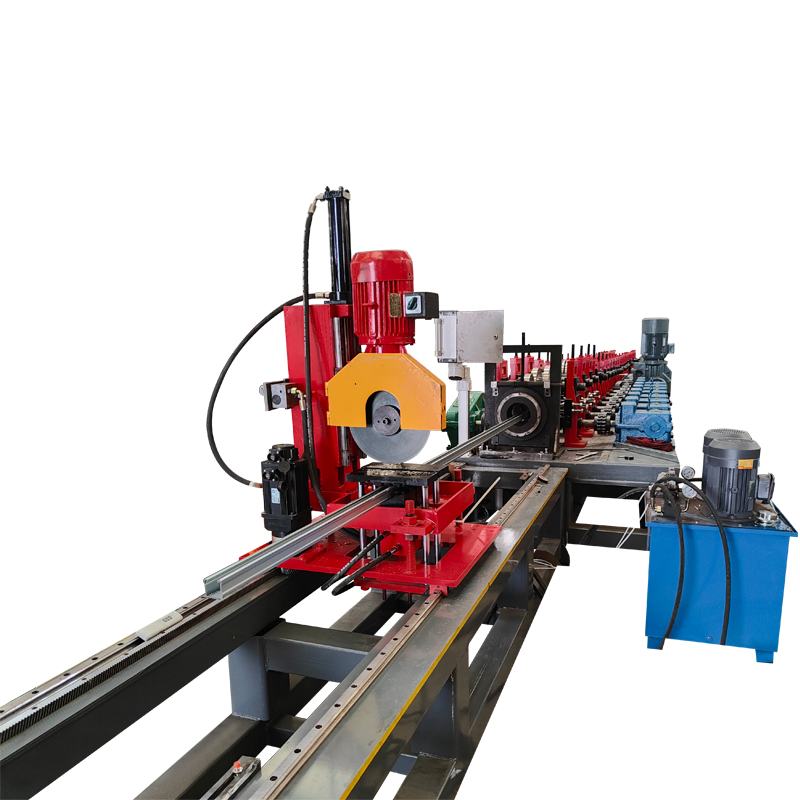

High-quality B Decking Roll Forming Machine for Efficient Production

By:Admin

The construction industry has seen a significant shift in recent years, with an increasing focus on innovative and efficient building methods. One such innovation that has been making waves in the industry is the B Decking Roll Forming Machine. This cutting-edge technology has been revolutionizing the way buildings are constructed, offering increased productivity, cost savings, and superior quality.

The B Decking Roll Forming Machine, developed by leading industry experts, is designed to produce high-quality B deck profiles with precision and efficiency. This state-of-the-art machine is capable of forming metal deck panels with optimal strength and load-carrying capacity, making it an ideal choice for a wide range of construction projects.

One of the key features of the B Decking Roll Forming Machine is its ability to produce B deck profiles of varying sizes and specifications, allowing for greater flexibility and customization. This means that construction companies can produce deck panels tailored to the specific requirements of each project, ensuring optimal performance and structural integrity.

Furthermore, the B Decking Roll Forming Machine is equipped with advanced automation and control systems, which enable seamless operation and precise production. This not only improves productivity but also reduces the likelihood of errors, leading to superior quality output.

In addition to its technical capabilities, the B Decking Roll Forming Machine is also designed with user convenience and safety in mind. With intuitive controls and safety features, operators can efficiently operate the machine without compromising on workplace safety.

The company behind the B Decking Roll Forming Machine, with a strong reputation for delivering cutting-edge solutions to the construction industry, has been at the forefront of innovation and technology. Their commitment to research and development has resulted in a range of advanced machinery and equipment that have helped shape the future of construction.

Having established a strong presence in the global market, the company has earned the trust and confidence of industry professionals and construction companies. Their dedication to providing reliable and efficient solutions has positioned them as a trusted partner for companies looking to enhance their construction processes.

