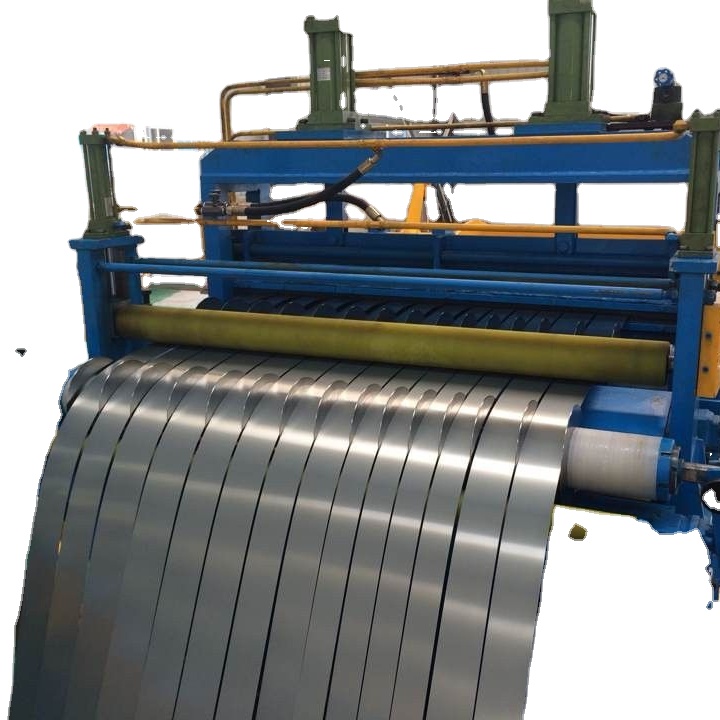

High-Quality Automatic Cut-To-Length Machine for Precision Cutting

By:Admin

The manufacturing industry is continuously evolving with the advancement of technology, and one company at the forefront of this evolution is {}. With a commitment to innovation and efficiency, they have recently introduced their latest addition to their production line – the Automatic Cut-To-Length Machine. This state-of-the-art machine is set to revolutionize the production process, offering precision, speed, and enhanced productivity.

The Automatic Cut-To-Length Machine is designed to streamline the process of cutting materials to specific lengths, catering to the diverse needs of various industries such as automotive, construction, and appliances. This machine is equipped with advanced features that enable it to effortlessly cut different materials including metals, plastics, and composites with utmost accuracy and consistency.

One of the key highlights of the Automatic Cut-To-Length Machine is its cutting-edge technology that allows for automated operation. This not only reduces the need for manual labor but also minimizes the margin of error, resulting in higher quality output. Additionally, with its rapid cutting speed, the machine significantly increases production efficiency, ultimately leading to cost savings for the company.

Furthermore, the Automatic Cut-To-Length Machine is integrated with intelligent software that enables precise customization and optimization of cutting processes. This ensures that the machine can meet the specific requirements of each customer, catering to a wide range of dimensions and tolerances. With such versatility, the machine offers a competitive edge in the market, allowing {} to provide tailored solutions to meet the unique demands of their clients.

In addition to its technical capabilities, the Automatic Cut-To-Length Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and ensuring seamless integration into the production line. This not only enhances the overall efficiency of the manufacturing process but also creates a safer working environment for the operators.

{} has a long-standing reputation for delivering high-quality, reliable machinery, and the introduction of the Automatic Cut-To-Length Machine is a testament to their commitment to continuous improvement and innovation. With a strong focus on research and development, the company has invested heavily in advancing their technological capabilities, ensuring that they remain at the forefront of the industry.

The launch of the Automatic Cut-To-Length Machine underscores {}'s dedication to meeting the evolving needs of their customers. By incorporating cutting-edge technology and automation into their production line, they are not only enhancing their own operational efficiency but also empowering their clients to achieve greater success in their respective industries.

Moreover, the introduction of the Automatic Cut-To-Length Machine aligns with {}'s long-term sustainability goals. By optimizing the cutting process and reducing material waste, the machine contributes to a more environmentally friendly manufacturing approach. This reflects {}'s commitment to conducting business in a responsible and ethical manner, prioritizing sustainability and resource efficiency.

