Top Quality Roll Former Machine for Efficient Production

By:Admin

A roll former machine is a piece of equipment that is used to produce continuous lengths of sheet metal by feeding a flat metal sheet through a series of rollers. These rollers gradually shape the metal into the desired profile, such as a corrugated pattern or a specific trim design. Roll former machines are widely used in the construction industry for creating metal roofing, siding, and other building components.

{Company Name} is a leading manufacturer of roll former machines, with a long history of innovation and excellence in the field of metal forming equipment. The company's roll former machines are known for their durability, precision, and versatility, making them a popular choice among construction professionals and manufacturers alike.

With a commitment to quality and customer satisfaction, {Company Name} offers a wide range of roll former machines to meet the diverse needs of its clients. From entry-level machines for small-scale operations to high-speed, fully automated systems for large-scale production, {Company Name} has a solution for every application.

In addition to producing roll former machines, {Company Name} also provides comprehensive support services to help its customers maximize the performance and longevity of their equipment. These services include installation, training, maintenance, and spare parts supply, ensuring that clients can rely on their {Company Name} equipment for many years to come.

The roll former machines offered by {Company Name} are designed to deliver consistent, high-quality results, making them a valuable asset for any business that requires precision metal forming. Whether it's creating custom profiles for architectural projects, manufacturing components for the automotive industry, or producing metal building materials for construction, {Company Name} roll former machines provide the reliability and performance that customers demand.

With a focus on continuous improvement and innovation, {Company Name} is constantly developing new technologies and features to enhance the capabilities of its roll former machines. This dedication to staying ahead of the curve ensures that customers can always access the latest advancements in metal forming technology, giving them a competitive edge in their respective markets.

In conclusion, {Company Name} is a trusted provider of high-quality roll former machines, offering a comprehensive range of products and services to meet the needs of its diverse customer base. With a strong commitment to excellence and a proven track record of success, {Company Name} is a name that businesses can rely on for their metal forming needs. Whether it's for roofing, siding, trim, or any other application, {Company Name} roll former machines are the solution for precision and performance.

Company News & Blog

Discover How a Metal Roofing Roller Machine Enhances Efficiency and Precision in Roofing Projects

[Company Name] Revolutionizing the Metal Roofing Industry with the Introduction of the Innovative Roofing Roller Machine[date][City, State] – Metal roofing has long been sought after for its durability and longevity. However, the installation process has traditionally been time-consuming and labor-intensive. In an effort to streamline this process and provide a more efficient solution, [Company Name], a leading manufacturer of roofing solutions, has recently launched their groundbreaking Metal Roofing Roller Machine.[Company Name] has been a driving force in the roofing industry for over three decades, constantly pushing the boundaries of innovation and technology. With a team of expert engineers and designers, the company has built a reputation for delivering high-quality products that not only meet industry standards but also exceed customer expectations.The Metal Roofing Roller Machine is the latest addition to their extensive line of roofing equipment. This state-of-the-art machine is designed to revolutionize the installation process, making it faster, easier, and more cost-effective. It eliminates the need for manual sheet bending and reshaping, thereby significantly reducing labor costs and minimizing the risk of human error.One of the key features of this machine is its ability to handle a wide range of metal roofing materials. Whether it be aluminum, steel, copper, or zinc, the Metal Roofing Roller Machine can effortlessly shape and reshape these materials according to the specifications of any roofing project. This versatility ensures that contractors and roofers can tackle a variety of projects without the need for multiple machines and tools, making it a cost-effective solution for businesses of all sizes.In addition to its versatility, the Metal Roofing Roller Machine is also remarkably user-friendly. Its intuitive interface and easy-to-use controls allow even inexperienced users to operate the machine with confidence. This eliminates the training time traditionally associated with new equipment, allowing contractors to scale their workforce quickly and meet project demands efficiently.Furthermore, the Roller Machine is equipped with advanced safety features to ensure the well-being of workers. An automatic shut-off mechanism is in place to prevent accidents, such as entanglement or injury, during operation. The robust construction of the machine also adds an extra layer of protection, ensuring its durability and longevity even in demanding working conditions.Since its launch, the Metal Roofing Roller Machine has garnered significant attention and praise from industry professionals. Roofers and contractors have lauded its ability to enhance productivity and streamline their operations. The machine's efficiency has enabled businesses to complete projects in record time, opening up new avenues for growth and profitability.[Company Name] understands the importance of sustainability in the roofing industry and has taken steps to reduce the environmental impact of their products. The Metal Roofing Roller Machine is designed to optimize material usage, minimizing waste and reducing carbon emissions. With this innovative machine, businesses can not only improve their efficiency but also contribute to a greener future.In conclusion, [Company Name]'s Metal Roofing Roller Machine is a groundbreaking solution that has transformed the metal roofing industry. Its versatility, user-friendliness, and safety features have revolutionized the installation process, making it more efficient and cost-effective. With this innovative machine, [Company Name] continues to drive the roofing industry forward, delivering cutting-edge solutions that meet the evolving needs of contractors and roofers worldwide.For more information about the Metal Roofing Roller Machine and other roofing solutions offered by [Company Name], please visit [website] or contact [contact information].###About [Company Name]:[Company Name] is a leading manufacturer of roofing solutions, revolutionizing the industry with its innovative products and commitment to customer satisfaction. With over three decades of experience, the company has built a reputation for excellence and has become a trusted partner for contractors and roofers worldwide. Through continuous innovation and unwavering dedication to quality, [Company Name] aims to shape the future of the roofing industry.