With the B Decking Roll Forming Machine, the company has once again demonstrated its commitment to driving innovation and efficiency in the construction industry. By offering a solution that streamlines the production of deck panels, the company is not only meeting the evolving needs of construction projects but also setting new standards for quality and performance.

As the construction industry continues to embrace technological advancements, the adoption of the B Decking Roll Forming Machine is expected to grow significantly. Its ability to deliver cost-effective, high-quality deck panels in a fraction of the time compared to traditional methods has made it a game changer in the industry.

In conclusion, the B Decking Roll Forming Machine is a testament to the relentless pursuit of innovation and excellence in the construction industry. With its advanced technology, superior quality output, and unparalleled efficiency, it has become a vital tool for companies looking to stay ahead in a rapidly evolving industry. As construction projects become more complex and demanding, the B Decking Roll Forming Machine is set to play a pivotal role in shaping the future of construction.

Company News & Blog

High-Quality C Purlin Roll Forming Machine: The Ultimate Guide

Manual Shape C Purlin Roll Forming Machine has recently been launched by the renowned company. This new roll forming machine will revolutionize the process of creating C-shaped steel purlins, providing a faster, more efficient, and more precise method for construction projects.The Manual Shape C Purlin Roll Forming Machine is designed to meet the needs of construction companies and steel fabrication industries. It is a versatile and cost-effective solution for producing high-quality C-shaped steel purlins, which are essential components in building structures, especially for supporting the roof and walls.The new roll forming machine is equipped with advanced technology and features a user-friendly interface, making it easy to operate and maintain. It is capable of producing C purlins of various sizes and thicknesses, providing flexibility for different construction requirements. With its high-speed production capability, this machine can significantly improve workflow efficiency and reduce labor costs.The Manual Shape C Purlin Roll Forming Machine is built to last, with a durable and robust construction that ensures long-term reliability and performance. Its precision engineering and high-quality components guarantee consistent production results, meeting the strictest quality standards for steel purlins.The company behind this innovative roll forming machine has a solid reputation in the industry for delivering cutting-edge solutions for steel fabrication. With decades of experience and expertise, they have gained the trust and confidence of their clients, providing them with reliable and efficient machinery for their manufacturing needs.In addition to the Manual Shape C Purlin Roll Forming Machine, the company offers a comprehensive range of roll forming equipment and accessories, including other types of purlin roll forming machines, metal roofing machines, and various custom solutions for specific production requirements. They are committed to delivering excellence in engineering and customer service, ensuring that their clients have access to the best tools and support for their operations.The launch of the Manual Shape C Purlin Roll Forming Machine marks a significant milestone for the company, as it represents their dedication to innovation and their ongoing mission to meet the evolving needs of the steel fabrication industry. By introducing this state-of-the-art machine, they aim to empower their clients with the latest technology and equipment, enabling them to stay competitive and maximize their productivity.The company's commitment to quality, reliability, and customer satisfaction sets them apart in the market, making them a trusted partner for businesses seeking efficient and effective solutions for their manufacturing processes. With the Manual Shape C Purlin Roll Forming Machine, they continue to uphold their reputation as a leading provider of roll forming machinery and a reliable source for industry expertise.As the construction industry continues to grow and evolve, the demand for advanced roll forming equipment remains high. The Manual Shape C Purlin Roll Forming Machine offers a timely solution for businesses looking to streamline their production and enhance their capabilities in producing C-shaped steel purlins. With its cutting-edge technology and proven performance, this machine is poised to make a significant impact in the industry, driving efficiency and innovation for construction projects of all scales.In conclusion, the launch of the Manual Shape C Purlin Roll Forming Machine represents a major advancement in roll forming technology, providing a game-changing solution for manufacturing C-shaped steel purlins. With the backing of a reputable and reliable company, this new roll forming machine promises to deliver superior results and drive productivity for construction and steel fabrication businesses.

