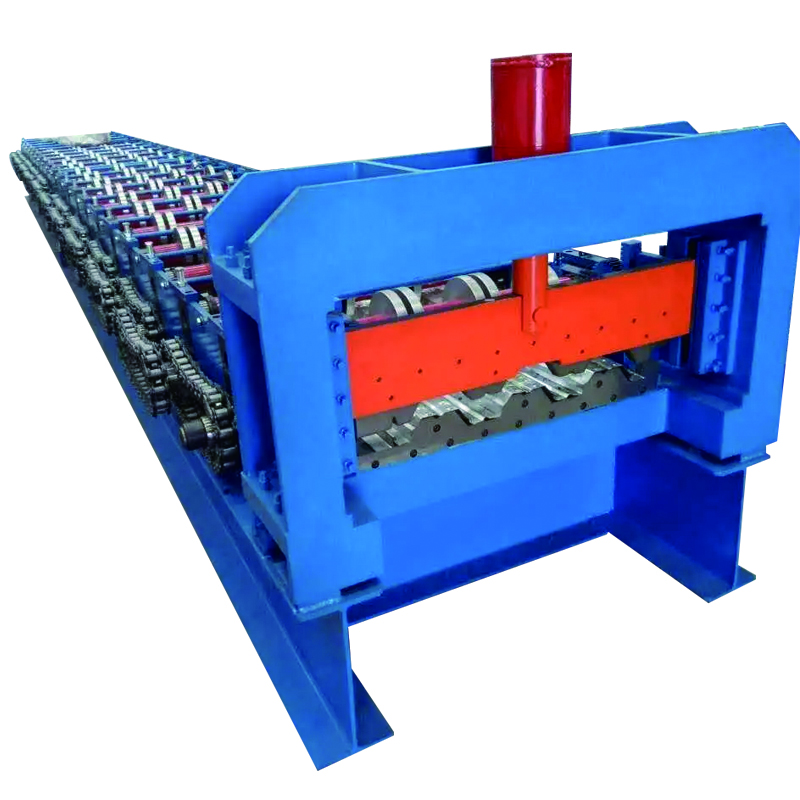

High-Quality Galvanized Steel Deck Floor Tile Making Machine for Sale

By:Admin

The galvanized steel deck floor tile making machine is designed to streamline the production of high-quality steel deck floor tiles. With its advanced technology and cutting-edge features, this machine is capable of producing tiles of various sizes and specifications, making it suitable for a wide range of construction projects.

The company behind this groundbreaking machine is a well-established manufacturer with a strong track record of delivering high-quality and innovative products to the market. With a focus on technological advancement and customer satisfaction, the company has built a reputation as a leader in the manufacturing industry.

The introduction of the galvanized steel deck floor tile making machine is a testament to the company's commitment to innovation and excellence. By investing in the development of this state-of-the-art machine, the company aims to provide construction professionals with the tools they need to improve efficiency and productivity. This, in turn, will help meet the growing demand for high-quality steel deck floor tiles in the construction industry.

One of the key features of this machine is its ability to produce galvanized steel deck floor tiles with exceptional precision and consistency. This is achieved through the use of advanced automation and control systems, which ensure that each tile meets the highest standards of quality and craftsmanship. Additionally, the machine is designed for ease of use, allowing operators to quickly set up and operate the equipment with minimal training.

The introduction of the galvanized steel deck floor tile making machine is expected to have a positive impact on the construction industry. By streamlining the production process and improving the quality of steel deck floor tiles, this machine will help construction companies meet the increasing demand for durable and reliable building materials. This, in turn, will contribute to the overall growth and development of the construction sector.

Furthermore, the company's commitment to sustainability is reflected in the design of the galvanized steel deck floor tile making machine. By using advanced technology and environmentally friendly materials, the machine minimizes waste and energy consumption, making it a more sustainable option for construction companies.

In addition to the introduction of the galvanized steel deck floor tile making machine, the company offers comprehensive support and services to its customers. This includes training, maintenance, and technical assistance, ensuring that construction professionals can maximize the machine's potential and achieve the best results.

In conclusion, the introduction of the galvanized steel deck floor tile making machine represents a significant milestone for the construction industry. With its advanced technology, precision manufacturing, and commitment to sustainability, this machine is set to make a positive impact on the production of steel deck floor tiles. As the company continues to innovate and develop new solutions, it is clear that they are dedicated to supporting the growth and success of the construction industry.

