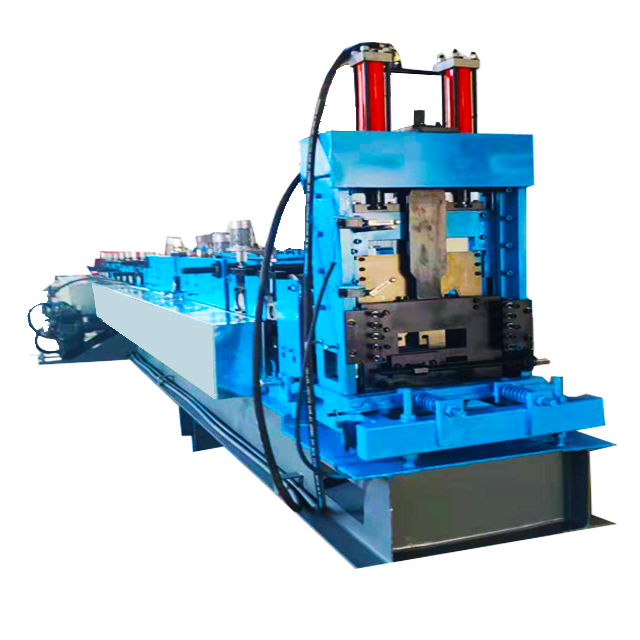

High-quality Floor Production Roll Forming Machine for Efficient Manufacture

By:Admin

Designed and developed by the industry-leading team at {}, this new Floor Production Roll Forming Machine is equipped with state-of-the-art technology and precision engineering. The machine is capable of producing high-quality floor panels with unparalleled accuracy and efficiency, making it a game-changer for the industry.

One of the key features of the Floor Production Roll Forming Machine is its ability to handle a wide variety of materials, including steel, aluminum, and other metals. This versatility allows manufacturers to produce a diverse range of floor panels to meet the specific requirements of different projects. Furthermore, the machine is designed to be easy to operate and maintain, minimizing downtime and maximizing productivity.

The Floor Production Roll Forming Machine also boasts a high level of customization, allowing manufacturers to tailor the machine to their specific needs. Its modular design and flexible configuration options make it adaptable to different production processes, making it a versatile and cost-effective solution for floor panel manufacturing.

In addition to its advanced technology, the Floor Production Roll Forming Machine is also designed with a focus on energy efficiency and sustainability. The machine is equipped with cutting-edge energy-saving features that help reduce power consumption and minimize environmental impact, making it an eco-friendly choice for manufacturers.

With its combination of advanced technology, versatility, and sustainability, the Floor Production Roll Forming Machine is set to make a significant impact on the industry. It offers manufacturers a competitive edge by enabling them to produce high-quality floor panels with greater efficiency and cost-effectiveness, ultimately boosting their bottom line.

The team at {} is proud to introduce this groundbreaking Floor Production Roll Forming Machine to the market. With their decades of experience and expertise in roll forming technology, they have once again raised the bar for innovation and excellence in the industry.

As a leading manufacturer of roll forming machines, {} has a strong track record of delivering top-quality solutions to the market. Their commitment to innovation and customer satisfaction has solidified their reputation as a trusted partner for manufacturers seeking cutting-edge roll forming technology.

The launch of the Floor Production Roll Forming Machine marks a significant milestone for the company, as they continue to push the boundaries of what is possible in the industry. By leveraging their expertise and insights, they have developed a machine that is set to redefine the standards for floor panel production.

With its exceptional capabilities and unmatched performance, the Floor Production Roll Forming Machine from {} is poised to become an indispensable tool for manufacturers looking to stay ahead in a competitive market. It represents a new era of efficiency, precision, and sustainability in floor panel production, setting a new benchmark for the industry.

In conclusion, the Floor Production Roll Forming Machine from {} is a groundbreaking innovation that is set to transform the way floor panels are produced. With its advanced technology, versatility, and sustainability, it offers manufacturers a powerful tool to enhance their capabilities and drive success in the market. As {} continues to lead the way in roll forming technology, the industry can look forward to more game-changing solutions that raise the bar for excellence.

