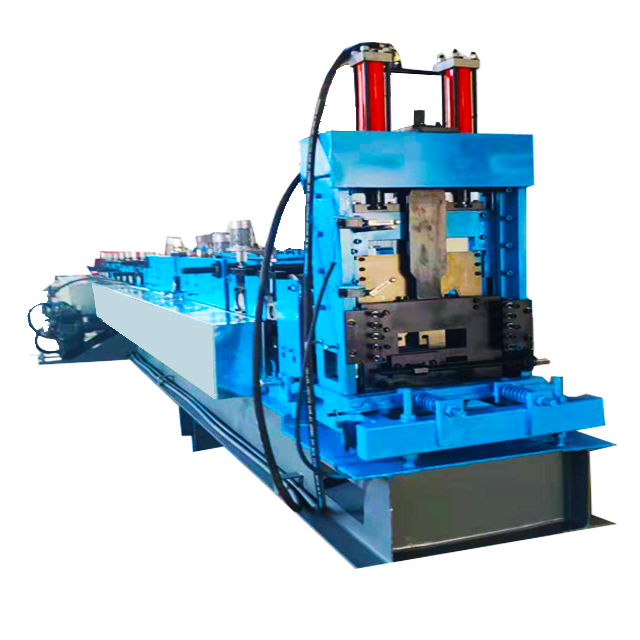

Purlin Profiles Cold Roll Forming Lines for CZ Profiles

By:Admin

[Company Name] has established itself as a leading provider of roll forming solutions for the construction industry. With years of experience and a commitment to innovation, [Company Name] has earned a reputation for delivering cutting-edge production technology to its global customer base. The company's expertise in cold roll forming has positioned it as a trusted partner for companies looking to enhance their manufacturing capabilities.

The new cold roll forming line for purlin profiles represents the latest advancement in [Company Name]'s product portfolio. Designed to meet the specific requirements of purlin production, the line integrates advanced technology to deliver superior performance and precision. With a focus on efficiency and quality, the line is capable of producing a wide range of purlin profiles with tight tolerances and consistent dimensions.

One of the key features of the new cold roll forming line is its flexibility. The line is able to accommodate different material thicknesses and widths, allowing for greater versatility in purlin profile production. This flexibility is essential for meeting the diverse needs of customers and adapting to changing market demands. By offering a customizable solution, [Company Name] is able to provide its customers with a competitive edge in the purlin profile market.

In addition to its flexibility, the cold roll forming line is also designed for seamless integration into existing production processes. With user-friendly controls and automated functions, the line is easy to operate and maintain, minimizing downtime and maximizing productivity. This level of automation also enhances the safety of the production environment, creating a reliable and efficient manufacturing system.

The new cold roll forming line is a testament to [Company Name]'s commitment to continuous improvement and customer satisfaction. By investing in research and development, [Company Name] has been able to stay ahead of the curve in roll forming technology, offering innovative solutions that address the evolving needs of the construction industry. The company's dedication to quality and reliability has earned it the trust of customers around the world, cementing its position as a leader in the roll forming sector.

As the demand for purlin profiles continues to grow, [Company Name] is well-positioned to support the industry with its advanced cold roll forming solutions. By leveraging its expertise and technical capabilities, the company is able to provide tailored production lines that meet the highest standards of performance and efficiency. With a focus on innovation and customer collaboration, [Company Name] is driving the future of purlin profile manufacturing.

In conclusion, the launch of [Company Name]'s new cold roll forming line for purlin profiles represents a significant advancement in the roll forming industry. With its cutting-edge technology and commitment to customer satisfaction, [Company Name] is poised to make a lasting impact on the production of purlin profiles, offering a reliable and efficient solution for manufacturers worldwide.