Company News & Blog

How to Choose a Reliable Glazed Tile Corrugation Machine for Color Steel Roofing Projects

Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes the Roofing Industry[date][City], [State] - [Company Name], a leading provider of advanced manufacturing solutions, has introduced a groundbreaking Color Steel Glazed Tile Corrugation Machine that is set to revolutionize the roofing industry. This cutting-edge technology is poised to transform the way roofing materials are produced, offering numerous benefits in terms of efficiency, durability, and aesthetics.The Color Steel Glazed Tile Corrugation Machine, designed and developed by [Company Name], incorporates state-of-the-art features that not only enhance productivity but also improve the overall quality of glazed tile roof panels. The machine is capable of producing perfectly corrugated tiles with a smooth surface finish, offering unmatched visual appeal and longevity to any building structure.One of the key advantages of the Color Steel Glazed Tile Corrugation Machine is its high efficiency. With advanced automation and precision engineering, this machine drastically reduces the time and effort required for tile production. This translates into higher output levels for manufacturers, enabling them to fulfill the growing demands of the market in a shorter span of time.Furthermore, the machine's ability to produce uniform and precise corrugated tiles ensures consistent quality throughout the manufacturing process. This consistency contributes to the overall durability of the finished roofing material, making it highly resistant to wear and tear, extreme weather conditions, and other external factors. The Color Steel Glazed Tile Corrugation Machine is built to last, providing long-lasting protection and aesthetic appeal to buildings.In addition to improving efficiency and durability, this innovative machine also offers enhanced aesthetic options. With a wide range of customizable features, manufacturers can now produce glazed tile roofs in various colors, patterns, and designs. This flexibility caters to diverse architectural needs and allows builders to create visually striking structures.The Color Steel Glazed Tile Corrugation Machine is equipped with advanced technology that facilitates quick and easy set-up, operation, and maintenance. Its user-friendly interface and intuitive controls ensure seamless integration into existing manufacturing processes and minimize downtime. This feature proves invaluable to manufacturers, who can now achieve optimal production levels without investing substantial time and resources into training employees.Moreover, [Company Name] stands out as an industry leader due to its commitment to sustainability. The Color Steel Glazed Tile Corrugation Machine is designed with eco-friendly measures, reducing waste generation, and optimizing energy efficiency. By adopting this machine, manufacturers can contribute to a greener future, aligning their operations with the global sustainability agenda.The introduction of the Color Steel Glazed Tile Corrugation Machine by [Company Name] marks a significant milestone in the roofing industry. Its cutting-edge features, including increased efficiency, enhanced durability, and improved aesthetics, provide manufacturers with a competitive edge. This machine is slated to reshape the roofing materials market and redefine industry standards.With its commitment to innovation, quality, and sustainability, [Company Name] continues to lead the way in the manufacturing sector. The Color Steel Glazed Tile Corrugation Machine is a testament to their dedication to developing advanced solutions that improve efficiency, durability, and aesthetics in roofing production.As the roofing industry embraces this revolutionary technology, buildings worldwide are set to benefit from the exceptional performance and appeal of glazed tile roofs. With the Color Steel Glazed Tile Corrugation Machine, [Company Name] has paved the way for a new era of excellence in the roofing industry.

High-Speed Corrugated Roll Forming Machine with Hydraulic Cutting - Ideal for 914mm and 1220mm Coil Width

