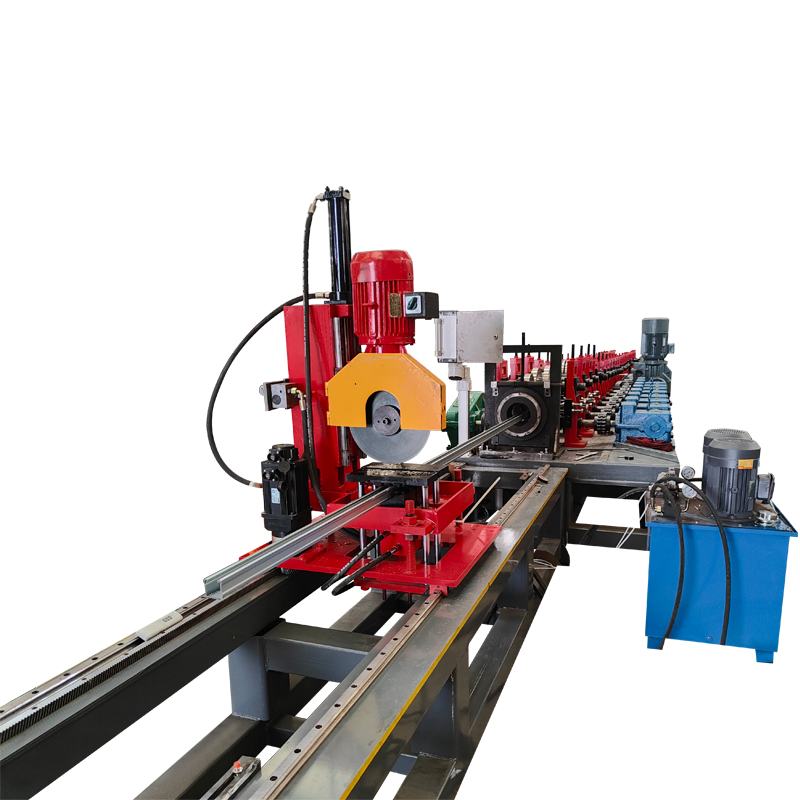

High-quality Steel Profile Manufacturing Machine for Your Business Needs

By:Admin

With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.

The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.

One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.

In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.

Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.

Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.

Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.

As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market.

"We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."

The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.

Company News & Blog

Efficient and Durable Roof Tile Forming Machine Helps Streamline Construction Processes

[News Title]: Advanced Roof Tile Forming Machine Revolutionizes Roofing Industry [News Content]:Introducing a revolutionary Roof Tile Forming Machine, an innovation that is set to redefine the roofing industry. Developed by a leading company with a proven track record of excellence and expertise in the field, this state-of-the-art machine is set to transform the way roof tiles are manufactured, offering unmatched precision, speed, and quality.Designed to remove the brand name, this Roof Tile Forming Machine takes advantage of the latest advancements in technology and engineering to streamline the entire manufacturing process. With its advanced features and capabilities, it promises to increase efficiency while reducing costs and environmental impact. The machine's innovative design allows for the production of custom-made roof tiles, catering to a variety of architectural requirements and design preferences.One of the standout features of the Roof Tile Forming Machine is its exceptional precision. Using cutting-edge technology, it ensures that each tile produced meets the highest standards of accuracy and consistency. This level of precision not only enhances the durability and functionality of the tiles but also gives them an aesthetically pleasing appearance.The speed at which the machine operates is another key aspect that sets it apart. With its automated production process, the Roof Tile Forming Machine can manufacture a high volume of roof tiles in a significantly shorter amount of time compared to traditional methods. This increased speed not only enables companies to meet demanding project timelines but also contributes to reducing the overall manufacturing costs.Moreover, the Roof Tile Forming Machine addresses the growing concern for sustainable practices in the industry. Embracing eco-friendly materials and processes, this machine minimizes waste production and energy consumption. By optimizing resource utilization, it aligns with the global push towards a greener and more sustainable future.The Roof Tile Forming Machine is also equipped with intelligent control systems, enabling seamless integration into existing manufacturing processes. Its user-friendly interface and intuitive operation ensure that both experienced professionals and newcomers can efficiently operate the machine. Additionally, comprehensive training and support are provided by the manufacturer to ensure the successful implementation and use of this cutting-edge technology.Since its launch, the Roof Tile Forming Machine has garnered significant attention and praise from industry experts. Many leading roofing companies have already embraced this innovation, recognizing its potential to revolutionize their manufacturing operations. By enhancing productivity, reducing costs, and offering superior quality, these companies gain a competitive edge in the market.Furthermore, the widespread adoption of this advanced machine is expected to have far-reaching implications for the construction industry as a whole. The increased availability of high-quality roof tiles will not only contribute to the overall improvement of buildings' structural integrity but will also enhance their aesthetic appeal. This, in turn, has the potential to stimulate economic growth and generate employment opportunities, thereby benefiting local communities.In conclusion, the Roof Tile Forming Machine is set to reshape the roofing industry through its advanced technology, superior precision, increased speed, and commitment to sustainability. As more companies recognize its transformative potential, it is anticipated that the machine will become an indispensable tool in the manufacturing of roof tiles worldwide. With its numerous advantages, this innovation promises to bring about a new era of efficiency, quality, and environmental consciousness in the roofing industry.

