Efficient Sheet Roll Forming Solutions for Your Business

By:Admin

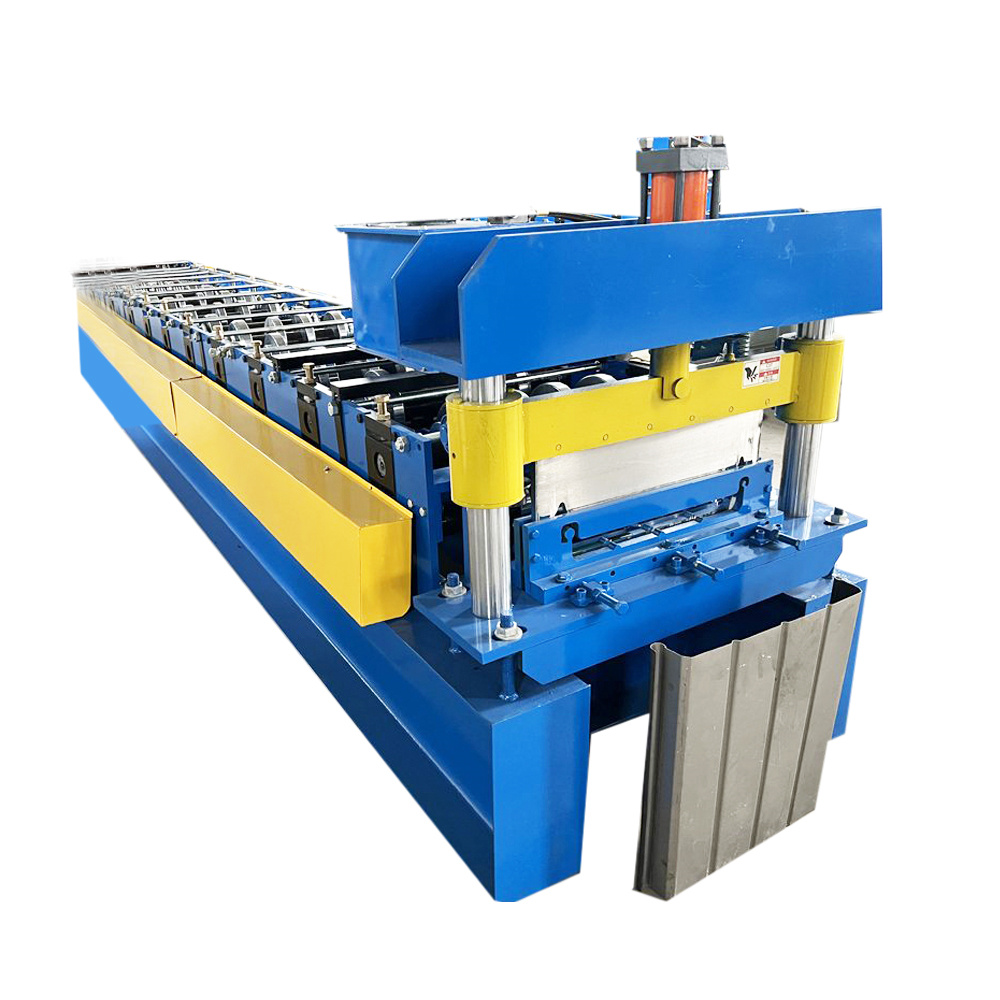

Metal fabrication has long been an essential part of the manufacturing industry, with various methods and technologies continually evolving to meet the increasing demands of modern production. One such innovation is the sheet roll forming process, a highly efficient and versatile method that has revolutionized the way metal sheets are manipulated and shaped.

Sheet roll forming involves feeding a metal sheet through a series of roll forming stations, where it is gradually bent, shaped, and formed into the desired profile. Unlike traditional metal fabrication methods such as cutting, stamping, or punching, sheet roll forming allows for continuous and precise shaping of the metal, resulting in a superior quality of the finished product.

The process begins with a flat metal sheet being fed into the first set of rolls, where it is gradually bent and formed into the desired shape. As the sheet progresses through each roll forming station, additional features such as holes, slots, and flanges can be added, resulting in a fully formed and customized metal component. The entire process is controlled by a series of precision-engineered rollers and dies, ensuring that the final product meets the exact specifications of the design.

The advantages of sheet roll forming are numerous, making it an indispensable tool for a wide range of industries. Due to its ability to produce complex and intricate shapes with minimal waste, sheet roll forming is highly cost-effective and can significantly reduce manufacturing time and labor costs. Additionally, the process allows for the use of a variety of metals, including steel, aluminum, and copper, further expanding its applicability across different industries.