Corrugated Sheet Forming Machine: A Revolutionary Solution for Modern BuildingBuilding construction is a vital industry that contributes significantly to the economy. Architects, builders, and property owners strive to create structures that are resilient and aesthetically appealing. However, the process requires heavy investment, and it's vital to use the best materials and tools. One crucial material is the corrugated sheet, which has become popular due to its durability, cost-effectiveness, and versatility. This is where the Corrugated Sheet Forming Machine comes in.The Corrugated Sheet Forming Machine is an innovative solution that has revolutionized the modern building industry. It is a machine designed to transform flat metal sheets into corrugated sheets, which are widely used for roofing, siding, and cladding applications. The machine uses a series of roller dies to create the corrugated profile, which can be customized to different shapes and sizes. It is a fast, efficient, and highly accurate way to produce high-quality corrugated sheets.One of the most important features of the Corrugated Sheet Forming Machine is its motorized cutting and fast drive system. This system allows for quick and easy processing of metal sheets, reducing the time and effort required to create corrugated sheets. Additionally, the hydraulic cutting system ensures precise cutting and minimal waste, further enhancing the machine's efficiency. The machine's 836 type, lengthened design, and 1220 mm coil width make it suitable for producing large volumes of sheets, making it ideal for commercial applications.The Corrugated Sheet Forming Machine is also highly customizable, allowing operators to create different corrugated profiles. This flexibility allows architects and builders to create unique designs that match their clients' preferences. The machine's versatility is further improved by its ability to process different metals, including galvanized steel, aluminum, and copper. This means that users can choose the material that best fits their project requirements, depending on factors such as durability, cost, and aesthetics.In conclusion, the Corrugated Sheet Forming Machine is an essential tool for the modern building industry. Its speed, accuracy, and versatility make it ideal for producing high-quality corrugated sheets for various applications. Whether you are constructing a commercial building, a residential house, or a metal structure, this machine can help you achieve your goals. If you are looking for a reliable and cost-effective way to produce corrugated sheets, the Corrugated Sheet Forming Machine is the perfect solution.

Quality Glazed Tile Roll Forming Machine and Corrugating Equipment for Sale

Glazed Tile Roll Forming And Corrugating Machine is a revolutionary piece of equipment that is set to change the game in the construction industry. This high-tech machine is designed to produce glazed tiles and corrugated sheets with precision and efficiency, making it an indispensable tool for construction companies and contractors all over the world.The Glazed Tile Roll Forming And Corrugating Machine is equipped with advanced technology and a state-of-the-art design that allows for seamless production of high-quality tiles and sheets. It is capable of working with a variety of materials, including steel, aluminum, and copper, making it a versatile choice for any construction project. The machine features a user-friendly interface, allowing operators to easily input their desired specifications and produce custom tiles and sheets with ease.One of the key features of the Glazed Tile Roll Forming And Corrugating Machine is its speed and efficiency. With the ability to produce up to 60 tiles or sheets per minute, this machine can significantly increase productivity and reduce production time, saving construction companies time and money. It also boasts a high degree of accuracy, ensuring that each tile or sheet meets the strictest quality standards.In addition to its impressive performance, the Glazed Tile Roll Forming And Corrugating Machine is also designed with sustainability in mind. It is equipped with energy-efficient components and is built to minimize waste, making it an environmentally-friendly choice for construction projects. This focus on sustainability aligns with our company's commitment to reducing our environmental impact and contributing to a greener future.Our company is a leading manufacturer of construction machinery, known for our innovative designs and commitment to quality. With over 20 years of experience in the industry, we have a proven track record of delivering reliable and efficient equipment that meets the needs of our customers. Our team of engineers and designers are dedicated to staying at the forefront of technological advancements, ensuring that our products are always cutting-edge and able to support the evolving needs of the construction industry.As part of our commitment to customer satisfaction, we offer comprehensive support services for the Glazed Tile Roll Forming And Corrugating Machine. Our team of technicians are available to provide training, technical support, and maintenance services, ensuring that our customers are able to maximize the performance of their equipment and achieve the best possible results. We also offer a range of financing options to make our equipment more accessible to a wider range of customers, allowing them to take advantage of the benefits of our cutting-edge technology.The introduction of the Glazed Tile Roll Forming And Corrugating Machine represents a significant advancement in the construction industry, offering a solution that is both efficient and sustainable. With its speed, precision, and versatility, this machine is set to revolutionize the way that construction companies produce tiles and sheets, allowing them to meet their project requirements with ease. As a leading manufacturer in the industry, we are proud to be at the forefront of this innovation and to continue supporting the success of our customers with our state-of-the-art equipment.

High Precision Automatic Aluminum Profile Cutting Machine for Efficient Manufacturing

