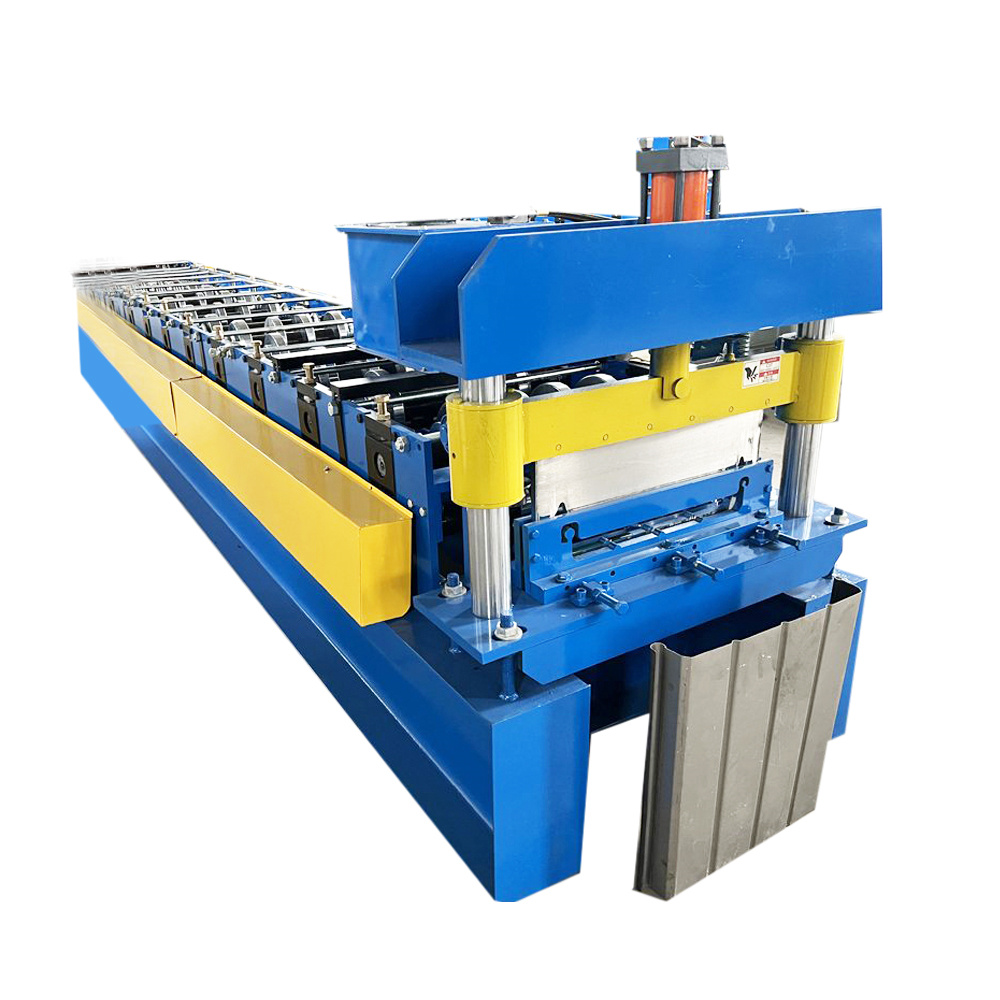

High-Quality Metal Roof Panel Machine for Sale: Get Your Business Up and Running

By:Admin

{Company Name}, a leading manufacturer in the field of metal forming machinery, has recently introduced their latest Metal Roof Panel Machine, which promises to revolutionize the way metal roof panels are produced.

The new machine boasts a host of advanced features and capabilities that set it apart from traditional machinery in the industry. With its cutting-edge technology and precision engineering, the Metal Roof Panel Machine is designed to deliver high-quality metal roof panels with exceptional speed and efficiency.

One of the key highlights of the Metal Roof Panel Machine is its versatility. The machine is capable of producing a wide variety of metal roof panels, catering to the diverse needs of different projects and clients. From standing seam panels to corrugated panels, the machine can seamlessly switch between different panel profiles, making it an ideal solution for manufacturers looking to diversify their product offerings.