High-Quality Automatic Cut-To-Length Machine for Precision Cutting

Automatic Cut-To-Length Machine Revolutionizing Production ProcessThe manufacturing industry is continuously evolving with the advancement of technology, and one company at the forefront of this evolution is {}. With a commitment to innovation and efficiency, they have recently introduced their latest addition to their production line – the Automatic Cut-To-Length Machine. This state-of-the-art machine is set to revolutionize the production process, offering precision, speed, and enhanced productivity.The Automatic Cut-To-Length Machine is designed to streamline the process of cutting materials to specific lengths, catering to the diverse needs of various industries such as automotive, construction, and appliances. This machine is equipped with advanced features that enable it to effortlessly cut different materials including metals, plastics, and composites with utmost accuracy and consistency.One of the key highlights of the Automatic Cut-To-Length Machine is its cutting-edge technology that allows for automated operation. This not only reduces the need for manual labor but also minimizes the margin of error, resulting in higher quality output. Additionally, with its rapid cutting speed, the machine significantly increases production efficiency, ultimately leading to cost savings for the company.Furthermore, the Automatic Cut-To-Length Machine is integrated with intelligent software that enables precise customization and optimization of cutting processes. This ensures that the machine can meet the specific requirements of each customer, catering to a wide range of dimensions and tolerances. With such versatility, the machine offers a competitive edge in the market, allowing {} to provide tailored solutions to meet the unique demands of their clients.In addition to its technical capabilities, the Automatic Cut-To-Length Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and ensuring seamless integration into the production line. This not only enhances the overall efficiency of the manufacturing process but also creates a safer working environment for the operators.{} has a long-standing reputation for delivering high-quality, reliable machinery, and the introduction of the Automatic Cut-To-Length Machine is a testament to their commitment to continuous improvement and innovation. With a strong focus on research and development, the company has invested heavily in advancing their technological capabilities, ensuring that they remain at the forefront of the industry.The launch of the Automatic Cut-To-Length Machine underscores {}'s dedication to meeting the evolving needs of their customers. By incorporating cutting-edge technology and automation into their production line, they are not only enhancing their own operational efficiency but also empowering their clients to achieve greater success in their respective industries.Moreover, the introduction of the Automatic Cut-To-Length Machine aligns with {}'s long-term sustainability goals. By optimizing the cutting process and reducing material waste, the machine contributes to a more environmentally friendly manufacturing approach. This reflects {}'s commitment to conducting business in a responsible and ethical manner, prioritizing sustainability and resource efficiency.With the introduction of the Automatic Cut-To-Length Machine, {} is poised to set new standards within the manufacturing industry. By leveraging cutting-edge technology and innovation, they are not just meeting the current demands of the market but also shaping the future of production processes. As the industry continues to evolve, {} remains dedicated to pushing boundaries and redefining what is possible in manufacturing.