With the introduction of the Automatic Cut-To-Length Machine, {} is poised to set new standards within the manufacturing industry. By leveraging cutting-edge technology and innovation, they are not just meeting the current demands of the market but also shaping the future of production processes. As the industry continues to evolve, {} remains dedicated to pushing boundaries and redefining what is possible in manufacturing.

Company News & Blog

High-Quality Color Steel Sheeting Roofing Panel Cold Roll Forming Machine - Efficient and Easy to Operate This hand-operated rolling machine is an affordable and reliable solution for producing high-quality color steel sheeting roofing panels. It boasts low energy consumption and a yield strength of 32MPa, making it ideal for small-scale production. The equipment includes a roll forming system, hydraulic cutter, hydraulic station, electric control system, counter, and product supporter. With a processing speed of 8m/min and thickness range of 0.3-1mm, this machine is efficient and easy to operate.

, Sheet Hand Operated Rolling Machine, Cold Roll Forming Machine, Roofing Panel Roll Forming Machine, Mechanical Kingdom.Sheet Hand Operated Rolling Machine - A Reliable and Low-Cost Solution for Color Steel Sheeting Roofing Panel ManufacturingThe sheet hand operated rolling machine is a cost-effective and efficient solution for manufacturing color steel sheeting roofing panels. With its reliable working mechanism, easy operation, and low energy consumption, the machine is an excellent choice for small to medium-scale manufacturing units.Certificate and SpecificationsThe sheet hand operated rolling machine adheres to the CE certification and comes with a 7.5 KW main motor power and 4 KW hydraulic station power. The machine's sprocket is P-25.4, with 20 roller station capacity, which can produce a yield strength of up to 32MPa. The diameter of the principal axis is 70mm, and the roller material is made of 45# steel hard chrome plating. The machine can process sheets with a thickness of 0.3-1mm and has an installation dimension of about (L*W*H) 10*1.5*0.8M.Functional Features and AdvantagesThe sheet hand operated rolling machine is designed with several functional features that make it a robust and reliable option for color steel sheeting roofing panel manufacturing. Some notable features include:Low-Cost and High Efficiency: The machine is a low-cost and high-efficiency solution that can complete the manufacturing process quickly and efficiently.Reliable Working Mechanism: The machine's working mechanism is reliable, ensuring that the quality of the products is consistent.Easy Operation: The machine is easy to operate, even for those with no prior experience in the field.Low Energy Consumption: The machine consumes minimal energy, making it an eco-friendly option that reduces the energy bills.Equipment PartsThe machine includes several equipment parts, including roll forming, hydraulic cutter, hydraulic station, electric controlling system, counter, and product supporter. These parts work together to ensure that the machine can produce high-quality color steel sheeting roofing panels.Manufacturers of Roll Forming MachinesMechanical Kingdom is a renowned manufacturer of roll forming machines, operating in this field for the past 12 years. They offer a wide range of products, including tile-crushing computer control systems, ancient glazed tile copy machines, Laura machines, beam-free arch making machines, great-span, and beam-free structure equipment, as well as motor car plate making machines.ConclusionIn conclusion, the sheet hand operated rolling machine is a reliable, low-cost, and efficient solution for color steel sheeting roofing panel manufacturing. With its easy operation, low energy consumption, and robust working mechanism, it is an excellent choice for small to medium-scale manufacturing units. Mechanical Kingdom is a reputable manufacturer of roll forming machines, offering a range of products that cater to various requirements.

High-Quality Floor Decking Roll Forming Machine Available in China - Wholesale and Export to Worldwide Market