In addition, the Metal Roof Panel Machine is equipped with state-of-the-art control systems that allow for seamless operation and precise panel production. This ensures that every panel that comes off the machine meets the highest quality standards, with consistent thickness, straight edges, and accurate dimensions.

Furthermore, the machine is designed with efficiency in mind. The Metal Roof Panel Machine is capable of high-speed production, enabling manufacturers to meet tight deadlines and production targets without compromising on quality. This not only helps to improve the overall productivity of the manufacturing process but also allows for greater flexibility and responsiveness to changing market demands.

The introduction of the Metal Roof Panel Machine comes at a time when the demand for metal roof panels is on the rise. As more and more the construction industry turns to metal roofing for its durability, environmental benefits, and aesthetic appeal, manufacturers are under increasing pressure to meet the growing demand. The Metal Roof Panel Machine from {Company Name} not only addresses this demand but also sets a new standard for quality and efficiency in the production of metal roof panels.

{Company Name} has a long-standing reputation for excellence in the metal forming machinery industry. With a track record of delivering innovative solutions and state-of-the-art machinery, the company has solidified its position as a trusted partner for manufacturers around the world.

In addition to the Metal Roof Panel Machine, {Company Name} offers a comprehensive range of metal forming machinery, including roll forming machines, slitting lines, and cut-to-length lines. With a strong focus on research and development, the company is committed to staying at the forefront of technological advancements in the industry and continuously improving its product offerings.

The launch of the Metal Roof Panel Machine is a testament to {Company Name}'s commitment to innovation and customer satisfaction. By addressing the evolving needs of manufacturers in the metal roofing industry, the company is poised to make a significant impact and set new industry standards.

As the construction industry continues to embrace the benefits of metal roofing, the demand for high-quality metal roof panels is only expected to grow. With the Metal Roof Panel Machine, {Company Name} is well-positioned to meet this demand and provide manufacturers with the tools they need to thrive in a competitive market.

In conclusion, the Metal Roof Panel Machine from {Company Name} represents a significant leap forward in the metal forming machinery industry. With its advanced capabilities, versatility, and efficiency, the machine is set to redefine the production of metal roof panels and support the growing demand for metal roofing solutions. As {Company Name} continues to lead the way in innovation and excellence, manufacturers can look forward to a brighter and more efficient future in the production of metal roof panels.

Company News & Blog

Advanced High-Speed Cut-To-Length Machines Revolutionize Industrial Operations

Title: Innovative High-Speed Cut-to-Length Machine Revolutionizes Industrial AutomationIntroduction:In today's ever-evolving manufacturing landscape, efficiency and precision are of paramount importance. As companies strive to optimize their production processes, a groundbreaking solution has emerged – the High-Speed Cut-to-Length Machine (CCLM) – a technological marvel that is set to revolutionize the industrial automation sector. Developed by an industry-leading manufacturer, this state-of-the-art machine combines cutting-edge technologies with a focus on speed, accuracy, and versatility. By improving productivity and ensuring higher quality outputs, the High-Speed CCLM promises to bring about a new era in manufacturing.[Paragraph 1: Background and Importance of Industrial Automation]Automation has long been a key imperative in the manufacturing sector, as it offers numerous benefits such as improved productivity, reduced labor costs, and enhanced product quality. However, until now, the cut-to-length process has remained a bottleneck for many industries. Traditional machinery often falls short in terms of accuracy, speed, and flexibility. The introduction of the High-Speed CCLM aims to address these limitations, enhancing efficiency while maintaining a high level of precision.[Paragraph 2: Overview of the High-Speed Cut-to-Length Machine]Developed by a leading manufacturer with a rich history of innovation, the High-Speed CCLM is a game-changer in the field of industrial automation. Boasting a combination of advanced technologies, meticulous engineering, and comprehensive user-centric design, this machine is capable of processing various materials at an unprecedented pace and accuracy. By seamlessly integrating automation features, such as robotic arms and powerful AI algorithms, the High-Speed CCLM is capable of precisely cutting and shaping an array of materials including metals, plastics, and composites.[Paragraph 3: Key Features and Advantages]The High-Speed CCLM differentiates itself from conventional machinery through several standout features that elevate it to a league of its own. First and foremost, this machine allows for rapid changeovers, enabling manufacturers to seamlessly transition between different types and sizes of materials. Furthermore, its high-speed operation significantly reduces manufacturing cycle times, leading to increased productivity and throughput. The use of advanced laser-guided technology ensures exceptional accuracy, while the incorporation of AI algorithms enables predictive maintenance, reducing downtime and maintenance costs.[Paragraph 4: Impact on Manufacturing Industry]The advent of the High-Speed CCLM is set to revolutionize the manufacturing industry as a whole. By streamlining the cut-to-length process, this machine eliminates the need for multiple manual interventions, thereby minimizing the risk of errors and accidents. Additionally, its high-speed capabilities enable manufacturers to meet ever-growing customer demands and tight production schedules efficiently. The automation features of the High-Speed CCLM also allow for simpler and more cost-effective scaling of operations, facilitating the growth of small-scale enterprises.[Paragraph 5: Case Studies and Customer Testimonials]Numerous businesses across various industries have already integrated the High-Speed CCLM into their manufacturing processes, yielding remarkable results. Companies that have implemented this innovative machine have reported significant improvements in productivity, waste reduction, and overall quality control. Customer testimonials highlight how the High-Speed CCLM has transformed their operations, saving them time and resources, while simultaneously enhancing their competitiveness in the market.[Paragraph 6: Conclusion]In conclusion, the introduction of the High-Speed Cut-to-Length Machine represents a significant milestone in the automation revolution within the manufacturing industry. With its advanced features, exceptional speed, and unmatched precision, this innovative machine is poised to redefine the way materials are cut and shaped, driving efficiency, and enhancing competitiveness for businesses across the globe. As industrial automation continues to evolve, the High-Speed CCLM sets a new benchmark for excellence, consolidating its position as a game-changer in the field.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.

