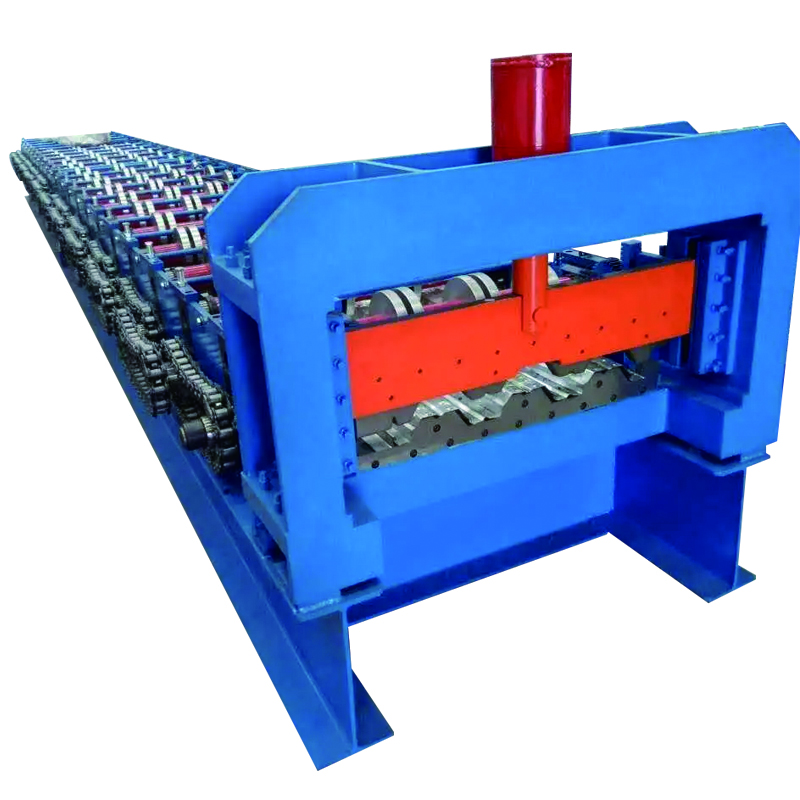

High-quality Colored Metal Trapezoidal Sheet Roll Forming Machine for Sale

By:Admin

The roofing industry has seen a significant transformation with the introduction of the state-of-the-art Colored Metal Trapezoidal Sheet Roll Forming Machine. This advanced equipment has been developed to meet the growing demand for efficient and high-quality roofing solutions in the construction sector.

The Colored Metal Trapezoidal Sheet Roll Forming Machine is designed to produce trapezoidal profiled metal sheets that are widely used in roofing and cladding applications. This machine is capable of forming metal sheets with precision and speed, making it an ideal choice for roofing manufacturers and contractors.

One of the key features of this cutting-edge roll forming machine is its ability to produce colored metal sheets, offering a wide range of options to meet the aesthetic and functional requirements of modern building designs. The machine's advanced technology allows for the application of vibrant and durable colors, ensuring that the finished products are not only visually appealing but also long-lasting.

In addition to its color capabilities, the Colored Metal Trapezoidal Sheet Roll Forming Machine boasts a high degree of customization, allowing users to create metal sheets in various lengths, widths, and thicknesses. This level of flexibility enables roofing professionals to cater to diverse project requirements with ease, ultimately enhancing their competitiveness in the market.

The company behind this innovative roll forming machine is a leading manufacturer of metal processing equipment {}The company's commitment to research and development has led to the creation of cutting-edge machinery that is at the forefront of technological advancement in the industry.

In addition to its advanced technology, the company has also established a strong reputation for delivering reliable and efficient equipment that meets the needs of its customers. With a focus on quality and customer satisfaction, the company has become a trusted partner for businesses seeking reliable solutions for their metal processing requirements.

The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine is a testament to the company's dedication to innovation and excellence. By pushing the boundaries of what is possible in metal forming technology, the company is setting new standards for the roofing industry and empowering its customers to achieve outstanding results in their projects.

The impact of this cutting-edge roll forming machine is already being felt across the industry, with roofing professionals embracing the opportunities it presents. Manufacturers and contractors are now able to meet the growing demand for colored metal roofing products while maintaining high standards of quality and efficiency.

With the Colored Metal Trapezoidal Sheet Roll Forming Machine, the future of the roofing industry looks brighter than ever. Its advanced capabilities, coupled with the expertise and support of the company behind it, are empowering businesses to take their operations to new heights and deliver superior roofing solutions to their clients.

