Latest Technology for Color Steel Glazed Tile Manufacturing Machine

By:Admin

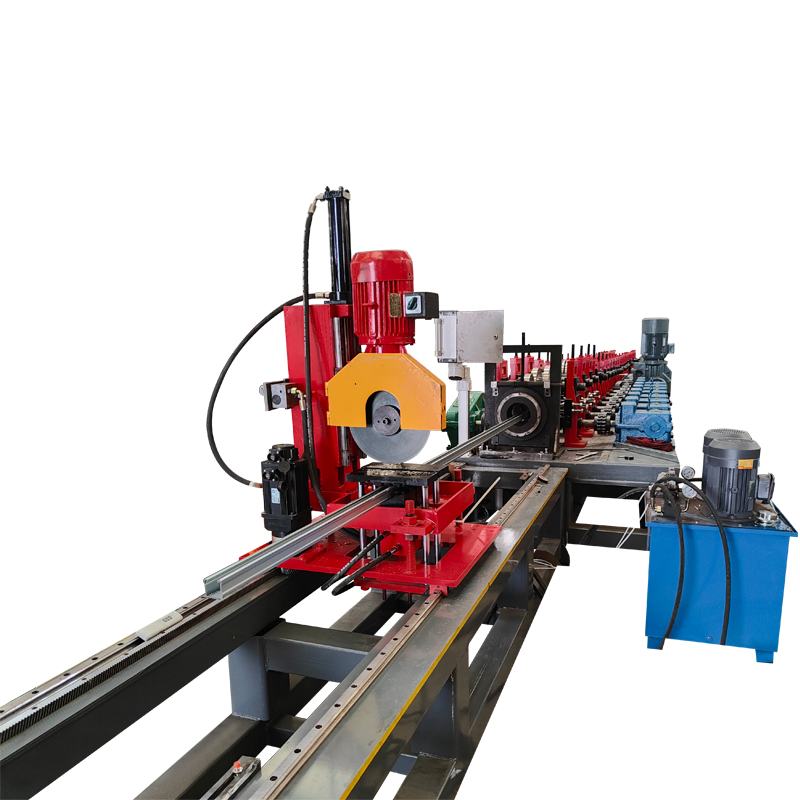

Innovation continues to drive the roofing industry forward with the introduction of the state-of-the-art Color Steel Glazed Tile Manufacturing Machine. This revolutionary machine, developed by a leading manufacturing company, is set to transform the production of glazed tiles for roofs, offering enhanced efficiency and quality in the process.

The Color Steel Glazed Tile Manufacturing Machine is a result of years of research and development by the company, which has a solid reputation for delivering innovative solutions to the construction and roofing sectors. With a strong focus on technology and engineering, the company has consistently pushed the boundaries of what is possible in roofing manufacturing, and the introduction of this new machine is a testament to their commitment to excellence.

The machine is designed to streamline the production of glazed tiles, ensuring a high level of precision and consistency in every tile produced. By utilizing advanced automation and cutting-edge manufacturing techniques, it is able to significantly increase the speed and efficiency of the production process, while also minimizing waste and errors. This not only benefits manufacturers in terms of cost savings and improved productivity but also ensures that end-users receive top-quality glazed tiles for their roofing needs.

One of the key features of the Color Steel Glazed Tile Manufacturing Machine is its versatility. It is capable of producing a wide range of glazed tiles in various colors, sizes, and designs, allowing manufacturers to cater to diverse customer preferences and project requirements. This flexibility sets it apart from traditional manufacturing equipment, which often has limitations in terms of customization and variety.

Furthermore, the machine is engineered for durability and reliability, making it a sound long-term investment for manufacturers. With minimal maintenance requirements and a robust construction, it is built to withstand the rigors of continuous operation, ensuring consistent performance over the years.

The company behind the Color Steel Glazed Tile Manufacturing Machine has a long history of serving the roofing industry with innovative solutions. Their commitment to research and development, coupled with a customer-centric approach, has earned them a strong position in the market. The introduction of this new machine further solidifies their reputation as a leading provider of advanced manufacturing equipment for the construction and roofing sectors.