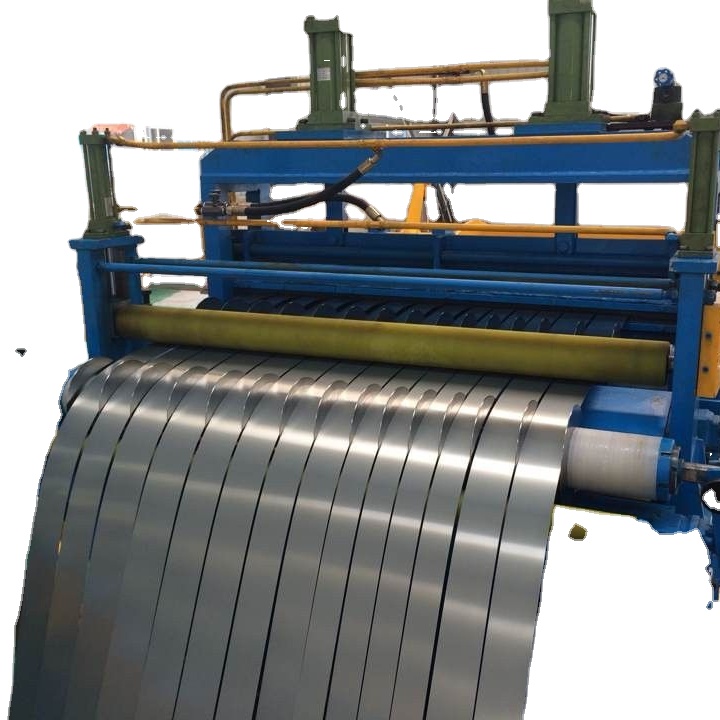

Efficient Automatic Roll Slitter: A Game-Changer in Manufacturing

Automatic roll slitter has become a significant part of the manufacturing process for many industries. It offers precision cutting and slitting of various materials, making it an essential tool for businesses looking to improve their production efficiency. [Company] is one of the leading providers of automatic roll slitter solutions, catering to the diverse needs of its clients in different industries.The automatic roll slitter offered by [Company] is designed to meet the high standards of precision and reliability required in modern manufacturing environments. With advanced technology and innovative features, the automatic roll slitter ensures accurate and consistent cutting of materials, including paper, film, fabric, and other flexible substrates. This level of precision is essential for achieving the desired quality and performance in the final products.One of the key benefits of the automatic roll slitter from [Company] is its versatility. It can handle a wide range of roll widths and thicknesses, making it suitable for various applications. Whether it's converting large rolls into smaller ones or creating custom-sized rolls for specific production requirements, the automatic roll slitter offers the flexibility needed to accommodate different manufacturing needs.In addition to its cutting capabilities, the automatic roll slitter also includes features for automated roll handling and positioning. This streamlines the process of loading and unloading rolls, minimizing downtime and maximizing productivity. Furthermore, the intuitive control system allows operators to set precise cutting parameters and monitor the slitting process, ensuring consistent results with minimal intervention.Another standout feature of the automatic roll slitter from [Company] is its user-friendly design. The machine is engineered for easy operation and maintenance, reducing the learning curve for operators and the overall cost of ownership for businesses. This simplicity, coupled with its robust construction, ensures long-term reliability and performance, delivering a high return on investment for customers.With a commitment to quality and customer satisfaction, [Company] provides comprehensive support for its automatic roll slitter solutions. From installation and training to ongoing technical assistance, the company's team of experts is dedicated to helping clients optimize the performance of their equipment and achieve their production goals. This level of support underscores [Company]'s reputation as a trusted partner for manufacturers seeking reliable and efficient roll slitting solutions.The automatic roll slitter from [Company] has garnered positive feedback from clients across various industries. The machine's combination of precision, versatility, and user-friendly operation has significantly improved their manufacturing processes, leading to increased efficiency and quality in their end products. For businesses looking to stay competitive in today's fast-paced market, the automatic roll slitter has proven to be a valuable asset for driving success and growth.[Company] continues to innovate and enhance its automatic roll slitter solutions, leveraging the latest technologies and industry best practices. As the manufacturing landscape evolves, the company remains at the forefront, delivering cutting-edge solutions that empower its clients to achieve their production objectives with confidence and ease.In conclusion, the automatic roll slitter from [Company] is a game-changer for manufacturers seeking to elevate their production capabilities. With its precision cutting, versatility, and user-friendly design, the machine offers a competitive edge in today's dynamic market. As [Company] continues to set the standard for roll slitting solutions, businesses can rely on its expertise and commitment to driving their success.