The benefits of sheet roll forming are not lost on the manufacturing industry, prompting companies to invest in state-of-the-art roll forming equipment to capitalize on its advantages. One such company that has embraced sheet roll forming is {}, a leading provider of metal fabrication solutions. With a strong focus on innovation and technology, {} has integrated sheet roll forming into its manufacturing processes, allowing for the production of highly intricate and customized metal components.

{}'s sheet roll forming capabilities have enabled the company to expand its product offerings and cater to a wider range of industries, including automotive, construction, and aerospace. By leveraging the efficiency and precision of sheet roll forming, {} has been able to meet the exacting requirements of its customers, delivering high-quality metal components that meet or exceed industry standards.

In addition to its manufacturing capabilities, {} has also invested in research and development to further enhance its sheet roll forming processes. By staying at the forefront of technological advancements, {} continues to push the boundaries of metal fabrication, offering innovative solutions that address the evolving needs of the industry.

As the demand for complex and customized metal components continues to grow, sheet roll forming is poised to play a pivotal role in shaping the future of metal fabrication. With its ability to produce high-quality, intricate, and cost-effective metal components, sheet roll forming has become an indispensable tool for manufacturers seeking to stay ahead in a competitive marketplace.

In conclusion, sheet roll forming represents a significant advancement in metal fabrication, offering unparalleled efficiency, precision, and versatility. With companies like {} at the forefront of this technology, the future of metal fabrication looks promising, as sheet roll forming continues to drive innovation and excellence in manufacturing.

Company News & Blog

High-Quality Metal Slitting Line for Sale – Different Gauges Available at SteelSlitter.com

RISHBIN Emerges as a Leading Slitting Line Machine Manufacturer Offering High-Quality Metal Slitting Line for SaleIn the dynamic world of manufacturing, industries are constantly seeking efficient and reliable solutions to meet their production needs. RISHBIN, a prominent player in the market, has emerged as one of the best slitting line machine manufacturers, offering high-quality metal slitting lines for sale. With a wide range of machines catering to different gauge requirements, RISHBIN continues to revolutionize the industry with its cutting-edge technology and exceptional product offerings.Slitting lines are a vital component of the metal processing industry, enabling precise cutting and resizing of coils into narrower widths. When it comes to manufacturing slitting line machines, RISHBIN stands out for its commitment to delivering superior quality and innovative features. With an experienced team of engineers and technicians, the company is at the forefront of technological advancements, ensuring that their machines meet the highest industry standards.RISHBIN's metal slitting lines are designed to handle various gauge requirements, ensuring flexibility and versatility for a wide range of applications. The availability of machines suitable for light, medium, and heavy gauge materials makes RISHBIN the go-to manufacturer for businesses operating in diverse sectors. Whether it's the automotive, construction, or packaging industry, RISHBIN's slitting lines provide optimal performance and accuracy.What sets RISHBIN apart from its competitors is its continuous focus on research and development. The company invests heavily in innovation, constantly enhancing its product offerings to meet evolving industry demands. By staying up-to-date with the latest technological advancements, RISHBIN ensures that its slitting line machines provide the most efficient and reliable solutions for its customers.In addition to its dedication to quality and innovation, RISHBIN is also renowned for its exceptional customer service. The company believes in establishing long-term relationships with its clients, prioritizing their needs and exceeding their expectations. RISHBIN's team of experts assists customers throughout the entire purchasing process, offering valuable guidance and support to help them make informed decisions.RISHBIN's commitment to quality and customer satisfaction is further reflected in its post-sales services. The company offers comprehensive maintenance and technical support to ensure that its machines continue to perform optimally throughout their lifespan. By providing timely servicing and spare parts availability, RISHBIN helps its customers maximize their productivity and minimize downtime.With its robust manufacturing capabilities, RISHBIN ensures that each slitting line machine is crafted to perfection. The company utilizes high-quality materials and rigorous quality control processes to guarantee the durability and efficiency of its products. RISHBIN's metal slitting lines are built to withstand heavy usage and deliver consistent performance, making them a reliable investment for businesses looking to enhance their manufacturing processes.As a socially responsible organization, RISHBIN is committed to sustainability and environmentally friendly practices. The company implements energy-efficient measures throughout its manufacturing processes, reducing its carbon footprint and promoting a greener future. By choosing RISHBIN's slitting line machines, customers not only benefit from high performance but also contribute to global sustainability efforts.In conclusion, RISHBIN has established itself as a leading slitting line machine manufacturer by delivering high-quality solutions tailored to different gauge requirements. With its focus on innovation, customer service, and sustainability, RISHBIN continues to drive the industry forward. As businesses strive for excellence in their manufacturing processes, RISHBIN's metal slitting lines emerge as the ideal choice, ensuring efficiency, accuracy, and long-term reliability.

