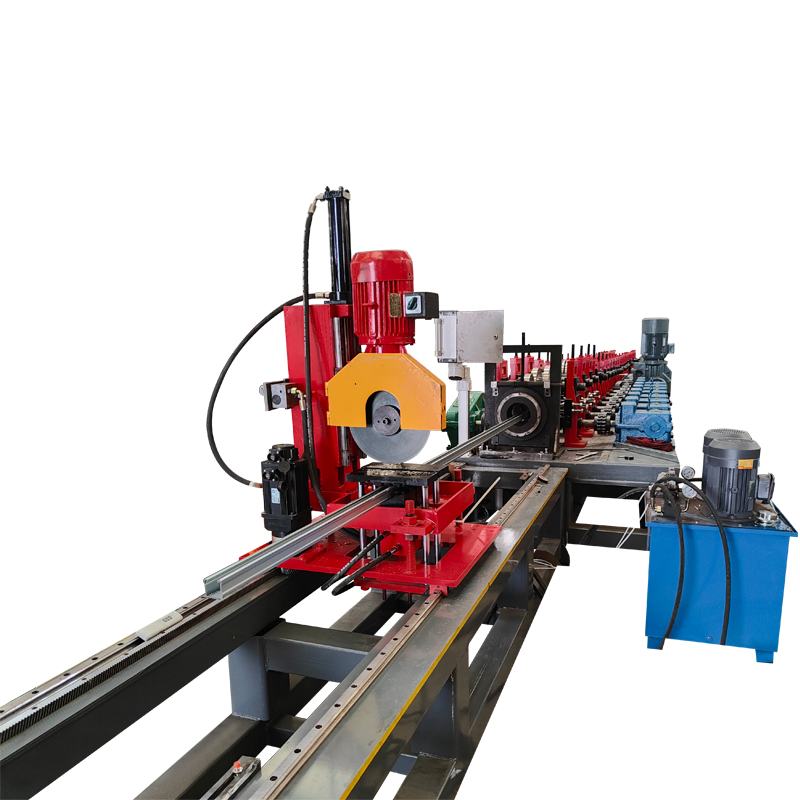

High-Quality Portable Metal Roll Forming Machine for Sale

By:Admin

In the world of construction, efficiency and precision are key factors that can make or break a project. With the advancement of technology, the construction industry has seen a significant transformation in recent years. One of the most important technological innovations that has revolutionized the industry is the Portable Metal Roll Forming Machine.

Portable Metal Roll Forming Machine, also known as portable roll forming machines, are cutting-edge equipment that has changed the way metal materials are formed and shaped on construction sites. These machines are designed to form continuous metal sheets into specific shapes and profiles, providing a cost-effective and efficient solution for a variety of construction applications.

One company at the forefront of this technological advancement is {}. Established in {}, the company has been a leader in providing innovative solutions for the construction industry. With a strong focus on research and development, they have continuously strived to introduce new and improved products that cater to the evolving needs of the construction sector.

The Portable Metal Roll Forming Machine offered by {} is a game-changer in the construction industry. With its portable and compact design, the machine can be easily transported to construction sites, eliminating the need for large and expensive equipment. This not only saves time and money, but also allows for on-site customization and production, reducing unnecessary waste and improving overall efficiency.

In addition to its portability, the {} Metal Roll Forming Machine is equipped with advanced technology and automation features that ensure precision and accuracy in the forming process. This means that complex metal profiles can be produced with minimal margin of error, resulting in high-quality and consistent end products.

The machine is also capable of forming a wide range of metal materials, including steel, aluminum, and copper, making it suitable for a variety of construction applications such as roofing, siding, and framing. This versatility allows contractors and construction companies to streamline their operations and meet the diverse needs of their clients without the need for multiple machines or processes.

Furthermore, the {} Metal Roll Forming Machine is designed with user-friendly controls and safety features, making it accessible and safe for operators of all skill levels. This means that even novice users can operate the machine with confidence, reducing the risk of accidents and errors.