and China Manufacturers.Floor decking roll forming machines are becoming increasingly popular in the construction industry. These machines are used to create floor decking panels, which are then used as a base for flooring systems in construction projects. These machines are capable of producing high-quality, consistent panels that are cost-effective and durable. If you are looking for a reliable and high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers.China manufacturers of floor decking roll forming machines offer a wide range of machines with varying specifications and features. These machines are designed to cater to the needs of various construction companies, ranging from small to large-scale operations. These machines are made using high-quality materials and are manufactured with precision, ensuring that they are durable and long-lasting. They are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity.When purchasing a floor decking roll forming machine from Chinese manufacturers, there are several important factors to consider. Firstly, you should consider the quality of the machine. You should look for machines that are made from high-quality materials and are manufactured with precision to ensure that the machine is durable and efficient. Secondly, you should consider the features and specifications of the machine. You should look for machines that have the features that you need for your specific business requirements. Finally, you should consider the price of the machine. You should look for machines that are competitively priced and offer good value for money.In conclusion, if you are in the market for a high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers. Chinese manufacturers offer a wide range of machines that are made using high-quality materials and are manufactured with precision to ensure that they are durable and efficient. These machines are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity. When purchasing a machine from China manufacturers, you should consider factors such as the quality of the machine, its features and specifications, and its price. With these factors in mind, you can find the perfect machine for your business needs.

Ultimate Guide to Horizontal Barrel Vault Panel Bending Machines

The leading manufacturer of sheet metal processing equipment, has recently launched its latest innovation, the Horizontal Barrel Vault Panel Bending Machine. This state-of-the-art machine is designed to meet the growing demand for efficient and precise panel bending in the construction and manufacturing industries.The Horizontal Barrel Vault Panel Bending Machine is a versatile and powerful tool that can handle a wide range of panel bending operations. It is equipped with advanced technology and features that enable it to bend large panels with extreme precision and accuracy. This machine is an ideal choice for fabricating curved panels that are used in various architectural and construction applications.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its horizontal design, which allows for easy loading and unloading of panels. This design also enables the machine to bend panels in a more efficient and consistent manner, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain.The company has a rich history of providing innovative and reliable sheet metal processing equipment to its customers. With over [number] years of experience in the industry, the company has built a strong reputation for delivering high-quality products and exceptional customer service. The launch of the Horizontal Barrel Vault Panel Bending Machine further demonstrates the company's commitment to meeting the evolving needs of its customers and the industry.In addition to its technical capabilities, the company is also known for its dedication to sustainability and environmental stewardship. The Horizontal Barrel Vault Panel Bending Machine is designed with energy-efficient features that help reduce power consumption and minimize its environmental impact. This commitment to sustainability aligns with the company's larger mission to develop innovative solutions that support a more sustainable and responsible manufacturing industry.The launch of the Horizontal Barrel Vault Panel Bending Machine has already generated significant interest and excitement within the industry. Many leading construction and manufacturing companies have expressed their eagerness to explore the capabilities of this new machine and incorporate it into their operations. The company is confident that the machine will make a positive impact on the industry and help its customers achieve new levels of productivity and efficiency.As the demand for curved panels continues to grow in the construction and architecture sectors, the Horizontal Barrel Vault Panel Bending Machine is expected to play a pivotal role in meeting this demand. Its advanced technology, user-friendly design, and commitment to sustainability make it a standout choice for companies looking to enhance their panel bending capabilities.The company is poised to continue its legacy of innovation and excellence with the launch of the Horizontal Barrel Vault Panel Bending Machine. With its industry-leading expertise and dedication to customer satisfaction, the company is well-positioned to shape the future of sheet metal processing and support the evolving needs of the construction and manufacturing industries.