How to Choose the Best Wall Panel Roll Forming Machine for Your Color Steel Project

Color Steel Wall Panel Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has witnessed a remarkable transformation. With the introduction of advanced technology and machinery, the process of constructing buildings has become faster, more efficient, and cost-effective. Among these technological advancements, the Color Steel Wall Panel Roll Forming Machine stands out as a game-changer, revolutionizing the construction industry.The Color Steel Wall Panel Roll Forming Machine, developed by a leading company in the field of construction machinery manufacturing, has become the go-to solution for producing high-quality steel wall panels. These panels are widely used in various applications, including residential, commercial, and industrial constructions.The machine excels in transforming raw materials into precisely shaped steel wall panels, ensuring uniformity and durability. Its automated system enables a seamless and continuous production process, eliminating the need for manual intervention and reducing the chances of errors. This streamlined process not only saves time but also greatly improves the overall efficiency of construction projects.One of the key factors that sets the Color Steel Wall Panel Roll Forming Machine apart is its ability to produce a wide range of panel profiles. Whether the construction project requires corrugated panels, trapezoidal panels, or any other specific profile, this machine can meet the diverse needs of builders and architects. This versatility allows for greater design flexibility and enables construction professionals to create unique structures that stand out from the crowd.Moreover, the Color Steel Wall Panel Roll Forming Machine ensures superior product quality. By employing advanced hydraulic and electrical components, the machine guarantees precision and accuracy in every step of the production process. The panels produced are of high strength, weather resistance, and thermal insulation, making them ideal for both exterior and interior applications. This high-quality output not only enhances the overall aesthetics of buildings but also offers long-lasting protection against harsh environmental conditions.Additionally, the Color Steel Wall Panel Roll Forming Machine contributes to sustainable construction practices. The machine's energy-efficient operation minimizes power consumption, reducing the overall carbon footprint of construction projects. Furthermore, the use of steel wall panels eliminates the need for traditional construction materials like bricks and cement, which require extensive natural resources during their production. This eco-friendly approach aligns with the growing global emphasis on sustainable development and supports the construction industry's efforts to reduce environmental impact.In line with its commitment to customer satisfaction, the company behind the Color Steel Wall Panel Roll Forming Machine also offers comprehensive after-sales services. A team of experienced technicians provides installation guidance, training programs, and maintenance support to ensure the smooth operation of the machine throughout its lifespan. This commitment to customer support has established the company as a reliable partner in the construction industry, attracting clients from all around the world.As the demand for efficient and sustainable construction practices continues to rise, the Color Steel Wall Panel Roll Forming Machine has emerged as an indispensable tool for builders and architects. Its ability to produce high-quality steel wall panels with precision, versatility, and efficiency has transformed the construction industry. By investing in this innovative machine, construction professionals can streamline their operations, reduce costs, and contribute to a greener future.In conclusion, the Color Steel Wall Panel Roll Forming Machine has revolutionized the construction industry, offering a superior and sustainable solution for producing steel wall panels. Its advanced technology, versatility, and commitment to customer support have made it a staple in modern construction practices. As the industry continues to evolve, the importance of embracing innovative machinery like the Color Steel Wall Panel Roll Forming Machine cannot be overstated. This powerful tool is reshaping the way we build, enabling architects and builders to bring their creative visions to life while improving efficiency and sustainability.

Manufacture Machine for Glazed Tiles: Roll Forming and Forming Machines from China