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

High-Quality Corrugated Roll Making Machine for Your Business

In the world of packaging and manufacturing, the demand for high-quality corrugated rolls is on the rise. As a result, the need for efficient and reliable corrugated roll making machines has become essential for companies looking to meet this demand. One company that has consistently met this need is {company name}, a leading manufacturer of corrugated roll making machines.With a history of innovation and dedication to excellence, {company name} has established itself as a trusted name in the industry. Their commitment to providing state-of-the-art machinery and exceptional service has set them apart from the competition. As a result, they have become the go-to choice for companies looking to invest in a corrugated roll making machine.One of {company name}'s standout offerings is their cutting-edge Corrugated Roll Making Machine, which is designed to deliver superior performance and efficiency. This machine is capable of producing high-quality corrugated rolls with precision and speed, making it an invaluable asset for companies looking to optimize their manufacturing processes.The {company name} Corrugated Roll Making Machine is equipped with advanced technology and features that set it apart from other machines on the market. The machine's robust construction and durable components ensure long-term reliability and consistent performance. Additionally, its user-friendly interface and intuitive controls make it easy to operate and maintain, minimizing downtime and maximizing productivity.Another key advantage of {company name}'s Corrugated Roll Making Machine is its versatility. Whether it's producing single-face, double-face, or triple-wall corrugated rolls, this machine can handle a wide range of applications with ease. This flexibility ensures that companies can meet the varied needs of their customers while maintaining high standards of quality.Furthermore, the {company name} Corrugated Roll Making Machine is designed with efficiency in mind. Its automated processes and precision engineering result in minimal material waste and optimal use of resources. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, a factor that is increasingly important to today's environmentally conscious consumers.In addition to the machine's impressive capabilities, {company name} is renowned for its exceptional customer support and service. From installation and training to ongoing maintenance and technical assistance, they are committed to ensuring that their customers get the most out of their investment. This level of support is a testament to {company name}'s dedication to forging long-lasting partnerships with their clients.The combination of cutting-edge technology, superior performance, and reliable support has made the {company name} Corrugated Roll Making Machine a standout choice for companies around the world. Whether it's a large-scale packaging operation or a smaller manufacturing facility, this machine has proven to be a game-changer for businesses seeking to streamline their production processes and deliver top-quality corrugated rolls to their customers.As the demand for corrugated packaging continues to grow, having the right machinery in place is crucial for companies looking to stay competitive. With {company name}'s Corrugated Roll Making Machine, businesses can be confident in their ability to meet this demand with efficiency, precision, and reliability, setting the stage for continued success and growth.In conclusion, the {company name} Corrugated Roll Making Machine represents the pinnacle of innovation and excellence in the industry. Its advanced technology, unmatched performance, and unwavering commitment to customer satisfaction make it the ideal choice for companies looking to invest in a high-quality corrugated roll making machine. With {company name} as a trusted partner, companies can be confident in their ability to meet the evolving needs of the market while achieving new levels of success.