In addition to the machine itself, the company offers comprehensive support and services to assist manufacturers in integrating it into their production processes. This includes training, technical assistance, and ongoing maintenance to ensure optimal performance and maximum return on investment. By partnering with the company, manufacturers can benefit from not only cutting-edge equipment but also the expertise and support needed to succeed in a competitive market.

The unveiling of the Color Steel Glazed Tile Manufacturing Machine represents a significant milestone in the evolution of the roofing industry. As demand for high-quality glazed tiles continues to grow, this innovative machine is set to play a pivotal role in meeting the needs of manufacturers and end-users alike. With its advanced capabilities, flexibility, and reliability, it is poised to set a new standard for the production of glazed tiles, driving the industry towards a more efficient and sustainable future.

In conclusion, the Color Steel Glazed Tile Manufacturing Machine is a game-changer for the roofing industry, offering unprecedented levels of efficiency, quality, and versatility. With the backing of a renowned manufacturing company and a strong focus on innovation, it is poised to make a significant impact in the market. As manufacturers embrace this cutting-edge technology, they are not only positioning themselves for success but also contributing to the advancement of the industry as a whole.

Company News & Blog

High-Quality and Efficient Sanding Machine for Deck Refinishing

Lithuanian Company Introduces Innovative Deck Sanding MachineLithuanian company, a leader in the woodworking industry, is excited to introduce its latest innovation - a revolutionary deck sanding machine that is set to transform the way decks are sanded and restored. This state-of-the-art machine, developed by a team of experienced engineers and woodworkers, is designed to deliver superior performance and efficiency, making it the go-to choice for professional woodworkers and DIY enthusiasts alike.The new deck sanding machine is equipped with advanced technology and features that set it apart from traditional sanding methods. With its powerful motor and precision-engineered sanding pads, this machine is capable of removing years of wear and tear, stains, and damage from any type of decking material, including wood, composite, and PVC. Its unique design allows for easy maneuverability and access to tight spaces, ensuring that every inch of the deck is sanded to perfection.One of the standout features of this deck sanding machine is its dust extraction system, which effectively captures and contains dust particles during the sanding process. This not only creates a cleaner working environment but also minimizes the risk of airborne dust, making it a safer and healthier option for both operators and surroundings. Additionally, the machine's ergonomic design and user-friendly controls make it easy to operate, reducing operator fatigue and ensuring maximum productivity.The company's dedication to innovation and quality is evident in the development of this deck sanding machine. With a strong focus on research and development, they have consistently pushed the boundaries of what is possible in the woodworking industry. By investing in cutting-edge technology and engineering expertise, they have been able to deliver products that meet the needs and exceed the expectations of their customers.In addition to its commitment to innovation, the company is also known for its exceptional customer service and after-sales support. From the initial purchase to ongoing maintenance and servicing, they are dedicated to providing their customers with the highest level of care and attention. This includes comprehensive training and support for using the deck sanding machine, as well as quick response times for any technical assistance or spare parts requirements.The introduction of this deck sanding machine reinforces the company's position as a leader in the woodworking industry, setting a new standard for quality and performance. Its cutting-edge technology, combined with the company's commitment to customer satisfaction, makes it a game-changer for anyone involved in deck restoration and refinishing. Whether it's a professional woodworking business or a homeowner looking to revitalize their outdoor space, this machine offers the perfect solution for achieving outstanding results.As the demand for high-quality deck restoration continues to grow, this innovative machine is poised to make a significant impact on the market. Its ability to deliver exceptional results in a fraction of the time of traditional sanding methods, combined with its ease of use and reliability, makes it a must-have tool for anyone looking to tackle deck sanding projects with confidence.With the introduction of this groundbreaking deck sanding machine, Lithuanian company continues to lead the way in the woodworking industry. Their passion for innovation and commitment to excellence have once again resulted in a product that is set to revolutionize the way decks are sanded and restored. As they continue to push the boundaries of what is possible, customers can expect to see even more exciting developments from this forward-thinking company in the future.

High-quality Metal Roof Tile Making Machine for Sale - Find Out More!

