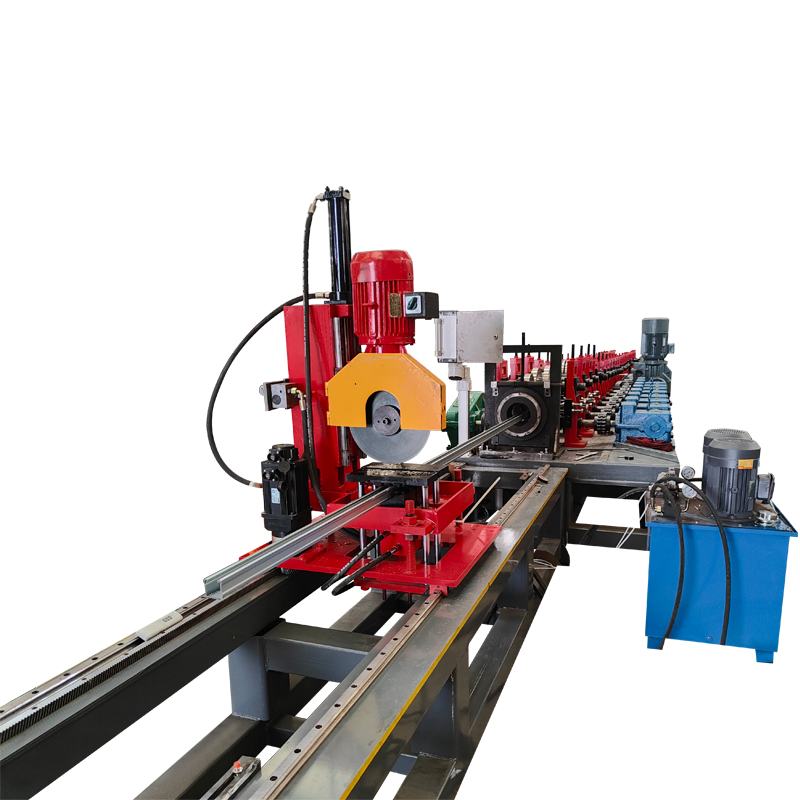

High-Quality Metal Deck Roll Forming Machine for Efficient Production

By:Admin

The construction industry has seen significant advancements in technology and machinery over the years, and one such innovation making waves in the industry is the Metal Deck Roll Forming Machine. This state-of-the-art equipment has revolutionized the way metal decking is manufactured, bringing increased efficiency and precision to the process.

The Metal Deck Roll Forming Machine, developed by a leading manufacturer in the industry, is designed to produce high-quality metal deck panels with exceptional speed and accuracy. The machine utilizes advanced roll forming technology to shape metal coils into the desired profile, creating strong and durable decking materials that are essential in modern construction projects.

With the ability to produce various sizes and profiles of metal deck panels, this machine offers unprecedented flexibility to contractors and construction companies. Whether it is for commercial, industrial, or residential purposes, the Metal Deck Roll Forming Machine is capable of meeting the diverse needs of the construction industry.

The company behind this cutting-edge technology has been a leader in the manufacturing of roll forming machinery for over two decades. With a strong focus on innovation and customer satisfaction, the company has continually pushed the boundaries of what is possible in the industry. Their commitment to quality and reliability has earned them a reputation as a trusted partner for construction companies around the world.

The Metal Deck Roll Forming Machine is just one of the many impressive products in the company's extensive lineup of roll forming equipment. From roofing and wall panel machines to purlin forming systems, the company offers a wide range of solutions for the metal construction industry. Their dedication to research and development ensures that their products are always at the forefront of technological advancements, providing customers with the tools they need to excel in their projects.

The benefits of employing the Metal Deck Roll Forming Machine are numerous. Not only does it streamline the manufacturing process, but it also minimizes material waste and reduces labor costs. The precision and consistency of the machine's output ensure that the metal deck panels produced are of the highest quality, meeting industry standards and exceeding customer expectations.

In addition to its efficiency and quality, the Metal Deck Roll Forming Machine also offers a level of customization that was previously unattainable. Contractors can now easily produce metal deck panels in different lengths, widths, and profiles, tailored to the specific requirements of each project. This flexibility allows for greater creativity and innovation in construction design, opening up new possibilities for architects and builders.