Quality Roll Forming Machine for Making Tiles: Find Out More!

The leading provider of tile roll forming machines, [company name], has recently announced the launch of their newest and most advanced machine yet. With a strong focus on innovation and quality, the company has set new standards in the industry with their state-of-the-art equipment that is designed to meet the needs of modern construction and roofing projects.The new tile roll forming machine is a result of years of research and development, as well as extensive testing and feedback from industry professionals. It is engineered to provide maximum efficiency and precision, allowing for seamless production of high-quality tile profiles. With the ability to handle a wide range of materials, including steel, aluminum, and copper, this machine is truly versatile and suitable for a variety of applications.One of the key features of the new tile roll forming machine is its speed and accuracy. Equipped with advanced servo technology, it is capable of producing tiles at a fast pace without compromising on the quality of the end product. This will not only help companies to increase their production capacity, but also deliver superior results to their clients.Furthermore, the machine is designed with user-friendly controls and interfaces, making it easy for operators to set up and operate. This not only saves time and effort, but also minimizes the risk of errors, ensuring consistent and reliable performance. Additionally, the machine is equipped with safety features to protect operators and prevent accidents in the workplace.In addition to its impressive performance, the tile roll forming machine is also designed with sustainability in mind. By optimizing material usage and minimizing waste, it helps companies to reduce their environmental impact and operate more responsibly. This aligns with the company's commitment to sustainable practices and their dedication to supporting a greener future.[Company name]'s dedication to quality and innovation has made them a trusted partner for many companies in the construction and roofing industry. With a strong emphasis on customer satisfaction, they offer comprehensive support and services to ensure that their clients get the most out of their equipment. This includes training, technical assistance, and aftermarket services to keep their machines running smoothly.With a global presence and a strong track record of success, [company name] has established itself as a leading provider of roll forming solutions. Their commitment to excellence and continuous improvement has helped them to stay ahead of the curve and deliver cutting-edge products to their clients. The new tile roll forming machine is a testament to their ongoing efforts to push the boundaries of what is possible in the industry.As the construction and roofing industry continues to evolve, the demand for efficient and reliable equipment is stronger than ever. With the introduction of their latest tile roll forming machine, [company name] has once again demonstrated their ability to meet these demands and anticipate the needs of their clients. This will undoubtedly solidify their position as a go-to source for high-quality roll forming solutions.