With the introduction of the Portable Metal Roll Forming Machine, {} is not only revolutionizing the construction industry, but also contributing to sustainable and environmentally friendly practices. By enabling on-site production and customization, the machine reduces the need for mass production and transportation of pre-formed metal materials, which in turn decreases carbon emissions and energy consumption.

In conclusion, the introduction of the Portable Metal Roll Forming Machine by {} marks a significant milestone in the construction industry. With its innovative design, advanced technology, and environmental benefits, this machine has the potential to transform the way construction projects are executed, leading to improved efficiency, cost-effectiveness, and sustainability. As the demand for high-quality and customized metal profiles continues to grow, the Portable Metal Roll Forming Machine is poised to become an indispensable tool for contractors and construction companies around the world.

Company News & Blog

Double Column Punching Machine for Aluminum Extrusion: Get Efficient Processing with Hydraulic Two Cylinder Punching Machine LY2-160

Title: Revolutionary Double Column Punching Machine Revolutionizes Aluminum Extrusion ProcessingIntroduction:Tjjunchiwy.com, a leading manufacturer of industrial machinery, introduces their latest innovation in the field of aluminum extrusion processing - the Hydraulic Two Cylinder Punching Machine LY2-160. This state-of-the-art machine is designed to simplify the hole and notch punching and processing of various plain profiles, enabling greater efficiency and precision in the production of aluminum windows and doors.Innovative Features and Specifications:The Hydraulic Two Cylinder Punching Machine LY2-160 incorporates a number of cutting-edge features that set it apart from its competitors. Here are some key specifications that make it a game-changer in the aluminum extrusion industry:1. Advanced Functionality: Equipped with a double column structure, the machine provides enhanced stability and rigidity throughout the punching process. This innovative design significantly reduces vibrations, resulting in high-quality, precise punching and processing of aluminum profiles.2. Versatility: The machine is designed to cater to a wide range of punching requirements for both single and assembled dies. Whether it's hole punching or notch processing, the LY2-160 can handle it all, ensuring streamlined operations in the production of aluminum doors and windows.3. Efficient Performance: With a punching force of up to 160 tons and a stroke length of 40mm, this robust machine guarantees efficient and accurate processing of aluminum profiles. It delivers consistent performance, allowing manufacturers to meet tight deadlines and achieve high production volumes.4. Intuitive Control System: The LY2-160 features a user-friendly control panel that allows operators to easily adjust punching parameters, such as punching depth, speed, and positioning. This intuitive interface ensures optimal productivity and minimizes errors during the manufacturing process.5. Advanced Safety Measures: Safety is paramount in any industrial setting, and this punching machine doesn't compromise in this aspect. Equipped with emergency stop buttons and safety guards, the system ensures operator safety during operation, reducing the risk of accidents.Company Overview: Tjjunchiwy.com has established itself as a renowned name in the machinery manufacturing industry, specializing in aluminum extrusion processing equipment. With a commitment to innovative solutions, the company has become a trusted partner for manufacturers worldwide, offering cutting-edge machines that enhance production efficiency and quality.Conclusion:The introduction of the Hydraulic Two Cylinder Punching Machine LY2-160 by Tjjunchiwy.com promises to revolutionize aluminum extrusion processing in the fabrication of windows and doors. Its exceptional features and specifications bring a new level of efficiency, precision, and versatility to the industry. With this state-of-the-art machine, manufacturers can expect increased productivity, reduced downtime, and improved product quality. As Tjjunchiwy.com continues to push technological boundaries, the future of aluminum extrusion processing looks brighter than ever before.