High-Quality Steel Coil Slitting Machines for Efficient Metal Sheet Cutting and Stainless Steel Strips

Stainless Steel Strip Slitting Machine: A Revolutionary Solution for Cutting and Slitting Metal SheetsWhen it comes to metalworking, precision and accuracy are critical factors in achieving quality results. One such process is slitting, which involves cutting a wide metal sheet into narrower strips to meet specific requirements. This process is necessary for industries that require smaller widths for their product manufacturing, such as automotive, electronics, and construction.To achieve this, manufacturers use a slitting machine, a unique piece of equipment that cuts and converts metal coils into narrower strips. One type of slitting machine that has gained popularity in recent years is the stainless steel strip slitting machine, which provides greater precision and efficiency in metal sheet cutting.What is a Stainless Steel Strip Slitting Machine?A stainless steel strip slitting machine is a piece of equipment specifically designed for cutting and slitting metal sheets, mainly made of stainless steel. This machine is equipped with a set of blades or knives that sever the material in smaller strips with the desired width. The blades or knives can be adjusted to achieve the desired cut and width of the strips, making it highly customizable.Uses of Stainless Steel Strip Slitting MachineStainless Steel Strip Slitting Machine is widely used in many industries that utilize metal sheets in their manufacturing processes. These include the automotive, aerospace, and construction industries. It is also useful for electronics, textile, and paper industries for creating smaller electronic components and packaging materials.Advantages of Stainless Steel Strip Slitting Machine1.Precision CuttingOne of the primary advantages of using a stainless steel strip slitting machine is its ability to produce precise cuts and meet the required specifications. The machine can cut narrow strips with the desired width and high accuracy, reducing material waste and saving production time.2. High ProductivityStainless Steel Strip Slitting Machine can work continuously, producing strips of varying widths with minimal operator intervention. This leads to increased productivity and output while ensuring consistent quality in products.3. CustomizationThe Stainless Steel Strip Slitting Machine can be customized to meet specific requirements, such as cutting thickness, strip widths, and number of pieces produced per roll.4. DurabilityAs the name suggests, the machine is made of stainless steel, making it resistant to corrosion and ensuring durability. The blades are also made of high-quality materials that can withstand the stress of cutting metal sheets for extended periods.ConclusionIn conclusion, the Stainless Steel Strip Slitting Machine is a revolutionary technology that has changed the game in metal sheet cutting and slitting. It offers high precision, customization, efficiency, and durability in metalworking, making it an excellent investment for industries that rely on metal sheets. With its versatile applications and advantages, it is no wonder why it has become popular among manufacturers. Keywords: Stainless Steel Strip Slitting Machine, Metal Sheet Cutting Machine, Steel Strip Slitting Machine.

High-quality Metal Roof Tile Making Machine for Sale - Find Out More!