High-Quality Metal Stud Roll Formers: Enhance Efficiency in Stud Construction

Title: Revolutionary Metal Stud Roll Former Offers Unmatched Efficiency and VersatilityIntroduction:In the ever-evolving construction industry, the demand for innovative machinery and solutions has reached new heights. One such ground-breaking addition is the Metal Stud Roll Former, a cutting-edge machine that promises a paradigm shift in efficiency and versatility. Developed by a leading manufacturer in the industry, this industry-transforming solution aims to streamline the process of metal stud production, ensuring faster turnaround times and higher quality output.Unmatched Efficiency:Traditionally, the production of metal studs has relied heavily on manual labor and outdated machinery, resulting in a slow and labor-intensive process. With the introduction of the Metal Stud Roll Former, manufacturers can now experience unparalleled efficiency. This revolutionary machine automates the stud production process, reducing human error, and significantly increasing the speed of manufacturing.Equipped with advanced technology, the Metal Stud Roll Former boasts an impressive production rate of [insert production per hour], enabling manufacturers to meet tight project deadlines without compromising quality. By eliminating the need for manual labor, this machinery also minimizes the risk of workplace injuries and fatigue, promoting a safer working environment.Versatility Redefined:The Metal Stud Roll Former stands out from its predecessors due to its exceptional versatility. Unlike traditional roll formers, which limit manufacturers to specific stud dimensions, this technologically advanced machine accommodates an extensive range of stud sizes, shapes, and profiles. From standard C and U profiles to custom designs, the Metal Stud Roll Former offers limitless possibilities, making it an ideal choice for diverse construction projects.The machine's adjustable settings empower manufacturers to effortlessly switch between different stud dimensions, eliminating the need for multiple production lines and reducing production costs significantly. Moreover, the Metal Stud Roll Former adapts to various metal gauges, accommodating the ever-expanding range of material preferences in the industry.Precision and Quality Control:The Metal Stud Roll Former incorporates state-of-the-art sensors and precision mechanisms that ensure impeccable accuracy and consistent quality. These sensors detect and correct any irregularities throughout the production process, resulting in studs that meet the highest industry standards. Manufacturers can rely on this machinery to deliver flawless, dimensionally accurate studs that are ready for assembly, minimizing delays and rework.Ease of Operation and Maintenance:To enhance user experience, the Metal Stud Roll Former is designed with user-friendly controls and intuitive interfaces. Operators can quickly learn to operate the machine, reducing training time and improving overall productivity. Additionally, the machine's low maintenance requirements result in reduced downtime and increased profitability for manufacturers.Contribution to Sustainability:In an era where environmental sustainability is a significant concern, the Metal Stud Roll Former stands out as an environmentally responsible solution. By minimizing material waste through precise measurements and efficient manufacturing processes, this machinery significantly reduces the carbon footprint associated with stud production. Manufacturers can take pride in utilizing this innovative technology, playing their part in the sustainable growth of the construction industry.Conclusion:The Metal Stud Roll Former introduces a new era of efficiency, versatility, and precision to the construction industry. Its ability to enhance production rates, facilitate custom designs, and ensure consistent quality makes it an indispensable asset for metal stud manufacturers. By adopting this revolutionary machine, manufacturers can unlock new levels of productivity while keeping pace with the ever-changing demands of the construction market. As the industry continues to evolve, the Metal Stud Roll Former sets the benchmark for cutting-edge technology and marks a significant milestone in improving construction productivity.

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

High-Quality Corrugated Roll Forming Machine for Sale - Find Out More!