High-quality Cold Roller Former for Efficient Metal Processing

Cold Roller Former, a cutting-edge technology developed by a leading manufacturing company, is making waves in the industry with its innovative and efficient cold rolling process. This revolutionary machine is designed to shape metallic materials into various components, providing a cost-effective and high-quality solution for a wide range of applications.The cold rolling process is a critical step in metal forming, as it helps to improve the surface finish and mechanical properties of the material. Unlike traditional hot rolling, cold rolling occurs at room temperature, which results in a smoother and more precise finish. This method is particularly important for industries such as automotive, aerospace, and construction, where the quality and integrity of the metal components are paramount.With the introduction of Cold Roller Former, manufacturers can now benefit from a streamlined and advanced cold rolling process. This machine is equipped with state-of-the-art technology, including precision control systems and high-speed capabilities, allowing for the efficient production of complex and high-quality components. Additionally, its modular design and customizable features make it adaptable to various production needs, providing flexibility and versatility to manufacturers.One of the key advantages of Cold Roller Former is its ability to produce parts with tighter tolerances and improved surface finish, resulting in higher precision and quality. This is particularly beneficial for industries that require components with intricate geometries and superior mechanical properties. With Cold Roller Former, manufacturers can achieve a level of consistency and accuracy that is not possible with traditional cold rolling methods, leading to enhanced product performance and reliability.Furthermore, Cold Roller Former is designed with efficiency in mind, offering a significant increase in productivity and cost savings for manufacturers. Its high-speed capabilities and advanced control systems enable faster production cycles and reduced material waste, resulting in a more streamlined and economical manufacturing process. This not only helps to improve the overall competitiveness of manufacturers but also contributes to a more sustainable and environmentally friendly production environment.In addition to its technological advancements, Cold Roller Former is backed by a dedicated team of experts who provide comprehensive support and expertise to ensure the successful implementation and operation of the machine. From initial consultation to ongoing maintenance and training, the company's commitment to customer satisfaction and knowledge sharing sets a new standard for excellence in the industry.As a testament to its success, Cold Roller Former has already made significant strides in the market, garnering attention and accolades from industry experts and customers alike. Its proven track record of delivering superior performance, cost-effectiveness, and reliability has positioned it as the go-to solution for manufacturers seeking to elevate their cold rolling capabilities.Looking ahead, the company is committed to further advancing and enhancing Cold Roller Former to meet the evolving needs of the industry. With ongoing research and development efforts, the company is dedicated to pushing the boundaries of cold rolling technology, ultimately redefining the standards of excellence and innovation in metal forming.In conclusion, Cold Roller Former represents a significant breakthrough in cold rolling technology, offering a game-changing solution for the manufacturing industry. With its advanced capabilities, efficiency, and reliability, this revolutionary machine is poised to shape the future of cold rolling and set a new benchmark for excellence in metal forming.