The impact of the Metal Deck Roll Forming Machine on the construction industry cannot be overstated. By simplifying and enhancing the manufacturing process for metal decking, the machine is helping to drive progress and efficiency in the industry. With its combination of speed, accuracy, and versatility, the machine is poised to become an indispensable tool for construction companies looking to stay ahead of the curve.

As the construction industry continues to evolve, the Metal Deck Roll Forming Machine represents a significant step forward in the quest for better, more efficient construction methods. With its potential to transform the way metal decking is manufactured and utilized, the machine has the power to reshape the landscape of the industry, setting new standards for quality and performance.

In conclusion, the Metal Deck Roll Forming Machine is a remarkable example of the innovative spirit driving the construction industry forward. Its impact on manufacturing efficiency, product quality, and design flexibility is a testament to the potential of cutting-edge technology in shaping the future of construction. As the demand for sustainable and cost-effective building materials continues to grow, the Metal Deck Roll Forming Machine stands as a symbol of progress and innovation in the industry.

For more information about the Metal Deck Roll Forming Machine and other roll forming solutions, visit the company's website {} to explore their comprehensive range of products and services.

Company News & Blog

V-slot Extrusion Aluminum Router/Spindle Mount for CNC Milling Machine Tool Parts M75455850120 [M75455850120] - Affordable and Versatile

Title: Enhance Your CNC Milling Experience with V-Slot Extrusion Aluminum Router/Spindle MountIntroduction:When it comes to CNC milling machines, having the right tool parts and accessories is crucial for maximizing efficiency and precision. One such essential component is the V-Slot Extrusion aluminum router/spindle mount, designed specifically for Makita/Dewalt 611/DW660/Colt OX CNC milling machines. This versatile mount offers incredible stability and durability for milling aluminum extrusions. In this blog, we will explore the benefits of this tool part and how it can revolutionize your CNC machining process.1. Superior Stability and Rigidity:The V-Slot Extrusion aluminum router/spindle mount excels in providing exceptional stability and rigidity during milling operations. Precision engineered with premium quality aluminum, this mount offers robust support to your router or spindle, reducing vibrations and ensuring accurate cuts. The V-slot design further enhances stability by securely anchoring the mount to the machine frame, minimizing unwanted movement during the milling process.2. Compatibility with Popular CNC Milling Machines:Designed with versatility in mind, this mount is compatible with major CNC milling machines such as Makita, Dewalt, DW660, and Colt OX. This widens the scope of applications, allowing users to choose their preferred milling machine without compromising on performance. Whether you are a professional or a DIY enthusiast, having a mount that fits your chosen milling machine is crucial for achieving the desired results.3. Optimal Heat Dissipation:The V-Slot Extrusion mount incorporates advanced heat dissipation features, ensuring efficient cooling during prolonged milling operations. Milling aluminum extrusions can generate significant heat, which may affect the performance and lifespan of the router or spindle. With its innovative design and aluminum construction, this mount effectively dissipates heat, promoting longevity for your machine and maintaining consistent milling accuracy.4. Easy Installation and Adjustment:Installing and adjusting the V-Slot Extrusion mount is a hassle-free process. Thanks to its intuitive design, attaching it to your CNC milling machine requires minimal effort. The mount's versatility allows for quick and precise adjustments, ensuring optimal alignment of the router or spindle. This user-friendly feature is particularly beneficial for users who frequently change router bits or require precise depth adjustments during milling operations.5. Longevity and Durability:The V-Slot Extrusion aluminum router/spindle mount is engineered to withstand the demands of CNC milling operations. Crafted from high-quality aluminum, it offers exceptional durability, withstanding the rigors of daily use in both professional and personal CNC machining settings. Its longevity ensures that you can rely on this tool part for years to come, providing you with consistent performance and precision.Conclusion:Investing in a high-quality V-Slot Extrusion aluminum router/spindle mount for your CNC milling machine is a game-changer that can transform your aluminum extrusion milling experience. The stability, compatibility, heat dissipation, easy installation, and durability offered by this mount make it an excellent addition to any CNC machining setup.So, if you are looking to optimize your CNC machining capabilities, consider upgrading to the V-Slot Extrusion aluminum router/spindle mount. Experience the enhanced stability, precision, and longevity it offers, enabling you to achieve remarkable results in your CNC milling endeavors.Keywords: CNC machine, aluminum extrusions, V-Slot Extrusion mount, router/spindle mount, Makita, Dewalt, DW660, Colt OX, stability, heat dissipation, durability, CNC milling operations.