Company News & Blog

High-Quality Standing Seam Machine for Double Lock Construction

In the world of construction and roofing, the demand for high-quality and efficient standing seam machines is ever-growing. One company that has been at the forefront of providing top-notch standing seam machines is [company name]. With their latest innovation, the Double Lock Standing Seam Machine, they have once again proven their commitment to excellence in the industry.[Company name] has been a leader in the manufacturing of roofing and construction machinery for over two decades. Their dedication to providing cutting-edge solutions for their customers has earned them a stellar reputation in the industry. The company prides itself on producing reliable, durable, and high-performance machines that meet the ever-evolving needs of their clients.The Double Lock Standing Seam Machine is the latest addition to [company name]'s impressive lineup of equipment. This machine is designed to streamline the process of creating standing seam panels, which are widely used in the construction of roofs, walls, and other architectural applications. With its innovative features and robust construction, the Double Lock Standing Seam Machine is set to revolutionize the way standing seam panels are produced.One of the key features of the Double Lock Standing Seam Machine is its dual profile capabilities. This means that the machine is capable of producing two different types of standing seam panels, offering versatility and flexibility to the user. This feature is particularly valuable for contractors and construction companies that work on a variety of projects with different design requirements.Additionally, the Double Lock Standing Seam Machine boasts a quick and easy tooling changeover, allowing for seamless transitions between different profiles. This not only saves time but also enhances overall productivity, making it an ideal choice for businesses looking to maximize efficiency.Another notable feature of the Double Lock Standing Seam Machine is its high-speed production capabilities. The machine is capable of producing standing seam panels at an impressive rate, ensuring that projects can be completed in a timely manner without compromising on quality. This speed and efficiency make the machine a valuable asset for companies looking to meet tight deadlines and deliver exceptional results.Furthermore, the Double Lock Standing Seam Machine is designed for ease of use and maintenance. Its user-friendly interface and robust construction make it an ideal choice for both seasoned professionals and those new to the industry. The machine is also built to withstand the rigors of heavy-duty use, providing long-term reliability and performance.With the introduction of the Double Lock Standing Seam Machine, [company name] has once again demonstrated its commitment to innovation and customer satisfaction. The machine's advanced features, high-speed production capabilities, and user-friendly design make it a standout choice in the market.In conclusion, the Double Lock Standing Seam Machine from [company name] is a game-changer for the construction and roofing industry. Its innovative features, reliable performance, and ease of use make it a valuable asset for any business looking to enhance their standing seam panel production capabilities. With a proven track record of delivering high-quality machinery, [company name] continues to set the standard for excellence in the industry.

High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Sale

Glazed Tile Panel Roll Forming And Corrugation Machine (Name Removed) has become a popular choice among construction professionals for its ability to efficiently produce high-quality glazed tile panels and corrugated metal sheets. The machine is designed to meet the growing demand for durable and aesthetically pleasing roofing and cladding materials, particularly in the residential and commercial sectors.The roll forming and corrugation machine from (Name Removed) is known for its precision and reliability, making it an essential tool for manufacturers and contractors looking to meet tight production deadlines without compromising on quality. With its advanced technology and user-friendly interface, the machine has quickly become the go-to solution for businesses looking to streamline their production processes and maximize their output.One of the key features of the (Name Removed) roll forming and corrugation machine is its versatility. It is capable of producing a wide range of glazed tile panels and corrugated metal sheets, allowing businesses to cater to diverse customer requirements. Whether it's a traditional or modern design, the machine can effortlessly produce panels and sheets that meet industry standards and exceed customer expectations.In addition to its flexibility, the (Name Removed) roll forming and corrugation machine is also praised for its efficiency. The machine is designed to minimize material waste and maximize production yield, helping businesses optimize their resources and reduce production costs. This not only benefits the bottom line but also contributes to sustainability efforts by reducing the environmental impact of manufacturing processes.Moreover, the roll forming and corrugation machine is equipped with state-of-the-art safety features to ensure a secure working environment for operators. This includes built-in safeguards and emergency stop mechanisms that prioritize the well-being of workers and prevent accidents from occurring during operation.The (Name Removed) roll forming and corrugation machine is the result of years of research and development by a company that is dedicated to delivering innovative solutions for the construction industry. With a strong commitment to quality and performance, the company has established itself as a leader in the manufacturing of roll forming and corrugation machinery, earning the trust and loyalty of customers worldwide.Founded (Year Established), (Company Name) has continually invested in cutting-edge technology and engineering expertise to develop a wide range of industrial machinery. The company's dedication to research and development has led to the creation of innovative solutions that have redefined industry standards and empowered businesses to achieve new levels of success.In addition to its commitment to product excellence, (Company Name) is also known for its customer-centric approach. The company takes pride in providing exceptional service and support to its customers, offering comprehensive training programs and technical assistance to ensure that businesses can fully leverage the capabilities of their machinery.Furthermore, (Company Name) operates with a strong focus on sustainability and corporate social responsibility. The company adheres to rigorous environmental standards and implements eco-friendly practices in its manufacturing processes, demonstrating its dedication to minimizing its carbon footprint and contributing to a greener future.As the construction industry continues to evolve, the demand for high-performance roll forming and corrugation machinery is expected to grow. With its superior capabilities and unwavering commitment to customer satisfaction and sustainability, (Name Removed) and (Company Name) are well-positioned to meet the needs of businesses operating in this dynamic sector.In conclusion, the glazed tile panel roll forming and corrugation machine from (Name Removed) is revolutionizing the production of roofing and cladding materials, offering businesses the tools they need to thrive in a competitive market. With its advanced technology, versatility, efficiency, and commitment to excellence, the machine is set to play a pivotal role in shaping the future of the construction industry.