Title: Revolutionizing Tile Manufacturing with the Color Steel Glazed Metal Tile Sheet Corrugation MachineIntroduction:In the dynamic landscape of modern construction, the demand for aesthetically pleasing tiles has surged exponentially. This has prompted the development of innovative manufacturing techniques, such as the Color Steel Glazed Metal Tile Sheet Corrugation Machine from Cangzhou Dixin Roll Forming Machine Co., Ltd (brand name omitted). This groundbreaking machinery has revolutionized the process of producing glazed tiles, offering enhanced efficiency, and superior quality. Let's delve into the features and benefits of this advanced roll forming technology.1. Understanding the Glazed Tiles Making Manufacture Machine:The Color Steel Glazed Metal Tile Sheet Corrugation Machine is a state-of-the-art roll forming machine designed to fabricate glazed tiles efficiently and precisely. This advanced technology is equipped with cutting-edge features that simplify the production process, ensuring the manufacture of high-quality glazed tiles.2. High-Speed Production:One of the key advantages of this machine is its remarkable production speed. By integrating cutting-edge automation and intelligent controls, the machine excels in generating an extensive number of tiles within a short span of time. This high-speed production capability ensures timely completion of construction projects, meeting market demand and helping construction companies achieve cost-effectiveness.3. Superior Tile Quality:The Color Steel Glazed Metal Tile Sheet Corrugation Machine guarantees exceptional tile quality due to its advanced design and precision engineering. The machine ensures accurate dimensions, smooth finishes, and consistent color application. Its innovative technology enables the production of uniformly shaped and visually appealing glazed tiles. These high-quality tiles enhance the overall aesthetics of buildings, elevating their charm and value.4. Flexibility in Design:With the Color Steel Glazed Metal Tile Sheet Corrugation Machine, manufacturers can explore various design options, offering customers an expansive range of glazing patterns, colors, and dimensions. This flexibility in design allows for customization, meeting the diverse requirements of architects and homeowners alike. The machine's adaptability further enables the production of unique and exclusive tile designs, delivering a competitive edge in the market.5. Energy Efficiency:In an era where sustainable practices are gaining prominence, the Color Steel Glazed Metal Tile Sheet Corrugation Machine stands out due to its energy-efficient design. The machine's optimized power consumption and minimal material wastage contribute to the reduction of ecological footprints, making it an eco-friendly choice. By aligning with green building practices, manufacturers using this machine can enhance their brand image and fulfill their corporate social responsibilities.6. Durability and Longevity:With its robust construction and utilization of high-quality materials, this glazed tile manufacturing machine ensures durability and longevity. The machine's reliability minimizes downtime, reduces maintenance costs, and provides consistent performance over an extended period. Manufacturers can rely on this machinery to deliver exceptional results consistently, thereby optimizing their production output and profitability.Conclusion:The introduction of the Color Steel Glazed Metal Tile Sheet Corrugation Machine has revolutionized the realm of glazed tile manufacturing. Its cutting-edge features and advanced technology ensure high-speed production, superior quality tiles, design flexibility, energy efficiency, and longevity. By embracing this innovative machine, manufacturers can streamline their operations, gain a competitive advantage, and cater to the ever-growing demand for glazed tiles in the construction industry.Keywords: Color Steel Glazed Metal Tile Sheet Corrugation Machine, glazed tiles, manufacturing, roll forming machine, sustainable practices, design flexibility, high-speed production, superior tile quality, energy efficiency, durability.

Glazed Tile Roll Forming Machine: A Reliable Solution for Roofing Sheet Production

Title: Introducing Dahezb's Cutting-Edge Glazed Tile Roll Forming Machine for Metal RoofingIntroduction:In the fast-paced world of construction and manufacturing, technological advancements are constantly emerging to improve efficiency and quality. Dahezb Metal presents its latest innovation, the Glazed Tile Roll Forming Machine, a state-of-the-art solution for producing metal roof tiles. With its ability to transform metal sheets into refined glazed roofing tiles, this machine proves to be a game-changer in the industry.Redefining Metal Roofing:Dahezb's Glazed Tile Roll Forming Machine is designed to cater to the specific needs of customers looking for robust metal roofing solutions. Capable of molding metal sheets ranging from 0.3mm to 0.6mm in thickness, this machine delivers top-notch precision and durability.Key Features and Benefits:1. Enhanced Efficiency: The Glazed Tile Roll Forming Machine operates with remarkable efficiency, allowing for smooth and continuous production. By eliminating the need for manual tile cutting, this machine saves time, labor, and material costs.2. Customized Solutions: Dahezb understands that every customer has unique requirements. Therefore, the Glazed Tile Roll Forming Machine offers flexibility in terms of tile shapes, sizes, and profiles. Whether it is a traditional or modern design, this machine can adapt to produce the desired glazed tiles for any roofing project.3. High-Quality Output: The Glazed Tile Roll Forming Machine ensures impeccable quality, maintaining consistency in tile thickness and dimensions. With precise control and advanced technology, it guarantees an aesthetically pleasing finish, giving metal roofing a sophisticated appeal.4. Durability: Metal roofs are known for their longevity, and the tiles produced by this machine are no exception. The Glazed Tile Roll Forming Machine manufactures tiles of exceptional strength, able to withstand harsh weather conditions and provide long-lasting protection.5. Advanced Automation: The machine's automation features streamline the production process, reducing the chances of human error. With user-friendly controls and easy-to-understand functions, operators can swiftly adapt to the machine's operations.6. Environmentally Friendly: Contributing to sustainable construction practices, the Glazed Tile Roll Forming Machine minimizes waste generated during production. By optimizing material usage and reducing scrap, it aligns with the industry's increasing focus on eco-friendly solutions.Growing Demand for Metal Roofing:The demand for metal roofing has been steadily rising due to its numerous advantages over traditional roofing materials. Metal roofs offer superior durability, remarkable energy efficiency, and significant cost savings in the long run. Additionally, they are fire-resistant and require minimal maintenance, making them an attractive choice for homeowners and businesses alike.Company Introduction: Dahezb Metal is a renowned manufacturer and provider of high-quality roll forming machines. Their expertise lies in designing and producing roofing and construction machinery that meets the evolving industry requirements. With a strong commitment to innovation and customer satisfaction, Dahezb Metal continues to be a trusted collaborator for businesses worldwide.Conclusion:With its cutting-edge Glazed Tile Roll Forming Machine, Dahezb Metal is revolutionizing the metal roofing industry. This advanced technology not only saves time and facilitates efficient production but also delivers outstanding quality and durability. As demands for eco-friendly and sustainable construction practices increase, Dahezb's Glazed Tile Roll Forming Machine stands as a valuable solution for any roofing project.