Title: Leading Manufacturer Introduces Advanced Corrugated Roll Forming MachineWith a commitment to innovation and excellence, {Company Name} is proud to introduce their latest technological innovation in the form of the Corrugated Roll Forming Machine. This cutting-edge machinery is set to revolutionize the production process for corrugated materials, bringing new levels of efficiency and quality to the industry.The Corrugated Roll Forming Machine is designed to meet the increasing demands for faster and more precise production of corrugated materials. With its advanced features and capabilities, this machine is expected to significantly enhance the manufacturing process for a wide range of industries, including packaging, construction, and automotive.{Company Name}, a leading manufacturer of roll forming machinery, has a long-standing reputation for delivering high-quality and reliable equipment to their global customer base. With over [X] years of experience in the industry, they have consistently pushed the boundaries of innovation to meet the evolving needs of their clients.The introduction of the Corrugated Roll Forming Machine is a testament to {Company Name}'s dedication to staying at the forefront of technological advancements. This state-of-the-art machine is the result of extensive research and development, aimed at addressing the challenges faced by manufacturers in the production of corrugated materials.One of the key features of the Corrugated Roll Forming Machine is its ability to accurately and consistently produce corrugated materials of varying sizes and specifications. This level of precision is achieved through the machine's advanced control systems and customizable settings, allowing manufacturers to meet the specific requirements of their customers with ease.Furthermore, the Corrugated Roll Forming Machine boasts a high level of efficiency, with rapid production capabilities that can significantly reduce turnaround times for manufacturers. This not only increases productivity but also improves overall operational efficiency, making it a valuable asset for businesses looking to streamline their production processes.In addition to its operational benefits, the Corrugated Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. This includes intuitive controls, automated processes, and built-in safety measures to ensure a seamless and secure working environment for operators.As a testament to its commitment to quality, {Company Name} has subjected the Corrugated Roll Forming Machine to rigorous testing and quality assurance procedures to ensure that it meets the highest standards of performance and reliability. This dedication to excellence is a hallmark of {Company Name}'s reputation as a trusted provider of roll forming machinery.In light of the global push for sustainable manufacturing practices, the Corrugated Roll Forming Machine is also designed with energy-efficient features to minimize its environmental impact. This aligns with {Company Name}'s commitment to promoting eco-friendly solutions and reducing the carbon footprint of their operations.The introduction of the Corrugated Roll Forming Machine is poised to have a transformative impact on the manufacturing industry, offering a solution that combines cutting-edge technology with practical functionality. {Company Name} is confident that this innovation will set a new standard for the production of corrugated materials and empower manufacturers to achieve new levels of success.With the launch of the Corrugated Roll Forming Machine, {Company Name} reaffirms its position as a leader in the roll forming machinery industry, delivering innovative solutions that enable businesses to thrive in an ever-evolving market. This latest addition to their product lineup is a testament to the company's unwavering commitment to driving progress and propelling the manufacturing industry forward.

High-Quality Roofing Sheet Roll Forming Machines for Efficient Sheet Rolls Forming Process

Roofing Sheet Roll Forming Machine: Revolutionizing the Roofing Industry[City], [Date] - [Company Name], a leading manufacturer of roll forming machines, is proud to introduce their latest innovation in the roofing industry - the Roofing Sheet Roll Forming Machine. This groundbreaking machine is set to revolutionize the way roofing sheets are manufactured, offering enhanced efficiency and superior quality products.The Roofing Sheet Roll Forming Machine is a state-of-the-art piece of equipment designed to produce roofing sheets with precision and speed. By utilizing advanced roll forming technology, this machine is capable of shaping metal sheets into a variety of profiles and dimensions, perfectly suited for roofing applications. With its efficient and automated production process, the machine is capable of meeting the demands of both small-scale roofing projects and large commercial operations.One of the key features of the Roofing Sheet Roll Forming Machine is its versatility. It can produce a wide range of roofing sheet profiles, including corrugated, trapezoidal, and standing seam designs. This flexibility allows roofing contractors and manufacturers to meet the diverse requirements of their customers, offering them a wide selection of roofing options.The machine's high-speed production capabilities make it an ideal choice for large-scale operations. With its precise and reliable roll forming process, the Roofing Sheet Roll Forming Machine can produce roofing sheets at an impressive rate, significantly reducing production time and costs. This increased productivity translates into higher profitability for roofing companies, allowing them to take on more projects and meet tight deadlines.Quality is of utmost importance in the roofing industry, and the Roofing Sheet Roll Forming Machine delivers exceptional results. By using top-quality materials and advanced manufacturing techniques, this machine ensures that every roofing sheet produced meets the highest quality standards. The machine's precision-engineered rollers and cutting blades contribute to the accurate shaping of the metal sheets, creating well-formed and dimensionally accurate roofing products.Additionally, the Roofing Sheet Roll Forming Machine offers excellent durability and reliability. Manufactured with robust components and built to withstand heavy-duty use, this machine can operate consistently even in demanding production environments. Its user-friendly design and intuitive controls make it easy to operate, requiring minimal maintenance and reducing downtime.By investing in the Roofing Sheet Roll Forming Machine, companies can streamline their production process and substantially improve their overall efficiency. With its superior speed, versatility, and quality output, this machine is set to become an indispensable asset in the roofing industry.[Company Name] is dedicated to providing exceptional after-sales service and technical support. With their extensive experience in roll forming machine manufacturing, they are committed to assisting customers in optimizing their production processes and ensuring the long-term performance of their machines.About [Company Name]:[Company Name] is a renowned manufacturer of roll forming machines, specializing in Roofing Sheet Roll Forming Machine, CZ Purlin Machine, and Light Steel Framing products. With a focus on delivering innovative and reliable solutions, they have become a trusted name in the industry. Their commitment to superior quality, advanced technology, and excellent customer service has earned them a reputation as a leading manufacturer in China. For more information, please visit [Company Website].For media inquiries:[Company Name][Contact Person][Phone Number][Email Address]