Advanced Color Steel Roll Forming Machine: Offering Double Layer Efficiency

Double Layers Color Steel Roll Forming Machine Revolutionizes the Steel Roll Forming IndustryThe demand for different types of roll forming machines is increasing rapidly, owing to the ever-growing construction and infrastructure development projects around the world. One company that has been at the forefront of this industry is renowned for its high-quality machinery and innovative solutions. With its latest offering, the Double Layers Color Steel Roll Forming Machine (name removed), the company is set to revolutionize the steel roll forming industry.The Double Layers Color Steel Roll Forming Machine is a state-of-the-art piece of equipment that boasts advanced features and cutting-edge technology. It is designed to cater to the diverse needs of the steel industry, providing utmost efficiency and precision in the roll forming process. Through its innovative design, the machine can produce double-layered color steel sheets with exceptional accuracy and speed, making it an indispensable tool for manufacturers in the sector.One of the key highlights of this machine is its ability to produce color steel sheets with different thicknesses, ranging from 0.3mm to 0.8mm. This versatility enables manufacturers to cater to a wide range of project requirements, making it a preferred choice over other roll forming machines in the market. Additionally, the machine's dual-layered design allows for the production of steel sheets with different colors on each side, further adding to its flexibility and application possibilities.The Double Layers Color Steel Roll Forming Machine is equipped with a high-performance control system that ensures precise and consistent production. It incorporates the latest automation technology, enabling operators to easily adjust and monitor various parameters of the machine, such as speed, thickness, and color. This not only enhances productivity but also minimizes human error, resulting in a higher quality end product.Furthermore, the machine has been engineered to provide exceptional durability and stability. Its robust construction, coupled with high-quality components, ensures a long service life and uninterrupted performance even in demanding industrial environments. This makes it a reliable and cost-effective solution for manufacturers, minimizing downtime and maintenance costs.In addition to its technical prowess, the company behind the Double Layers Color Steel Roll Forming Machine prides itself on its commitment to customer satisfaction. With decades of experience in the industry, they have a deep understanding of the challenges faced by manufacturers. Their dedicated team of engineers and technicians provides comprehensive support, including installation, training, and after-sales service, ensuring a seamless experience for their customers.The introduction of the Double Layers Color Steel Roll Forming Machine has already garnered significant attention from industry experts and manufacturers alike. It is hailed as a game-changer for the steel roll forming industry, with its ability to produce double-layered color steel sheets with unmatched precision and efficiency. As infrastructure development continues to soar globally, this innovative machine is poised to become a key tool for manufacturers, enabling them to meet the growing demands of the construction sector.In conclusion, the Double Layers Color Steel Roll Forming Machine is a groundbreaking innovation that showcases the company's dedication to excellence and customer satisfaction. With its advanced features, versatility, and unparalleled performance, it is set to redefine the steel roll forming industry. As manufacturers strive to meet the demands of the evolving construction sector, this machine will undoubtedly play a pivotal role in shaping the future of steel production.

Efficient Purlin Forming Machine for Strong and Durable Structures

Title: Advanced Purlin Forming Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced construction industry, efficiency and precision are key factors that drive successful projects. Providing solutions to these demands, a cutting-edge Purlin Forming Machine has emerged, enabling construction companies to streamline their processes and deliver outstanding results. This innovative machinery is set to revolutionize the way purlins are produced, enhancing construction efficiency, cost-effectiveness, and overall project quality.Streamlined Purlin Manufacturing Process:The Purlin Forming Machine, developed and manufactured by a leading engineering firm, has been designed with utmost precision and state-of-the-art technology. This machine enables steel purlins to be produced rapidly and accurately, eliminating traditional manual methods that are time-consuming and error-prone.By automating the purlin manufacturing process, the machine ensures consistent quality and eliminates human error, resulting in a more precise and reliable end product. It utilizes sophisticated computer-controlled mechanisms and advanced software to ensure seamless operation, allowing construction companies to meet tight project deadlines with ease.Efficiency and Cost-effectiveness:The innovative Purlin Forming Machine optimizes the use of materials and reduces wastage significantly. Its intelligent design and engineering contribute to a drastic reduction in material costs, resulting in more affordable projects. The machine's automated nature not only increases productivity but also reduces labor costs, enhancing overall project profitability.Moreover, the machine's ability to produce purlins of various sizes and designs offers construction companies unparalleled versatility. It eliminates the need to source purlins from different suppliers, saving time and money, while maintaining consistent quality throughout the project duration.Enhanced Construction Quality:Traditionally, manual purlin production processes are prone to human error and inconsistency, leading to compromised structural integrity. The Purlin Forming Machine tackles this issue by producing purlins with exceptional accuracy, ensuring that they fit seamlessly in the construction framework.The machine's advanced technology and precise measurements guarantee that each purlin manufactured is uniform in size, shape, and strength. Consequently, the overall structural integrity of buildings is vastly improved, minimizing the risk of complications or failures during construction and enhancing the longevity of the completed structures.Environmental Friendly Manufacturing:In addition to its exceptional performance, the Purlin Forming Machine adheres to environmentally friendly manufacturing practices. By optimizing material usage and minimizing waste generation, it contributes to a sustainable construction environment. The machine's energy-efficient operations also reduce energy consumption, making it an eco-conscious choice for construction companies.Future Prospects and Competitiveness:The Purlin Forming Machine presents a significant opportunity for construction companies to enhance their competitiveness. By leveraging this advanced technology, companies can not only expedite their project timelines but also offer superior quality deliverables. This cutting-edge machinery equips construction firms to take on larger projects with improved efficiency and precision, ultimately strengthening their position in the industry.Conclusion:The advanced Purlin Forming Machine has emerged as a game-changer in the construction industry, offering numerous benefits to construction companies. Its ability to automate and streamline the purlin manufacturing process leads to improved efficiency, cost-effectiveness, and construction quality. Alongside its positive environmental impact and contribution to sustainable construction practices, this innovative machinery is poised to revolutionize the industry and shape the future of construction.