[Company Introduction]Based in [Location], [Company Name] is a leading manufacturer and supplier of high-quality metal roof tile making machines. With years of experience in the industry, the company has established a strong reputation for delivering innovative and reliable equipment to its customers around the world. The company prides itself on its commitment to providing cutting-edge technology and exceptional customer service, making it a trusted partner for businesses in the roofing industry.[News Content]Metal Roof Tile Making Machine Revolutionizes Roofing IndustryIn the fast-paced world of construction and building materials, innovation is key to staying competitive. With the demand for durable, eco-friendly, and aesthetically pleasing roofing solutions on the rise, companies are constantly seeking advanced technologies to meet these requirements. One company that has been at the forefront of this innovation is [Company Name], which has recently introduced its latest metal roof tile making machine, revolutionizing the roofing industry.The new metal roof tile making machine from [Company Name] boasts an impressive set of features that sets it apart from traditional machines. The advanced technology and precision engineering behind the machine ensure that it can produce high-quality metal roof tiles with unparalleled efficiency and accuracy. This level of performance not only meets the needs of modern roofing projects but also exceeds industry standards, making it a game-changer for businesses in the roofing sector.One of the key highlights of the machine is its versatility. It is capable of producing a wide range of metal roof tile profiles, allowing for customization and flexibility to meet the specific requirements of different roofing projects. This flexibility is a significant advantage for roofing contractors, as it enables them to cater to diverse customer demands without the need for multiple machines or extensive retooling.Furthermore, the machine is designed for ease of use and maintenance, making it an ideal solution for businesses of all sizes. With user-friendly controls and a robust construction, operators can expect efficient production processes and minimal downtime, ultimately leading to increased productivity and profitability.The introduction of this cutting-edge metal roof tile making machine is a testament to [Company Name]'s commitment to innovation and customer satisfaction. By continuously investing in research and development, the company has been able to deliver advanced solutions that address the evolving needs of the roofing industry. This dedication to excellence has earned [Company Name] a reputation as a trusted partner for businesses looking to elevate their roofing capabilities.In addition to the machine's technical prowess, [Company Name] has also ensured that it aligns with environmentally friendly practices. The machine has been designed to minimize waste and energy consumption, contributing to sustainable manufacturing processes. As sustainability becomes an increasingly important consideration for businesses and consumers alike, this feature further enhances the appeal of the metal roof tile making machine.With the unveiling of this state-of-the-art metal roof tile making machine, [Company Name] has set a new standard for the roofing industry. Its technological advancements, versatility, and sustainability features position it as a game-changing solution for businesses looking to stay ahead in a competitive market.As the demand for high-quality metal roof tiles continues to grow, [Company Name] remains committed to supporting its customers with innovative equipment that not only meets but exceeds their expectations. The new metal roof tile making machine is a reflection of this dedication, and it is poised to make a significant impact on the roofing industry, driving efficiency, quality, and sustainability for years to come.

High-Quality Roofing Roll Forming Machines for Steel Material

Steel Roofing Roll Forming Machines have become an essential part of the construction and roofing industry, providing a fast and efficient way to produce high-quality metal roofing and cladding panels. These machines are designed to efficiently transform metal coils into perfectly shaped roofing panels, providing a cost-effective and durable solution for a variety of buildings and structures.One of the leading manufacturers of Steel Roofing Roll Forming Machines, {}, has been at the forefront of technological innovation and industry expertise. With a strong focus on research and development, the company has continuously improved and updated its product line to meet the evolving needs of the construction industry.The importance of Steel Roofing Roll Forming Machines in the construction industry cannot be overstated. These machines have revolutionized the way metal roofing and cladding panels are produced, offering a highly efficient and cost-effective solution for roofing contractors and building owners. By using Steel Roofing Roll Forming Machines, manufacturers can produce large quantities of roofing panels with minimal waste and labor, resulting in significant cost savings for their customers.The versatility of Steel Roofing Roll Forming Machines also allows for the production of a wide range of roofing profiles, including standing seam, corrugated, and concealed-fastener panels. This flexibility enables manufacturers to meet the unique design and performance requirements of different building projects, from residential homes to commercial and industrial facilities. Furthermore, the precision and consistency provided by these machines ensure that each panel meets the highest standards of quality and durability.In addition to their efficiency and versatility, Steel Roofing Roll Forming Machines are also known for their durability and low maintenance requirements. Built with high-quality materials and advanced engineering, these machines are designed to withstand the rigors of continuous use in demanding manufacturing environments. This durability ensures that manufacturers can rely on their Steel Roofing Roll Forming Machines to consistently deliver high-quality roofing panels, year after year.Furthermore, {} has established itself as a trusted and reliable partner for manufacturers worldwide. With a strong commitment to customer satisfaction, the company provides comprehensive support and training to ensure that customers can maximize the performance of their Steel Roofing Roll Forming Machines. This includes installation and commissioning services, as well as ongoing technical assistance and spare parts availability.As the construction industry continues to evolve and demand for high-quality, cost-effective roofing solutions grows, Steel Roofing Roll Forming Machines will play a crucial role in meeting these needs. With their ability to efficiently produce a wide range of roofing profiles, while delivering exceptional quality and durability, these machines are well-positioned to remain a key technology in the construction industry for years to come.In conclusion, Steel Roofing Roll Forming Machines have become an indispensable tool for the modern construction industry. With their efficiency, versatility, and durability, these machines enable manufacturers to produce high-quality metal roofing panels in a cost-effective and sustainable manner. As a leading manufacturer of Steel Roofing Roll Forming Machines, {} continues to drive innovation and excellence, ensuring that its customers can meet the evolving demands of the construction industry with confidence and success.