Steel Coil Slitting Line: Streamlining Precision Cutting and Efficiency in the Manufacturing Industry

Steel Coil Slitting Line is one of the most important machines for the steel industry. It is a machine that is used to cut large coils of steel into smaller strips of the required width. This process is necessary for various applications, such as manufacturing of pipes, tubes, metal sheets, and so on. In this regard, machine suppliers, including {brand name removed}, are vital for the steel industry.{Supplier name removed} is a leading supplier of steel processing machines that includes Steel Coil Slitting Line. The company is a prominent entity in the industry and has carved a niche for itself in the international market. It has established a reputation for quality, durability, and reliability, which has made the company a preferred choice for organizations that deal in the manufacture of steel products.The Steel Coil Slitting Line from {supplier name removed} is built to cater to the diverse needs of customers worldwide. It is designed with cutting-edge technology and equipment that makes it highly productive, efficient, and accurate. This machine is easy to operate and requires minimal maintenance, which further enhances its reliability and durability.Furthermore, this Steel Coil Slitting Line is versatile and capable of handling different types of steel coils. It can process various types of steel materials and thicknesses with ease. Its high precision and accuracy ensure that customers are provided with consistent cuts, which is crucial for the successful production of quality steel products.{Supplier name removed} understands the significance of customer satisfaction and strives to provide top-notch products and exceptional after-sales support to its customers. They have a team of experts who are always available to assist their clients, ranging from machine installation, training, maintenance, and upgrades.Steel Coil Slitting Line has numerous benefits that make it a necessary machine for the steel industry. Firstly, it allows for efficient utilization of steel coils, which reduces the cost of production and waste. Secondly, it is flexible and can accommodate different widths and thicknesses of coils, which offers flexibility in production processes. Thirdly, its high precision and accuracy ensure that customers receive products with consistent quality.In conclusion, Steel Coil Slitting Line is a vital machine for the steel industry. It facilitates efficient and consistent production processes, reduces waste, and enhances the overall quality of steel products. {Supplier name removed} is a renowned supplier of high-quality steel processing machines, and their Steel Coil Slitting Line is one of the best in the market. The company's commitment to excellence, reliability, and customer satisfaction makes them a preferred choice for organizations that require the best steel processing machines in the industry. With {supplier name removed}, customers can count on getting the best value for their investment in steel processing machines.