New Study Reveals Surprising Findings in the Roll Forming Industry

Total Roll Forming, a leading manufacturer of roll forming and metal shaping solutions, has recently announced the expansion of its operations to meet the increasing demand for its products and services. The company, known for its innovative and high-quality solutions, has a long-standing reputation in the industry for providing reliable and cost-effective roll forming technology.With the expansion of its operations, Total Roll Forming is set to further solidify its position as a top provider of roll forming solutions. The company's state-of-the-art manufacturing facilities, coupled with its team of experienced engineers and technicians, enable it to offer a wide range of roll forming capabilities to meet the needs of diverse industries.Total Roll Forming's roll forming solutions are used in various applications, including automotive, construction, aerospace, and appliance industries. The company's expertise in custom roll forming enables it to cater to the specific needs of its clients, offering tailored solutions that meet the highest standards of quality and precision.Furthermore, Total Roll Forming is committed to sustainability and environmentally friendly manufacturing practices. The company continuously invests in research and development to improve its processes and reduce its environmental footprint. This commitment to sustainability has earned Total Roll Forming a reputation as an industry leader in eco-friendly roll forming solutions.In addition to its manufacturing capabilities, Total Roll Forming provides comprehensive support and services to its clients. From design and engineering to prototyping and production, the company works closely with its customers to ensure that their exact specifications are met. Total Roll Forming's dedication to customer satisfaction has resulted in long-lasting partnerships with some of the most renowned companies in the industry.Total Roll Forming's expansion comes at a time when the demand for roll forming solutions is on the rise. The company's ability to offer custom roll forming solutions that are tailored to the unique requirements of its clients has set it apart from its competitors. As a result, Total Roll Forming has experienced significant growth in recent years and is now well-positioned to capitalize on the increasing demand for its products and services."We are excited to announce the expansion of our operations to better serve our clients and meet the growing demand for our roll forming solutions," said [Company Spokesperson]. "Total Roll Forming is committed to providing innovative, high-quality, and sustainable solutions to our customers, and we believe that our expanded capabilities will enable us to further enhance our offerings and solidify our position as a leader in the industry."Total Roll Forming's expansion is a testament to the company's commitment to excellence and its determination to meet the evolving needs of its clients. With its expanded operations, Total Roll Forming is poised to continue setting the standard for roll forming technology and shaping the future of the industry.

High-Quality Standing Seam Machine for Double Lock Construction

In the world of construction and roofing, the demand for high-quality and efficient standing seam machines is ever-growing. One company that has been at the forefront of providing top-notch standing seam machines is [company name]. With their latest innovation, the Double Lock Standing Seam Machine, they have once again proven their commitment to excellence in the industry.[Company name] has been a leader in the manufacturing of roofing and construction machinery for over two decades. Their dedication to providing cutting-edge solutions for their customers has earned them a stellar reputation in the industry. The company prides itself on producing reliable, durable, and high-performance machines that meet the ever-evolving needs of their clients.The Double Lock Standing Seam Machine is the latest addition to [company name]'s impressive lineup of equipment. This machine is designed to streamline the process of creating standing seam panels, which are widely used in the construction of roofs, walls, and other architectural applications. With its innovative features and robust construction, the Double Lock Standing Seam Machine is set to revolutionize the way standing seam panels are produced.One of the key features of the Double Lock Standing Seam Machine is its dual profile capabilities. This means that the machine is capable of producing two different types of standing seam panels, offering versatility and flexibility to the user. This feature is particularly valuable for contractors and construction companies that work on a variety of projects with different design requirements.Additionally, the Double Lock Standing Seam Machine boasts a quick and easy tooling changeover, allowing for seamless transitions between different profiles. This not only saves time but also enhances overall productivity, making it an ideal choice for businesses looking to maximize efficiency.Another notable feature of the Double Lock Standing Seam Machine is its high-speed production capabilities. The machine is capable of producing standing seam panels at an impressive rate, ensuring that projects can be completed in a timely manner without compromising on quality. This speed and efficiency make the machine a valuable asset for companies looking to meet tight deadlines and deliver exceptional results.Furthermore, the Double Lock Standing Seam Machine is designed for ease of use and maintenance. Its user-friendly interface and robust construction make it an ideal choice for both seasoned professionals and those new to the industry. The machine is also built to withstand the rigors of heavy-duty use, providing long-term reliability and performance.With the introduction of the Double Lock Standing Seam Machine, [company name] has once again demonstrated its commitment to innovation and customer satisfaction. The machine's advanced features, high-speed production capabilities, and user-friendly design make it a standout choice in the market.In conclusion, the Double Lock Standing Seam Machine from [company name] is a game-changer for the construction and roofing industry. Its innovative features, reliable performance, and ease of use make it a valuable asset for any business looking to enhance their standing seam panel production capabilities. With a proven track record of delivering high-quality machinery, [company name] continues to set the standard for excellence in the industry.