[Company Introduction]Based in [Location], [Company Name] is a leading manufacturer and supplier of high-quality metal roof tile making machines. With years of experience in the industry, the company has established a strong reputation for delivering innovative and reliable equipment to its customers around the world. The company prides itself on its commitment to providing cutting-edge technology and exceptional customer service, making it a trusted partner for businesses in the roofing industry.[News Content]Metal Roof Tile Making Machine Revolutionizes Roofing IndustryIn the fast-paced world of construction and building materials, innovation is key to staying competitive. With the demand for durable, eco-friendly, and aesthetically pleasing roofing solutions on the rise, companies are constantly seeking advanced technologies to meet these requirements. One company that has been at the forefront of this innovation is [Company Name], which has recently introduced its latest metal roof tile making machine, revolutionizing the roofing industry.The new metal roof tile making machine from [Company Name] boasts an impressive set of features that sets it apart from traditional machines. The advanced technology and precision engineering behind the machine ensure that it can produce high-quality metal roof tiles with unparalleled efficiency and accuracy. This level of performance not only meets the needs of modern roofing projects but also exceeds industry standards, making it a game-changer for businesses in the roofing sector.One of the key highlights of the machine is its versatility. It is capable of producing a wide range of metal roof tile profiles, allowing for customization and flexibility to meet the specific requirements of different roofing projects. This flexibility is a significant advantage for roofing contractors, as it enables them to cater to diverse customer demands without the need for multiple machines or extensive retooling.Furthermore, the machine is designed for ease of use and maintenance, making it an ideal solution for businesses of all sizes. With user-friendly controls and a robust construction, operators can expect efficient production processes and minimal downtime, ultimately leading to increased productivity and profitability.The introduction of this cutting-edge metal roof tile making machine is a testament to [Company Name]'s commitment to innovation and customer satisfaction. By continuously investing in research and development, the company has been able to deliver advanced solutions that address the evolving needs of the roofing industry. This dedication to excellence has earned [Company Name] a reputation as a trusted partner for businesses looking to elevate their roofing capabilities.In addition to the machine's technical prowess, [Company Name] has also ensured that it aligns with environmentally friendly practices. The machine has been designed to minimize waste and energy consumption, contributing to sustainable manufacturing processes. As sustainability becomes an increasingly important consideration for businesses and consumers alike, this feature further enhances the appeal of the metal roof tile making machine.With the unveiling of this state-of-the-art metal roof tile making machine, [Company Name] has set a new standard for the roofing industry. Its technological advancements, versatility, and sustainability features position it as a game-changing solution for businesses looking to stay ahead in a competitive market.As the demand for high-quality metal roof tiles continues to grow, [Company Name] remains committed to supporting its customers with innovative equipment that not only meets but exceeds their expectations. The new metal roof tile making machine is a reflection of this dedication, and it is poised to make a significant impact on the roofing industry, driving efficiency, quality, and sustainability for years to come.

High-Quality Metal Slitting Line for Sale: Buy Different Gauge Slitting Line Machines

In the manufacturing industry, slitting lines are crucial machines that are used to cut wide metal coils into narrower strips of specific widths. These narrower strips can then be used for various applications, such as the production of pipes, automotive parts, and household appliances.As one of the leading manufacturers of slitting lines, {Steel Slitting Line} is committed to delivering high-quality machines that are designed to meet the needs of their customers. Their slitting lines are available in light, medium, and heavy gauge options, making it easier for customers to find the right machine based on their specific requirements.One of the main advantages of using a slitting line from {Steel Slitting Line} is that it is designed to minimize material waste. This is accomplished by using a looping pit that allows for tighter control over the material feeding process. Additionally, {Steel Slitting Line} slitting lines are designed with precision in mind, which ensures that the strips produced are of consistent widths.Another key feature of {Steel Slitting Line} slitting lines is their ease of use. These machines are designed to be user-friendly, with simple controls that allow operators to quickly and easily adjust the machine settings. This makes it easier for manufacturers to produce high-quality metal strips in a timely and efficient manner.When it comes to choosing a slitting line, there are a few important factors to consider. One of the most important is the gauge of the material being processed. {Steel Slitting Line} offers slitting lines for light, medium, and heavy gauge materials, making it easier for manufacturers to find the right machine for their specific needs.Another important factor to consider is the speed of the slitting line. Depending on the size of the coils being processed and the required strip widths, different machines will operate at different speeds. {Steel Slitting Line} offers machines with varying speed options, allowing manufacturers to choose a machine that is best suited for their specific production needs.At the end of the day, choosing the right slitting line can be the difference between success and failure for many manufacturing businesses. With the high-quality machines from {Steel Slitting Line}, manufacturers can rest assured that they are investing in a reliable and efficient machine that will help them meet their production goals. So if you're in the market for a new slitting line, be sure to check out the offerings from {Steel Slitting Line}.