Sheet Forming and Corrugating Machine for Glazed Tile Production

Title: Streamlining Roofing Innovation: Advanced Glazed Tile Sheet Forming and Corrugating Machine Revolutionizes the Construction IndustryIntroductionIn a significant breakthrough for the construction industry, a leading manufacturing company (name withheld) has recently unveiled its highly advanced Glazed Tile Sheet Forming and Corrugating Machine. Revolutionizing the way roofs are built, this cutting-edge machinery promises to streamline the roofing process, enhance durability, and exhibit exceptional aesthetic qualities. With its innovative design and state-of-the-art technology, this new machine is set to transform the way buildings are constructed.Enhanced Efficiency and ProductivityThe advanced Glazed Tile Sheet Forming and Corrugating Machine combines speed, precision, and versatility to deliver a highly efficient roofing solution. Equipped with automatic controls, this machinery significantly reduces human error and increases production rates, allowing construction companies to meet demanding project deadlines seamlessly. By automating the previously labor-intensive and time-consuming manual processes, the machine can form and shape glazed tiles quickly and efficiently.Unmatched Durability and QualityDesigned to produce robust and long-lasting glazed tiles, the machine utilizes high-quality materials and cutting-edge techniques. This results in the creation of tiles that are resistant to harsh weather conditions, corrosion, and daily wear and tear. By employing a unique corrugation process, the machine enhances the strength and rigidity of the tiles, providing added protection against extreme temperatures and structural damage. This ensures that buildings constructed with these tiles will maintain their durability and aesthetics over an extended period.Aesthetic Appeal and CustomizationThe Glazed Tile Sheet Forming and Corrugating Machine offers a myriad of possibilities when it comes to designing roofs. With its customizable features, architects and construction professionals can effortlessly create visually stunning structures. The machine enables the creation of various tile shapes, sizes, and finishes, ensuring that each project can be tailored to meet the client's specific requirements. This flexibility empowers architects to bring their creative visions to life and adds a touch of elegance to any construction project.Sustainable and Environmentally FriendlyWith increasing emphasis on sustainability, the Glazed Tile Sheet Forming and Corrugating Machine aims to contribute positively to the environment. The use of energy-efficient technology reduces carbon emissions, making it an eco-friendly solution for the construction sector. Additionally, the long lifespan of the tiles produced by this machinery reduces the need for frequent replacements, minimizing waste and conserving resources. As the industry moves towards greener practices, this machine represents an essential step towards a more sustainable future.Market Impact and Global AdoptionGiven the comprehensive benefits offered by this advanced Glazed Tile Sheet Forming and Corrugating Machine, it is expected to leave a significant impact on the roofing industry worldwide. Its ability to drastically improve efficiency, durability, and design flexibility makes it an attractive solution for construction companies across the globe. The machine's potential to revolutionize the way roofs are built is likely to be met with widespread adoption, driving market growth and setting new industry standards.ConclusionThe unveiling of the advanced Glazed Tile Sheet Forming and Corrugating Machine marks an important milestone in the construction industry. Its combination of efficiency, durability, customization, and sustainability gives birth to a new era of roofing solutions. As construction companies embrace this cutting-edge technology, it is anticipated that buildings will be constructed more swiftly and cost-effectively while maintaining exceptional quality and aesthetic appeal. With its remarkable potential, this revolutionary machine will undoubtedly reshape the future of the roofing industry.