As the construction sector continues to evolve, the demand for innovative and sustainable building materials is on the rise. The Colored Metal Trapezoidal Sheet Roll Forming Machine is well-positioned to meet this demand, offering a solution that not only meets the highest standards of performance and durability but also contributes to the aesthetic appeal of modern architectural designs.

In conclusion, the introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine marks a significant milestone in the roofing industry. With its advanced technology, customization capabilities, and commitment to quality, this machine is revolutionizing the way metal roofing products are manufactured and setting new standards for excellence in the construction sector. As the industry continues to embrace innovative solutions, the Colored Metal Trapezoidal Sheet Roll Forming Machine is poised to play a key role in shaping the future of roofing technology.

Company News & Blog

Cut to Length Machine for Efficient Coil Processing

The Coil Cut To Length Machine from a leading manufacturing company has been making waves in the industry for its cutting-edge technology and precision engineering. This innovative machine is designed to cut and straighten coiled steel, stainless steel, aluminum, and other metal materials with remarkable accuracy and efficiency.The company behind this impressive piece of equipment is a global leader in the manufacturing and supply of metal processing machinery. With a strong focus on research and development, they have been able to consistently deliver state-of-the-art solutions to meet the evolving needs of the metal processing industry. Their commitment to quality and innovation has made them a trusted partner for businesses across the globe.The Coil Cut To Length Machine is a prime example of the company's dedication to excellence. It is equipped with advanced features that set it apart from traditional cutting machines. The precision leveling system ensures that the material is perfectly straightened before cutting, resulting in high-quality end products. Additionally, the machine is capable of handling a wide range of material thicknesses and widths, making it a versatile and reliable choice for various industrial applications.One of the key benefits of this machine is its ability to increase productivity and efficiency in metal processing operations. By automating the cutting and straightening process, it minimizes the need for manual labor and reduces the risk of errors. This not only saves time and labor costs but also enhances the overall quality of the finished products. Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, allowing for seamless integration into existing production lines.Another impressive aspect of the Coil Cut To Length Machine is its durability and low maintenance requirements. Built to withstand the rigors of heavy-duty industrial use, it is constructed with high-quality materials and components that ensure long-term reliability. Additionally, the machine is designed for easy maintenance, with accessible parts and a straightforward servicing process, minimizing downtime and optimizing production uptime.In line with the company's commitment to customer satisfaction, they offer comprehensive support and service for their Coil Cut To Length Machine. Their team of knowledgeable and experienced technicians is readily available to provide installation, training, and ongoing maintenance to ensure that the machine operates at peak performance. With a global network of service centers, they are able to offer timely assistance and support to their customers worldwide.The company's dedication to continuous improvement and innovation has established them as a trailblazer in the metal processing industry. They are constantly striving to develop new technologies and solutions that push the boundaries of what is possible in metal processing, driving the industry forward and empowering businesses to achieve new levels of success.As the demand for high-quality metal products continues to rise, the Coil Cut To Length Machine from this renowned manufacturing company is set to play a pivotal role in meeting this demand. With its precision, efficiency, and reliability, it is a game-changing solution for businesses looking to enhance their metal processing capabilities and stay ahead of the competition. With a track record of excellence and a commitment to customer satisfaction, this company is poised to lead the way in shaping the future of metal processing technology.

The Latest Technology in Ag Panel Roll Forming Machines - Discover the Benefits Today