High-Quality Glazed Roofing Sheet Roll Forming Machine for Color Steel

Color Steel Glazed Roofing Sheet Roll Forming Machine Revolutionizes Manufacturing ProcessWith the increasing demand for high-quality roofing materials, the construction industry has seen a significant rise in the use of color steel glazed roofing sheets. These sheets are not only durable and aesthetically pleasing, but also provide excellent insulation and weather resistance. To meet the growing demand for these roofing sheets, a leading manufacturing company has recently introduced a state-of-the-art color steel glazed roofing sheet roll forming machine.This cutting-edge machine is designed to revolutionize the manufacturing process of color steel glazed roofing sheets. It is equipped with advanced technology and precision engineering, allowing for the seamless production of high-quality roofing sheets with minimal human intervention. The machine is capable of producing a wide range of roofing sheet profiles, with customizable options to meet the specific requirements of construction projects.The company behind this innovative machine has been a pioneer in the manufacturing industry for over two decades. With a strong focus on research and development, they have consistently introduced groundbreaking technologies to improve the efficiency and quality of their products. This latest addition to their lineup is a testament to their commitment to innovation and excellence.In addition to its advanced technology, the color steel glazed roofing sheet roll forming machine is also designed with environmental sustainability in mind. It is equipped with energy-efficient components and utilizes recycled materials in the production process, reducing its overall carbon footprint. This aligns with the company's dedication to environmentally responsible manufacturing practices.Furthermore, the machine’s user-friendly interface and automation capabilities make it easy to operate and maintain. With minimal training, operators can quickly master the machine, ensuring a smooth and efficient production process. This not only saves time and labor costs but also enhances overall productivity.The introduction of the color steel glazed roofing sheet roll forming machine is expected to have a significant impact on the construction industry. With its ability to produce high-quality roofing sheets at a faster rate, construction projects can be completed more efficiently, saving time and resources. Additionally, the customizable options offered by the machine allow for greater design flexibility, catering to the diverse needs of architects and builders.The company's CEO expressed his excitement about the launch of the new machine, stating, "We are incredibly proud to introduce this groundbreaking technology to the market. Our color steel glazed roofing sheet roll forming machine represents a major advancement in the manufacturing process, and we believe it will greatly benefit the construction industry. We are confident that this machine will set a new standard for roofing sheet production and greatly contribute to the growth and development of the industry."As the construction industry continues to evolve, the demand for high-quality roofing materials will only increase. The introduction of the color steel glazed roofing sheet roll forming machine is a testament to the company's commitment to meeting this demand with cutting-edge technology and innovative solutions.In conclusion, the launch of the color steel glazed roofing sheet roll forming machine represents a significant milestone in the manufacturing industry. With its advanced technology, environmental sustainability, and user-friendly design, this machine is poised to revolutionize the production of roofing sheets and contribute to the advancement of the construction industry. As the company continues to lead the way in innovation, we can expect to see further advancements that will shape the future of manufacturing.