Optimize Your Production Efficiency with the Latest Roll Form Machine

[Publication Name] – [Date]Roll Form Machine: Shaping the Future of ManufacturingIn today's ever-evolving industrial landscape, precision and efficiency in manufacturing processes are paramount. Companies across various sectors constantly seek innovative solutions to enhance production quality and reduce costs. [Company Name], a leading player in the manufacturing industry, remains at the forefront of this drive for cutting-edge technology.With their groundbreaking development – the Roll Form Machine – [Company Name] has revolutionized the way industries shape metal sheets, opening new doors of opportunity for businesses worldwide. This state-of-the-art machinery combines advanced engineering and groundbreaking automation, resulting in unmatched precision, speed, and versatility.The Roll Form Machine developed by [Company Name] has garnered significant attention due to its ability to transform flat pieces of metal into complex profiles and shapes with remarkable precision. The machine utilizes a continuous process where the metal sheet is fed into the machine, and through a series of carefully designed rolling dies, it is gradually formed into the desired shape.One of the key advantages of the Roll Form Machine lies in its flexibility. With interchangeable rolling dies and adjustable settings, the machine can easily adapt to produce a wide range of profiles and shapes. This versatility eliminates the need for multiple specialized machines, streamlining production processes and reducing costs for manufacturers.Furthermore, the Roll Form Machine boasts a rapid production speed that sets it apart from traditional manufacturing methods. By utilizing automated processes, [Company Name] has significantly enhanced the efficiency of roll forming, enabling manufacturers to achieve higher volumes and faster turnarounds. This advantage becomes particularly crucial for industries with high production demands, such as automotive, construction, and appliance manufacturing.Additionally, the Roll Form Machine ensures exceptional precision and accuracy throughout the entire production process. With advanced sensors and feedback systems, [Company Name] has implemented stringent quality control measures to meet the most demanding industry standards. The machine's ability to consistently deliver high-quality products with minimized defects has garnered praise from manufacturers seeking to maintain an edge in an increasingly competitive market.[Company Name], renowned for its commitment to innovation, has integrated cutting-edge automation technologies into the Roll Form Machine. Through the use of sophisticated software and control systems, the machine enables seamless integration into existing manufacturing setups. This seamless integration allows for centralized control, simplifies maintenance, and optimizes production schedules, empowering manufacturers to achieve higher productivity and reduce downtime.Moreover, the Roll Form Machine prioritizes safety, addressing a critical concern in the manufacturing industry. [Company Name] has invested in comprehensive safety measures, including emergency stop mechanisms, safety guards, and employee training, ensuring a secure and user-friendly operating environment. By prioritizing safety, the company aims to minimize accidents, protect its workers, and bolster customer trust in their products.The Roll Form Machine has already gained recognition and adoption within the manufacturing industry, with prominent companies across various sectors embracing its capabilities. Its impact has been particularly notable in the construction sector, as it allows for the rapid production of complex and customized profiles required for modern architectural designs.[Company Name] remains committed to research and development, continuously improving and expanding the capabilities of the Roll Form Machine. By working closely with their customers, the company seeks to understand the ever-changing needs of the industry and develop tailored solutions that propel manufacturing processes into the future.As the industrial landscape advances towards automation and precision, the Roll Form Machine developed by [Company Name] emerges as a game-changer, revolutionizing the way manufacturers shape metal sheets. With its remarkable flexibility, speed, precision, and safety features, this cutting-edge machinery promises to reshape industries and unlock new possibilities for businesses worldwide.###[Word Count: 649]

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

High-Strength Multi-Heads Rotary Woodworking CNC Machine for Efficient Wood Processing

Title: Multi-Head Rotary Woodworking CNC Machine: Advancing Efficiency in Residential and Commercial Woodwork ProjectsIntroductionIn the world of woodworking, the demand for precision and efficiency is paramount. With advancements in technology, the introduction of Multi-Head Rotary Woodworking CNC Machines has revolutionized the industry. HBHongchen.com proudly presents a woodworking CNC router that is designed to meet the diverse needs of both residential and commercial projects, offering a range of advantages that make it an essential tool for anyone involved in the woodworking field.High-Strength Design and Enhanced SpeedOne of the key advantages of the woodworking CNC router is its high-strength body design. Equipped with double driving motors on the Y-axis, the machine operates with more remarkable precision and efficiency than ever before. The more reasonable and advanced design ensures fast processing speeds, reducing project completion times significantly. This improved speed is a boon for both large-scale commercial projects and intricate residential woodworking endeavors.Easy Operation and Low MaintenanceThe woodworking CNC router prides itself on its user-friendly interface, making it easily operable even by novices in the woodworking field. The machine's design incorporates simplicity, allowing operators to quickly grasp its functionalities and navigate through its various features effortlessly. Additionally, the easy-operated maintenance feature allows users to perform routine checks and troubleshoot efficiently, minimizing downtime and optimizing productivity.Reduced Fault Rate for Increased ReliabilityWoodworking projects can often be time-consuming, and any unanticipated faults in the machinery can result in costly delays. However, the woodworking CNC router boasts an exceptionally low fault rate, ensuring reliability throughout the production process. This unwavering performance provides peace of mind for both individual craftsmen and commercial manufacturers, allowing them to focus on their core woodworking tasks without unnecessary interruptions.Premium Drivers and MotorsA key component of the woodworking CNC router's efficiency lies in the integration of famous brand drivers and motors. It is important to note that specific brand names have been omitted for this content. However, the woodworking CNC machine incorporates renowned components that meet and exceed industry standards. These premium drivers and motors ensure smooth and precise operations, providing consistent results regardless of the scale or complexity of the project.Synergy with C Z Purlin Multi-Size Purlin Making MachineHBHongchen.com has also established itself as a leading provider of the C Z Purlin Multi-Size Purlin Making Machine. This innovative equipment enables the efficient production of C and Z-shaped steel purlins, commonly used in residential and commercial building construction. By combining the woodworking CNC router with the C Z Purlin Making Machine, manufacturers can seamlessly transition between woodworking and metalworking, streamlining their production processes and maximizing productivity.ConclusionThe Multi-Head Rotary Woodworking CNC Machine provided by HBHongchen.com offers a range of advantages that elevate its performance in residential and commercial woodworking projects. With its high-strength body design, fast processing speeds, easy operation, low maintenance requirements, and premium quality drivers and motors, this woodworking CNC router redefines efficiency and reliability in the woodworking industry.Furthermore, by integrating it with the C Z Purlin Multi-Size Purlin Making Machine, manufacturers can seamlessly achieve a smoother transition between woodworking and metalworking processes. For professionals in the woodworking field, investing in this state-of-the-art machinery ensures optimal performance, increased productivity, and cost-effective woodworking solutions. HBHongchen.com leaves no stone unturned in providing woodworking enthusiasts and professionals with the best tools to realize their creative visions while optimally meeting the demands of the industry.