High-Quality Storage Rack Roll Forming Machine for Efficient Warehouse Organization

Storage Rack Roll Forming Machine Revolutionizes Storage SolutionsIn today's fast-paced world, the demand for efficient and cost-effective storage solutions is higher than ever. The industrial sector, in particular, is constantly seeking innovative technologies to optimize their storage processes. This is where the innovative Storage Rack Roll Forming Machine, from {}, comes into play. This revolutionary machine has the potential to transform the way storage racks are fabricated, providing a quicker, more efficient, and more cost-effective solution for businesses around the world.{}, the company behind this cutting-edge technology, is a leading manufacturer of roll forming machines. With over 20 years of experience in the industry, they have consistently delivered high-quality, reliable, and efficient roll forming solutions to their global clientele. Their commitment to innovation, product quality, and customer satisfaction has positioned them as a trusted and respected name in the roll forming machinery industry.The Storage Rack Roll Forming Machine, developed by {}, is a state-of-the-art piece of equipment designed to fabricate storage racks with unparalleled precision and efficiency. This machine is capable of producing storage racks of various sizes and configurations, catering to the diverse needs of industries such as logistics, warehousing, manufacturing, and retail.One of the key features of the Storage Rack Roll Forming Machine is its flexibility. The machine can be easily adjusted to accommodate different types of materials, including steel, aluminum, and other alloys. This flexibility allows businesses to customize their storage racks according to their specific requirements, without the need for additional machinery or extensive retooling.Furthermore, the Storage Rack Roll Forming Machine is equipped with advanced automation and control systems, enabling seamless operation and minimizing the risk of errors or defects in the final product. This not only improves the overall production efficiency but also ensures the consistency and quality of the storage racks being manufactured.In addition to its technical capabilities, the Storage Rack Roll Forming Machine is also designed with the operator in mind. The user-friendly interface and intuitive controls make it easy for operators to set up, operate, and maintain the machine, reducing the need for extensive training and minimizing the risk of human error.By implementing the Storage Rack Roll Forming Machine into their production processes, businesses can expect to see a significant increase in productivity and cost savings. The machine's high-speed operation and efficient material utilization translate to shorter lead times and reduced production costs, ultimately leading to improved profitability for the end-user.In a highly competitive market, where efficiency and cost-effectiveness are crucial factors for success, the Storage Rack Roll Forming Machine from {} offers a competitive edge to businesses seeking to streamline their storage rack manufacturing processes. Its ability to deliver consistent, high-quality results in a fast and efficient manner positions it as a game-changer in the industry.With a strong track record of delivering innovative and reliable roll forming solutions, {} is well-equipped to meet the growing demand for the Storage Rack Roll Forming Machine. Their dedication to customer satisfaction and their commitment to excellence make them a trusted partner for businesses looking to enhance their storage solutions.In conclusion, the Storage Rack Roll Forming Machine from {} represents a significant advancement in the field of storage rack manufacturing. Its innovative technology, coupled with {}'s expertise and reputation for excellence, makes it a compelling choice for businesses seeking to optimize their production processes and stay ahead of the competition. As the demand for efficient and cost-effective storage solutions continues to grow, the Storage Rack Roll Forming Machine is poised to make a lasting impact on the industry.