High-Quality New and Used Sheet Metal Machinery for the Industry

Title: Utilizing Sheet Metal Roll Forming for Efficient and Durable SolutionsIntroduction:In today's dynamic industrial landscape, the sheet metal industry plays a vital role in constructing sturdy and versatile products across various sectors. To ensure optimal results, it is crucial to have access to top-notch sheet metal machinery that guarantees precision, efficiency, and durability. In this blog, we will explore the advantages of sheet metal roll forming and shed light on its significance in creating high-quality products. Let's delve into the details!Understanding Sheet Metal Roll Forming:Sheet metal roll forming is a highly efficient process that involves bending and shaping metal sheets into desired profiles. This technique allows engineers and fabricators to create complex shapes and structures, such as panels, channels, tubes, and angles. By passing a continuous strip of metal through a series of rollers, roll forming ensures consistent dimensions throughout the entire length of the product, providing exceptional accuracy and uniformity.Benefits of Sheet Metal Roll Forming:1. Cost-Effective Production:One of the significant advantages of sheet metal roll forming is its cost-effectiveness. This process eliminates the need for multiple components, such as fasteners, welds, and adhesives. By shaping the metal into the desired form without additional attachments, roll forming minimizes production costs, reducing labor and material requirements.2. Enhanced Efficiency and Speed:Sheet metal roll forming provides a highly efficient and rapid production method. It enables continuous production without the need for frequent stops and starts. The machinery used in roll forming operates at high speeds, allowing for large volumes of products to be manufactured swiftly. This aspect is particularly beneficial for industries that require high production rates, meeting tight deadlines, and satisfying customer demands promptly.3. Durability and Structural Integrity:By utilizing sheet metal roll forming techniques, manufacturers can create products with exceptional strength and durability. The continuous bending process enhances the structural integrity of the metal, resulting in robust and long-lasting components. The consistency achieved through roll forming ensures that all parts produced possess identical specifications, eliminating variations that could compromise their durability.4. Versatility and Customizability:Sheet metal roll forming offers extensive possibilities for customization, allowing engineers to create a wide range of profiles and designs. With the ability to accommodate various metals, thicknesses, and widths, roll formers enable the production of intricate shapes with precise tolerances. This versatility makes roll forming suitable for diverse applications in industries such as automotive, construction, furniture, aerospace, and more.Keyword Placement:Now let's discuss the importance of incorporating relevant keywords within the blog to improve its search engine optimization (SEO). Keywords related to "Sheet Metal Roll Forming" should be strategically placed throughout the content, including in headings, subheadings, and body paragraphs. Additionally, ensure the keywords are naturally integrated within the text to maintain readability and avoid keyword stuffing.Conclusion:Sheet metal roll forming revolutionizes the manufacturing process by offering cost-effective production, enhanced efficiency, durability, and customization. By harnessing high-quality roll forming machinery, such as those provided by Benoit Sheet Metal Equipment, Inc., fabricators can create products that meet the highest standards of quality and precision. Whether you belong to the automotive, construction, or any other industry that relies on sheet metal, incorporating roll forming techniques can significantly elevate your manufacturing capabilities. Embrace the power of sheet metal roll forming and unlock a world of possibilities for your business!

High-Quality Metal Roll Forming Machine Available for Purchase – Roof Panel Roll Forming Machine Supplier

Machine, Roll Forming Machine, Roof Panel Roll Forming Machine, Metal Roll Forming, Forming Machine, Metal Roll, Metal Roll Forming Machine for Sale, Buy Metal Roll Forming Machine, Metal Roll Forming Machine Wholesaler, Metal Roll Forming Machine Seller, Top-quality Metal Roll Forming Machine, Benefits of Using Metal Roll Forming Machine, Roll Forming Process, Metal Roll Forming vs Other Forming Techniques, Applications of Metal Roll Forming Machine, Factors to Consider when Buying Metal Roll Forming Machine.Title: Advancing Manufacturing with Metal Roll Forming MachineIntroduction:In the ever-evolving manufacturing industry, metal roll forming machines have become an essential tool for efficiently producing high-quality metal components. This blog will explore the benefits of using metal roll forming machines, discuss the roll forming process, compare metal roll forming with other forming techniques, highlight the applications of metal roll forming machines, and provide insights on factors to consider when purchasing these machines.Benefit 1: Top-quality Metal ComponentsMetal roll forming machines offer superior precision and accuracy in producing metal components. The continuous bending process ensures consistent dimensions, smooth edges, and precise shapes across multiple pieces, resulting in high-quality finished products. Additionally, the ability to control forming speeds and pressures allows for the production of complex and intricate designs, meeting various industry specifications.Benefit 2: Cost-effective ProductionMetal roll forming machines facilitate cost-effective production due to their ability to handle high volumes of material with minimal wastage. By using coil stock material, roll forming eliminates the need for traditional sheet metal blanks, reducing material costs and minimizing scrap. Furthermore, the continuous operation of roll formers decreases labor requirements and enhances production efficiency, ultimately reducing overall manufacturing costs.Benefit 3: Versatile ApplicationsMetal roll forming machines find applications in various industries, including automotive, construction, aerospace, and furniture. These machines offer versatility in creating a wide range of metal profiles, such as roof panels, wall cladding, gutters, window frames, and door frames. The flexibility in material thickness, width, and length allows manufacturers to cater to diverse customer requirements and adapt to market trends effectively.Roll Forming Process:The roll forming process involves feeding coil stock material into a series of contoured rolls, gradually bending and shaping the metal. As the material moves through multiple stations, the rolls progressively form the desired profile. Each station performs a specific shaping operation, such as punching, notching, embossing, or cutting. By adjusting the roll spacing, manufacturers can achieve precise dimensions and shapes. The formed metal components are then cut to the desired length using a flying shear or cut-off press.Metal Roll Forming vs Other Forming Techniques:Compared to other forming techniques like stamping and press braking, metal roll forming offers several advantages. First, roll forming allows for continuous production with minimal interruptions, reducing operational downtime. Second, roll forming eliminates the need for pre-formed blanks or separate operations for joining multiple pieces, resulting in faster production cycles. Finally, roll-formed components exhibit improved structural integrity due to the continuous grain flow, enhancing their strength and durability.Applications of Metal Roll Forming Machines:1. Automotive Industry: Metal roll forming machines are widely used in manufacturing automotive body components, including chassis, roof rails, door frames, and window frames. The ability to produce complex profiles and maintain tight tolerances makes roll forming an ideal choice for this industry.2. Construction Industry: Roll-formed profiles for roofing panels, wall cladding, and structural components are in high demand in the construction sector. The cost-effectiveness and precision of metal roll forming machines make them indispensable for producing these architectural elements.3. Furniture Industry: Roll forming technology is employed in the production of metal furniture components like frame elements, brackets, and decorative fittings. The versatility and high-quality output of metal roll forming machines contribute to the aesthetic appeal and functionality of modern furniture designs.Factors to Consider when Buying Metal Roll Forming Machines:1. Machine Size and Capacity: Consider the required profile dimensions, thickness, and material type to ensure compatibility with the selected machine's specifications.2. Material Handling and Coil Weight: Evaluate the machine's ability to handle heavy coil stock material and ensure that it suits your production requirements.3. Tooling Flexibility: Check if the machine allows for easy changeovers between different profiles and if additional tooling options are available to expand its capabilities.4. Automation and Integration: Decide if integrating automation features, like computer numerical control (CNC) systems, is necessary to enhance production efficiency and reduce human error.5. After-sales Support: Research the reputation of the manufacturer and evaluate the availability of technical support, spare parts, and maintenance services.Conclusion:Metal roll forming machines offer numerous benefits, including top-quality production, cost-effectiveness, and versatility. The roll forming process, with its continuous bending and shaping, ensures consistent dimensions and smooth edges. Metal roll forming outperforms other forming techniques in terms of efficiency, structural integrity, and faster production cycles. These machines find applications in diverse industries like automotive, construction, and furniture manufacturing. When purchasing a metal roll forming machine, considering factors such as machine size, capacity, tooling flexibility, and after-sales support will help manufacturers make informed decisions and achieve optimal results in their production processes.