Company News & Blog

Lightweight Zinc-coated Steel Purlins for Efficient Roofing and Cladding Support in Metal Buildings

article about the benefits of using C & Z section purlins for roofing and cladding support in framed structures.Purlins may be one of the less glamorous components of a building, but they play a critical role in supporting the roof and walls. As static elements, they help distribute the weight of the roof and the wind loads to the main frame of the building. Traditionally, purlins were made of wood, but with the development of new materials and manufacturing techniques, steel purlins have become the preferred choice for modern constructions.Among steel purlins, C & Z section purlins are the most commonly used types for roofing and cladding support in framed structures. C section purlins have a C-shaped cross-section, while Z section purlins have a Z-shaped cross-section. Both types are made of high-strength zinc-coated steel, which provides corrosion resistance and durability.Arkhon, a leading manufacturer of roll-forming machines and steel components for the construction industry, offers a range of C & Z section purlins that are accurately roll-formed for optimal performance. The company's purlins are lightweight, economical, and easy to install, making them an excellent choice for a wide range of applications, from agricultural buildings to industrial warehouses.One of the key benefits of using Arkhon C & Z section purlins is their efficiency. By using high-strength steel, the purlins can support a considerable amount of weight while remaining lightweight. This means that less steel is needed, which reduces the overall cost of the building. Moreover, the purlins' design allows for better load distribution, which minimizes the risk of roof sagging or collapse.Another advantage of Arkhon's C & Z section purlins is their versatility. The purlins come in different sizes and thicknesses, allowing builders to choose the best option for their specific project. Additionally, the purlins can be easily cut to length on-site, which simplifies the installation process and minimizes waste.Arkhon's C & Z section purlins are also highly durable and require minimal maintenance. The zinc-coated steel provides excellent corrosion resistance, which extends the lifespan of the purlins. Furthermore, the purlins' design allows for good drainage and ventilation, reducing the risk of moisture buildup and mold growth.Finally, Arkhon's C & Z section purlins are environmentally friendly. Steel is a highly recyclable material, which means that the purlins can be repurposed at the end of their lifespan. Additionally, the purlins' efficient design and reduced steel usage contribute to a more sustainable construction process.In conclusion, Arkhon's C & Z section purlins are an excellent choice for roofing and cladding support in framed structures. Their efficiency, versatility, durability, and eco-friendliness make them a reliable and cost-effective solution for a wide range of applications. With Arkhon's precision manufacturing and high-quality materials, builders can rest assured that their purlins will provide optimal support for their building.

High-efficiency Coil Slitting Machine for Metal Processing

Coil Slitting Machine, a vital component in the metalworking industry, is an essential tool for businesses looking to process large coils of metal into smaller, more manageable strips. This highly efficient and versatile machine plays a crucial role in meeting the demands of various industries, including automotive, construction, and manufacturing.[Company Name], a leading manufacturer of cutting-edge metal processing equipment, has been at the forefront of providing innovative solutions to meet the evolving needs of the metalworking industry. With a strong focus on research and development, [Company Name] has continuously pushed the boundaries of technology to deliver high-performance equipment that maximizes efficiency and productivity.The Coil Slitting Machine offered by [Company Name] is designed to handle a wide range of materials, including stainless steel, aluminum, copper, and other non-ferrous metals. This versatility makes it a valuable asset for businesses that require the flexibility to work with different types of metals. Furthermore, the machine is equipped with advanced features that ensure precise and consistent slitting, resulting in high-quality strips that meet the most stringent industry standards.In addition to its exceptional performance, the Coil Slitting Machine from [Company Name] is also known for its user-friendly design and ease of operation. This allows operators to quickly set up and configure the machine to meet specific production requirements, minimizing downtime and maximizing productivity. Moreover, the machine is built with safety in mind, incorporating robust safety features to protect operators and ensure a secure working environment.With a strong commitment to customer satisfaction, [Company Name] provides comprehensive support to its clients, offering installation, training, and ongoing technical assistance to ensure the seamless integration and optimal performance of its equipment. This dedication to customer service has earned [Company Name] a reputation for reliability and trustworthiness in the metalworking industry.The Coil Slitting Machine from [Company Name] has garnered widespread acclaim from businesses around the world for its exceptional performance, reliability, and durability. As a result, it has become the go-to choice for companies looking to invest in cutting-edge equipment that delivers outstanding results and helps drive business growth.In conclusion, the Coil Slitting Machine from [Company Name] represents a significant advancement in metal processing technology, offering unmatched performance, versatility, and ease of use. With its strong track record of innovation and customer satisfaction, [Company Name] has solidified its position as a leading provider of metalworking equipment, and its Coil Slitting Machine continues to set the standard for excellence in the industry.