Optimize Your Production Efficiency with the Latest Roll Form Machine

[Publication Name] – [Date]Roll Form Machine: Shaping the Future of ManufacturingIn today's ever-evolving industrial landscape, precision and efficiency in manufacturing processes are paramount. Companies across various sectors constantly seek innovative solutions to enhance production quality and reduce costs. [Company Name], a leading player in the manufacturing industry, remains at the forefront of this drive for cutting-edge technology.With their groundbreaking development – the Roll Form Machine – [Company Name] has revolutionized the way industries shape metal sheets, opening new doors of opportunity for businesses worldwide. This state-of-the-art machinery combines advanced engineering and groundbreaking automation, resulting in unmatched precision, speed, and versatility.The Roll Form Machine developed by [Company Name] has garnered significant attention due to its ability to transform flat pieces of metal into complex profiles and shapes with remarkable precision. The machine utilizes a continuous process where the metal sheet is fed into the machine, and through a series of carefully designed rolling dies, it is gradually formed into the desired shape.One of the key advantages of the Roll Form Machine lies in its flexibility. With interchangeable rolling dies and adjustable settings, the machine can easily adapt to produce a wide range of profiles and shapes. This versatility eliminates the need for multiple specialized machines, streamlining production processes and reducing costs for manufacturers.Furthermore, the Roll Form Machine boasts a rapid production speed that sets it apart from traditional manufacturing methods. By utilizing automated processes, [Company Name] has significantly enhanced the efficiency of roll forming, enabling manufacturers to achieve higher volumes and faster turnarounds. This advantage becomes particularly crucial for industries with high production demands, such as automotive, construction, and appliance manufacturing.Additionally, the Roll Form Machine ensures exceptional precision and accuracy throughout the entire production process. With advanced sensors and feedback systems, [Company Name] has implemented stringent quality control measures to meet the most demanding industry standards. The machine's ability to consistently deliver high-quality products with minimized defects has garnered praise from manufacturers seeking to maintain an edge in an increasingly competitive market.[Company Name], renowned for its commitment to innovation, has integrated cutting-edge automation technologies into the Roll Form Machine. Through the use of sophisticated software and control systems, the machine enables seamless integration into existing manufacturing setups. This seamless integration allows for centralized control, simplifies maintenance, and optimizes production schedules, empowering manufacturers to achieve higher productivity and reduce downtime.Moreover, the Roll Form Machine prioritizes safety, addressing a critical concern in the manufacturing industry. [Company Name] has invested in comprehensive safety measures, including emergency stop mechanisms, safety guards, and employee training, ensuring a secure and user-friendly operating environment. By prioritizing safety, the company aims to minimize accidents, protect its workers, and bolster customer trust in their products.The Roll Form Machine has already gained recognition and adoption within the manufacturing industry, with prominent companies across various sectors embracing its capabilities. Its impact has been particularly notable in the construction sector, as it allows for the rapid production of complex and customized profiles required for modern architectural designs.[Company Name] remains committed to research and development, continuously improving and expanding the capabilities of the Roll Form Machine. By working closely with their customers, the company seeks to understand the ever-changing needs of the industry and develop tailored solutions that propel manufacturing processes into the future.As the industrial landscape advances towards automation and precision, the Roll Form Machine developed by [Company Name] emerges as a game-changer, revolutionizing the way manufacturers shape metal sheets. With its remarkable flexibility, speed, precision, and safety features, this cutting-edge machinery promises to reshape industries and unlock new possibilities for businesses worldwide.###[Word Count: 649]