High-Quality Standing Seam Roller Machine for Efficient Metal Roofing

Introducing the Latest Standing Seam Roller Machine from a Leading Industry ExpertIn the ever-evolving world of manufacturing and construction machinery, there is a constant need for innovation and advancement to meet the growing demand for efficiency and performance. One company that has consistently been at the forefront of this industry is [Company Name]. With a rich history of expertise and a deep commitment to quality and excellence, [Company Name] has been a trailblazer in the field of machinery manufacturing, and their latest offering, the Standing Seam Roller Machine, is a testament to their dedication to pushing the boundaries and setting new standards in the industry.The Standing Seam Roller Machine is a cutting-edge product that has been designed and developed to cater to the specific needs of the construction and roofing industry. It is a versatile and high-performing machine that is capable of producing superior quality standing seam panels with ease and precision. This state-of-the-art equipment is an essential addition to any manufacturing or construction operation that requires the highest standard of standing seam panel production.One of the key features of the Standing Seam Roller Machine is its advanced technology and robust construction. The machine is engineered using the latest manufacturing techniques and top-quality materials to ensure optimal performance, longevity, and reliability. This means that it is built to withstand the rigors of a demanding work environment, making it a valuable investment for any company looking to enhance their production capabilities.Moreover, the Standing Seam Roller Machine is designed for efficiency and user-friendliness. It boasts intuitive controls and a user-friendly interface that allows operators to quickly and easily set up and adjust the machine for different panel sizes and specifications. This not only saves time but also minimizes the risk of errors, ensuring consistent and accurate output.In addition to its cutting-edge technology and user-friendly design, the Standing Seam Roller Machine is also highly adaptable. It is capable of producing a wide range of standing seam panel profiles, giving manufacturers and contractors the flexibility to cater to diverse project requirements. Whether it's a commercial building, residential property, or industrial facility, this machine can deliver the desired panel profiles with utmost precision and efficiency.Furthermore, the Standing Seam Roller Machine is backed by [Company Name]’s unwavering commitment to customer satisfaction. With a team of highly skilled and knowledgeable professionals, the company offers comprehensive support and maintenance services to ensure that their customers get the most out of their investment. This includes training, troubleshooting, and regular maintenance to keep the machine in peak operating condition.With the introduction of the Standing Seam Roller Machine, [Company Name] has once again raised the bar for innovation and excellence in the manufacturing and construction machinery industry. This latest offering is a testament to the company's dedication to providing cutting-edge solutions that empower their customers to achieve superior results in their respective fields.As the demand for high-quality standing seam panels continues to grow, [Company Name] is proud to offer a solution that not only meets but exceeds the expectations of their customers. With its advanced technology, robust construction, user-friendly design, adaptability, and comprehensive support services, the Standing Seam Roller Machine is set to become a game-changer for manufacturing and construction operations worldwide.In conclusion, the Standing Seam Roller Machine from [Company Name] represents the perfect blend of innovation, performance, and reliability. It is a product that has been engineered to deliver exceptional results and set new benchmarks in the industry. With this latest offering, [Company Name] solidifies its position as a leading expert in manufacturing and construction machinery and demonstrates their unwavering commitment to driving progress and success for their customers.