High-Quality Metal Sheet Roof Roll Forming Machine: A Complete Guide

Metal Sheet Roof Roll Forming Machine: Revolutionizing Roofing IndustryThe roofing industry has seen significant advancements in recent years, and one of the key technologies driving this progress is the Metal Sheet Roof Roll Forming Machine. This innovative machinery is transforming the way metal roofs are manufactured, providing a cost-effective and efficient solution for producing high-quality roofing materials.{Company Name}, a leading manufacturer of roll forming machines, has been at the forefront of this groundbreaking technology. With years of experience and expertise in the field of roll forming, {Company Name} has engineered a state-of-the-art Metal Sheet Roof Roll Forming Machine that is setting new standards in the industry.The Metal Sheet Roof Roll Forming Machine manufactured by {Company Name} is designed to produce metal roofing sheets with unmatched precision and speed. Unlike traditional methods of manufacturing metal roofs, which are time-consuming and labor-intensive, this advanced machine is capable of producing large volumes of roofing materials in a fraction of the time. This not only increases productivity but also reduces labor costs, making it an attractive option for roofing manufacturers.One of the key features of the Metal Sheet Roof Roll Forming Machine is its versatility. It can accommodate a wide range of metal sheet materials, including galvanized steel, aluminum, and copper, allowing manufacturers to produce a variety of roofing products to meet market demands. The machine is also equipped with advanced technology to ensure the accuracy and consistency of the formed metal sheets, resulting in superior quality roofing materials.In addition to its efficiency and versatility, the Metal Sheet Roof Roll Forming Machine is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it accessible to operators of varying skill levels, minimizing the need for extensive training and reducing the risk of errors during the production process.Furthermore, {Company Name} has implemented stringent quality control measures to ensure that each Metal Sheet Roof Roll Forming Machine meets the highest standards of performance and durability. This commitment to excellence has earned {Company Name} a reputation for delivering reliable and robust machinery that stands the test of time.The impact of the Metal Sheet Roof Roll Forming Machine on the roofing industry has been significant. With its ability to streamline the manufacturing process and improve the quality of metal roofing materials, it has become a game-changer for roofing manufacturers around the world. The machine has empowered these manufacturers to meet the growing demand for durable and aesthetically pleasing metal roofs, while also staying ahead of the competition.Moreover, the Metal Sheet Roof Roll Forming Machine has also contributed to the sustainability of the roofing industry. By optimizing material usage and minimizing waste, it aligns with the industry's shift towards eco-friendly practices. This not only benefits the environment but also resonates with consumers who are increasingly conscious of the environmental impact of the products they purchase.As the demand for metal roofing continues to grow, the role of the Metal Sheet Roof Roll Forming Machine in shaping the future of the industry cannot be overstated. Its ability to drive efficiency, improve quality, and support sustainability makes it an indispensable tool for roofing manufacturers.In conclusion, the Metal Sheet Roof Roll Forming Machine manufactured by {Company Name} represents a significant advancement in the roofing industry. Its impact on the manufacturing process, product quality, and industry sustainability is undeniable. As the demand for metal roofing continues to rise, this innovative machinery is set to play a pivotal role in meeting the needs of the market and shaping the future of the roofing industry.