Ag Panel Roll Forming Machine Revolutionizes Agricultural Equipment ManufacturingThe agricultural industry has always been at the forefront of technological advancements, continuously looking for ways to improve efficiency and productivity. One such innovation that has been making waves in the industry is the introduction of the Ag Panel Roll Forming Machine. This state-of-the-art machinery has been developed to revolutionize the manufacturing of agricultural equipment, making the production process faster, more efficient, and cost-effective.This groundbreaking technology is the brainchild of {}, a leading manufacturer of roll forming machinery with over 20 years of experience in the industry. The company has a solid reputation for delivering high-quality, reliable, and innovative machinery to a wide range of industries, including automotive, construction, and now, agriculture.The Ag Panel Roll Forming Machine is specifically designed to meet the unique needs of agricultural equipment manufacturers. It is capable of producing a variety of panel profiles used in the construction of agricultural buildings, such as barns, silos, and storage facilities. The machine can form panels of different lengths and widths, with customizable rib patterns and gauge thickness, allowing for great flexibility in design and application.One of the key features of the Ag Panel Roll Forming Machine is its speed and efficiency. With its high-speed production capability, the machine can significantly reduce manufacturing time, increasing productivity and output. This is a game-changer for agricultural equipment manufacturers, as it allows them to meet the growing demand for their products more effectively and efficiently.In addition to its speed, the machine also boasts of its precision and accuracy. With advanced control systems and cutting-edge technology, the machine can produce panels with consistent quality and exact specifications, ensuring the perfect fit and finish for agricultural structures. This level of precision is essential for maintaining the structural integrity and longevity of the buildings, which is crucial in the agricultural industry.Furthermore, the Ag Panel Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. The intuitive control interface allows operators to set up and adjust the machine parameters quickly, minimizing downtime and maximizing production uptime. This user-friendly design also reduces the need for extensive training, making it accessible to a wide range of operators with varying levels of experience.Moreover, the machine is built with durability and reliability in mind, using high-quality materials and components to withstand the rigors of continuous operation. This ensures that the machine can deliver consistent performance and long-term value for agricultural equipment manufacturers, making it a sound investment for their business.The introduction of the Ag Panel Roll Forming Machine is undoubtedly a game-changer for the agricultural industry. It represents a significant leap forward in the manufacturing of agricultural buildings and equipment, offering unparalleled speed, precision, and efficiency. With this innovative technology, agricultural equipment manufacturers can meet the demands of their customers more effectively, while staying ahead of the competition.In conclusion, the Ag Panel Roll Forming Machine is a testament to the commitment of {} to delivering cutting-edge solutions that drive progress and innovation in the industry. With its innovative technology, user-friendly design, and reliable performance, this machine is set to revolutionize the way agricultural equipment is manufactured, setting new standards for efficiency and productivity in the industry. As the agricultural industry continues to evolve and grow, the Ag Panel Roll Forming Machine is poised to play a pivotal role in shaping its future.

High-Quality CZ Purlin Roll Forming Machine: Made in China

Are you in the construction industry and looking for a reliable and efficient way to manufacture CZ Purlins? Look no further, as HangZhou Roll Forming Machinery Co.,Ltd has the perfect solution for you - their advanced CZ Purlin Roll Forming Machine, which is making waves in the market. In this blog post, we will dive into the details of this remarkable product, exploring its features, benefits, and why it is a game-changer in the steel manufacturing industry.What is a CZ Purlin, you may ask? Well, it is a structural member found in roof trusses and walls to provide support and stability to a building. CZ Purlins are widely used in industrial and commercial construction due to their versatility and strength. With the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd, producing these components becomes a breeze.Now, let's take a closer look at this exceptional machine. Equipped with cutting-edge technology, the CZ Purlin Roll Forming Machine is designed to optimize efficiency and productivity. Its high-speed production capability can churn out CZ Purlins with incredible precision and accuracy, meeting the strictest industry standards. With this machine, you can say goodbye to manual labor-intensive processes and hello to automated precision manufacturing.One of the notable features of the CZ Purlin Roll Forming Machine is its versatility. It can handle various sizes and thicknesses of CZ Purlins, allowing you to cater to different construction needs. This flexibility is a huge advantage, as it eliminates the need to invest in multiple machines for different CZ Purlin specifications. With just one machine, you can produce a wide range of CZ Purlins, saving both space and resources.The CZ Purlin Roll Forming Machine boasts a user-friendly interface, making it accessible to operators of all skill levels. Its intuitive controls and adjustable parameters empower operators to customize output according to specific project requirements. Whether you need CZ Purlins for low-rise or high-rise buildings, this machine can adapt to meet your demands.Durability and reliability are crucial when it comes to machinery, and the CZ Purlin Roll Forming Machine does not disappoint. Built with top-quality materials, it can withstand heavy-duty usage and deliver consistent results over an extended period. This machine is engineered to endure the demands of high-volume production without compromising on its precision and performance.However, the advantages of the CZ Purlin Roll Forming Machine go beyond its features. Investing in this machine can yield significant benefits for your business. Firstly, it eliminates the need for outsourcing CZ Purlin production, saving you time and money. By bringing the manufacturing process in-house, you gain better control over your supply chain, ensuring uninterrupted production and timely delivery.Secondly, the CZ Purlin Roll Forming Machine enhances the overall quality of your CZ Purlins, which boosts customer satisfaction and improves your reputation. With precise dimensions, consistent results, and superior strength, your clients will have confidence in your product. This, in turn, leads to increased customer loyalty and repeat business.Moreover, the CZ Purlin Roll Forming Machine promotes sustainability. By being more energy-efficient and reducing material waste, it aligns with environmental regulations and supports your company's commitment to a greener future. Not only will you benefit from cost savings, but you will also contribute positively to the environment.In conclusion, the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd is a game-changer in the steel manufacturing industry. Its advanced technology, versatility, user-friendly interface, durability, and numerous benefits make it a must-have for any construction company. With this machine, you can streamline your production process, enhance your product quality, and position your business for growth and success. Say goodbye to manual labor and inefficiency, and embrace automation and precision with the CZ Purlin Roll Forming Machine.