High-Quality Roofing Sheet Forming Machine for Efficient Production

New Roofing Sheet Forming Machine Revolutionizes the IndustryWith the increasing demand for high-quality roofing materials, the roofing industry is constantly evolving and innovating to keep up with consumer needs. One of the latest advancements in the field is the cutting-edge Roofing Sheet Forming Machine, developed by a leading manufacturer in the industry.This state-of-the-art machine is designed to streamline the process of producing roofing sheets, offering improved efficiency, precision, and quality. It is equipped with advanced technology and features that set it apart from traditional forming machines, making it a game-changer for roofing companies looking to stay ahead of the competition.The Roofing Sheet Forming Machine is capable of producing a wide range of roofing sheet profiles, including corrugated, trapezoidal, and ribbed sheets, with customizable options to meet specific customer requirements. Its high-speed production capabilities and automated operation ensure a faster turnaround time, allowing companies to meet tight deadlines and maximize productivity.In addition to its speed and efficiency, the machine is also designed for optimal precision and consistency in forming roofing sheets. This means that every sheet produced is of the highest quality, with uniform dimensions and a smooth finish. Its advanced control system and monitoring features further enhance its accuracy, minimizing material waste and reducing the need for rework.Furthermore, the Roofing Sheet Forming Machine focuses on user-friendly operation and maintenance, with intuitive controls and easy access for servicing and adjustments. This not only simplifies the production process but also increases overall safety and reliability, contributing to a seamless workflow for roofing companies.As a leading manufacturer in the roofing industry, the company behind the Roofing Sheet Forming Machine has a solid reputation for producing top-of-the-line equipment and providing comprehensive solutions for roofing needs. With a strong focus on research and development, they are dedicated to staying at the forefront of technological advancements and continually improving their products to meet evolving market demands.The company's commitment to quality extends beyond its machines, as they also offer extensive training and support services to help their customers maximize the potential of their equipment. This includes hands-on training for machine operation and maintenance, as well as technical assistance and troubleshooting to address any concerns or issues that may arise.In addition, the company's dedication to sustainability is reflected in its manufacturing processes, as they strive to minimize environmental impact and promote energy efficiency in their operations. This aligns with the growing emphasis on eco-friendly practices within the roofing industry, as more companies seek to reduce their carbon footprint and adopt sustainable solutions.Overall, the introduction of the Roofing Sheet Forming Machine represents a significant advancement for the roofing industry, offering a modernized approach to the production of high-quality roofing materials. With its innovative technology, efficiency, and commitment to excellence, it is poised to make a positive impact on the way roofing companies operate and serve their customers.As the roofing industry continues to evolve, the Roofing Sheet Forming Machine stands out as a beacon of progress, providing a glimpse into the future of roofing manufacturing. Its combination of advanced capabilities, user-friendly design, and comprehensive support services makes it a valuable asset for companies looking to thrive in today's competitive market.

High-Quality Metal Roof Panel Machine for Sale - Find Out More!