High-Quality Cut To Length And Slitting Machine for Efficient Industrial Use

Innovative Machinery Introduces New Cut To Length And Slitting MachineInnovative Machinery, a leading provider of manufacturing solutions, has recently unveiled their latest cutting-edge innovation - the Cut To Length And Slitting Machine. This state-of-the-art machine is designed to revolutionize the metal processing industry by offering unparalleled precision, efficiency, and productivity.The Cut To Length And Slitting Machine is a versatile and high-performance solution for processing metal coils into flat sheets and slitting them into narrow strips with precision and consistency. It is ideal for a wide range of applications, including the production of metal roofing, siding, and automotive components. With its advanced technology and user-friendly design, this machine is set to streamline the manufacturing process for various industries, leading to increased productivity and cost savings.One of the key features of the Cut To Length And Slitting Machine is its ability to handle a wide range of materials, including steel, stainless steel, aluminum, and other non-ferrous metals. This versatility makes it an essential tool for metal processing facilities that require flexibility in their production processes. In addition, the machine can accommodate different coil widths and thicknesses, allowing for customized cutting and slitting operations to meet specific customer requirements.The precision and accuracy of the Cut To Length And Slitting Machine are further enhanced by its advanced control system and cutting-edge technology. The machine is equipped with high-performance servo motors and PLC control to ensure smooth and precise operation, minimizing material waste and maximizing production efficiency. Furthermore, it features automatic tension control and edge guiding systems to deliver consistent and accurate results with minimal setup time and operator intervention.Innovative Machinery has a long-standing reputation for delivering cutting-edge manufacturing solutions to its customers. With a team of highly skilled engineers and technicians, the company is committed to providing innovative and reliable machinery that meets the evolving needs of the metal processing industry. The introduction of the Cut To Length And Slitting Machine is a testament to their dedication to pushing the boundaries of technology and delivering solutions that drive operational excellence for their clients.In addition to its technical capabilities, the Cut To Length And Slitting Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to set up, operate, and maintain, reducing the need for extensive training and minimizing the risk of human error. This, in turn, leads to improved productivity and a safer working environment for the manufacturing workforce.As a company committed to sustainability and environmental responsibility, Innovative Machinery has also incorporated energy-efficient features into the design of the Cut To Length And Slitting Machine. By optimizing power consumption and reducing waste, the machine helps to minimize the environmental impact of metal processing operations, aligning with the industry's growing focus on sustainability and resource efficiency.Overall, the introduction of the Cut To Length And Slitting Machine represents a significant milestone for Innovative Machinery and the metal processing industry as a whole. With its advanced capabilities, versatility, and user-friendly design, this innovative machine is poised to set new standards for precision, efficiency, and productivity in metal processing operations. As the demand for high-quality metal products continues to grow, the Cut To Length And Slitting Machine is positioned to become an indispensable asset for manufacturers looking to stay ahead of the competition and achieve operational excellence.

New Innovations in Light Steel Keel Machinery Revolutionize Construction Industry

Title: Innovative Light Steel Keel Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking move, a well-established company in the construction sector has developed a state-of-the-art Light Steel Keel Machine, which promises to revolutionize the way buildings are constructed. This advanced machine, designed and manufactured by the company, seeks to streamline the construction process, enhance cost-efficiency, and improve the overall quality of steel structures. With an unwavering commitment to innovation and excellence, the company aims to lead the industry into a new era of construction technology.Body:1. The Light Steel Keel Machine: (Company's Name) has introduced its cutting-edge Light Steel Keel Machine, a robust and highly automated equipment that fabricates light steel frames with utmost precision. By leveraging intelligent design, this machine can accurately produce light steel keels, also known as studs or channels, used to create the primary framework for various buildings. 2. Features and Functionality: The advanced Light Steel Keel Machine boasts a range of exceptional features, ensuring superior quality and efficiency. Equipped with sophisticated technology, it has the ability to roll, cut, punch, and perforate light steel keels with great accuracy and speed. Moreover, the machine is compatible with various thicknesses and dimensions, making it versatile for different building requirements. 3. Streamlined Construction Process: Integrating the Light Steel Keel Machine into the construction process significantly streamlines the entire procedure. This innovative technology removes the need for manual cutting and shaping of the steel keels, reducing labor costs and minimizing human error. By automating the fabrication process, construction timelines are expedited, accelerating the completion of projects and enabling faster occupancy of buildings. 4. Enhanced Cost-Efficiency: The Light Steel Keel Machine offers a cost-effective solution in the construction industry. By optimizing production efficiency, construction companies can save on labor expenses and reduce material waste. Additionally, the machine's compatibility with different steel thicknesses helps minimize material costs, further contributing to overall cost savings. 5. Improved Structural Stability: The precision and accuracy of the Light Steel Keel Machine ensure the creation of sound and reliable light steel frames. Through this advanced fabrication process, the machine eliminates potential human errors and inconsistencies, resulting in structurally stable buildings that meet stringent safety standards. This enhanced structural integrity increases the longevity and durability of the constructed buildings. 6. Superior Quality and Aesthetics: Light steel frames, produced using the state-of-the-art machine, boast exceptional quality and aesthetics. The machine's ability to produce standardized components with minimal variations results in consistent quality across all construction projects. Moreover, the machine's precise cutting and shaping capabilities create sleek and visually appealing steel frames, enhancing the overall aesthetic value of the buildings. 7. Environmental Benefits: The Light Steel Keel Machine aligns with the growing demand for sustainable and eco-friendly construction practices. By reducing material waste and optimizing production efficiency, the machine promotes environmental responsibility in the construction industry. Furthermore, light steel frames are inherently recyclable, minimizing the carbon footprint associated with traditional construction materials. Conclusion:As the construction industry paves the way for innovative technologies, the introduction of the Light Steel Keel Machine represents a significant milestone. This cutting-edge equipment, developed by (Company's Name), offers numerous benefits, including streamlined construction processes, enhanced cost-efficiency, improved structural stability, and superior quality and aesthetics. With the potential to revolutionize the way buildings are constructed, this remarkable machine embodies the company's commitment to innovation, advancement, and sustainable practices.