Roll Forming Machine Manufacturers For Sale in China - Superior Quality

Roll Forming Machine Manufacturers in China are Dedicated to Providing High-Quality MachinesIn today's world, the demand for roll forming machines has drastically increased. Roll forming machines are used by manufacturers in diverse industries to create uniform shapes of metal sheets. These machines are highly efficient and produce high-quality products in a short time. There are many roll forming machine manufacturers in China, and RISHBIN is committed to providing customers with the best quality roll forming machines.Founded in 1998, RISHBIN is a sheet metal roll forming machine manufacturer that offers a comprehensive range of roll forming machines for different applications. Over the years, the company has built a reputation for producing high-quality machines that are reliable, efficient, and durable. RISHBIN roll forming machines are used in the construction, automobile, HVAC, and packaging industries.The company prides itself on providing customized solutions to meet the specific needs of their customers. This is possible because RISHBIN has a team of experienced engineers who develop unique designs for their customers. The engineers use modern software to design and simulate the machines before production to ensure that the final product meets the customer's specifications.RISHBIN roll forming machines are designed to be highly efficient in terms of speed and accuracy. The machines are manufactured using the latest technology and high-quality materials to ensure they last longer and require minimal maintenance. The company uses top-quality components such as Mitsubishi, Siemens, and Schneider for the electrical parts, and SKF, NSK, and Timken for the bearings to ensure the machines' high stability and reliability.The company's roll forming machines are available in different models, including simple manual machines, hydraulic machines, and fully automated roll forming machines. This range of machinery allows customers to choose a product that suits their production needs and budget.RISHBIN is also committed to providing excellent customer service. The company has a team of trained and experienced customer service representatives who are available 24/7 to provide support and answer customer questions. This ensures that customers can have peace of mind knowing that they will receive prompt and efficient after-sales service.In conclusion, RISHBIN is committed to providing customers with the best quality roll forming machines. The company's commitment to quality, efficiency, and customer service has earned it a reputation as one of the leading roll forming machine manufacturers in China. By working with RISHBIN, customers can be assured of getting customized products that meet their specific requirements and budgets.

High-Quality Ridge Cap Machine for Sale - Find Out More!