Discover the Latest Advancements in Roofing Metal Forming Machines

Roofing Metal Forming Machine Offers an Efficient Solution for Manufacturing Metal Roofing SheetsRoofing Metal Forming Machine (need remove brand name), a leading manufacturer and supplier of metal forming machines, offers an efficient solution for producing metal roofing sheets. The machine is designed to provide a cost-effective and reliable method for manufacturing roofing sheets while meeting the required specifications.The company has gained a reputation as a trusted supplier of metal forming machines due to its focus on quality, reliability, and innovation. By combining advanced technology with skilled engineering, the company has created a range of metal forming machines that offer superior performance, efficiency, and durability.The Roofing Metal Forming Machine (need remove brand name) is an excellent example of the company's commitment to innovation and quality. The machine is designed to produce high-quality roofing sheets with consistent thickness, length, and width. It is capable of processing different types of metal, including steel, aluminum, and copper, with varying thicknesses and widths.One of the main advantages of the Roofing Metal Forming Machine (need remove brand name) is its versatility. The machine can be customized to produce roofing sheets of different profiles, including corrugated, trapezoidal, and standing seam profiles. This flexibility enables manufacturers to cater to different market requirements and produce roofing sheets that meet the specific needs of their customers.The machine is also easy to operate, thanks to its user-friendly interface and automated features. The operator can easily program the machine to produce roofing sheets with the desired length and width, and the machine will automatically adjust its settings to ensure consistent quality and accuracy.The Roofing Metal Forming Machine (need remove brand name) is also designed to reduce material waste, which is a major concern for manufacturers in the metal forming industry. The machine is equipped with a precision cutting system that minimizes material waste and ensures optimal usage of raw materials.In addition to its outstanding performance and efficiency, the Roofing Metal Forming Machine (need remove brand name) is also known for its durability and low maintenance requirements. The machine is built to withstand heavy-duty usage and can operate continuously for extended periods with minimal downtime.The company offers comprehensive support services to ensure that its customers get the most out of their investment in the Roofing Metal Forming Machine (need remove brand name). The services include installation, training, and ongoing technical support, which enable customers to operate the machine efficiently and maximize their production output.Overall, the Roofing Metal Forming Machine (need remove brand name) is a reliable and cost-effective solution for manufacturing high-quality metal roofing sheets. Its advanced features, versatility, and user-friendly interface make it an excellent choice for manufacturers looking to optimize their production processes and increase their competitiveness in the market.About the CompanyRoofing Metal Forming Machine (need remove brand name) is a leading manufacturer and supplier of metal forming machines. The company specializes in designing and producing machines for the metal roofing and cladding industry, including roll forming machines, slitting machines, and cut-to-length machines.The company has been in business for over 20 years and has gained a reputation for its commitment to quality, reliability, and innovation. Its machines are used by manufacturers in various industries across the world, including Europe, North America, South America, Africa, and Asia.Roofing Metal Forming Machine (need remove brand name) has a team of skilled engineers and technicians who use advanced technology and materials to create machines that meet the highest standards. The company also offers comprehensive support services, including installation, training, and technical support, to ensure that its customers get the most out of their investment.

High-Quality Metal Slitting Line for Sale – Different Gauges Available at SteelSlitter.com