New Steel Sheet Crimping Machine Offers Enhanced Performance and Durability

Steel Sheet Crimping Machine Revolutionizes Metalworking IndustryIn the metalworking industry, the need for efficient and precise machinery has never been greater. Manufacturers are constantly seeking innovative solutions that can streamline their production processes and improve the quality of their products. In response to this demand, the {company name} has developed a groundbreaking new machine that is set to revolutionize the industry: the Steel Sheet Crimping Machine.The Steel Sheet Crimping Machine is a state-of-the-art piece of equipment that is designed to crimp and shape steel sheets with unparalleled precision and speed. It is equipped with advanced technology that allows it to handle a wide range of sheet thickness and material types, making it an extremely versatile tool for metalworking companies of all sizes.One of the key features of the Steel Sheet Crimping Machine is its ability to produce consistently high-quality results, even when working with challenging materials such as stainless steel or aluminum. This level of precision is achieved through the machine's innovative crimping mechanism, which is capable of creating complex patterns and shapes with incredible accuracy.Furthermore, the machine is incredibly easy to operate, thanks to its intuitive interface and user-friendly controls. This means that even unskilled operators can quickly learn how to use the machine, reducing the need for extensive training and minimizing the risk of human error.The introduction of the Steel Sheet Crimping Machine represents a major leap forward for the metalworking industry, as it enables companies to increase their production capacity and improve the overall quality of their products. By automating the crimping process, the machine also helps to reduce the labor and time required for this task, allowing manufacturers to operate more efficiently and cost-effectively.In addition to its technical capabilities, the Steel Sheet Crimping Machine also reflects {company name}'s commitment to innovation and customer satisfaction. The company has a long-standing reputation for developing cutting-edge solutions that address the specific needs of its clients, and the new machine is a testament to this ethos.{Company name} has also made it a priority to ensure that the Steel Sheet Crimping Machine meets the highest standards of safety and reliability. The machine is built to withstand the rigors of heavy industrial use, and is equipped with multiple safety features to protect both the operator and the workpiece.As news of the Steel Sheet Crimping Machine spreads throughout the industry, it is clear that {company name} has once again set a new standard for metalworking machinery. The machine's combination of precision, versatility, and ease of use make it an invaluable asset for any manufacturer looking to stay ahead of the curve in today's competitive market.To learn more about the Steel Sheet Crimping Machine and how it can benefit your business, please visit {company website} or contact {company name} directly. With this groundbreaking new machine, the future of metalworking has never looked brighter.

