee that they are always at the forefront of innovation.In conclusion, the Glazed Tile Sheet Forming And Corrugating Machine by this Chinese-based manufacturing company is a game-changer in the industry, offering manufacturers a reliable, efficient, and cost-effective solution to produce high-quality glazed tile sheets. With its unique features, ease of use, and precision, the machine is bound to revolutionize the glazed tile sheet manufacturing industry and set new standards for quality, productivity, and customer service.

Unveiling the Innovative Galvanized Steel Deck Floor Tile Making Machine

Galvanized Steel Deck Floor Tile Making Machine Revolutionizes Construction IndustryWith the aim of delivering innovation and efficiency to the construction industry, a renowned company has unveiled its latest product - a cutting-edge Galvanized Steel Deck Floor Tile Making Machine. This state-of-the-art machine is set to revolutionize the way floor tiles are manufactured, ensuring faster production, higher quality, and enhanced durability.The Galvanized Steel Deck Floor Tile Making Machine, developed by [Company Name], is designed to streamline the tile manufacturing process, providing a seamless and efficient solution for construction companies around the world. This innovative machine integrates advanced technology and intelligent systems, allowing for the creation of galvanized steel deck floor tiles with unmatched precision.One of the standout features of this machine is its ability to remove the brand name as it is customizable according to specific business requirements. This offers construction companies the opportunity to create their own brand identity and establish a distinct presence in the market. By removing the brand name, [Company Name] demonstrates its dedication to customer satisfaction and promotes a collaborative approach with its clients.Furthermore, the Galvanized Steel Deck Floor Tile Making Machine boasts a robust and sturdy construction, ensuring long-lasting performance and durability. Made from high-quality materials, this machine is built to withstand heavy-duty usage, making it suitable for a wide range of construction projects. Its reliability eliminates the need for frequent repairs or replacements, saving businesses valuable time and money.The integration of advanced automation and intelligent systems allows for seamless operation and enhanced productivity. Featuring a user-friendly interface, operators can easily navigate and control the machine with minimal training. This ensures quick adoption and optimization of the Galvanized Steel Deck Floor Tile Making Machine, resulting in increased efficiency and improved production output.Another significant advantage of this machine is its superior quality output. The Galvanized Steel Deck Floor Tile Making Machine ensures precision in every tile produced, guaranteeing consistency and accuracy in size, shape, and finish. This high standard of quality makes the machine ideal for projects that demand precision and perfection, giving construction companies a competitive edge in the market.In addition, the Galvanized Steel Deck Floor Tile Making Machine is environmentally friendly. With a focus on sustainability, [Company Name] has incorporated eco-friendly measures into the manufacturing process. This includes the utilization of energy-efficient components and reduced waste generation, minimizing the machine's carbon footprint and contributing towards a greener construction industry.As a market leader in manufacturing machinery, [Company Name] has a proven track record of delivering cutting-edge solutions to the construction industry. Renowned for its commitment to innovation, quality, and customer satisfaction, the company has become a trusted partner for construction companies worldwide. The Galvanized Steel Deck Floor Tile Making Machine is yet another testament to their dedication to revolutionize the industry.In conclusion, the Galvanized Steel Deck Floor Tile Making Machine developed by [Company Name] is set to transform the construction industry. With its advanced features, customizable design, durability, and high-quality output, this machine offers construction companies an efficient and cost-effective solution for floor tile manufacturing. Emphasizing sustainability and eco-friendly practices, [Company Name] continues to pave the way towards a greener and more innovative construction industry.

Revolutionary Panel Bending Machine Redefines Horizontal Profiled Bending

Title: Advanced Profiled Panel Bending Machine Revolutionizes Manufacturing IndustryIntroduction:Innovation and cutting-edge technology have always been at the heart of the manufacturing industry's growth and development. One such example is the recently unveiled Horizontal Profiled Panel Bending Machine, designed to redefine the way profiled panels are bent and shaped. Developed by a leading industrial machinery company, this state-of-the-art machine is set to streamline and enhance the production processes for a range of industries.Main Body:1. Introduction to the Horizontal Profiled Panel Bending Machine:The Horizontal Profiled Panel Bending Machine represents a breakthrough in the field of panel bending technology. Developed by skilled engineers and industry experts, this precision machine offers exceptional bending accuracy and flexibility. The machine's unique design incorporates advanced software and cutting-edge components, ensuring precise and efficient panel bending operations.2. Unprecedented Bending Accuracy:The Horizontal Profiled Panel Bending Machine boasts an unrivaled level of accuracy in bending profiled panels. This is achieved through its state-of-the-art computer-controlled system, which continuously monitors and adjusts various parameters during the bending process. As a result, manufacturing errors are drastically reduced, guaranteeing consistently high-quality finished products.3. Versatile Applications:With its adaptable nature, the Horizontal Profiled Panel Bending Machine caters to a wide range of industries and sectors. From automotive to construction, furniture, and signage, this machine revolutionizes the possibilities for shaping profiled panels. Its ability to handle various materials, including aluminum, stainless steel, and composite alloys, further expands its versatility, making it an indispensable tool for modern manufacturing.4. Enhanced Efficiency and Cost Reduction:The Horizontal Profiled Panel Bending Machine brings significant improvements in production efficiency and cost reduction. By automating and streamlining the bending process, it eliminates the need for manual labor, which was time-consuming and prone to errors. Additionally, the machine's optimized design reduces material waste, saving valuable resources and cutting down costs for manufacturers.5. Safety Features and Ease of Use:Ensuring workplace safety is paramount, and the Horizontal Profiled Panel Bending Machine addresses this crucial aspect. Equipped with advanced safety measures, such as emergency stop buttons and protective barriers, operators can work with confidence, minimizing the risk of accidents. Furthermore, the machine's user-friendly interface and simple controls make it accessible to both seasoned professionals and novice operators.6. The Impact on the Manufacturing Industry:The introduction of the Horizontal Profiled Panel Bending Machine promises to bring transformative changes to the manufacturing industry. By optimizing production processes and reducing reliance on manual labor, manufacturers can boost productivity, improve product quality, and accelerate time-to-market. As a result, both large-scale industrial enterprises and small businesses have an opportunity to stay competitive in an evolving market.7. Positive Environmental Footprint:In addition to its operational benefits, the Horizontal Profiled Panel Bending Machine also promotes environmental sustainability. With its production efficiency and resource optimization, it reduces waste generation and energy consumption. By embracing this advanced machinery, manufacturers can align with eco-friendly practices and contribute to building a greener future.Conclusion:The Horizontal Profiled Panel Bending Machine's cutting-edge technology and versatility open up new horizons for the manufacturing industry. With its unparalleled precision, efficiency, and safety features, it is set to redefine the standard for profiled panel bending. As industries evolve and demand innovative solutions, this advanced machine ensures that manufacturers can meet customer expectations while achieving remarkable productivity gains and cost efficiencies. Embracing this technology not only drives industry growth but also contributes to a sustainable and prosperous future.