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

Efficient and Reliable Highway Guardrail Forming Machine Delivers Top-Notch Performance

Highway Guardrail Forming Machines Revolutionizing Roadway SafetyEnsuring roadway safety has always been a top priority for the transportation industry. Over the years, highway guardrails have proven to be an effective safety measure to prevent vehicles from colliding with hazardous objects such as trees, utility poles, bridges, and other vehicles. However, traditional guardrail systems can be prone to failures such as breakage, detachment, and other issues that can cause accidents. As a result, there has been a growing demand for advanced highway guardrail systems that provide better protection and improved durability. This is where highway guardrail forming machines come into play.Highway guardrail forming machines have revolutionized the manufacturing process of guardrails. These machines are capable of producing a wide range of high-quality guardrails that are highly durable, strong, and resistant to wear and tear. The forming process involves using raw materials such as steel coils or sheets, which are fed through the machine and transformed into various shapes and sizes. The resulting guardrails are then installed along the sides of highways, providing an effective barrier system to prevent collisions.One company that has been at the forefront of this industry is a Chinese manufacturing company that specializes in producing highway guardrail forming machines. The company has been in operation for more than 15 years and has a strong reputation for producing high-quality machines that can produce guardrails with exceptional strength and durability. The company's machines are designed to offer a high level of precision, flexibility, and efficiency, making them ideal for use in manufacturing different types of guardrails.According to a spokesperson from the company, "Our highway guardrail forming machines are designed to meet the needs of different customers. We offer customized machines that are tailored to meet specific requirements and produce different types of guardrails. Our machines are easy to operate and maintain, and they offer a high level of reliability and stability, resulting in consistent and high-quality output."The company's highway guardrail forming machines are designed to produce various types of guardrails, including corrugated beam guardrails, W-beam guardrails, and thrie beam guardrails. These guardrails are produced to meet international standards, and they are widely used in road construction and transportation applications around the world. The machines are also designed to produce guardrails of different sizes and thicknesses, making them highly versatile.In addition to producing highway guardrail forming machines, the company also provides installation, training, and after-sales services to ensure that customers get the most out of their equipment. The company has a team of experienced engineers and technicians who work closely with customers to ensure that their needs are met. The company also offers comprehensive technical support, including troubleshooting, maintenance, and repair services.The company's highway guardrail forming machines have gained popularity in various countries, including the United States, Canada, Australia, and Africa. In the US, the machines have been used to produce guardrails for major highway projects, including the construction of the Tappan Zee Bridge in New York and the expansion of the I-35 and I-90 in Texas. In Australia, the machines have been used to produce guardrails for the Pacific Highway Upgrade project. In Africa, the machines have been used to produce guardrails for roads in Tanzania and Kenya.Overall, highway guardrail forming machines have proven to be a game-changer in the transportation industry, providing a reliable and cost-effective solution for enhancing roadway safety. As the demand for advanced highway guardrail systems continues to grow, companies like this Chinese manufacturing firm are well-positioned to provide innovative solutions to meet the needs of customers around the world.