Automatic Aluminum Profile Cutting Machine Revolutionizes Manufacturing IndustryThe manufacturing industry has seen a significant leap forward thanks to the introduction of the Automatic Aluminum Profile Cutting Machine. This state-of-the-art machine, developed by a leading manufacturer in the industry, is set to revolutionize the way aluminum profiles are cut and processed, promising greater efficiency, precision, and cost-effectiveness.The Automatic Aluminum Profile Cutting Machine comes equipped with advanced technology that allows for automated cutting of aluminum profiles with remarkable accuracy and speed. This machine is designed to handle a wide range of aluminum profiles, catering to the diverse needs of the manufacturing industry. Its high-speed cutting capability, combined with precision engineering, ensures that the finished products meet the strictest quality standards.This cutting-edge machine is a game-changer for manufacturers, offering a more efficient and streamlined production process. With its automated features, the machine significantly reduces the need for manual labor, saving time and resources while increasing productivity. The precision cutting capabilities also minimize material waste, optimizing the use of aluminum profiles and reducing production costs.In addition to its efficiency and precision, the Automatic Aluminum Profile Cutting Machine is designed with user-friendly features, making it easy to operate and maintain. This ensures that manufacturers can maximize the machine's potential without the need for extensive training or technical expertise. The machine's intuitive interface and remote monitoring capabilities further contribute to its appeal, providing manufacturers with real-time insights into the production process.The introduction of this cutting-edge machine is a testament to the continuous innovation and commitment to excellence of the manufacturing industry. This technological advancement not only improves the production process but also opens up new possibilities for product design and customization. The flexibility and versatility of the Automatic Aluminum Profile Cutting Machine allow manufacturers to explore new creative avenues and bring their innovative ideas to life.Furthermore, the company behind the development of the Automatic Aluminum Profile Cutting Machine has a long-standing reputation for delivering high-quality manufacturing solutions. With a proven track record of excellence and a commitment to customer satisfaction, the company has established itself as a trusted partner for manufacturers seeking cutting-edge technology and reliable support.The company's dedication to innovation and continuous improvement is reflected in the design and performance of the Automatic Aluminum Profile Cutting Machine. By leveraging their expertise and industry knowledge, they have created a machine that not only meets the current demands of the manufacturing industry but also anticipates future needs and challenges.The introduction of the Automatic Aluminum Profile Cutting Machine is set to have a profound impact on the manufacturing industry, offering manufacturers a competitive edge in a rapidly evolving market. With its efficiency, precision, and user-friendly features, this machine represents a significant step forward in the quest for more advanced and sustainable manufacturing processes.As the industry continues to embrace technological advancements, the Automatic Aluminum Profile Cutting Machine stands out as a groundbreaking innovation that paves the way for a more efficient, cost-effective, and environmentally friendly future in manufacturing. With its potential to revolutionize the production of aluminum profiles, this machine is poised to drive unprecedented growth and innovation across the industry.

Ultimate Guide to Horizontal Barrel Vault Panel Bending Machines

The leading manufacturer of sheet metal processing equipment, has recently launched its latest innovation, the Horizontal Barrel Vault Panel Bending Machine. This state-of-the-art machine is designed to meet the growing demand for efficient and precise panel bending in the construction and manufacturing industries.The Horizontal Barrel Vault Panel Bending Machine is a versatile and powerful tool that can handle a wide range of panel bending operations. It is equipped with advanced technology and features that enable it to bend large panels with extreme precision and accuracy. This machine is an ideal choice for fabricating curved panels that are used in various architectural and construction applications.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its horizontal design, which allows for easy loading and unloading of panels. This design also enables the machine to bend panels in a more efficient and consistent manner, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain.The company has a rich history of providing innovative and reliable sheet metal processing equipment to its customers. With over [number] years of experience in the industry, the company has built a strong reputation for delivering high-quality products and exceptional customer service. The launch of the Horizontal Barrel Vault Panel Bending Machine further demonstrates the company's commitment to meeting the evolving needs of its customers and the industry.In addition to its technical capabilities, the company is also known for its dedication to sustainability and environmental stewardship. The Horizontal Barrel Vault Panel Bending Machine is designed with energy-efficient features that help reduce power consumption and minimize its environmental impact. This commitment to sustainability aligns with the company's larger mission to develop innovative solutions that support a more sustainable and responsible manufacturing industry.The launch of the Horizontal Barrel Vault Panel Bending Machine has already generated significant interest and excitement within the industry. Many leading construction and manufacturing companies have expressed their eagerness to explore the capabilities of this new machine and incorporate it into their operations. The company is confident that the machine will make a positive impact on the industry and help its customers achieve new levels of productivity and efficiency.As the demand for curved panels continues to grow in the construction and architecture sectors, the Horizontal Barrel Vault Panel Bending Machine is expected to play a pivotal role in meeting this demand. Its advanced technology, user-friendly design, and commitment to sustainability make it a standout choice for companies looking to enhance their panel bending capabilities.The company is poised to continue its legacy of innovation and excellence with the launch of the Horizontal Barrel Vault Panel Bending Machine. With its industry-leading expertise and dedication to customer satisfaction, the company is well-positioned to shape the future of sheet metal processing and support the evolving needs of the construction and manufacturing industries.