High-quality Floor Production Roll Forming Machine for Efficient Manufacture

Floor Production Roll Forming Machine revolutionizes the industry with its advanced technology and innovative features. This cutting-edge machine is set to redefine the way floor production is done, offering a range of benefits and advantages that are unmatched in the market.Designed and developed by the industry-leading team at {}, this new Floor Production Roll Forming Machine is equipped with state-of-the-art technology and precision engineering. The machine is capable of producing high-quality floor panels with unparalleled accuracy and efficiency, making it a game-changer for the industry.One of the key features of the Floor Production Roll Forming Machine is its ability to handle a wide variety of materials, including steel, aluminum, and other metals. This versatility allows manufacturers to produce a diverse range of floor panels to meet the specific requirements of different projects. Furthermore, the machine is designed to be easy to operate and maintain, minimizing downtime and maximizing productivity.The Floor Production Roll Forming Machine also boasts a high level of customization, allowing manufacturers to tailor the machine to their specific needs. Its modular design and flexible configuration options make it adaptable to different production processes, making it a versatile and cost-effective solution for floor panel manufacturing.In addition to its advanced technology, the Floor Production Roll Forming Machine is also designed with a focus on energy efficiency and sustainability. The machine is equipped with cutting-edge energy-saving features that help reduce power consumption and minimize environmental impact, making it an eco-friendly choice for manufacturers.With its combination of advanced technology, versatility, and sustainability, the Floor Production Roll Forming Machine is set to make a significant impact on the industry. It offers manufacturers a competitive edge by enabling them to produce high-quality floor panels with greater efficiency and cost-effectiveness, ultimately boosting their bottom line.The team at {} is proud to introduce this groundbreaking Floor Production Roll Forming Machine to the market. With their decades of experience and expertise in roll forming technology, they have once again raised the bar for innovation and excellence in the industry.As a leading manufacturer of roll forming machines, {} has a strong track record of delivering top-quality solutions to the market. Their commitment to innovation and customer satisfaction has solidified their reputation as a trusted partner for manufacturers seeking cutting-edge roll forming technology.The launch of the Floor Production Roll Forming Machine marks a significant milestone for the company, as they continue to push the boundaries of what is possible in the industry. By leveraging their expertise and insights, they have developed a machine that is set to redefine the standards for floor panel production.With its exceptional capabilities and unmatched performance, the Floor Production Roll Forming Machine from {} is poised to become an indispensable tool for manufacturers looking to stay ahead in a competitive market. It represents a new era of efficiency, precision, and sustainability in floor panel production, setting a new benchmark for the industry.In conclusion, the Floor Production Roll Forming Machine from {} is a groundbreaking innovation that is set to transform the way floor panels are produced. With its advanced technology, versatility, and sustainability, it offers manufacturers a powerful tool to enhance their capabilities and drive success in the market. As {} continues to lead the way in roll forming technology, the industry can look forward to more game-changing solutions that raise the bar for excellence.

How to Choose the Best Corrugated Roofing Sheet Forming Machine for Your Project

Corrugated Roofing Sheet Forming Machine Revolutionizes Roofing IndustryIn a groundbreaking development for the construction and roofing industries, a new Corrugated Roofing Sheet Forming Machine is set to take the market by storm. This state-of-the-art machine, designed and manufactured by [Company Name], is set to revolutionize the way roofing sheets are produced, bringing unprecedented levels of efficiency and precision to the process.[Company Name] has a long-standing reputation for innovation and excellence in the field of industrial machinery. With a focus on advanced technology and continuous research and development, the company has become a leading provider of cutting-edge solutions for the construction and manufacturing sectors.The new Corrugated Roofing Sheet Forming Machine is the latest addition to [Company Name]'s impressive portfolio of products. By leveraging the latest advancements in engineering and materials science, the machine is capable of producing high-quality roofing sheets with unmatched speed and accuracy.One of the key features of the Corrugated Roofing Sheet Forming Machine is its advanced automation capabilities. The machine is equipped with state-of-the-art control systems that allow for precise control of the forming process, resulting in consistently high-quality products. This level of automation not only reduces the margin of error but also significantly speeds up the production process, allowing for increased output and reduced lead times.In addition to its efficiency, the Corrugated Roofing Sheet Forming Machine offers unparalleled flexibility. The machine is capable of producing a wide range of corrugated roofing sheet profiles, allowing for customization to meet the specific needs of each project. This flexibility is invaluable for construction companies and roofing contractors, who often require a variety of sheet profiles to accommodate different architectural styles and functional requirements.Furthermore, the machine is designed with durability and reliability in mind. Built to withstand the rigors of continuous operation, the Corrugated Roofing Sheet Forming Machine offers a long service life and minimal maintenance requirements, ensuring a high return on investment for its users.With its advanced features and capabilities, the new Corrugated Roofing Sheet Forming Machine is set to disrupt the roofing industry. By streamlining the production process and elevating the quality of finished products, the machine promises to deliver significant benefits to manufacturers, construction companies, and end-users alike.In response to the upcoming launch of the Corrugated Roofing Sheet Forming Machine, [Company Name] has announced plans to offer comprehensive training and support services to its customers. This includes on-site installation and commissioning, as well as ongoing technical assistance and maintenance to ensure optimal performance and long-term reliability.As the construction and roofing industries continue to evolve, innovative solutions like the Corrugated Roofing Sheet Forming Machine are poised to play a pivotal role in shaping the future of the market. With its cutting-edge technology and unwavering commitment to excellence, [Company Name] is well-positioned to lead the way in this transformative era.Overall, the introduction of the new Corrugated Roofing Sheet Forming Machine marks a significant milestone for [Company Name] and the industries it serves. As the machine prepares to make its debut on the market, industry professionals and stakeholders are eagerly anticipating the positive impact it will have on the efficiency, quality, and overall landscape of roofing sheet production.