Ridge Cap Machine Revolutionizing the Roofing IndustryIn today's fast-paced construction industry, efficiency and quality are crucial factors that companies look for in their production processes. This is where Ridge Cap Machine (RCM) comes into play, offering cutting-edge solutions to meet the demands of the roofing industry.RCM has made a name for itself by providing innovative machinery that is designed to streamline the production of ridge caps, a critical component of any roofing system. With a focus on accuracy, speed, and durability, RCM's machines have become a game-changer for companies looking to enhance their manufacturing capabilities.The company's flagship product, the Ridge Cap Machine, is a prime example of their commitment to delivering high-quality solutions. This state-of-the-art machine is equipped with advanced technology that allows for precise shaping and cutting of ridge caps. Furthermore, its automated features significantly reduce the need for manual labor, thereby increasing efficiency and productivity for users.In addition to its cutting-edge technology, RCM also takes pride in its dedication to customer satisfaction. The company offers comprehensive support services to ensure that their clients are able to maximize the full potential of their machines. From installation and training to maintenance and repairs, RCM is committed to being a reliable partner for the businesses that invest in their products.Furthermore, RCM's machines are designed to be versatile and adaptable to different manufacturing environments. Whether it's a small-scale operation or a large production facility, RCM's machines can be customized to meet specific requirements, making them a viable option for businesses of all sizes.With a strong focus on research and development, RCM continues to innovate and improve its products to stay ahead of the curve. The company is constantly exploring new technologies and techniques to further enhance the performance and capabilities of their machines, ensuring that they remain at the forefront of the industry.The impact of RCM's machines on the roofing industry has been significant. Companies that have incorporated RCM's technology into their production processes have reported notable improvements in efficiency and product quality. By automating and optimizing the production of ridge caps, RCM's machines have helped businesses reduce costs and waste while increasing output and profit.Furthermore, RCM's commitment to sustainability is evident in the design and operation of their machines. By minimizing energy consumption and maximizing resource utilization, RCM's machines are environmentally friendly, aligning with the growing demand for eco-conscious manufacturing practices.In conclusion, RCM has undoubtedly made a mark in the roofing industry with its cutting-edge machinery and unwavering dedication to customer satisfaction. As the demand for high-quality ridge caps continues to rise, RCM is poised to play a crucial role in meeting the needs of businesses around the world. With their innovative solutions and commitment to excellence, RCM is revolutionizing the way ridge caps are produced, setting a new standard for efficiency and quality in the roofing industry.

Flat Roof Rubber Sheet: Unparalleled Corrugated Metal Roof for Pergolas Unmatched Corrugated Metal Roofing Sheets in Scotland Tile Effect Metal Roofing Sheets, Radiant Barrier Material, Galvanized Steel Sheet Metal, Wood Support Brackets, Eagle Carports, Target Stand, Colored Metal Panels, Mono Pitch Roof Calculator, Tom Roof, Charcoal Roof Tiles, Corrugated Colorbond Sheets: The Ultimate Solution Premium Quality Flat Roof Rubber Sheet for Your Roofing Needs

Title: A New Approach to Roofing Solutions: Horizontal Corrugated Roof PanelIntroduction:In a world where sustainability and durability are becoming paramount, the roofing industry has witnessed tremendous advancements. This article focuses on an innovative product, the Horizontal Corrugated Roof Panel, offered by (need to remove brand name), which aims to revolutionize traditional roofing solutions. With its exceptional features and benefits, this unique product has garnered significant attention in the market.A Versatile Solution for All: The Horizontal Corrugated Roof Panel offers versatility in terms of its applications. The product is designed to cater to various roofing needs, including pergolas, carports, and commercial and residential buildings. Whether it's a traditional or contemporary architectural design, this panel effortlessly complements any structure, showcasing its adaptability.Unmatched Durability and Longevity:One significant advantage of the Horizontal Corrugated Roof Panel is its exceptional durability. Made of high-quality galvanized steel sheet metal, this product offers unparalleled strength and resistance against harsh weather conditions, including heavy rains, intense UV exposure, and strong winds. Additionally, the panel's unique design ensures its longevity, offering a sustainable roofing solution that requires minimal maintenance.Enhancing Energy Efficiency:The Horizontal Corrugated Roof Panel is a high-performance roofing material that integrates a radiant barrier material within its structure. This innovative feature reflects heat away from the structure, reducing the amount of heat transferred inside. As a result, buildings experience improved energy efficiency, reducing the reliance on HVAC systems and resulting in substantial energy cost savings.Aesthetically Pleasing and Customizable:Gone are the days when roofing sheets were merely utilitarian. The Horizontal Corrugated Roof Panel embraces contemporary design trends, presenting itself as a visually appealing option. With its tile effect metal roofing sheets, buildings can achieve a desirable aesthetic appeal that replicates the beauty of traditional tile roofs. Additionally, the product comes in a variety of colors, allowing for customization and personalization to suit individual preferences.Easy Installation and Cost-Effective Solution:Not only does the Horizontal Corrugated Roof Panel offer exceptional durability and aesthetics, but it also provides an easy and hassle-free installation process. With its wood support brackets, the panels can be quickly assembled, reducing labor costs and project timelines. This efficiency makes it an ideal option for both small-scale residential projects and large-scale commercial installations.Environmental Sustainability:In a time when sustainability is of paramount importance, the Horizontal Corrugated Roof Panel stands out for its environmentally conscious approach. Made with recyclable materials such as galvanized steel, this product is an eco-friendly alternative to traditional roofing options. Additionally, its ability to enhance energy efficiency contributes to reducing carbon emissions and overall environmental impact.Conclusion:The Horizontal Corrugated Roof Panel offered by (need to remove brand name) is revolutionizing roofing solutions with its durability, energy efficiency, aesthetic appeal, and sustainability. As the need for reliable and cost-effective roofing materials grows, this innovative product emerges as a game-changer in the industry. Whether for residential or commercial applications, this versatile and long-lasting roofing solution provides a viable alternative for those seeking excellence in both functionality and design.