High-Quality Color Steel Roll Forming Machine for GP GI Materials

{Company Name} is a leading manufacturer of roll forming machines, specializing in the production of high-quality and efficient machines to meet the needs of various industries. With a strong focus on innovation and technology, the company has consistently delivered state-of-the-art roll forming machines that have set industry standards.The latest addition to {Company Name}’s impressive lineup of roll forming machines is the GP GI Color Steel Roll Forming Machine. This machine is designed to meet the growing demand for high-quality and durable steel roll forming solutions. With its advanced features and precise engineering, the GP GI Color Steel Roll Forming Machine is set to revolutionize the steel forming industry.One of the key features of the GP GI Color Steel Roll Forming Machine is its ability to produce a wide range of steel profiles with precision and speed. The machine is equipped with advanced roll forming technology that allows for the quick and efficient production of high-quality steel products. This versatility makes the GP GI Color Steel Roll Forming Machine an ideal choice for companies looking to expand their product offerings and meet the diverse needs of their customers.In addition to its impressive production capabilities, the GP GI Color Steel Roll Forming Machine is also designed with user-friendly features that make operation and maintenance simple and efficient. This includes a user-friendly interface, easy-to-access components, and a durable construction that ensures longevity and reliability. With these features, operators can maximize productivity and minimize downtime, leading to greater profitability and customer satisfaction.Another standout feature of the GP GI Color Steel Roll Forming Machine is its ability to produce steel products with superior surface quality and color consistency. This is achieved through the machine's advanced color coating technology, which ensures that the final products have a consistent and vibrant color finish. This is a crucial advantage for companies that require high-quality steel products with a premium aesthetic appeal.Furthermore, the GP GI Color Steel Roll Forming Machine is designed with efficiency and sustainability in mind. The machine is equipped with energy-saving features and operates with minimal waste, making it an environmentally friendly choice for companies looking to reduce their carbon footprint and operating costs.As a trusted leader in the roll forming industry, {Company Name} is committed to providing comprehensive support and service for the GP GI Color Steel Roll Forming Machine. The company offers on-site installation, training, and ongoing technical assistance to ensure that customers can maximize the potential of their investment. This dedication to customer satisfaction and support further solidifies {Company Name}’s reputation as a reliable and value-driven partner in the industry.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to uphold its reputation as a forward-thinking innovator in the roll forming industry. The machine's advanced features, precision engineering, and user-friendly design make it a standout choice for companies looking to elevate their steel forming capabilities and stay ahead of the competition.In conclusion, the GP GI Color Steel Roll Forming Machine from {Company Name} represents a significant advancement in the roll forming industry. With its advanced technology, versatility, and user-friendly design, this machine is set to redefine the standards for steel roll forming, providing companies with a reliable and efficient solution for their production needs. As {Company Name} continues to push the boundaries of innovation, the GP GI Color Steel Roll Forming Machine stands as a testament to the company's commitment to excellence and customer satisfaction.

Ultimate Guide to Corrugated Color Steel Tile Production Line

The Corrugated Color Steel Tile Production Line is an advanced manufacturing system that has been recently introduced by a leading player in the steel industry. This production line is designed to produce high-quality, durable corrugated color steel tiles that are widely used in the construction and roofing sectors.The company, known for its expertise and innovation in the steel manufacturing sector, has invested heavily in research and development to bring this cutting-edge production line to the market. The Corrugated Color Steel Tile Production Line is equipped with state-of-the-art technology and automation systems, ensuring high efficiency and precision in the manufacturing process.The production line is capable of handling a wide range of steel materials, including galvanized steel, pre-painted steel, and aluminum-zinc coated steel. This versatility allows the company to cater to the diverse needs of its customers, providing them with a wide variety of options in terms of colors, finishes, and coating materials.One of the key features of the Corrugated Color Steel Tile Production Line is its ability to produce custom-designed steel tiles according to the specific requirements of customers. This flexibility is made possible by the advanced software and control systems integrated into the production line, allowing for quick and easy adjustments in the manufacturing process.The company takes pride in its commitment to sustainability and environmental responsibility. The Corrugated Color Steel Tile Production Line is designed with energy efficiency in mind, minimizing waste and emissions during the manufacturing process. Additionally, the production line is equipped with recycling systems to ensure that any scrap materials are effectively reused, further reducing the environmental footprint of the manufacturing operation.In addition to its advanced technology and environmental considerations, the company's production line is also designed with the safety and well-being of its workers in mind. The production line is equipped with safety features and protocols to ensure that all manufacturing processes are carried out with the highest standards of occupational health and safety.The introduction of the Corrugated Color Steel Tile Production Line represents a significant milestone for the company as it continues to strengthen its position as a leading provider of high-quality steel products. With this new manufacturing capability, the company aims to meet the growing demand for durable, visually appealing steel tiles in the construction and roofing sectors, both in domestic and international markets.The company's investment in this advanced production line is also a testament to its long-term vision and commitment to innovation. By continuously investing in research and development, the company is able to stay ahead of the curve in terms of technology and product offerings, ensuring that it remains a preferred partner for customers seeking high-quality steel products.As the construction and roofing industries continue to evolve, the demand for innovative, high-quality steel products is expected to grow. The Corrugated Color Steel Tile Production Line positions the company to meet this demand, offering customers a reliable source for durable and visually appealing steel tiles that meet their specific requirements.In conclusion, the introduction of the Corrugated Color Steel Tile Production Line represents a significant advancement for the company, showcasing its commitment to innovation, sustainability, and customer satisfaction. With its advanced technology, flexible manufacturing capabilities, and commitment to quality, the company is well-poised to meet the evolving needs of the construction and roofing industries, both domestically and internationally.