Short Lead Time for Plastic PVC Profile Making Machine - PE Hollow Grid Sheet Production Line by JEEBO Machinery: China Qingdao JBD Machinery Introduction

PE Hollow profile sheet is becoming an increasingly popular material in various industries due to its unique properties. With its high light transmittance, weather resistance, fire resistance, impact resistance, lightweight nature, heat insulation, and UV resistance, it has a wide range of applications.One of the main applications of PE Hollow profile sheet is in light covers. Due to its high light transmittance, it allows light to pass through easily, providing ample illumination while still offering protection. This makes it ideal for use in lighting fixtures, such as lamps, ceiling lights, and outdoor lighting. The transparent nature of the sheet ensures that the full brightness of the light source is maintained, without any loss in intensity.Another common application of PE Hollow profile sheet is in greenhouses. Its weather resistance and light transmittance properties make it an ideal material for creating a controlled environment for plants to grow. The sheet allows sunlight to enter the greenhouse, providing the necessary light for photosynthesis, while protecting the plants from harsh weather conditions. Its UV resistance ensures that the plants are not exposed to harmful rays, preventing damage and ensuring healthy growth.PE Hollow profile sheet is also widely used in interior decor. Its lightweight nature makes it easy to handle and install, allowing for creative design possibilities. It can be used to create partitions, room dividers, ceiling panels, and decorative screens. The sheet's high light transmittance can be utilized to create a bright and open space, while its impact resistance ensures durability and longevity.Soundproofing is another application where PE Hollow profile sheet excels. Its unique structure and material composition make it an effective barrier against sound waves. The sheet can be used to create soundproof partitions, walls, and enclosures, reducing noise levels and providing a peaceful environment. Whether it is for residential, commercial, or industrial applications, the sheet's soundproofing properties make it a valuable asset.When it comes to manufacturing PE Hollow profile sheet, a Profile Sheet Making Machine is essential. This machine is specifically designed to produce high-quality profile sheets with precision and efficiency. The Short Lead Time for Plastic PVC Profile Making Machine offered by JEEBO Machinery in China is an excellent choice for this purpose.By investing in this state-of-the-art machine, manufacturers can ensure a smooth and seamless production process. The machine's advanced features and technology enable it to produce profile sheets with consistent quality, meeting the required specifications. Its short lead time ensures a quick turnaround, allowing manufacturers to fulfill customer orders promptly.With the increasing demand for PE Hollow profile sheet, it is crucial to have a reliable and efficient Profile Sheet Making Machine. JEEBO Machinery, with its years of experience and expertise in the industry, provides top-quality machines that are designed to meet the diverse needs of manufacturers. Their commitment to delivering exceptional products and services has made them a trusted name in the market.In conclusion, PE Hollow profile sheet has revolutionized many industries due to its exceptional properties. Whether it is for light covers, greenhouses, interior decor, soundproofing, or any other application, this versatile material offers numerous advantages. To ensure a smooth production process and high-quality output, investing in a reliable Profile Sheet Making Machine is crucial. JEEBO Machinery stands out as a leading manufacturer in China, providing top-notch machines with a short lead time. With their expertise and commitment to customer satisfaction, they are the ideal choice for all profile sheet manufacturing needs.