Metal Deck Forming Machine for Floor Construction

We are pleased to announce that {} has recently launched a new Floor Metal Deck Forming Machine that is set to revolutionize the construction industry. This innovative machine is designed to significantly increase the efficiency and quality of floor metal deck forming, making it an essential tool for construction companies and contractors.The Floor Metal Deck Forming Machine is equipped with advanced technology and features that allow for precise and quick metal deck forming. It is capable of handling various types of metal materials, including steel and aluminum, and can produce different profiles and sizes to meet the specific needs of each project. This versatility makes it a valuable asset for construction companies working on a wide range of projects.One of the key highlights of this machine is its ability to automate the metal deck forming process, minimizing the need for manual labor and reducing the risk of errors. This not only saves time and labor costs but also ensures consistent and high-quality results. With the Floor Metal Deck Forming Machine, construction companies can expect to complete their projects more efficiently and with superior structural integrity.In addition to its cutting-edge technology, the Floor Metal Deck Forming Machine is also designed with user-friendliness in mind. Its intuitive interface and controls make it easy for operators to set up and operate the machine, allowing for seamless integration into existing workflows. This ensures that construction companies can quickly adapt to using the machine without significant downtime or disruption.We spoke with the spokesperson for {} to learn more about their vision for the Floor Metal Deck Forming Machine and how it aligns with their commitment to driving innovation in the construction industry. They shared, "At {}, we are constantly striving to develop solutions that address the evolving needs of the construction sector. The Floor Metal Deck Forming Machine is a testament to our dedication to providing cutting-edge equipment that enhances productivity and quality in construction projects."They added, "We understand the challenges that construction companies face when it comes to floor metal deck forming, and we believe that our machine will be a game-changer in addressing these challenges. By streamlining the forming process and delivering consistent, high-quality results, we aim to empower construction companies to take on more complex projects with confidence."The launch of the Floor Metal Deck Forming Machine comes at a time when the construction industry is experiencing a growing demand for efficient and reliable equipment. As construction projects become more complex and timelines more stringent, there is a greater need for innovative tools that can optimize processes and deliver superior outcomes. The Floor Metal Deck Forming Machine is poised to meet these needs and set a new standard for floor metal deck forming in the industry.With its exceptional capabilities and user-friendly design, the Floor Metal Deck Forming Machine is set to become an indispensable asset for construction companies looking to stay ahead of the curve. Its potential to streamline operations, improve efficiency, and elevate the quality of construction projects makes it a must-have for any company looking to take their floor metal deck forming to the next level.In conclusion, the launch of the Floor Metal Deck Forming Machine signifies a significant advancement in the construction industry, thanks to the innovative approach and commitment to excellence that {} brings to the table. As construction companies prepare for the next era of building projects, this machine promises to be a cornerstone in their pursuit of greater efficiency, productivity, and quality.