Unveiling the Innovative Galvanized Steel Deck Floor Tile Making Machine

Galvanized Steel Deck Floor Tile Making Machine Revolutionizes Construction IndustryWith the aim of delivering innovation and efficiency to the construction industry, a renowned company has unveiled its latest product - a cutting-edge Galvanized Steel Deck Floor Tile Making Machine. This state-of-the-art machine is set to revolutionize the way floor tiles are manufactured, ensuring faster production, higher quality, and enhanced durability.The Galvanized Steel Deck Floor Tile Making Machine, developed by [Company Name], is designed to streamline the tile manufacturing process, providing a seamless and efficient solution for construction companies around the world. This innovative machine integrates advanced technology and intelligent systems, allowing for the creation of galvanized steel deck floor tiles with unmatched precision.One of the standout features of this machine is its ability to remove the brand name as it is customizable according to specific business requirements. This offers construction companies the opportunity to create their own brand identity and establish a distinct presence in the market. By removing the brand name, [Company Name] demonstrates its dedication to customer satisfaction and promotes a collaborative approach with its clients.Furthermore, the Galvanized Steel Deck Floor Tile Making Machine boasts a robust and sturdy construction, ensuring long-lasting performance and durability. Made from high-quality materials, this machine is built to withstand heavy-duty usage, making it suitable for a wide range of construction projects. Its reliability eliminates the need for frequent repairs or replacements, saving businesses valuable time and money.The integration of advanced automation and intelligent systems allows for seamless operation and enhanced productivity. Featuring a user-friendly interface, operators can easily navigate and control the machine with minimal training. This ensures quick adoption and optimization of the Galvanized Steel Deck Floor Tile Making Machine, resulting in increased efficiency and improved production output.Another significant advantage of this machine is its superior quality output. The Galvanized Steel Deck Floor Tile Making Machine ensures precision in every tile produced, guaranteeing consistency and accuracy in size, shape, and finish. This high standard of quality makes the machine ideal for projects that demand precision and perfection, giving construction companies a competitive edge in the market.In addition, the Galvanized Steel Deck Floor Tile Making Machine is environmentally friendly. With a focus on sustainability, [Company Name] has incorporated eco-friendly measures into the manufacturing process. This includes the utilization of energy-efficient components and reduced waste generation, minimizing the machine's carbon footprint and contributing towards a greener construction industry.As a market leader in manufacturing machinery, [Company Name] has a proven track record of delivering cutting-edge solutions to the construction industry. Renowned for its commitment to innovation, quality, and customer satisfaction, the company has become a trusted partner for construction companies worldwide. The Galvanized Steel Deck Floor Tile Making Machine is yet another testament to their dedication to revolutionize the industry.In conclusion, the Galvanized Steel Deck Floor Tile Making Machine developed by [Company Name] is set to transform the construction industry. With its advanced features, customizable design, durability, and high-quality output, this machine offers construction companies an efficient and cost-effective solution for floor tile manufacturing. Emphasizing sustainability and eco-friendly practices, [Company Name] continues to pave the way towards a greener and more innovative construction industry.