Innovative Sheet Machine Technology: A Game Changer for the Industry

High-Tech Company Develops Innovative Profile Sheet Machine to Revolutionize Manufacturing IndustryIn today’s fast-paced and competitive manufacturing industry, the demand for advanced technologies and innovative solutions continues to rise. Recognizing this need, [Company Name], a leading high-tech company, has developed a cutting-edge Profile Sheet Machine that is set to revolutionize the way profiles and sheets are manufactured.With a focus on precision, efficiency, and versatility, the Profile Sheet Machine is designed to meet the diverse needs of various industries, including construction, automotive, aerospace, and beyond. By leveraging the latest technological advancements, [Company Name] has created a state-of-the-art machine that offers unmatched capabilities and performance.The Profile Sheet Machine is equipped with advanced automation features, allowing for seamless and precise production of profiles and sheets. This not only minimizes the margin of error but also significantly enhances productivity and throughput. The machine also boasts a user-friendly interface, making it easy for operators to set up and monitor the manufacturing process, further increasing efficiency and reducing downtime.One of the key highlights of the Profile Sheet Machine is its ability to accommodate a wide range of materials, including aluminum, stainless steel, and various alloys. This flexibility enables manufacturers to produce an extensive array of profiles and sheets to meet the specific requirements of their projects. Whether it’s creating intricate designs or large-scale components, the machine delivers consistent and high-quality results.Furthermore, the Profile Sheet Machine is designed to optimize material usage, thereby reducing waste and ultimately contributing to a more sustainable manufacturing process. By implementing advanced cutting and forming techniques, the machine ensures minimal material loss while maintaining utmost accuracy and precision.In addition to its technical capabilities, [Company Name] has also prioritized the safety and maintenance aspects of the Profile Sheet Machine. The machine is equipped with comprehensive safety features to protect operators and maintain a secure working environment. Moreover, it is designed for easy maintenance, with accessible components and a robust build that ensures longevity and reliability.As a pioneer in high-tech solutions, [Company Name] has a long-standing reputation of delivering cutting-edge products and services to its clients. With a strong focus on research and development, the company is committed to pushing the boundaries of innovation and continuously enhancing its offerings to address the evolving needs of the industry.With the launch of the Profile Sheet Machine, [Company Name] aims to set new industry standards and empower manufacturers to achieve new levels of efficiency and quality in their production processes. By providing a reliable and advanced solution that meets the demands of modern manufacturing, the company is poised to make a significant impact on the industry landscape.The unveiling of the Profile Sheet Machine is a testament to [Company Name]’s unwavering dedication to technological advancement and customer satisfaction. As the manufacturing industry continues to evolve, the company remains at the forefront, driving progress and ushering in a new era of innovation.In conclusion, the Profile Sheet Machine represents a breakthrough in manufacturing technology, offering unparalleled capabilities and performance. With its advanced features, flexibility, and commitment to quality, the machine is set to redefine the way profiles and sheets are produced, empowering manufacturers to meet the demands of the modern market. As [Company Name] continues to lead the charge in high-tech solutions, the Profile Sheet Machine stands as a testament to the company’s vision and commitment to driving progress in the industry.

Highly Efficient and Advanced Roll Forming Machine for Light Gauge Steel Keels

Light Gauge Steel Keel Roll Forming Machine – Revolutionizing the Construction Industry{Company Introduction}The construction industry has seen significant advancement in recent years with the introduction of new technologies and equipment. One such innovation that has gained tremendous popularity is the light gauge steel keel roll forming machine. These machines are used to produce steel keels that are widely used in construction projects.As the name suggests, light gauge steel keel roll forming machines are designed to produce lightweight steel keels that are used for various purposes in construction projects, such as drywall partitioning, suspended ceilings, and wall framing. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy.The Advantages of Light Gauge Steel Keel Roll Forming MachinesOne of the biggest advantages of light gauge steel keel roll forming machines is their ability to produce steel keels of various sizes and shapes. This means that these machines can produce steel keels that are tailor-made to suit specific construction needs. The use of steel keels produced by these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects.Another significant advantage of light gauge steel keel roll forming machines is their efficiency. These machines are designed to operate at high speeds, which results in a higher production rate and reduced labor costs. Additionally, the use of these machines reduces the need for on-site welding, which not only saves time but also results in higher quality work. Furthermore, these machines can produce steel keels continuously, which means that the production process is faster, more efficient, and more streamlined.Light gauge steel keel roll forming machines are also highly versatile. These machines can produce steel keels of different thicknesses, lengths, and shapes, which means that they can be used in a wide range of construction projects. Moreover, these machines are easy to set up, operate, and maintain, which ensures that they can be used by both large-scale and small-scale construction companies.The Future of Light Gauge Steel Keel Roll Forming MachinesThe demand for light gauge steel keel roll forming machines has been steadily increasing in recent years. This trend is expected to continue in the future as more construction companies realize the benefits of using these machines. The rapid urbanization and industrialization of many countries have also contributed to the growing demand for these machines as they can produce high-quality steel keels that are essential for modern construction.Given these factors, it is safe to say that the future of light gauge steel keel roll forming machines looks bright. Advances in technology are expected to make these machines even more efficient, versatile, and user-friendly than they already are. As a result, more construction companies are expected to adopt these machines, leading to increased productivity, reduced labor costs, and improved quality of work.ConclusionThe light gauge steel keel roll forming machine has revolutionized the construction industry by making the production of steel keels more efficient, versatile, and cost-effective. These machines are capable of producing steel keels of different sizes and shapes with great precision and accuracy, making them ideal for a wide range of construction projects. Additionally, the use of these machines results in faster construction process, higher durability, and better resistance to fire, moisture, and insects. With the growing demand for these machines, it is safe to say that they will continue to play a major role in the construction industry for years to come.