Sheet Forming and Corrugating Machine for Glazed Tile Production

Title: Streamlining Roofing Innovation: Advanced Glazed Tile Sheet Forming and Corrugating Machine Revolutionizes the Construction IndustryIntroductionIn a significant breakthrough for the construction industry, a leading manufacturing company (name withheld) has recently unveiled its highly advanced Glazed Tile Sheet Forming and Corrugating Machine. Revolutionizing the way roofs are built, this cutting-edge machinery promises to streamline the roofing process, enhance durability, and exhibit exceptional aesthetic qualities. With its innovative design and state-of-the-art technology, this new machine is set to transform the way buildings are constructed.Enhanced Efficiency and ProductivityThe advanced Glazed Tile Sheet Forming and Corrugating Machine combines speed, precision, and versatility to deliver a highly efficient roofing solution. Equipped with automatic controls, this machinery significantly reduces human error and increases production rates, allowing construction companies to meet demanding project deadlines seamlessly. By automating the previously labor-intensive and time-consuming manual processes, the machine can form and shape glazed tiles quickly and efficiently.Unmatched Durability and QualityDesigned to produce robust and long-lasting glazed tiles, the machine utilizes high-quality materials and cutting-edge techniques. This results in the creation of tiles that are resistant to harsh weather conditions, corrosion, and daily wear and tear. By employing a unique corrugation process, the machine enhances the strength and rigidity of the tiles, providing added protection against extreme temperatures and structural damage. This ensures that buildings constructed with these tiles will maintain their durability and aesthetics over an extended period.Aesthetic Appeal and CustomizationThe Glazed Tile Sheet Forming and Corrugating Machine offers a myriad of possibilities when it comes to designing roofs. With its customizable features, architects and construction professionals can effortlessly create visually stunning structures. The machine enables the creation of various tile shapes, sizes, and finishes, ensuring that each project can be tailored to meet the client's specific requirements. This flexibility empowers architects to bring their creative visions to life and adds a touch of elegance to any construction project.Sustainable and Environmentally FriendlyWith increasing emphasis on sustainability, the Glazed Tile Sheet Forming and Corrugating Machine aims to contribute positively to the environment. The use of energy-efficient technology reduces carbon emissions, making it an eco-friendly solution for the construction sector. Additionally, the long lifespan of the tiles produced by this machinery reduces the need for frequent replacements, minimizing waste and conserving resources. As the industry moves towards greener practices, this machine represents an essential step towards a more sustainable future.Market Impact and Global AdoptionGiven the comprehensive benefits offered by this advanced Glazed Tile Sheet Forming and Corrugating Machine, it is expected to leave a significant impact on the roofing industry worldwide. Its ability to drastically improve efficiency, durability, and design flexibility makes it an attractive solution for construction companies across the globe. The machine's potential to revolutionize the way roofs are built is likely to be met with widespread adoption, driving market growth and setting new industry standards.ConclusionThe unveiling of the advanced Glazed Tile Sheet Forming and Corrugating Machine marks an important milestone in the construction industry. Its combination of efficiency, durability, customization, and sustainability gives birth to a new era of roofing solutions. As construction companies embrace this cutting-edge technology, it is anticipated that buildings will be constructed more swiftly and cost-effectively while maintaining exceptional quality and aesthetic appeal. With its remarkable potential, this revolutionary machine will undoubtedly reshape the future of the roofing industry.