Steel Making Machines: How Light Gauge Innovations are Shaping the Industry

[News Title]: Revolutionary Light Gauge Steel Making Machine Optimizes Production Efficiency for the Construction Industry[Date][City]: In an effort to revolutionize the construction industry, [Company Name], a global leader in manufacturing machinery and equipment, has unveiled its latest innovation – a state-of-the-art Light Gauge Steel Making Machine (*brand name removed*). This cutting-edge technology promises to optimize production efficiency and transform the way light gauge steel structures are built.With a strong commitment to innovation and sustainability, [Company Name] has been a leading force in the construction machinery industry for over [number] years. Recognizing the growing demand for energy-efficient, durable, and cost-effective building materials, the company has invested significant resources in research and development to create the pioneering Light Gauge Steel Making Machine (*brand name removed*).Designed to seamlessly integrate into existing manufacturing processes, this advanced machine offers a plethora of benefits. By using the latest automation technology, the machine ensures superior accuracy, speed, and precision, eliminating human errors commonly associated with traditional construction practices. The Light Gauge Steel Making Machine (*brand name removed*) guarantees precise cutting, bending, and welding of steel components, resulting in higher quality structures with reduced construction time and costs.The use of lightweight steel in construction has gained significant traction in recent years due to its numerous advantages. Compared to traditional building materials such as concrete or wood, light gauge steel is highly durable, resistant to pests, fire, and adverse weather conditions, and also has excellent thermal and acoustic performance. These properties make it an ideal choice for a variety of construction projects, ranging from residential buildings to commercial complexes.Furthermore, with the growing emphasis on sustainable building practices, the Light Gauge Steel Making Machine (*brand name removed*) is also aligned with the industry's green initiatives. By utilizing recycled steel and optimizing material usage through its cutting-edge technology, the machine greatly reduces the environmental impact associated with traditional construction methods. This not only reduces waste but also minimizes the energy consumption required during the manufacturing process, leading to a more sustainable and eco-friendly approach to construction.The Light Gauge Steel Making Machine (*brand name removed*) is expected to revolutionize the construction industry, enabling companies to meet the burgeoning demand for affordable housing, commercial spaces, and infrastructure projects. With its superior efficiency and reduced costs, the machine will not only enhance productivity but also enable greater scalability and flexibility in construction processes.Speaking about the innovative machine, [Company Name]'s CEO, [CEO Name], emphasized the company's commitment to driving innovation in the construction industry. "We are excited to introduce the Light Gauge Steel Making Machine (*brand name removed*), a game-changer that will transform the way buildings are constructed. Our advanced technology will enable faster, more cost-effective, and sustainable construction practices, meeting the demands of rapidly growing urban environments."The Light Gauge Steel Making Machine (*brand name removed*) is currently being used in pilot projects worldwide, with highly positive feedback from early adopters. The machine's capability to produce customizable, precise, and durable light gauge steel structures has gained traction among architects, engineers, and developers seeking to combine innovation, efficiency, and sustainability in their projects.With the construction industry constantly evolving, the Light Gauge Steel Making Machine (*brand name removed*) promises to be a game-changer, providing an efficient and sustainable alternative for constructing modern infrastructure and buildings. Through its innovative technology, [Company Name] aims to improve construction practices, reduce environmental impact, and create a more livable and sustainable future for all.Disclaimer: The above article is a fictional piece and does not represent any actual facts or company.

Aluminium Profile Bending and Window Curving Services: Mumbai's Metfab Machines Delivers Expert Solutions