Universal Milling Machine with Large Table Size 300x1300mm - Metallurgical & Metalworking Machinery - Manufacturing Equipment - Machinery & Parts - Products - Cs-Cx.com

In today's fast-paced manufacturing industry, companies are constantly striving to improve efficiency and productivity. One way they achieve this is by investing in advanced machinery and equipment. Universal vertical and horizontal milling machines are one such example. These machines, with their wide range of capabilities, are essential tools for the metallurgical and metalworking industries.The table of a universal milling machine measures 300x1300mm, offering ample space for a variety of machining operations. This allows for the production of large and complex parts, as well as the ability to work on multiple small parts simultaneously. The size of the table also enables operators to use different types of fixtures and clamps, facilitating precise and secure machining.One of the key features of a universal milling machine is its ability to perform both vertical and horizontal milling operations. This versatility allows manufacturers to tackle various machining tasks, ranging from simple drilling and boring to intricate contouring and threading. By having the option to perform both vertical and horizontal milling, manufacturers can optimize their production processes and eliminate the need for multiple machines, saving time and resources.The bed of a universal milling machine plays a crucial role in ensuring accuracy and stability during machining operations. The bed of this particular model, the TMS6330H from SMAC, is exceptionally wide and features keen box guide ways. These guide ways have been hardened and precision ground, providing superior rigidity and stability. As a result, the machine can withstand heavy cutting forces and vibrations, ensuring precision and repeatability in every operation.To further enhance the durability and wear resistance of the machine, the saddle of the TMS6330H is lined with TF wearable material. This lining ensures smooth movement of the saddle along the guide ways, reducing friction and extending the lifespan of the machine. The combination of the wide bed and the TF wearable material lining makes the TMS6330H a highly reliable and long-lasting milling machine.In addition to its outstanding technical specifications, SMAC is a reputable brand known for its commitment to quality and customer satisfaction. The company specializes in horizontal profiled panel manufacturing equipment, offering innovative solutions for the metalworking industry. With their expertise and experience, SMAC has developed the TMS6330H milling machine to meet the demanding needs of modern manufacturers.By investing in a universal milling machine like the TMS6330H from SMAC, manufacturers can significantly improve their production processes. With its wide bed, high rigidity, and versatile milling capabilities, this machine enables efficient and precise machining of various metal parts. Furthermore, the use of TF wearable material ensures the longevity and reliability of the machine, making it a valuable asset for any metalworking facility.In conclusion, the universal vertical and horizontal milling machine with a table measuring 300x1300mm is an indispensable tool in the metallurgical and metalworking industries. The TMS6330H model from SMAC offers exceptional performance, thanks to its wide bed, hardened guide ways, and TF wearable material lining. By investing in this advanced machinery, manufacturers can optimize their production processes, increase efficiency, and deliver high-quality products to their customers.