High-Quality CNC Machine for Aluminum Extrusions

A leading aluminum extrusion company, [Company Name], has recently introduced a state-of-the-art CNC machine for aluminum extrusions to enhance its manufacturing capabilities. This new addition to their production line is expected to improve efficiency, precision, and overall quality of their extruded aluminum products.The CNC (Computer Numerical Control) machine is a highly advanced and automated piece of equipment that is capable of performing a wide range of machining tasks with extreme accuracy and consistency. With the ability to program specific designs and shapes into the machine's software, [Company Name] can now produce intricate and complex aluminum extrusions with ease.The company's decision to invest in this cutting-edge technology demonstrates its commitment to staying at the forefront of the industry and meeting the evolving needs of its customers. By integrating the CNC machine into their manufacturing processes, [Company Name] aims to streamline production, reduce lead times, and ensure the highest level of precision in every extruded aluminum product they deliver.In addition to its advanced capabilities, the CNC machine is also designed to handle a variety of aluminum alloys, further expanding [Company Name]'s ability to cater to a diverse range of industrial and commercial applications. Whether it's standard extrusions or custom-designed profiles, the CNC machine can accommodate the production of different shapes, sizes, and specifications with unparalleled accuracy.Furthermore, the CNC machine is equipped with advanced cooling and lubrication systems to maintain optimal operating conditions during the machining process. This not only helps prolong the lifespan of the cutting tools and equipment but also contributes to the overall efficiency and productivity of [Company Name]'s manufacturing operations.The implementation of the CNC machine is expected to have a significant impact on [Company Name]'s ability to meet the growing demand for high-quality aluminum extrusions in various industries, including construction, automotive, aerospace, and beyond. With the ability to produce more complex and precise extruded aluminum components, the company is well-positioned to serve a wide range of applications and projects with superior technical capabilities.In addition to the technological advancements, [Company Name] is known for its strict adherence to quality standards and industry certifications. The introduction of the CNC machine further enhances their ability to consistently deliver top-notch aluminum extrusions that meet or exceed the most stringent quality requirements.As part of its ongoing commitment to innovation and customer satisfaction, [Company Name] has also invested in training and upskilling its workforce to operate and maintain the CNC machine effectively. This ensures that the company's team members have the necessary expertise to leverage the full potential of this advanced technology and deliver the best possible results to their clients.Furthermore, the introduction of the CNC machine aligns with [Company Name]'s overall sustainability goals. By optimizing its manufacturing processes and reducing material waste through precise machining, the company aims to minimize its environmental impact and contribute to a more sustainable industry.The investment in the CNC machine for aluminum extrusions underscores [Company Name]'s dedication to continuous improvement and innovation in the field of aluminum extrusion manufacturing. As the company looks towards the future, this advanced technology will play a crucial role in driving its growth, expanding its capabilities, and maintaining its position as a leader in the industry.In conclusion, the introduction of the CNC machine for aluminum extrusions represents a significant milestone for [Company Name], as it signifies a leap forward in manufacturing capabilities and quality standards. With this cutting-edge technology at their disposal, the company is poised to meet the increasing demand for high-precision aluminum extrusions across a wide spectrum of industries, while also ensuring operational efficiency, sustainability, and customer satisfaction.

High-Quality Glazed Tile Roll Forming Machine for Metal Roofing Production

Are you in need of a high-quality glazed tile roll forming machine for your metal roofing production? Look no further than the Color Steel Glazed Metal Tile Roll Forming Machine from Dahezb.Designed for producing metal roof tiles in thicknesses ranging from 0.3-0.6mm, this machine specializes in creating aluminum roofing step tile and glazed tiles for roofing sheets. Using advanced automatic technology, it ensures fast and efficient production with consistent results, making it the perfect choice for industrial settings.One of the key advantages of the Color Steel Glazed Metal Tile Roll Forming Machine is its versatility. It can be used with a wide range of raw materials, including color steel, galvanized steel, and aluminum, giving you greater flexibility in your production processes. Additionally, it boasts a high level of precision, thanks to its advanced integrated control system that ensures every tile is made to exacting standards.Another benefit of this glazed tile roll forming machine is its ease of use. With a simple and easy-to-follow interface, it can be operated by personnel with minimal training, reducing the learning curve and saving you time and money. Its compact design also makes it ideal for smaller facilities, and it can be easily transported between locations.Finally, the Color Steel Glazed Metal Tile Roll Forming Machine is built to last. It is constructed from durable materials that can withstand heavy use, and its high-quality components ensure that it requires minimal maintenance over its lifetime. This translates to a lower total cost of ownership and a higher return on investment for your business.In conclusion, if you're looking for a reliable, efficient, and user-friendly glazed tile roll forming machine for your metal roofing production, the Color Steel Glazed Metal Tile Roll Forming Machine from Dahezb is an excellent choice. With its advanced technology, precision, versatility, and durability, it will help you take your business to the next level and meet even the most demanding production requirements.