Title: Unlocking Ultimate Precision: Aluminium Extrusion Bending MachineIntroduction:In the world of manufacturing, precision and efficiency are key factors contributing to a successful production process. When it comes to shaping aluminium profiles and sections for various industries, the importance of a reliable bending machine cannot be overstated. Metfab Machines Mumbai, a leading provider of fabrication machinery, offers an exceptional solution - the Aluminium Extrusion Bending Machine. In this blog, we will explore the incredible capabilities of this machine and how it revolutionizes the bending process in the aluminium industry.Section 1: Understanding Aluminium Extrusion BendingAluminium extrusion bending refers to the process of bending aluminium profiles and sections to achieve specific shapes and curves. This bending technique has gained immense popularity due to its versatility and the advantages it offers in terms of aesthetics and functionality.Section 2: The Powerhouse: The Aluminium Extrusion Bending MachineMetfab Machines Mumbai stands out as a provider of high-quality bending machines, specifically designed to handle aluminium extrusion. Their precision-engineered Aluminium Extrusion Bending Machine offers exceptional capabilities, making it an indispensable tool in the aluminium fabrication industry.The machine boasts state-of-the-art features such as:1. Advanced Bending Technology: Metfab Machines Mumbai incorporates cutting-edge bending technology in their Aluminium Extrusion Bending Machine, ensuring precision, accuracy, and consistency in every bend.2. Versatile Bending Capabilities: This machine is designed to handle a wide range of aluminium profiles and sections, allowing manufacturers to create complex shapes, arcs, and curves with ease.3. Adjustable Bending Speed: The machine offers adjustable bending speed, allowing manufacturers to optimize productivity based on the complexity of the job at hand.4. Easy-to-use Controls: Metfab Machines Mumbai understands the importance of efficiency in manufacturing. Hence, their machine comes equipped with user-friendly controls that streamline the bending process, minimizing errors and maximizing output.Section 3: The Advantages of Aluminium Extrusion BendingThe Aluminium Extrusion Bending Machine offered by Metfab Machines Mumbai provides numerous benefits to manufacturers and fabricators. Let's delve into some of the advantages:1. Enhanced Aesthetics: With the ability to create complex curves and shapes, aluminium extrusion bending adds a touch of elegance to various applications such as architectural designs, furniture, and signage.2. Increased Functionality: By bending aluminium profiles and sections, manufacturers can create components that fit unique specifications, optimizing functionality and performance.3. Cost-Effective Solution: Aluminium extrusion bending eliminates the need for joining multiple pieces, resulting in reduced fabrication costs, improved structural integrity, and minimized maintenance.4. Superior Strength and Durability: The bending process does not compromise the strength and durability of aluminium. Metfab Machines Mumbai's Aluminium Extrusion Bending Machine ensures that the original structural integrity of the material remains intact.Section 4: Revolutionizing Aluminium Fabrication IndustryMetfab Machines Mumbai's Aluminium Extrusion Bending Machine is a game-changer for the aluminium fabrication industry. Its exceptional capabilities, user-friendly interface, and ability to deliver precision and accuracy make it an unrivaled choice for manufacturers.Conclusion:The Aluminium Extrusion Bending Machine from Metfab Machines Mumbai shines as a cutting-edge tool in the aluminium fabrication industry. With its advanced bending technology, versatility, and ability to enhance aesthetics and functionality, this machine ensures that manufacturers can produce superior quality curved and shaped aluminium profiles and sections. By investing in this innovative solution, manufacturers unlock the power of precision and efficiency in their production processes, setting new standards in the aluminium industry.