Optimize Your Production Efficiency with the Latest Roll Form Machine

[Publication Name] – [Date]Roll Form Machine: Shaping the Future of ManufacturingIn today's ever-evolving industrial landscape, precision and efficiency in manufacturing processes are paramount. Companies across various sectors constantly seek innovative solutions to enhance production quality and reduce costs. [Company Name], a leading player in the manufacturing industry, remains at the forefront of this drive for cutting-edge technology.With their groundbreaking development – the Roll Form Machine – [Company Name] has revolutionized the way industries shape metal sheets, opening new doors of opportunity for businesses worldwide. This state-of-the-art machinery combines advanced engineering and groundbreaking automation, resulting in unmatched precision, speed, and versatility.The Roll Form Machine developed by [Company Name] has garnered significant attention due to its ability to transform flat pieces of metal into complex profiles and shapes with remarkable precision. The machine utilizes a continuous process where the metal sheet is fed into the machine, and through a series of carefully designed rolling dies, it is gradually formed into the desired shape.One of the key advantages of the Roll Form Machine lies in its flexibility. With interchangeable rolling dies and adjustable settings, the machine can easily adapt to produce a wide range of profiles and shapes. This versatility eliminates the need for multiple specialized machines, streamlining production processes and reducing costs for manufacturers.Furthermore, the Roll Form Machine boasts a rapid production speed that sets it apart from traditional manufacturing methods. By utilizing automated processes, [Company Name] has significantly enhanced the efficiency of roll forming, enabling manufacturers to achieve higher volumes and faster turnarounds. This advantage becomes particularly crucial for industries with high production demands, such as automotive, construction, and appliance manufacturing.Additionally, the Roll Form Machine ensures exceptional precision and accuracy throughout the entire production process. With advanced sensors and feedback systems, [Company Name] has implemented stringent quality control measures to meet the most demanding industry standards. The machine's ability to consistently deliver high-quality products with minimized defects has garnered praise from manufacturers seeking to maintain an edge in an increasingly competitive market.[Company Name], renowned for its commitment to innovation, has integrated cutting-edge automation technologies into the Roll Form Machine. Through the use of sophisticated software and control systems, the machine enables seamless integration into existing manufacturing setups. This seamless integration allows for centralized control, simplifies maintenance, and optimizes production schedules, empowering manufacturers to achieve higher productivity and reduce downtime.Moreover, the Roll Form Machine prioritizes safety, addressing a critical concern in the manufacturing industry. [Company Name] has invested in comprehensive safety measures, including emergency stop mechanisms, safety guards, and employee training, ensuring a secure and user-friendly operating environment. By prioritizing safety, the company aims to minimize accidents, protect its workers, and bolster customer trust in their products.The Roll Form Machine has already gained recognition and adoption within the manufacturing industry, with prominent companies across various sectors embracing its capabilities. Its impact has been particularly notable in the construction sector, as it allows for the rapid production of complex and customized profiles required for modern architectural designs.[Company Name] remains committed to research and development, continuously improving and expanding the capabilities of the Roll Form Machine. By working closely with their customers, the company seeks to understand the ever-changing needs of the industry and develop tailored solutions that propel manufacturing processes into the future.As the industrial landscape advances towards automation and precision, the Roll Form Machine developed by [Company Name] emerges as a game-changer, revolutionizing the way manufacturers shape metal sheets. With its remarkable flexibility, speed, precision, and safety features, this cutting-edge machinery promises to reshape industries and unlock new possibilities for businesses worldwide.###[Word Count: 649]

Efficient and Reliable Tile Roll Forming Machine for Step Tile Production

Step Tile Roll Forming Machine Revolutionizes Roofing IndustryIn today's fast-paced world, technological advancements are not only changing the way we live and work but also revolutionizing industries across the board. One such industry that is currently experiencing a transformation is the roofing industry, thanks to the innovative Step Tile Roll Forming Machine.The XYZ Company has recently introduced the Step Tile Roll Forming Machine, which is set to redefine the way roofing materials are manufactured and installed. This cutting-edge machine is designed to produce high-quality step tile roofing sheets with incredible precision and efficiency, making it a game-changer for roofing companies and construction projects.The Step Tile Roll Forming Machine utilizes state-of-the-art technology to roll and form metal sheets into step tiles, which are widely used in residential and commercial roofing applications. The machine is equipped with advanced features such as automatic material feeding, precise profiling, and adjustable cutting systems, allowing for seamless and accurate production of step tile roofing sheets.One of the key advantages of the Step Tile Roll Forming Machine is its ability to increase productivity and reduce production costs for roofing companies. With its high-speed operation and minimal material wastage, the machine enables manufacturers to meet the growing demand for step tile roofing sheets while maintaining a competitive edge in the market.Furthermore, the Step Tile Roll Forming Machine offers unparalleled versatility, allowing for the customization of step tile profiles to meet specific project requirements. This flexibility ensures that roofing contractors can cater to a wide range of architectural designs and building styles, providing their clients with tailored roofing solutions.The introduction of the Step Tile Roll Forming Machine is a testament to XYZ Company's commitment to innovation and excellence in the roofing industry. With years of experience and expertise in manufacturing roll forming machines, the company has established itself as a leader in the field, delivering cutting-edge solutions that meet the evolving needs of the market.In addition to the Step Tile Roll Forming Machine, XYZ Company also offers comprehensive training and technical support to help roofing professionals integrate the machine into their operations seamlessly. This dedication to customer satisfaction and after-sales service sets the company apart and reinforces its position as a trusted partner for roofing businesses.The impact of the Step Tile Roll Forming Machine is already being felt across the roofing industry, with early adopters praising its efficiency, reliability, and cost-saving benefits. As more companies embrace this innovative technology, it is expected to drive a significant shift in the way step tile roofing sheets are manufactured and installed, setting new standards for quality and performance.In conclusion, the Step Tile Roll Forming Machine from XYZ Company marks a significant milestone in the roofing industry, ushering in a new era of efficiency and precision in the production of step tile roofing sheets. With its advanced features and unparalleled capabilities, the machine is poised to revolutionize the way roofing materials are made, ultimately benefiting roofing companies, construction projects, and the end-users. As the demand for high-quality and customizable roofing solutions continues to rise, the Step Tile Roll Forming Machine stands ready to meet the challenges of the future and redefine the standards of excellence in the industry.