Innovative Purlin Machine Revolutionizes Metal Fabrication Processes

The latest technological advancement from the renowned steel processing machinery company, known for its innovative solutions and top-quality equipment, has sparked interest and excitement in the industry. The unveiling of the Stacker for the CZ Purline Machine has created a buzz among manufacturers and steel processing experts worldwide.The CZ Purline Machine, developed by the company, has been widely praised for its efficiency, precision, and reliability in producing high-quality CZ purlins for a variety of construction and industrial applications. With the addition of the Stacker, the entire process of CZ purlin manufacturing is set to become even more streamlined and productive.The Stacker for the CZ Purline Machine is designed to automate the stacking of finished CZ purlins, eliminating the need for manual handling and significantly reducing production time. This innovative addition is equipped with advanced technology that allows for seamless integration with the CZ Purline Machine, ensuring smooth and uninterrupted operation.The company's commitment to pushing the boundaries of steel processing technology is evident in the development of the Stacker. By addressing the need for increased automation and efficiency in the production process, the company continues to set new standards in the industry and solidify its position as a leading force in steel manufacturing machinery.With a proven track record of delivering high-performance equipment and cutting-edge solutions, the company has gained the trust and confidence of manufacturers and steel processors around the globe. The introduction of the Stacker for the CZ Purline Machine further cements the company's reputation for excellence and innovation.In addition to its dedication to providing top-quality machinery, the company is also known for its exceptional customer service and support. The team of experts at the company is committed to assisting clients in optimizing their production processes and achieving maximum efficiency and productivity.The company's state-of-the-art manufacturing facilities and research and development capabilities have enabled it to consistently deliver groundbreaking solutions that meet the evolving needs of the steel processing industry. The Stacker for the CZ Purline Machine is a testament to the company's unwavering commitment to innovation and technological advancement.As the demand for high-quality steel products continues to grow, the company remains at the forefront of the industry, providing manufacturers with the tools they need to stay ahead in a competitive market. The Stacker for the CZ Purline Machine is poised to revolutionize the production of CZ purlins, offering manufacturers a powerful tool to enhance their operations and meet the increasing demands of their customers.In conclusion, the unveiling of the Stacker for the CZ Purline Machine represents a significant milestone for the company and the steel processing industry as a whole. With its cutting-edge technology, seamless integration, and potential for increased efficiency, the Stacker is set to transform the way CZ purlins are manufactured. As the company continues to lead the way in steel processing machinery, manufacturers can look forward to more groundbreaking innovations that will shape the future of the industry.