Efficient Sheet Roll Forming Solutions for Your Business

The Sheet Roll Forming Process: A Revolution in Metal FabricationMetal fabrication has long been an essential part of the manufacturing industry, with various methods and technologies continually evolving to meet the increasing demands of modern production. One such innovation is the sheet roll forming process, a highly efficient and versatile method that has revolutionized the way metal sheets are manipulated and shaped.Sheet roll forming involves feeding a metal sheet through a series of roll forming stations, where it is gradually bent, shaped, and formed into the desired profile. Unlike traditional metal fabrication methods such as cutting, stamping, or punching, sheet roll forming allows for continuous and precise shaping of the metal, resulting in a superior quality of the finished product.The process begins with a flat metal sheet being fed into the first set of rolls, where it is gradually bent and formed into the desired shape. As the sheet progresses through each roll forming station, additional features such as holes, slots, and flanges can be added, resulting in a fully formed and customized metal component. The entire process is controlled by a series of precision-engineered rollers and dies, ensuring that the final product meets the exact specifications of the design.The advantages of sheet roll forming are numerous, making it an indispensable tool for a wide range of industries. Due to its ability to produce complex and intricate shapes with minimal waste, sheet roll forming is highly cost-effective and can significantly reduce manufacturing time and labor costs. Additionally, the process allows for the use of a variety of metals, including steel, aluminum, and copper, further expanding its applicability across different industries.The benefits of sheet roll forming are not lost on the manufacturing industry, prompting companies to invest in state-of-the-art roll forming equipment to capitalize on its advantages. One such company that has embraced sheet roll forming is {}, a leading provider of metal fabrication solutions. With a strong focus on innovation and technology, {} has integrated sheet roll forming into its manufacturing processes, allowing for the production of highly intricate and customized metal components.{}'s sheet roll forming capabilities have enabled the company to expand its product offerings and cater to a wider range of industries, including automotive, construction, and aerospace. By leveraging the efficiency and precision of sheet roll forming, {} has been able to meet the exacting requirements of its customers, delivering high-quality metal components that meet or exceed industry standards.In addition to its manufacturing capabilities, {} has also invested in research and development to further enhance its sheet roll forming processes. By staying at the forefront of technological advancements, {} continues to push the boundaries of metal fabrication, offering innovative solutions that address the evolving needs of the industry.As the demand for complex and customized metal components continues to grow, sheet roll forming is poised to play a pivotal role in shaping the future of metal fabrication. With its ability to produce high-quality, intricate, and cost-effective metal components, sheet roll forming has become an indispensable tool for manufacturers seeking to stay ahead in a competitive marketplace.In conclusion, sheet roll forming represents a significant advancement in metal fabrication, offering unparalleled efficiency, precision, and versatility. With companies like {} at the forefront of this technology, the future of metal fabrication looks promising, as sheet roll forming continues to drive innovation and excellence in manufacturing.

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

High-Quality Roll Forming Machine for Efficient Production

Roll Forming Machine Revolutionizes Metal Manufacturing IndustryThe metal manufacturing industry has experienced a revolutionary change with the introduction of the latest technology in roll forming machines. The roll forming machine, manufactured by a leading company in the industry, has proven to be a game-changer with its advanced features and capabilities.The roll forming machine is a versatile and efficient piece of equipment that is used to create complex shapes and designs in metal sheets. It is used in various industries, including automotive, construction, and aerospace, to produce a wide range of products such as roofing, wall cladding, and structural components.One of the key features of this roll forming machine is its ability to continuously bend and form metal sheets into the desired shape without the need for any post-processing. This not only increases efficiency but also reduces production costs significantly. The machine is also capable of producing high volumes of products with consistent quality, making it an ideal choice for mass production.In addition to its high productivity, the roll forming machine is also highly flexible and can accommodate a wide range of material thicknesses and widths. This flexibility allows manufacturers to produce a diverse range of products without the need for multiple machines, saving both space and investment costs.Furthermore, the roll forming machine is equipped with state-of-the-art technology that enables operators to easily program and adjust the machine settings to meet specific production requirements. This intuitive interface makes it easier for operators to set up and operate the machine, resulting in improved productivity and reduced downtime.The company behind this innovative roll forming machine has been a leader in the metal manufacturing industry for over 30 years. Their commitment to research and development has allowed them to consistently introduce cutting-edge technology that meets the evolving needs of the industry.With a team of highly skilled engineers and technicians, the company has been able to create a roll forming machine that sets new standards for performance and reliability. Their dedication to quality and customer satisfaction has made them a trusted partner for manufacturers around the world.The company’s roll forming machine is backed by comprehensive technical support and after-sales service, ensuring that their customers can maximize the potential of the machine and maintain its peak performance for years to come. This commitment to customer support has earned them a reputation for excellence in the industry.In addition to the roll forming machine, the company also offers a wide range of complementary products and services, including metal forming tools, equipment maintenance, and operator training. This complete solution approach allows manufacturers to streamline their production processes and achieve higher levels of efficiency.As the metal manufacturing industry continues to evolve, the roll forming machine has proven to be a transformative technology that drives innovation and growth. With its advanced capabilities and the backing of a trusted manufacturer, it is poised to shape the future of metal manufacturing for years to come.