Highly Efficient Steel Sheet Roller Forming Machine for Automated Production

Automatic Steel Sheet Roller Forming MachineIn the world of industrial machinery, the demand for efficiency and precision is constantly increasing. This has led to the development of advanced technology that can streamline production processes and improve the overall quality of output. One such advancement is the Automatic Steel Sheet Roller Forming Machine, which has been making waves in the manufacturing industry for its ability to produce high-quality steel sheet products with unparalleled accuracy and speed.The Automatic Steel Sheet Roller Forming Machine, developed by [Company Name], is a cutting-edge piece of equipment that is designed to revolutionize the way steel sheets are manufactured. With its advanced automation and precise control systems, this machine is capable of processing steel sheets with utmost precision and consistency, delivering products of superior quality while minimizing human error.The machine is equipped with a set of rollers that are designed to bend and shape steel sheets with extreme precision. These rollers are powered by a high-performance motor and are controlled by a sophisticated computer system that ensures every bend and fold is executed with utmost accuracy. This level of precision allows for the creation of complex and intricate steel sheet products that meet the highest standards of quality and craftsmanship.In addition to its precision, the Automatic Steel Sheet Roller Forming Machine is also designed for efficiency. Its advanced automation capabilities allow for seamless operations, reducing the need for manual intervention and increasing productivity. This means that manufacturers can produce a higher volume of steel sheet products in a shorter amount of time, ultimately improving their overall output and profitability.To further enhance its efficiency, the machine is also equipped with a user-friendly interface that allows operators to easily program and control its operations. This intuitive interface simplifies the machine's setup and operation, making it accessible to a wide range of operators with varying levels of experience and expertise.Moreover, the Automatic Steel Sheet Roller Forming Machine is also designed for versatility. It is capable of producing a wide range of steel sheet products, from simple bends and folds to more intricate and complex designs. This flexibility allows manufacturers to meet the diverse needs of their customers and expand their product offerings, ultimately enhancing their competitiveness in the market.[Company Name] is a leading manufacturer of industrial machinery, with a strong focus on innovation and quality. With a track record of delivering cutting-edge solutions to the manufacturing industry, [Company Name] has established itself as a trusted partner for businesses seeking to enhance their production processes and streamline their operations.The development of the Automatic Steel Sheet Roller Forming Machine is a testament to [Company Name]'s commitment to driving innovation in the manufacturing industry. By leveraging its expertise in industrial machinery and technology, [Company Name] has succeeded in developing a state-of-the-art solution that is set to redefine the way steel sheet products are manufactured.With its precision, efficiency, and versatility, the Automatic Steel Sheet Roller Forming Machine represents a significant leap forward in the manufacturing industry. It promises to revolutionize the production of steel sheet products, offering manufacturers a competitive edge in delivering high-quality products with unparalleled precision and speed.As the demand for high-quality steel sheet products continues to grow, the Automatic Steel Sheet Roller Forming Machine is poised to become an indispensable tool for manufacturers seeking to meet the evolving needs of the market. With its advanced technology and cutting-edge capabilities, this machine is set to transform the way steel sheets are manufactured, setting new standards for quality, efficiency, and productivity in the industry.

High-Quality Corrugated Roll Making Machine for Your Business

In the world of packaging and manufacturing, the demand for high-quality corrugated rolls is on the rise. As a result, the need for efficient and reliable corrugated roll making machines has become essential for companies looking to meet this demand. One company that has consistently met this need is {company name}, a leading manufacturer of corrugated roll making machines.With a history of innovation and dedication to excellence, {company name} has established itself as a trusted name in the industry. Their commitment to providing state-of-the-art machinery and exceptional service has set them apart from the competition. As a result, they have become the go-to choice for companies looking to invest in a corrugated roll making machine.One of {company name}'s standout offerings is their cutting-edge Corrugated Roll Making Machine, which is designed to deliver superior performance and efficiency. This machine is capable of producing high-quality corrugated rolls with precision and speed, making it an invaluable asset for companies looking to optimize their manufacturing processes.The {company name} Corrugated Roll Making Machine is equipped with advanced technology and features that set it apart from other machines on the market. The machine's robust construction and durable components ensure long-term reliability and consistent performance. Additionally, its user-friendly interface and intuitive controls make it easy to operate and maintain, minimizing downtime and maximizing productivity.Another key advantage of {company name}'s Corrugated Roll Making Machine is its versatility. Whether it's producing single-face, double-face, or triple-wall corrugated rolls, this machine can handle a wide range of applications with ease. This flexibility ensures that companies can meet the varied needs of their customers while maintaining high standards of quality.Furthermore, the {company name} Corrugated Roll Making Machine is designed with efficiency in mind. Its automated processes and precision engineering result in minimal material waste and optimal use of resources. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, a factor that is increasingly important to today's environmentally conscious consumers.In addition to the machine's impressive capabilities, {company name} is renowned for its exceptional customer support and service. From installation and training to ongoing maintenance and technical assistance, they are committed to ensuring that their customers get the most out of their investment. This level of support is a testament to {company name}'s dedication to forging long-lasting partnerships with their clients.The combination of cutting-edge technology, superior performance, and reliable support has made the {company name} Corrugated Roll Making Machine a standout choice for companies around the world. Whether it's a large-scale packaging operation or a smaller manufacturing facility, this machine has proven to be a game-changer for businesses seeking to streamline their production processes and deliver top-quality corrugated rolls to their customers.As the demand for corrugated packaging continues to grow, having the right machinery in place is crucial for companies looking to stay competitive. With {company name}'s Corrugated Roll Making Machine, businesses can be confident in their ability to meet this demand with efficiency, precision, and reliability, setting the stage for continued success and growth.In conclusion, the {company name} Corrugated Roll Making Machine represents the pinnacle of innovation and excellence in the industry. Its advanced technology, unmatched performance, and unwavering commitment to customer satisfaction make it the ideal choice for companies looking to invest in a high-quality corrugated roll making machine. With {company name} as a trusted partner, companies can be confident in their ability to meet the evolving needs of the market while achieving new levels of success.