Trapezoid Profile Metal Roofing Sheet Machine: Everything You Need to Know

Metal Roofing Sheet Trapezoid Profile Machine is a revolutionary piece of equipment that is set to transform the roofing industry. This state-of-the-art machine is designed to produce high-quality trapezoid profile metal roofing sheets, which are known for their durability and aesthetic appeal. With the ability to create custom trapezoid profile sheets in a variety of sizes and materials, this machine is expected to be a game-changer for roofing contractors and businesses.The technology behind the Metal Roofing Sheet Trapezoid Profile Machine is truly innovative, allowing for precise and efficient production of trapezoid profile sheets. The machine is equipped with advanced automated features that ensure consistent quality and accuracy in each sheet that is produced. This is crucial for ensuring that the roofing sheets are a perfect fit and provide excellent protection against the elements.One of the key benefits of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It is capable of working with a wide range of materials, including steel, aluminum, and other metals commonly used in roofing. This means that roofing contractors and businesses can easily adapt to different project requirements and client preferences without having to invest in multiple machines.In addition to its versatility, the Metal Roofing Sheet Trapezoid Profile Machine is also designed for speed and efficiency. The machine has a high production capacity, allowing for quick turnaround times on orders. This is essential for meeting tight project deadlines and maximizing productivity for businesses in the roofing industry.Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, reducing the need for extensive training and streamlining the production process. This is particularly beneficial for businesses looking to optimize their efficiency and minimize production costs.As a leading provider of innovative roofing solutions, {} is proud to introduce the Metal Roofing Sheet Trapezoid Profile Machine to the market. With decades of experience in the industry, the company has a strong track record of delivering high-quality roofing products and machinery. The introduction of this advanced machine is a testament to the company's commitment to staying at the forefront of technological advancements in the roofing sector.In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {} offers a comprehensive range of roofing materials and equipment to meet the needs of residential, commercial, and industrial projects. The company's dedication to quality, reliability, and customer satisfaction has established them as a trusted partner for roofing professionals and businesses.With the introduction of the Metal Roofing Sheet Trapezoid Profile Machine, {} is poised to empower roofing contractors and businesses with the tools they need to elevate their capabilities and deliver exceptional results. The machine's ability to produce high-quality trapezoid profile sheets with speed and precision is set to have a significant impact on the roofing industry, setting a new standard for efficiency and excellence.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine represents a major leap forward for the roofing industry. Its innovative technology, versatility, and efficiency make it a valuable asset for roofing contractors and businesses looking to enhance their capabilities and deliver superior results. With the backing of {}'s expertise and reputation for quality, the machine is set to become a game-changing tool for the production of trapezoid profile metal roofing sheets.

Roll Forming Machine Manufacturers For Sale in China - Superior Quality

Roll Forming Machine Manufacturers in China are Dedicated to Providing High-Quality MachinesIn today's world, the demand for roll forming machines has drastically increased. Roll forming machines are used by manufacturers in diverse industries to create uniform shapes of metal sheets. These machines are highly efficient and produce high-quality products in a short time. There are many roll forming machine manufacturers in China, and RISHBIN is committed to providing customers with the best quality roll forming machines.Founded in 1998, RISHBIN is a sheet metal roll forming machine manufacturer that offers a comprehensive range of roll forming machines for different applications. Over the years, the company has built a reputation for producing high-quality machines that are reliable, efficient, and durable. RISHBIN roll forming machines are used in the construction, automobile, HVAC, and packaging industries.The company prides itself on providing customized solutions to meet the specific needs of their customers. This is possible because RISHBIN has a team of experienced engineers who develop unique designs for their customers. The engineers use modern software to design and simulate the machines before production to ensure that the final product meets the customer's specifications.RISHBIN roll forming machines are designed to be highly efficient in terms of speed and accuracy. The machines are manufactured using the latest technology and high-quality materials to ensure they last longer and require minimal maintenance. The company uses top-quality components such as Mitsubishi, Siemens, and Schneider for the electrical parts, and SKF, NSK, and Timken for the bearings to ensure the machines' high stability and reliability.The company's roll forming machines are available in different models, including simple manual machines, hydraulic machines, and fully automated roll forming machines. This range of machinery allows customers to choose a product that suits their production needs and budget.RISHBIN is also committed to providing excellent customer service. The company has a team of trained and experienced customer service representatives who are available 24/7 to provide support and answer customer questions. This ensures that customers can have peace of mind knowing that they will receive prompt and efficient after-sales service.In conclusion, RISHBIN is committed to providing customers with the best quality roll forming machines. The company's commitment to quality, efficiency, and customer service has earned it a reputation as one of the leading roll forming machine manufacturers in China. By working with RISHBIN, customers can be assured of getting customized products that meet their specific requirements and budgets.