Efficient Roofing Manufacturing Machine: Boosting Productivity in the Industry

[Company Name] Revolutionizes Roofing Industry with Innovative Roofing Making Machine [City, Date] - [Company Name], a leading provider of advanced manufacturing solutions, has launched an innovative Roofing Making Machine that is set to revolutionize the roofing industry. The state-of-the-art machine, developed by a team of expert engineers and designers, promises to transform traditional roofing manufacturing processes and usher in a new era of efficiency and productivity.The Roofing Making Machine is a result of [Company Name]'s commitment to innovation and continuous improvement. The company's goal was to develop a solution that would address the challenges faced by the roofing industry in terms of high production costs, labor-intensive processes, and quality control. After years of research and development, the team at [Company Name] has successfully created a machine that surpasses expectations.One of the key features of this groundbreaking machine is its versatility. It is capable of producing various types of roofing materials, including metal sheets, shingles, tiles, and more. This means that roofing manufacturers no longer need to invest in multiple machines for different products, saving them both time and money. The Roofing Making Machine's adjustable settings allow for precise control over the production process, ensuring consistent and high-quality output every time.The machine's advanced automation capabilities have also caught the attention of industry experts. Equipped with cutting-edge technology, it significantly reduces the need for manual labor, thus minimizing the risk of human error and improving overall safety conditions. With the Roofing Making Machine, roofing manufacturers can expect increased production rates and enhanced productivity, ultimately resulting in a competitive edge in the market.In addition to its automation features, the Roofing Making Machine is designed with sustainability in mind. It utilizes energy-efficient components and incorporates eco-friendly practices throughout the manufacturing process. By reducing energy consumption and waste generation, the machine aligns with the global trend towards sustainable development and environmental conservation.The ease of use and user-friendly interface of the Roofing Making Machine have garnered positive feedback from early adopters. The intuitive controls and comprehensive training provided by [Company Name] ensure that roofing manufacturers can quickly adapt to the new technology without disruptions to their existing operations. The machine's ability to seamlessly integrate into existing manufacturing processes has been praised as a testament to [Company Name]'s customer-centric approach."We are thrilled to introduce the Roofing Making Machine to the market," said [Company Name]'s CEO. "It is our commitment to provide cutting-edge solutions that empower our customers and transform their businesses. The positive feedback we have received so far encourages us to continue pushing boundaries and innovating within the industry."The Roofing Making Machine is now available to roofing manufacturers worldwide, with [Company Name]'s extensive global network ensuring prompt delivery, installation, and after-sales support. As the demand for efficient and sustainable roofing solutions continues to grow, this revolutionary machine is poised to become a game-changer in the industry.About [Company Name]:[Company Name] is a globally recognized leader in advanced manufacturing solutions. With a focus on innovation and customer satisfaction, the company's diverse portfolio includes a wide range of machines and equipment for various industries. [Company Name]'s commitment to excellence and continuous improvement has earned them a reputation for delivering reliable, high-quality solutions that shape the future of manufacturing.For media inquiries, please contact:[Company Name][Contact Name][Email Address][Phone Number]