Europe Standard C Z Purlin Punching Holes Interchangeable Making Machine

Title: Advanced CZ Purlin Punching Holes Interchangeable Making Machine Sets New Industry StandardIntroduction (100 words):In an era marked by technological advancements and growing industrial demands, companies are continuously seeking innovative solutions to enhance efficiency and productivity. Recognizing this need, a leading manufacturing firm has successfully launched the all-new CZ Purlin Punching Holes Interchangeable Making Machine in Europe. Developed in accordance with the highest industry standards, this cutting-edge machine offers numerous benefits, from streamlining production processes to ensuring unparalleled accuracy. By removing specific brand names, we can focus on shed light on the machine's specifications, features, and potential impact on the market.Body:1. Industry Overview (150 words):The construction industry is witnessing a constant surge in demand, driving companies to adopt state-of-the-art machinery and equipment. CZ purlins, widely used in construction projects, provide structural support, making them crucial components. However, traditional manufacturing processes often present challenges in terms of efficiency, productivity, and accuracy. Addressing these concerns, the newly launched CZ Purlin Punching Holes Interchangeable Making Machine paves the way for enhanced production capabilities and superior quality outputs.2. Key Features and Specifications (200 words):The CZ Purlin Punching Holes Interchangeable Making Machine boasts several noteworthy features. Manufactured according to European standards, this machine ensures optimal performance and durability. Its punching holes are interchangeable, offering flexibility and versatility in shaping CZ purlins with different specifications. A robust hydraulic system facilitates smooth operations and consistent accuracy, reducing errors and enhancing overall output quality.Additionally, the machine incorporates advanced computer numerical control (CNC) technology. This cutting-edge system enables seamless integration with computer-aided design (CAD) software, enabling precise customization and design adjustments. As a result, manufacturers can effortlessly adapt to diverse project requirements while significantly shortening lead times.3. Advantages and Benefits (200 words):By utilizing the CZ Purlin Punching Holes Interchangeable Making Machine, manufacturers can experience a multitude of benefits. Notably, the machine streamlines the entire production process, enhancing efficiency and reducing operational costs. The interchangeable punching holes allow for quick reconfiguration, significantly enhancing flexibility and adaptability. This enables manufacturers to seamlessly switch between different CZ purlin specifications, minimizing downtime and maximizing productivity.Moreover, the precise punching process ensures superior quality outputs with minimal wastage. The machine's CNC integration further enhances accuracy and customization possibilities, allowing manufacturers to meet even the most intricate design requirements. By optimizing production processes, manufacturers can meet tight project deadlines, gain a competitive edge, and increase customer satisfaction.4. Market Outlook and Conclusion (150 words):The introduction of the CZ Purlin Punching Holes Interchangeable Making Machine signals a paradigm shift in the construction industry's manufacturing landscape. With its advanced features and adherence to European standards, this machine has the potential to disrupt the market by offering unparalleled efficiency and accuracy.As manufacturers become increasingly conscious of the need for sustainable practices and streamlined processes, the CZ Purlin Punching Holes Interchangeable Making Machine is well-positioned to cater to these demands. By investing in this innovative solution, companies can stay ahead of the competition, streamline production workflows, and optimize resource allocation.In conclusion, this new CZ Purlin Punching Holes Interchangeable Making Machine is poised to revolutionize the construction industry, delivering high-quality CZ purlins with precision and efficiency. With its ability to adapt to diverse project requirements, manufacturers can enhance productivity while meeting expanding market demands.