Highly Efficient Steel Sheet Roller Forming Machine for Automated Production

Automatic Steel Sheet Roller Forming MachineIn the world of industrial machinery, the demand for efficiency and precision is constantly increasing. This has led to the development of advanced technology that can streamline production processes and improve the overall quality of output. One such advancement is the Automatic Steel Sheet Roller Forming Machine, which has been making waves in the manufacturing industry for its ability to produce high-quality steel sheet products with unparalleled accuracy and speed.The Automatic Steel Sheet Roller Forming Machine, developed by [Company Name], is a cutting-edge piece of equipment that is designed to revolutionize the way steel sheets are manufactured. With its advanced automation and precise control systems, this machine is capable of processing steel sheets with utmost precision and consistency, delivering products of superior quality while minimizing human error.The machine is equipped with a set of rollers that are designed to bend and shape steel sheets with extreme precision. These rollers are powered by a high-performance motor and are controlled by a sophisticated computer system that ensures every bend and fold is executed with utmost accuracy. This level of precision allows for the creation of complex and intricate steel sheet products that meet the highest standards of quality and craftsmanship.In addition to its precision, the Automatic Steel Sheet Roller Forming Machine is also designed for efficiency. Its advanced automation capabilities allow for seamless operations, reducing the need for manual intervention and increasing productivity. This means that manufacturers can produce a higher volume of steel sheet products in a shorter amount of time, ultimately improving their overall output and profitability.To further enhance its efficiency, the machine is also equipped with a user-friendly interface that allows operators to easily program and control its operations. This intuitive interface simplifies the machine's setup and operation, making it accessible to a wide range of operators with varying levels of experience and expertise.Moreover, the Automatic Steel Sheet Roller Forming Machine is also designed for versatility. It is capable of producing a wide range of steel sheet products, from simple bends and folds to more intricate and complex designs. This flexibility allows manufacturers to meet the diverse needs of their customers and expand their product offerings, ultimately enhancing their competitiveness in the market.[Company Name] is a leading manufacturer of industrial machinery, with a strong focus on innovation and quality. With a track record of delivering cutting-edge solutions to the manufacturing industry, [Company Name] has established itself as a trusted partner for businesses seeking to enhance their production processes and streamline their operations.The development of the Automatic Steel Sheet Roller Forming Machine is a testament to [Company Name]'s commitment to driving innovation in the manufacturing industry. By leveraging its expertise in industrial machinery and technology, [Company Name] has succeeded in developing a state-of-the-art solution that is set to redefine the way steel sheet products are manufactured.With its precision, efficiency, and versatility, the Automatic Steel Sheet Roller Forming Machine represents a significant leap forward in the manufacturing industry. It promises to revolutionize the production of steel sheet products, offering manufacturers a competitive edge in delivering high-quality products with unparalleled precision and speed.As the demand for high-quality steel sheet products continues to grow, the Automatic Steel Sheet Roller Forming Machine is poised to become an indispensable tool for manufacturers seeking to meet the evolving needs of the market. With its advanced technology and cutting-edge capabilities, this machine is set to transform the way steel sheets are manufactured, setting new standards for quality, efficiency, and productivity in the industry.