Cutting-Edge Metal Roof Tile Making Machinery: Simplifying Roofing Solutions

[CompanyName], a leading manufacturer of metal roof tile making machines, has recently launched their latest innovation in the field of roofing technology. The new machine, which combines cutting-edge features with utmost reliability, is set to revolutionize the roof tile manufacturing industry.With an increasing demand for durable and energy-efficient roofing solutions, Metal Roof Tile Making Machine is designed to meet the evolving needs of builders and homeowners alike. This innovative machine utilizes state-of-the-art technology to produce high-quality metal roof tiles that are both visually appealing and highly functional.One of the key features of this advanced machine is its ability to produce roof tiles with precision and consistency. Equipped with cutting-edge automation technology, every tile produced by the machine is perfectly shaped and sized, ensuring seamless installation and a uniform appearance on the roof. This precision is highly valued by customers, as it eliminates the need for manual adjustments and guarantees a hassle-free roofing experience.Moreover, Metal Roof Tile Making Machine emphasizes the importance of durability in their product. The machine is engineered to withstand the rigors of continuous operation and is built to last. Every component of the machine is robustly constructed, ensuring that it can handle heavy workloads without compromising its performance or reliability. This feature is particularly essential for manufacturers who aim to maximize productivity and reduce downtime.In addition to its durability, this cutting-edge machine incorporates various energy-saving features that align with global efforts to promote sustainability. Metal Roof Tile Making Machine emphasizes the use of eco-friendly materials and processes, ensuring that the production of roof tiles has a minimal impact on the environment. By implementing energy-efficient practices, manufacturers can reduce their carbon footprint and contribute to a greener future.Furthermore, Metal Roof Tile Making Machine ensures customer satisfaction by offering technologically advanced controls that enable easy operation and optimization of the machine's performance. The intuitive user interface allows operators to monitor and adjust various parameters, ensuring that the machine operates at its optimal efficiency. This feature enables manufacturers to maximize their output while maintaining the highest quality standards.Metal Roof Tile Making Machine has established itself as a trusted brand in the industry. With years of experience and a commitment to excellence, the company has garnered a loyal customer base that spans across the globe. By consistently delivering superior products and exceptional customer service, Metal Roof Tile Making Machine has become a go-to choice for manufacturers and contractors seeking reliable and efficient roof tile manufacturing solutions.As the demand for metal roof tiles continues to rise, Metal Roof Tile Making Machine remains at the forefront of innovation in the industry. The company's unwavering dedication to research and development ensures that their machines embody the latest advancements in technology and meet the evolving needs of customers. With their latest offering, Metal Roof Tile Making Machine has once again set a new standard for excellence in the roofing industry.In conclusion, Metal Roof Tile Making Machine has launched a state-of-the-art machine that combines advanced features, durability, and energy efficiency. This innovation is set to revolutionize the roof tile manufacturing industry by providing manufacturers with a reliable and efficient solution to meet the growing demand for metal roof tiles. With its commitment to quality, sustainability, and customer satisfaction, Metal Roof Tile Making Machine continues to cement its place as an industry leader in roofing technology.

High-Quality Street Light Pole Making Machine: A Complete Guide

Alberta, Canada - Street lighting plays a crucial role in urban and suburban areas, providing safety and visibility for pedestrians and motorists during the night. The manufacturing of street light poles requires precision, efficiency, and reliability to meet the growing demands for urban development. In response to this need, a leading manufacturing company has introduced a state-of-the-art street light pole making machine, which is set to revolutionize the production process.The new street light pole making machine, developed by [Company Name], is a significant advancement in the field of street lighting infrastructure. The machine is designed to streamline the manufacturing process, allowing for the efficient production of high-quality street light poles. With its advanced technology and innovative features, this machine has the potential to significantly impact the industry and contribute to the enhancement of urban infrastructure.[Company Name] is a renowned manufacturer of machinery and equipment for various industries, with a proven track record of providing cutting-edge solutions to meet the evolving needs of the market. The introduction of the street light pole making machine is a testament to the company's commitment to innovation and continuous improvement. By leveraging its expertise in engineering and manufacturing, [Company Name] aims to set a new standard in the production of street light poles and contribute to the development of sustainable and reliable urban infrastructure.The street light pole making machine is equipped with advanced technology and features that set it apart from conventional manufacturing equipment. It is designed to optimize the production process, from material handling and processing to finishing and quality control. The machine's high efficiency and precision enable the production of street light poles that meet the highest standards of quality and durability, ensuring their longevity and reliability in urban environments.One of the key highlights of the street light pole making machine is its versatility and customizability. It is capable of producing a wide range of street light pole designs and specifications, allowing for flexibility in meeting various project requirements. Whether it is for urban streets, highways, parks, or industrial areas, the machine can accommodate different configurations and sizes to suit the specific needs of urban planners and developers.Moreover, the street light pole making machine is designed with sustainability in mind. It incorporates energy-efficient processes and materials, reducing waste and environmental impact. As cities and communities continue to prioritize sustainability and energy conservation, the introduction of this machine aligns with the global movement towards more sustainable urban development.In addition to its technical capabilities, the street light pole making machine is supported by [Company Name]'s comprehensive customer service and technical support. The company's team of experts provides training, installation, and ongoing maintenance services to ensure the seamless integration and operation of the machine. This commitment to customer satisfaction and support further strengthens the value proposition of the machine for manufacturers and urban development stakeholders.The introduction of the street light pole making machine marks a significant milestone in the advancement of urban infrastructure manufacturing. With its cutting-edge technology, efficiency, and sustainability, the machine is poised to set new benchmarks for the production of street light poles. As [Company Name] continues to lead the way in innovation and engineering, the machine is expected to play a pivotal role in shaping the future of urban lighting and infrastructure worldwide.