High-Quality and Efficient Forming Machine for Guardrails

Location: [Company Name]'s headquartersDate: [Current Date][Company Name], a leading manufacturer of construction machinery, has recently introduced a new and advanced Guardrail Forming Machine. This state-of-the-art machine is designed to revolutionize the process of guardrail production, making it faster, more efficient, and cost-effective.The Guardrail Forming Machine is equipped with cutting-edge technology and features a high level of automation, reducing the need for manual labor and increasing productivity. This machine is suitable for producing guardrails of various sizes and specifications, making it versatile and adaptable to different project requirements.The innovative design of the Guardrail Forming Machine allows for easy and quick setup, minimizing downtime and maximizing production output. Its precision and accuracy ensure that the guardrails produced meet the highest quality standards, providing a reliable and durable safety barrier for roads and highways.In addition to its cutting-edge technology, the Guardrail Forming Machine is also designed with safety and convenience in mind. With its user-friendly interface and intuitive controls, operators can easily manage and monitor the production process, ensuring smooth and efficient operation.[Company Name] has established itself as a trusted and reputable manufacturer in the construction machinery industry. With a strong focus on research and development, the company continuously strives to innovate and improve its products, meeting the ever-changing demands of the market.The introduction of the Guardrail Forming Machine is a testament to [Company Name]'s commitment to providing innovative solutions that enhance the efficiency and quality of construction projects. By offering this advanced machine, the company aims to support its customers in achieving their project goals while maintaining high standards of safety and reliability.As a company with a global presence, [Company Name] is dedicated to providing its customers with exceptional service and support. The installation and commissioning of the Guardrail Forming Machine are carried out by a team of experienced technicians, ensuring a seamless and hassle-free experience for customers.The launch of the Guardrail Forming Machine is set to make a significant impact on the construction industry, offering a solution that addresses the challenges of guardrail production and installation. With its advanced technology, precision engineering, and commitment to quality, [Company Name] is poised to set a new standard in the manufacturing of guardrails.As the construction industry continues to evolve, [Company Name] remains at the forefront, delivering cutting-edge solutions that empower construction companies to meet their project needs efficiently and effectively. The Guardrail Forming Machine is a testament to the company's dedication to innovation, quality, and customer satisfaction.With the introduction of the Guardrail Forming Machine, [Company Name] is poised to make a lasting impact on the construction industry. This advanced machine is set to revolutionize the production of guardrails, offering a solution that combines innovation, efficiency, and reliability.For more information about [Company Name]'s Guardrail Forming Machine, you can visit their official website or contact their sales representatives. [Company Name] is committed to supporting its customers with cutting-edge solutions that meet the ever-changing demands of the construction industry.