Automatic Reinforcement Iron Bar Making Machine: Everything You Need to Know

Ibr Making Machine: Revolutionizing the Roofing IndustryIn the world of construction and roofing, innovation and technology play a vital role in improving efficiency and quality of work. One such innovation that has recently been making waves in the industry is the Ibr Making Machine. This state-of-the-art machine is changing the way roofing materials are manufactured and is set to revolutionize the roofing industry as we know it.The Ibr Making Machine, produced by a leading manufacturing company in the field of construction machinery, is a fully automated, high-speed machine that is capable of producing a wide range of roofing materials with precision and efficiency. From galvanized steel to aluminum, the machine can effortlessly handle various materials, ensuring versatility and high quality in the final products.One of the key features of this machine is its ability to produce IBR (Inverted Box Rib) profiles, a popular choice for roofing material due to its strength and durability. The machine's precision rollers and cutting mechanisms ensure that each sheet produced is of consistent quality and precise dimensions, meeting the highest standards in the industry. This consistency is crucial for roofing projects, as it ensures a seamless and watertight installation, ultimately leading to greater customer satisfaction and long-lasting roofs.Furthermore, the Ibr Making Machine is equipped with advanced technology that allows for seamless customization of roofing materials. This means that contractors and builders can easily adjust the dimensions, thickness, and even colors of the roofing sheets to suit the specific requirements of each project. This level of customization not only provides flexibility but also reduces material waste, ultimately leading to cost savings for the roofing companies and their clients.The company behind the Ibr Making Machine prides itself on its commitment to innovation and quality. With a team of experienced engineers and technicians, the company has dedicated extensive resources to research and development, ensuring that their machines are at the forefront of technological advancements in the industry. In addition, the company places great emphasis on customer service and support, ensuring that their clients are well-trained and supported in the operation and maintenance of the machines.The impact of the Ibr Making Machine on the roofing industry has been profound. Many roofing companies that have adopted this technology have reported significant improvements in their production processes, from faster turnaround times to higher quality products. The machine's efficiency has also allowed these companies to take on larger and more complex projects, expanding their business and ultimately improving their bottom line.Moreover, the Ibr Making Machine has had a positive environmental impact as well. By reducing material waste and energy consumption, the machine contributes to sustainable and eco-friendly manufacturing practices, aligning with the global push for greener and more sustainable construction methods.As the demand for high-quality roofing materials continues to grow, the Ibr Making Machine is poised to become an indispensable asset for roofing companies around the world. Its ability to produce top-notch roofing materials with speed, efficiency, and customization capabilities make it a game-changer in the industry. With the backing of a reputable and innovative manufacturing company, the Ibr Making Machine is set to shape the future of roofing, providing solutions that meet the evolving needs of the construction industry.