Latest Technology for Color Steel Glazed Tile Manufacturing Machine

Color Steel Glazed Tile Manufacturing Machine Revolutionizes Roofing IndustryInnovation continues to drive the roofing industry forward with the introduction of the state-of-the-art Color Steel Glazed Tile Manufacturing Machine. This revolutionary machine, developed by a leading manufacturing company, is set to transform the production of glazed tiles for roofs, offering enhanced efficiency and quality in the process.The Color Steel Glazed Tile Manufacturing Machine is a result of years of research and development by the company, which has a solid reputation for delivering innovative solutions to the construction and roofing sectors. With a strong focus on technology and engineering, the company has consistently pushed the boundaries of what is possible in roofing manufacturing, and the introduction of this new machine is a testament to their commitment to excellence.The machine is designed to streamline the production of glazed tiles, ensuring a high level of precision and consistency in every tile produced. By utilizing advanced automation and cutting-edge manufacturing techniques, it is able to significantly increase the speed and efficiency of the production process, while also minimizing waste and errors. This not only benefits manufacturers in terms of cost savings and improved productivity but also ensures that end-users receive top-quality glazed tiles for their roofing needs.One of the key features of the Color Steel Glazed Tile Manufacturing Machine is its versatility. It is capable of producing a wide range of glazed tiles in various colors, sizes, and designs, allowing manufacturers to cater to diverse customer preferences and project requirements. This flexibility sets it apart from traditional manufacturing equipment, which often has limitations in terms of customization and variety.Furthermore, the machine is engineered for durability and reliability, making it a sound long-term investment for manufacturers. With minimal maintenance requirements and a robust construction, it is built to withstand the rigors of continuous operation, ensuring consistent performance over the years.The company behind the Color Steel Glazed Tile Manufacturing Machine has a long history of serving the roofing industry with innovative solutions. Their commitment to research and development, coupled with a customer-centric approach, has earned them a strong position in the market. The introduction of this new machine further solidifies their reputation as a leading provider of advanced manufacturing equipment for the construction and roofing sectors.In addition to the machine itself, the company offers comprehensive support and services to assist manufacturers in integrating it into their production processes. This includes training, technical assistance, and ongoing maintenance to ensure optimal performance and maximum return on investment. By partnering with the company, manufacturers can benefit from not only cutting-edge equipment but also the expertise and support needed to succeed in a competitive market.The unveiling of the Color Steel Glazed Tile Manufacturing Machine represents a significant milestone in the evolution of the roofing industry. As demand for high-quality glazed tiles continues to grow, this innovative machine is set to play a pivotal role in meeting the needs of manufacturers and end-users alike. With its advanced capabilities, flexibility, and reliability, it is poised to set a new standard for the production of glazed tiles, driving the industry towards a more efficient and sustainable future.In conclusion, the Color Steel Glazed Tile Manufacturing Machine is a game-changer for the roofing industry, offering unprecedented levels of efficiency, quality, and versatility. With the backing of a renowned manufacturing company and a strong focus on innovation, it is poised to make a significant impact in the market. As manufacturers embrace this cutting-edge technology, they are not only positioning themselves for success but also contributing to the advancement of the industry as a whole.

Quality Horizontal Profiled Sheet Forming Equipment for Sale

Horizontal Profiled Sheet Forming Equipment is continuing to make waves in the industry and set new standards for engineering and innovation. With its sleek design and cutting-edge technology, the equipment is revolutionizing the way profiled sheet forming is done. The company behind this groundbreaking technology, {}, is at the forefront of the manufacturing industry, consistently delivering top-notch products and driving progress through its dedication to excellence.{} specializes in producing high-quality equipment for the construction and manufacturing sectors, and its Horizontal Profiled Sheet Forming Equipment is no exception. Boasting advanced features and precision engineering, this equipment has been well-received by companies around the world for its ability to streamline the production of profiled sheets while maintaining exceptional quality.One of the key features of the Horizontal Profiled Sheet Forming Equipment is its versatility. It is capable of forming a wide range of profiled sheets, allowing manufacturers to cater to diverse customer demands without the need for multiple machines. This not only saves on costs but also maximizes efficiency and increases productivity. In addition, the equipment is designed to be user-friendly, with intuitive controls and easy setup, making it a valuable asset for any production facility.Another noteworthy aspect of {}'s Horizontal Profiled Sheet Forming Equipment is its exceptional precision and consistency. The equipment is engineered to deliver precise and uniform results, ensuring that every profiled sheet meets the highest standards of quality. This level of consistency is essential for construction and manufacturing projects, where even the slightest deviation can lead to inefficiencies and delays.In addition to its technical prowess, {} is committed to sustainability and environmental responsibility. The Horizontal Profiled Sheet Forming Equipment is designed to minimize waste and energy consumption, aligning with the company's dedication to sustainable manufacturing practices. By prioritizing eco-friendly solutions, {} is setting an example for the industry and contributing to a more sustainable future.Furthermore, {} offers comprehensive support and maintenance services for its Horizontal Profiled Sheet Forming Equipment, ensuring that customers can rely on their investment for years to come. With a team of skilled technicians and engineers, the company is dedicated to providing prompt assistance and expertise, building long-lasting relationships with its clients.The success of {}'s Horizontal Profiled Sheet Forming Equipment is a testament to the company's commitment to innovation and excellence. By consistently pushing the boundaries of engineering and manufacturing, {} has established itself as a leader in the industry, earning the trust and admiration of customers worldwide.To learn more about {} and its Horizontal Profiled Sheet Forming Equipment, visit their website or contact their team for personalized assistance. With a track record of exceptional products and a dedication to customer satisfaction, {} is poised to continue driving progress and setting new benchmarks for the industry.