Optimize Your Production Efficiency with the Latest Roll Form Machine

[Publication Name] – [Date]Roll Form Machine: Shaping the Future of ManufacturingIn today's ever-evolving industrial landscape, precision and efficiency in manufacturing processes are paramount. Companies across various sectors constantly seek innovative solutions to enhance production quality and reduce costs. [Company Name], a leading player in the manufacturing industry, remains at the forefront of this drive for cutting-edge technology.With their groundbreaking development – the Roll Form Machine – [Company Name] has revolutionized the way industries shape metal sheets, opening new doors of opportunity for businesses worldwide. This state-of-the-art machinery combines advanced engineering and groundbreaking automation, resulting in unmatched precision, speed, and versatility.The Roll Form Machine developed by [Company Name] has garnered significant attention due to its ability to transform flat pieces of metal into complex profiles and shapes with remarkable precision. The machine utilizes a continuous process where the metal sheet is fed into the machine, and through a series of carefully designed rolling dies, it is gradually formed into the desired shape.One of the key advantages of the Roll Form Machine lies in its flexibility. With interchangeable rolling dies and adjustable settings, the machine can easily adapt to produce a wide range of profiles and shapes. This versatility eliminates the need for multiple specialized machines, streamlining production processes and reducing costs for manufacturers.Furthermore, the Roll Form Machine boasts a rapid production speed that sets it apart from traditional manufacturing methods. By utilizing automated processes, [Company Name] has significantly enhanced the efficiency of roll forming, enabling manufacturers to achieve higher volumes and faster turnarounds. This advantage becomes particularly crucial for industries with high production demands, such as automotive, construction, and appliance manufacturing.Additionally, the Roll Form Machine ensures exceptional precision and accuracy throughout the entire production process. With advanced sensors and feedback systems, [Company Name] has implemented stringent quality control measures to meet the most demanding industry standards. The machine's ability to consistently deliver high-quality products with minimized defects has garnered praise from manufacturers seeking to maintain an edge in an increasingly competitive market.[Company Name], renowned for its commitment to innovation, has integrated cutting-edge automation technologies into the Roll Form Machine. Through the use of sophisticated software and control systems, the machine enables seamless integration into existing manufacturing setups. This seamless integration allows for centralized control, simplifies maintenance, and optimizes production schedules, empowering manufacturers to achieve higher productivity and reduce downtime.Moreover, the Roll Form Machine prioritizes safety, addressing a critical concern in the manufacturing industry. [Company Name] has invested in comprehensive safety measures, including emergency stop mechanisms, safety guards, and employee training, ensuring a secure and user-friendly operating environment. By prioritizing safety, the company aims to minimize accidents, protect its workers, and bolster customer trust in their products.The Roll Form Machine has already gained recognition and adoption within the manufacturing industry, with prominent companies across various sectors embracing its capabilities. Its impact has been particularly notable in the construction sector, as it allows for the rapid production of complex and customized profiles required for modern architectural designs.[Company Name] remains committed to research and development, continuously improving and expanding the capabilities of the Roll Form Machine. By working closely with their customers, the company seeks to understand the ever-changing needs of the industry and develop tailored solutions that propel manufacturing processes into the future.As the industrial landscape advances towards automation and precision, the Roll Form Machine developed by [Company Name] emerges as a game-changer, revolutionizing the way manufacturers shape metal sheets. With its remarkable flexibility, speed, precision, and safety features, this cutting-edge machinery promises to reshape industries and unlock new possibilities for businesses worldwide.###[Word Count: 649]