How to Build a Sheet Metal Barn in 6 Simple Steps

Title: How to Build a Sheet Metal Barn in 6 Easy StepsIntroduction:Sheet metal barns provide an excellent solution for storage and shelter needs. Not only are they durable and cost-effective, but they can also be constructed relatively easily. In this article, we will outline a step-by-step guide on how to build a sheet metal barn in six simple steps. Whether you have experience in construction or are a DIY enthusiast, this guide will help you create your very own sheet metal barn.Step 1: Planning and PreparationBefore starting any project, careful planning is essential. Determine the size and design of your barn based on your requirements. Take measurements of the desired area and sketch out the barn's layout. Consult local building codes and acquire any necessary permits. Once you have a clear plan, gather the required materials.Step 2: Foundation and Frame ConstructionCreate a solid foundation for your sheet metal barn. Excavate the area, level the ground, and lay a sturdy foundation using concrete or treated wood. Next, construct the frame using the plywood pallets. Cut them to the desired size and connect them securely using screws and nuts, ensuring stability and durability.Step 3: Installing RoofingSelect the appropriate sheet metal for the roofing of your barn. Galvanized sheet metal provides excellent protection against rust and corrosion. Measure and cut the sheet metal to fit the roof frame, leaving a slight overhang for drainage. Secure the roofing sheets to the frame using screws or nails, ensuring proper alignment and sealing.Step 4: Wall ConstructionMeasure and cut additional plywood panels to serve as walls for your sheet metal barn. Attach them securely to the frame, leaving space for doors and windows as needed. Ensure tight joints and smooth surfaces for a professional finish.Step 5: Doors and WindowsInstall suitable doors and windows into the wall structure. Depending on your requirements, you can choose ready-made options or customize your own. Ensure proper insulation and weatherproofing to protect your belongings from the elements.Step 6: Finishing TouchesTake time to inspect your sheet metal barn for any loose screws or nails. Replace or tighten them as necessary. Consider adding ventilation systems, gutters, or additional storage options such as shelves or hooks. Apply a protective finish, such as paint or weather-resistant coatings, to increase the longevity and aesthetics of your barn.Conclusion:Building a sheet metal barn is a satisfying project that offers both functionality and durability. By following these six easy steps, you can construct your own barn and enjoy the benefits of efficient storage and shelter. Whether you are a DIY enthusiast or a seasoned builder, creating a sheet metal barn can be achieved with the right materials, tools, and patience. Embrace your creativity and get started on your own sheet metal barn project today!

Cutting-Edge Technology Unveiled: Revolutionary Glazed Tile Sheet Forming and Corrugating Machine Takes Industry by Storm