Standing Seam Metal Roof Roll Former - A Must-Have for Roofing Professionals

Standing Seam Metal Roof Roll Former Revolutionizes Metal Roofing IndustryMetal roofing has always been a popular choice for commercial and industrial buildings, thanks to its durability and longevity. However, the installation process has often been time-consuming and labor-intensive, requiring skilled labor and a considerable amount of effort. This has caused some builders and property managers to shy away from metal roofing in favor of other materials.However, all of this is about to change with the introduction of the innovative Standing Seam Metal Roof Roll Former from (company name). This revolutionary piece of equipment has the potential to completely transform the metal roofing industry, making the installation process faster, more efficient, and more cost-effective than ever before.The Standing Seam Metal Roof Roll Former is a state-of-the-art machine that is designed to produce standing seam metal roofing panels on-site. This eliminates the need for pre-fabricated panels, which are often costly to transport and can be challenging to maneuver and install. With this roll former, contractors can produce custom metal roofing panels of any length directly at the job site, resulting in a quicker and more streamlined installation process.One of the key features of the Standing Seam Metal Roof Roll Former is its ability to produce panels with precise and consistent dimensions, ensuring a tight and secure fit that minimizes the risk of leaks and other issues. This level of precision is crucial for the long-term performance of the roof, as it helps to maintain the integrity of the building and protect it from water damage.In addition to its efficiency and precision, the Standing Seam Metal Roof Roll Former is also incredibly versatile. It can be used to produce a wide range of panel profiles, allowing contractors to offer their clients a variety of design options. Whether a building owner is looking for a sleek and modern appearance or a more traditional look, this roll former can deliver the perfect solution.Furthermore, the Standing Seam Metal Roof Roll Former from (company name) is designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to a wide range of contractors and roofing professionals. This accessibility opens up new opportunities for smaller companies and contractors who may not have had the resources to invest in traditional metal roofing equipment.The introduction of the Standing Seam Metal Roof Roll Former is a game-changer for the metal roofing industry, and (company name) is proud to be at the forefront of this innovative technology. With this roll former, the company is committed to helping contractors and property owners take advantage of the many benefits of metal roofing, including its durability, energy efficiency, and low maintenance requirements.The company has a long history of providing high-quality metal roofing solutions, and the Standing Seam Metal Roof Roll Former is the latest addition to its lineup of cutting-edge products. With a focus on innovation and customer satisfaction, (company name) is dedicated to pushing the boundaries of what is possible in the metal roofing industry.As the demand for metal roofing continues to grow, the introduction of the Standing Seam Metal Roof Roll Former couldn't have come at a better time. It represents a significant step forward for the industry, making metal roofing more accessible and desirable than ever before. With this innovative technology, the future of metal roofing looks brighter than ever, and (company name) is proud to be leading the way.

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

The Ultimate Guide to Color Steel Roofing Roll Forming Machines

Color Steel Roofing Roll Forming Machine is providing a revolutionary solution in the roofing industry, offering a high-quality and efficient method for producing steel roofing panels. With state-of-the-art technology and advanced manufacturing processes, this machine is set to redefine the standards for roofing production.The Color Steel Roofing Roll Forming Machine is designed to produce roofing panels with precision and speed. It is equipped with a series of rollers and other essential components that enable it to efficiently roll and shape steel coils into roof panels of various sizes and designs. This automated process ensures that the panels are produced with consistent quality and accuracy, meeting the industry's stringent standards.The machine's capabilities extend to a wide range of roofing profiles, including corrugated, trapezoidal, and standing seam designs, offering versatility to cater to different customer requirements. With its programmable control system, operators can easily adjust the machine settings to produce panels of different dimensions and specifications, providing flexibility in meeting the diverse demands of the market.One of the key features of the Color Steel Roofing Roll Forming Machine is its high production capacity. The machine is capable of producing roofing panels at a rapid pace, significantly increasing the output of a production facility. This efficiency not only reduces production time but also lowers labor costs, making it a cost-effective solution for roofing manufacturers.In addition to its efficiency, the Color Steel Roofing Roll Forming Machine is also known for its durability and reliability. Constructed with high-quality materials and built to withstand the rigors of continuous operation, this machine is designed for long-term use, ensuring a dependable solution for roofing panel production.The company behind the Color Steel Roofing Roll Forming Machine, (remove brand name), is a renowned leader in the manufacturing of roll forming equipment. With years of experience and expertise in the industry, the company has garnered a reputation for delivering innovative and high-performance machines that meet the evolving needs of the market.At the heart of the company's success is its commitment to technological advancement and product development. (remove brand name) employs a team of skilled engineers and technicians who work tirelessly to design and engineer cutting-edge solutions for the roll forming industry. This dedication to research and development has enabled the company to stay ahead of the competition and deliver state-of-the-art machines like the Color Steel Roofing Roll Forming Machine.Furthermore, (remove brand name) places a strong emphasis on quality control and customer satisfaction. Every machine that leaves their facility undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. Additionally, the company provides comprehensive training and support to its customers, ensuring that they can maximize the potential of their machines and achieve optimal results in their production processes.The introduction of the Color Steel Roofing Roll Forming Machine represents a significant leap forward in the roofing industry. With its advanced technology, high production capacity, and exceptional reliability, this machine is poised to transform the way roofing panels are manufactured, setting new benchmarks for efficiency and quality.As the market continues to demand superior roofing solutions, the Color Steel Roofing Roll Forming Machine stands as a testament to (remove brand name)'s commitment to innovation and excellence. With its proven track record and dedication to customer satisfaction, (remove brand name) is set to remain a leading force in the roll forming industry, continually pushing the boundaries of what is possible in roofing production.