Metal Roof Panel Machine Revolutionizes Manufacturing ProcessMetal roofing has become an increasingly popular option for commercial and industrial buildings, thanks to its durability, energy efficiency, and low maintenance requirements. However, up until now, the manufacturing process for metal roof panels has been a time-consuming and labor-intensive task.Enter the Metal Roof Panel Machine, a revolutionary piece of equipment that is set to transform the industry. Developed by a leading machinery manufacturer, this state-of-the-art machine streamlines the production of metal roof panels, making the process faster, more efficient, and cost-effective.With the Metal Roof Panel Machine, companies can now produce high-quality metal roof panels in a fraction of the time it takes using traditional methods. This not only increases productivity and reduces labor costs but also allows for quicker turnaround times, enabling manufacturers to meet the growing demand for metal roofing products.The machine is equipped with advanced technology that allows for precise shaping and cutting of metal sheets, ensuring consistent quality and accuracy in every panel produced. Its automated features and user-friendly interface make it easy to operate, requiring minimal training for operators.In addition, the Metal Roof Panel Machine is designed to be versatile, capable of producing a wide range of metal roof panel profiles to meet the unique needs of different projects. Whether it's a standing seam, corrugated, or ribbed panel, this machine can handle it all, giving manufacturers the flexibility to cater to diverse customer requirements.The company behind this groundbreaking innovation, {}, has been a leader in the manufacturing and distribution of machinery for the metal construction industry for over 30 years. With a strong focus on research and development, they have consistently introduced cutting-edge solutions that have transformed the way metal buildings are constructed.{}’s commitment to innovation and excellence is reflected in the Metal Roof Panel Machine, which sets a new standard for metal roof panel production. By integrating the latest technologies and engineering expertise, they have created a game-changing solution that is poised to revolutionize the manufacturing process for metal roofing.As the demand for metal roofing continues to rise, the Metal Roof Panel Machine comes at a crucial time for the industry. With its ability to significantly increase production capacity and improve efficiency, it will enable manufacturers to keep up with the growing market demand and stay competitive in the industry.Furthermore, the machine's energy-efficient design and reduced material waste contribute to sustainability, aligning with the industry's push for eco-friendly and sustainable building solutions. By minimizing the environmental impact of metal roof panel production, it also positions manufacturers as responsible stewards of the environment.In conclusion, the Metal Roof Panel Machine is a game-changer for the metal construction industry. With its ability to streamline production, increase efficiency, and improve quality, it represents a significant leap forward in the manufacturing of metal roof panels. As the industry continues to evolve, this innovative solution from {} is set to play a pivotal role in shaping the future of metal roofing.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

Rent Wood Deck Sanding Machine for Your Next Project

Wood Deck Sanding Machine Rental Now Available at {Company Name}{City, State} - {Company Name} is pleased to announce the addition of wood deck sanding machine rentals to their extensive list of offerings. As a leader in the equipment rental industry, {Company Name} is continually expanding their inventory to provide customers with the tools they need to complete any project.The wood deck sanding machine is the latest addition to {Company Name}'s rental fleet, and it is already generating significant interest from homeowners and contractors alike. With the ability to quickly and efficiently sand and refinish wooden decks, this machine is a game-changer for anyone looking to improve the appearance and longevity of their outdoor living space."Our goal at {Company Name} is to provide our customers with the best tools and equipment to help them take on their projects with confidence," said {Spokesperson Name}, {Title} at {Company Name}. "With the addition of the wood deck sanding machine to our rental fleet, we are excited to offer a solution to anyone looking to revitalize their outdoor space."The wood deck sanding machine is designed for ease of use, with features that make it suitable for both novices and experienced contractors. Its powerful motor and ergonomic design allow for efficient and precise sanding, resulting in professional-quality finishes. Additionally, the machine's dust collection system ensures a clean and safe work environment.{Company Name} is proud to offer flexible rental options for the wood deck sanding machine, including daily, weekly, and monthly rates to accommodate projects of any size. Their team of knowledgeable staff are available to assist customers in selecting the best equipment for their specific needs and provide guidance on how to use it effectively.In addition to the wood deck sanding machine, {Company Name} offers an extensive range of equipment for rent, including construction tools, landscaping machinery, and maintenance equipment. With a commitment to customer satisfaction, they strive to provide a seamless rental experience from start to finish."Whether you are a homeowner looking to tackle a DIY project or a professional contractor in need of specialized equipment, {Company Name} is here to support you," said {Spokesperson Name}. "We take pride in offering top-quality rentals and exceptional customer service to ensure that every customer has a positive experience with us."{Company Name} is excited to bring the wood deck sanding machine rental to {City, State} and looks forward to empowering customers to enhance their outdoor spaces with this innovative tool. For more information about the wood deck sanding machine or to inquire about other rental offerings, customers are encouraged to contact {Company Name}.About {Company Name}:{Company Name} has been a trusted name in the equipment rental industry for [number] years. With a wide selection of tools and machinery available for rent, they serve customers in {City, State} and beyond. {Company Name} is dedicated to providing exceptional rentals, expert guidance, and reliable service to support customers in achieving their project goals.For media inquiries, please contact:{Contact Person}{Company Name}Phone: [Phone Number]Email: [Email Address]Website: [Website]