article:Glazed Tile Sheet Forming And Corrugating Machine Making Waves in Manufacturing IndustryThe new generation of Glazed Tile Sheet Forming And Corrugating Machine by a well-known Chinese-based manufacturing company has taken the industry by storm. The state-of-the-art machine is revolutionizing the manufacturing process of glazed tile sheets, enabling manufacturers to produce high-quality products in less time and at low production costs.The economically designed Glazed Tile Sheet Forming And Corrugating Machine is ideal for obtaining glazed sheets of different dimensions and shapes that are used in various roofing and cladding applications. The machine is composed of a steel base, a corrugated roll former, a hydraulic punching and forming device, an automatic cutting system, an electrical control system, and a product stacking device. These components not only ensure the efficiency and functionality of the machine but also provide the much-needed precision and accuracy while producing the glazed sheets.According to the company's press release, the Glazed Tile Sheet Forming And Corrugating Machine boasts several features that differentiates it from conventional machines in the market. First, the hydraulic punching and forming device can form an array of patterns that greatly improves the aesthetic appeal of the final product. Second, the exclusive rolling mechanism produces a high-quality surface finish that resists corrosion, abrasion, and scratching. Third, the machine can produce over 10 meters of glazed tiles per minute, which translates to over 300 pieces per hour.The Glazed Tile Sheet Forming And Corrugating Machine also has a user-friendly interface that simplifies the operation and maintenance process. With only a few button clicks, users can load and unload raw materials, adjust the machine's speed, and troubleshoot common problems. The machine is also equipped with an automatic lubricant system that reduces wear and tear, prolongs the machine's lifespan, and reduces maintenance costs.The company behind the Glazed Tile Sheet Forming And Corrugating Machine has been at the forefront of producing innovative, high-quality, and affordable machinery for various industries globally. The company, which has over 20 years of experience in the manufacturing industry, has invested heavily in research and development, production, and quality control which has earned them an undisputed reputation in the industry.Their Glazed Tile Sheet Forming And Corrugating Machine have been popular among small, medium, and large-scale manufacturers worldwide, as it provides a cost-effective solution for producing high-quality glazed tile sheets without compromising on quality. Furthermore, the machine is suitable for a wide range of materials, including zinc, galvanized steel, and color-coated steel, giving manufacturers an extensive range of options to choose from.The company's commitment to providing superior customer service also stands out, with a team of dedicated customer service representatives who offer after-sales service, technical assistance, and training to ensure customers get the most out of their machines. Additionally, the company's technical team ensures the machines are regularly updated and upgraded with the latest technology to guarantee that they are always at the forefront of innovation.In conclusion, the Glazed Tile Sheet Forming And Corrugating Machine by this Chinese-based manufacturing company is a game-changer in the industry, offering manufacturers a reliable, efficient, and cost-effective solution to produce high-quality glazed tile sheets. With its unique features, ease of use, and precision, the machine is bound to revolutionize the glazed tile sheet manufacturing industry and set new standards for quality, productivity, and customer service.

Top Metal Roll Former for Efficient Sheet Metal Production

Metal Roll Former: The Latest Technology in Metal FormingIn the world of modern manufacturing, versatility and efficiency are key factors that can make or break a company's success. This is especially true in the metal forming industry, where innovative technologies can provide a competitive edge. One such technology that is making waves in the industry is the Metal Roll Former, a state-of-the-art machine that has revolutionized the way metal is formed and shaped.Metal Roll Former is a leading manufacturer of metal forming machinery, known for its cutting-edge technology and high-quality products. With a long history of providing innovative solutions to the metal forming industry, Metal Roll Former has established itself as a trusted name in the market.The Metal Roll Former is a versatile piece of equipment that is capable of forming a wide range of metal products, including roofing panels, siding panels, and other custom profiles. It is designed to be highly efficient, with the ability to produce large quantities of accurately formed metal components in a short amount of time.One of the key features of the Metal Roll Former is its ability to produce complex shapes and profiles with precision. This is made possible by its advanced technology and computer-controlled systems, which allow for accurate and consistent forming of metal materials. This level of precision is crucial in the manufacturing process, as it ensures that the final products meet the highest quality standards.In addition to its versatility and precision, the Metal Roll Former is also known for its efficiency. Its high-speed forming capabilities allow for fast production cycles, making it the ideal choice for manufacturers looking to increase their output without compromising on quality. This can result in significant cost savings for companies, as they are able to produce more products in less time.Furthermore, Metal Roll Former is committed to sustainability and environmental responsibility. The company has implemented energy-efficient technologies in its machinery, reducing the overall carbon footprint of the manufacturing process. This focus on sustainability has made Metal Roll Former a preferred choice for companies looking to adopt eco-friendly practices in their operations.Metal Roll Former is also dedicated to providing exceptional customer support, offering comprehensive training and technical assistance to ensure that its customers are able to maximize the potential of its machinery. The company's team of experts is available to provide guidance and support throughout the entire process, from initial set-up to ongoing maintenance and troubleshooting.Overall, the Metal Roll Former is a game-changer in the metal forming industry, offering unmatched versatility, precision, and efficiency. Its advanced technology and commitment to sustainability make it a valuable asset for any manufacturer looking to stay ahead of the curve. With its proven track record and commitment to customer satisfaction, Metal Roll Former is poised to continue leading the way in the metal forming industry for years to come.