Industrial Street Light Pole Machine/Equipment for Manufacturing Lamp Posts from China Manufacturer

Title: China Manufacturer Introduces Cutting-Edge Industrial Street Light Pole Making EquipmentIntroduction:As the demand for efficient and reliable street lighting continues to grow globally, manufacturers are seeking innovative solutions to meet these needs. In a significant development, a leading Chinese manufacturer has unveiled its state-of-the-art Industrial Street Light Pole Making Equipment, revolutionizing the production process for lamp posts. This machinery promises to enhance the quality, efficiency, and durability of light poles, ensuring safer and brighter streets in cities around the world.Innovative Features and Technologies:The newly introduced Industrial Street Light Pole Making Equipment integrates cutting-edge technologies and offers an array of impressive features. Employing advanced manufacturing techniques, the machine boasts enhanced precision and efficacy, guaranteeing superior quality lamp posts every time.One of the key features of this equipment is its automated operation, significantly reducing the risk of human error and improving overall production efficiency. Through the integration of computer-controlled programmable logic systems, the machine ensures precise bending, shaping, and cutting of the street light poles. Moreover, the production line can be easily customized to accommodate various pole designs, ensuring flexibility for diverse urban lighting requirements.With an emphasis on sustainability, the equipment optimizes energy consumption by incorporating smart energy-saving mechanisms. By utilizing energy-efficient motors and minimizing material wastage, this innovative machine helps conserve resources and reduce the project's environmental impact.Quality Assurance and Certification:Recognizing the critical role played by street light poles in ensuring public safety, the manufacturer has prioritized quality in their machinery. Compliance with international quality standards is ensured through rigorous testing and inspections at various stages of the production process.Furthermore, the manufacturer has obtained industry certifications from trusted authorities, highlighting its commitment to delivering reliable and durable products. These certifications serve as an assurance of the machinery's ability to withstand harsh weather conditions and provide long-lasting performance.Employment Opportunities and Local Economy Boost:The introduction of this top-of-the-line industrial equipment is set to stimulate economic growth by generating employment opportunities. The machinery requires skilled operators and technicians to ensure its smooth operation, creating job prospects within the region.Moreover, this venture contributes to the growth of the local economy. With the increased production of lamp posts, there will be a rise in the demand for raw materials and ancillary services. This, in turn, incentivizes local suppliers and service providers, supporting the overall development and prosperity of the region.Global Implications:The release of this Industrial Street Light Pole Making Equipment by a prominent Chinese manufacturer has implications that extend beyond the domestic market. As street lighting remains a crucial aspect of urban infrastructure worldwide, this efficient and cost-effective machine has the potential to revolutionize the industry on a broader scale.Exporting this advanced machinery to international markets allows cities worldwide to adopt high-quality light poles designed for durability, improved energy efficiency, and enhanced public safety. By investing in this innovative solution, municipalities can elevate the standard of their urban lighting infrastructure, positively impacting the quality of life for their citizens.Conclusion:The introduction of the Industrial Street Light Pole Making Equipment by this renowned Chinese manufacturer signifies a major breakthrough, reinforcing China's position as a global leader in industrial machinery. This cutting-edge technology promises to revolutionize the production of light poles worldwide, ensuring safer and brighter streets for urban populations and stimulating economic growth in the process. With its commitment to quality, sustainability, and innovation, this manufacturer is setting new benchmarks in the street lighting industry.