Portable Standing Seam Metal Roof Roll Forming Machine for Small-Sized Panels

Title: Enhancing Roofing Efficiency with a Portable Standing Seam Roll Forming MachineIntroduction:Roofing is a crucial aspect of any construction project, as it offers protection against harsh weather conditions and guarantees the longevity of the structure. Traditional roof installation methods often involve time-consuming processes that require extensive manpower. However, advancements in technology have led to the development of efficient solutions such as the Portable Standing Seam Roll Forming Machine. This innovative equipment offers remarkable precision, versatility, and convenience, making it a game-changer in the roofing industry.The Specifications of the Standing Seam Roof Panel Machine:Xiamen Xinhonghua Machinery Co., Ltd. has introduced a high-quality Portable Standing Seam Metal Roof Roll Forming Machine - the KLS25- 220-530. This compact-sized machine is designed to produce standing seam roof panels efficiently, providing numerous benefits for construction projects of all sizes. Let's delve into its impressive specifications:1) Main Technical Data:- Size: KLS38-220-530 (hydraulic cutting) or KLS25-220-530 (manual cutting)- Dimension: [Measurements could be provided, but they are not available in the given information]- [Additional features that are relevant to the machine's performance and functionality can be mentioned here]The Advantages of a Portable Standing Seam Roll Forming Machine:1. Versatility: The standing seam roof panel machine can produce panels of various lengths and designs, allowing for customization according to the specific requirements of each project. This flexibility ensures that every customer receives a tailor-made roofing solution.2. Ease of Use: Unlike traditional roof installation methods that require extensive manual labor, the roll forming machine reduces the dependency on manpower. Its user-friendly design allows operators to navigate the machine efficiently, ensuring seamless production and reduced installation time. The ability to produce panels on-site eliminates the need for transporting pre-built panels, further reducing costs and time.3. Precise and Consistent Panel Production: The roll forming process ensures the panels are produced with exceptional precision, maintaining consistency throughout the entire production run. This precision enhances the overall quality of the roof, ensuring a tight fit between the panels and eliminating potential leaks. As a result, the end product offers superior weather resistance and durability.4. Enhanced Efficiency: The use of a roll forming machine significantly increases the speed of panel production, ensuring faster completion of projects. This eliminates the need for multiple installation teams, reducing labor costs and increasing overall efficiency. With the portable nature of the machine, it can easily be maneuvered around the site, allowing for continuous panel production.5. Longevity and Durability: The panels produced by the standing seam roll forming machine exhibit exceptional strength and durability. Constructed from high-quality metal materials, they can withstand extreme weather conditions, including heavy rain, snow, and strong winds. Their longevity ensures long-term protection for the structure while minimizing the need for maintenance or repairs.Conclusion:The introduction of the Portable Standing Seam Metal Roof Roll Forming Machine has revolutionized the roofing industry by providing numerous benefits to construction projects. Its compact design, versatility, ease of use, and precise panel production have made it an indispensable tool for roof installation. By investing in this advanced technology, construction companies can streamline their operations, reduce costs, and deliver top-notch roofing solutions that guarantee long-term structural integrity.