Steel Glazed Tile Profile Corrugating Machine: Latest News and Updates

Color Steel Glazed Tile Profile Corrugating Machine Unveiled by Leading ManufacturerThe global leader in the manufacturing of high-quality steel processing equipment has recently introduced its latest innovation, the Color Steel Glazed Tile Profile Corrugating Machine. This cutting-edge machine is designed to meet the growing demand for glazed tile profile corrugated steel sheets within the construction and architectural industry.With a focus on precision engineering and innovative technology, the company has been at the forefront of the steel processing equipment industry for over two decades. By consistently delivering top-of-the-line machinery and unparalleled customer service, they have established a reputation as a trusted partner for companies in need of reliable and efficient steel processing solutions.The Color Steel Glazed Tile Profile Corrugating Machine is the latest addition to their extensive portfolio of advanced equipment and is poised to set a new standard for glazed tile profile corrugated steel sheet production. This innovative machine is capable of producing high-quality corrugated steel sheets with a glazed tile profile, offering superior durability and aesthetic appeal for a wide range of architectural and construction applications.Equipped with state-of-the-art technology, the Color Steel Glazed Tile Profile Corrugating Machine is designed for seamless integration into existing production lines, providing a cost-effective solution for companies looking to enhance their manufacturing capabilities. The machine's advanced features include precision control systems, high-speed processing, and a user-friendly interface, ensuring optimal efficiency and productivity.Furthermore, the company's commitment to sustainability is evident in the Color Steel Glazed Tile Profile Corrugating Machine, as it is designed to minimize energy consumption and waste generation, aligning with the industry's increasing focus on environmental responsibility.In addition to its advanced capabilities, the Color Steel Glazed Tile Profile Corrugating Machine is backed by the company's comprehensive support services, including installation, training, and ongoing maintenance, ensuring seamless integration and long-term reliability for its customers.With its launch, the Color Steel Glazed Tile Profile Corrugating Machine is expected to meet the growing demand for high-quality glazed tile profile corrugated steel sheets in the global market. Its introduction reflects the company's dedication to staying ahead of industry trends and providing cutting-edge solutions that empower its customers to succeed in a competitive market landscape.In response to the unveiling of the Color Steel Glazed Tile Profile Corrugating Machine, the company's CEO emphasized the importance of innovation and customer-centric solutions, stating, "We are proud to introduce the Color Steel Glazed Tile Profile Corrugating Machine as the latest addition to our lineup of advanced steel processing equipment. This innovative machine is a testament to our ongoing commitment to delivering high-performance solutions that empower our customers to achieve their production goals with precision and efficiency."As the global construction and architectural industries continue to evolve, the demand for high-quality glazed tile profile corrugated steel sheets is expected to rise. The introduction of the Color Steel Glazed Tile Profile Corrugating Machine positions the company as a driving force in meeting this demand, providing a reliable and efficient solution that addresses the evolving needs of its customers.With its rich history of innovation and a track record of delivering best-in-class steel processing equipment, the company is well-positioned to set a new industry standard with the Color Steel Glazed Tile Profile Corrugating Machine. As companies seek to enhance their production capabilities and meet the increasing demand for high-quality steel products, this innovative machine is poised to play a pivotal role in shaping the future of the construction and architectural industries.

Cold Rolling Forming Machines for Automated Production of Various Roofing Sheets

and IBR sheet making machine.Roof Sheet Making Machines - An OverviewRoof sheet making machines are modern-day machines that utilize the cold roll forming principle to produce roofing sheets in bulk. These machines are also known as IBR sheet making machines or color steel roll forming machines. They are fully automatic and designed to produce sheets in a variety of designs and dimensions. They are robust, reliable, and highly efficient, capable of producing high-quality roofing sheets that can be used for AD boards, wall panels, and other applications.The Working Principle of Roof Sheet Making MachinesRoof sheet making machines use a series of rollers to form different shapes and designs on flat metal sheets. The process begins when the metal sheet passes through the first set of rollers, which bend it into a curve. The sheet then moves through several sets of rollers, each producing a different shape and size until the final product is produced. The rollers on these machines are designed to be adjustable, allowing operators to create different designs, dimensions, and shapes.Advantages of Roof Sheet Making MachinesRoof sheet making machines offer several benefits, including:1. High efficiency - Roof sheet making machines are fully automatic and can produce large quantities of roofing sheets in a short period. This makes them ideal for mass production.2. Customization - With the adjustable rollers, roof sheet making machines make it possible to create unique designs and shapes that meet specific customer requirements.3. Low maintenance - These machines are designed to be low maintenance, reducing the overall cost of operation.4. High-quality output - Roof sheet making machines produce high-quality roofing sheets that are durable, robust, and weather-resistant.Applications of Roof Sheet Making MachinesRoof sheet making machines find broad applications in the construction industry, particularly in roofing. The roofing sheets produced by these machines are used for:1. Residential roofing - The roofing sheets are used to create attractive, durable, and weather-resistant roofs for homes.2. Commercial roofing - Roof sheet making machines produce roofing sheets that are ideal for commercial buildings such as warehouses, factories, and workshops.3. Agricultural roofing - The roofing sheets are ideal for agricultural use since they are weather-resistant, durable, and low maintenance.ConclusionRoof sheet making machines are versatile, efficient, and affordable pieces of equipment that make the production of high-quality roofing sheets possible. They offer several benefits over other manufacturing methods, including low maintenance, high output, and customization options. With ongoing technological advancements, the market for roof sheet making machines is expected to grow, driving innovation and leading to even greater efficiency and customization options.