RISHBIN Emerges as a Leading Slitting Line Machine Manufacturer Offering High-Quality Metal Slitting Line for SaleIn the dynamic world of manufacturing, industries are constantly seeking efficient and reliable solutions to meet their production needs. RISHBIN, a prominent player in the market, has emerged as one of the best slitting line machine manufacturers, offering high-quality metal slitting lines for sale. With a wide range of machines catering to different gauge requirements, RISHBIN continues to revolutionize the industry with its cutting-edge technology and exceptional product offerings.Slitting lines are a vital component of the metal processing industry, enabling precise cutting and resizing of coils into narrower widths. When it comes to manufacturing slitting line machines, RISHBIN stands out for its commitment to delivering superior quality and innovative features. With an experienced team of engineers and technicians, the company is at the forefront of technological advancements, ensuring that their machines meet the highest industry standards.RISHBIN's metal slitting lines are designed to handle various gauge requirements, ensuring flexibility and versatility for a wide range of applications. The availability of machines suitable for light, medium, and heavy gauge materials makes RISHBIN the go-to manufacturer for businesses operating in diverse sectors. Whether it's the automotive, construction, or packaging industry, RISHBIN's slitting lines provide optimal performance and accuracy.What sets RISHBIN apart from its competitors is its continuous focus on research and development. The company invests heavily in innovation, constantly enhancing its product offerings to meet evolving industry demands. By staying up-to-date with the latest technological advancements, RISHBIN ensures that its slitting line machines provide the most efficient and reliable solutions for its customers.In addition to its dedication to quality and innovation, RISHBIN is also renowned for its exceptional customer service. The company believes in establishing long-term relationships with its clients, prioritizing their needs and exceeding their expectations. RISHBIN's team of experts assists customers throughout the entire purchasing process, offering valuable guidance and support to help them make informed decisions.RISHBIN's commitment to quality and customer satisfaction is further reflected in its post-sales services. The company offers comprehensive maintenance and technical support to ensure that its machines continue to perform optimally throughout their lifespan. By providing timely servicing and spare parts availability, RISHBIN helps its customers maximize their productivity and minimize downtime.With its robust manufacturing capabilities, RISHBIN ensures that each slitting line machine is crafted to perfection. The company utilizes high-quality materials and rigorous quality control processes to guarantee the durability and efficiency of its products. RISHBIN's metal slitting lines are built to withstand heavy usage and deliver consistent performance, making them a reliable investment for businesses looking to enhance their manufacturing processes.As a socially responsible organization, RISHBIN is committed to sustainability and environmentally friendly practices. The company implements energy-efficient measures throughout its manufacturing processes, reducing its carbon footprint and promoting a greener future. By choosing RISHBIN's slitting line machines, customers not only benefit from high performance but also contribute to global sustainability efforts.In conclusion, RISHBIN has established itself as a leading slitting line machine manufacturer by delivering high-quality solutions tailored to different gauge requirements. With its focus on innovation, customer service, and sustainability, RISHBIN continues to drive the industry forward. As businesses strive for excellence in their manufacturing processes, RISHBIN's metal slitting lines emerge as the ideal choice, ensuring efficiency, accuracy, and long-term reliability.

New Study Reveals Surprising Findings in the Roll Forming Industry

Total Roll Forming, a leading manufacturer of roll forming and metal shaping solutions, has recently announced the expansion of its operations to meet the increasing demand for its products and services. The company, known for its innovative and high-quality solutions, has a long-standing reputation in the industry for providing reliable and cost-effective roll forming technology.With the expansion of its operations, Total Roll Forming is set to further solidify its position as a top provider of roll forming solutions. The company's state-of-the-art manufacturing facilities, coupled with its team of experienced engineers and technicians, enable it to offer a wide range of roll forming capabilities to meet the needs of diverse industries.Total Roll Forming's roll forming solutions are used in various applications, including automotive, construction, aerospace, and appliance industries. The company's expertise in custom roll forming enables it to cater to the specific needs of its clients, offering tailored solutions that meet the highest standards of quality and precision.Furthermore, Total Roll Forming is committed to sustainability and environmentally friendly manufacturing practices. The company continuously invests in research and development to improve its processes and reduce its environmental footprint. This commitment to sustainability has earned Total Roll Forming a reputation as an industry leader in eco-friendly roll forming solutions.In addition to its manufacturing capabilities, Total Roll Forming provides comprehensive support and services to its clients. From design and engineering to prototyping and production, the company works closely with its customers to ensure that their exact specifications are met. Total Roll Forming's dedication to customer satisfaction has resulted in long-lasting partnerships with some of the most renowned companies in the industry.Total Roll Forming's expansion comes at a time when the demand for roll forming solutions is on the rise. The company's ability to offer custom roll forming solutions that are tailored to the unique requirements of its clients has set it apart from its competitors. As a result, Total Roll Forming has experienced significant growth in recent years and is now well-positioned to capitalize on the increasing demand for its products and services."We are excited to announce the expansion of our operations to better serve our clients and meet the growing demand for our roll forming solutions," said [Company Spokesperson]. "Total Roll Forming is committed to providing innovative, high-quality, and sustainable solutions to our customers, and we believe that our expanded capabilities will enable us to further enhance our offerings and solidify our position as a leader in the industry."Total Roll Forming's expansion is a testament to the company's commitment to excellence and its determination to meet the evolving needs of its clients. With its expanded operations, Total Roll Forming is poised to continue setting the standard for roll forming technology and shaping the future of the industry.