Cutting-Edge C-Channel Making Machine Revolutionizes Manufacturing Process

Title: All-New C-Channel Making Machine: Revolutionizing the Construction IndustryIntroduction: The construction industry is entering a new era of efficiency and productivity with the introduction of an innovative C-Channel Making Machine. This cutting-edge technology, developed by a prominent industry player, is poised to revolutionize the manufacturing process of C-channels, offering numerous benefits to the construction sector. By enhancing precision, reducing production time, and streamlining operations, this machine is set to reshape the landscape of construction projects worldwide.Streamlining C-Channel Production:With the new C-Channel Making Machine, construction companies can now streamline the production of C-channels, a key component in various structures such as bridges, buildings, and frameworks. The machine automates the manufacturing process, eliminating the need for manual labor and significantly reducing the chances of human error. By utilizing advanced robotics and automated systems, this solution ensures precision and consistency throughout the production line. The result is a reliable and high-quality end product, enhancing the overall structural integrity of the construction project.Efficiency in Design and Production:The C-Channel Making Machine utilizes advanced software and modeling capabilities to optimize the design and production process. With its integrated CAD (Computer-Aided Design) system, engineers and architects can create intricate and complex C-channel designs with ease. This technology allows for greater customization and flexibility, catering to specific project requirements. Furthermore, the machine's ability to quickly convert design files into production instructions ensures a seamless transition from concept to finished product. This streamlines the production timeline and reduces overall project costs.Enhanced Productivity and Time Savings:One of the most significant advantages of the C-Channel Making Machine is its ability to expedite the production process, leading to substantial time savings. By automating various tasks that were previously time-consuming and labor-intensive, the machine boosts overall productivity. Its rapid fabrication capabilities allow for a faster turnover of C-channels, enabling construction companies to meet tight project deadlines effortlessly. This efficiency not only saves valuable time but also reduces labor costs, making the manufacturing process more cost-effective in the long run.Quality Control and Consistency:Maintaining consistent quality throughout the production cycle is crucial for the success of any construction project. The C-Channel Making Machine is equipped with advanced sensors and quality control mechanisms that constantly monitor the production process. This ensures that each C-channel produced adheres to the highest standards and specifications. By minimizing defects and inconsistencies, the machine guarantees an enhanced level of quality and reliability in the final products.Sustainable and Environmentally Friendly:In addition to its various technical benefits, the C-Channel Making Machine demonstrates a commitment to sustainability. By optimizing material usage through precision cutting and minimizing waste, this technology reduces the carbon footprint associated with traditional C-channel production methods. Additionally, the automated system allows for precise measurements and accurate cuts, further limiting material waste. With a focus on environmentally conscious manufacturing, this machine aligns with the growing demand for sustainable practices in the construction industry.Conclusion:The advent of the all-new C-Channel Making Machine signifies a transformative shift in the construction industry. With its ability to streamline production, enhance efficiency, and improve overall quality, this technology holds immense potential for revolutionizing the construction sector. Construction companies worldwide can now benefit from reduced production time, cost savings, and superior precision, ultimately leading to enhanced project completion rates and client satisfaction. As the industry embraces these advancements, the C-Channel Making Machine promises to reshape the way C-channels are manufactured for the better.

Cut to Length Machine: A Complete Guide for Steel Cutting Operations

Steel Cut To Length Machine revolutionizing the metalworking industryIn the world of metalworking, precision and efficiency are key components of success. The Steel Cut To Length Machine, produced by a leading manufacturer in the industry, is revolutionizing the way steel is processed and cut. This state-of-the-art machine combines cutting-edge technology with the company's expertise and dedication to excellence, making it a game-changer for businesses in the metalworking sector.With a strong commitment to innovation and quality, {company name} has established itself as a leader in the manufacturing of metalworking machinery. The Steel Cut To Length Machine is a testament to the company's dedication to providing cutting-edge solutions to its customers. With a focus on precision and efficiency, this machine is designed to streamline the process of cutting steel, providing businesses with a cost-effective and reliable solution for their metalworking needs.One of the key features of the Steel Cut To Length Machine is its advanced cutting technology. Equipped with high-precision blades and state-of-the-art automation, this machine is capable of cutting steel with unparalleled accuracy and speed. This precision cutting technology ensures that businesses can produce high-quality steel products with minimal waste, saving both time and money in the production process.Another notable feature of the Steel Cut To Length Machine is its versatility. This machine is designed to handle a wide range of steel thicknesses and widths, making it suitable for a variety of metalworking applications. Whether businesses are working with thin-gauge steel or heavy-duty materials, this machine is capable of delivering consistent and precise cuts, ensuring that the finished products meet the highest standards of quality.In addition to its cutting-edge technology and versatility, the Steel Cut To Length Machine is also designed with user-friendliness in mind. The machine's intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, streamlining the production process and minimizing the potential for errors. This user-friendly design is a testament to {company name}'s commitment to providing its customers with practical and efficient solutions for their metalworking needs.For businesses in the metalworking industry, investing in the Steel Cut To Length Machine represents a step forward in achieving greater productivity and efficiency. By incorporating this cutting-edge machine into their operations, businesses can optimize their production processes, reduce waste, and ultimately improve their bottom line. With the support of {company name}'s expertise and commitment to excellence, the Steel Cut To Length Machine is helping businesses in the metalworking sector stay ahead of the competition.In conclusion, the Steel Cut To Length Machine, produced by {company name}, is transforming the metalworking industry with its cutting-edge technology, versatility, and user-friendly design. With a focus on precision and efficiency, this machine is empowering businesses to achieve greater productivity and cost-effectiveness in their operations. As the demand for high-quality steel products continues to grow, the Steel Cut To Length Machine is positioning businesses in the metalworking sector for success, driving innovation and progress in an ever-evolving industry.