Steel Roll Forming Machine for GP GI Color Sheets: The Ultimate Guide

Introducing the GP GI Color Steel Roll Forming Machine, a state-of-the-art equipment designed to meet the growing demand for high-quality steel products in the construction industry. This advanced technology is set to revolutionize the way steel products are manufactured, and it comes from a company that prides itself on delivering excellence and innovation in the field of metal forming.The GP GI Color Steel Roll Forming Machine is the latest addition to the company's line of roll forming equipment. With its cutting-edge technology and precision engineering, this machine is capable of producing a wide range of steel products, including roofing panels, wall cladding, and structural components with remarkable speed and accuracy. The machine's ability to work with galvanized and pre-painted steel makes it a versatile solution for a variety of applications in the construction and manufacturing industries.The company behind this groundbreaking machine has a long history of delivering top-notch metal forming solutions to its clients. With years of experience in the industry, the company has established itself as a leader in the field of roll forming equipment, offering a comprehensive range of products and services to meet the diverse needs of its customers. From custom design and engineering to manufacturing and installation, the company provides end-to-end solutions to ensure the success of its clients' projects.In addition to its commitment to excellence in manufacturing, the company also prioritizes innovation and continuous improvement in its operations. The GP GI Color Steel Roll Forming Machine is a prime example of this dedication to staying at the forefront of technology and offering cutting-edge solutions to its clients. By investing in state-of-the-art equipment like this roll forming machine, the company demonstrates its commitment to meeting the evolving needs of the market and maintaining its position as a leading provider of metal forming solutions.The GP GI Color Steel Roll Forming Machine is not only a testament to the company's expertise in metal forming but also a reflection of its dedication to sustainability and environmental responsibility. With its efficient production processes and high-quality output, this machine enables the company to minimize waste and reduce its environmental footprint. By choosing this machine for their steel forming needs, clients can be confident that they are investing in a sustainable and eco-friendly solution.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is backed by a team of skilled and knowledgeable professionals who are committed to providing exceptional service and support to clients. From technical assistance and training to ongoing maintenance and customer support, the company's team is dedicated to ensuring the success of every project and the satisfaction of every client. With their expertise and dedication, clients can trust that they are in good hands when they choose the GP GI Color Steel Roll Forming Machine.In conclusion, the introduction of the GP GI Color Steel Roll Forming Machine represents a significant milestone for the company and the industry as a whole. With its advanced technology, commitment to excellence, and focus on sustainability, this machine sets a new standard for steel forming equipment. As the company continues to push the boundaries of innovation and deliver top-quality solutions to its clients, the GP GI Color Steel Roll Forming Machine stands as a testament to its dedication to excellence and its vision for the future of metal forming.

High-Quality Metal Deck Roll Forming Machines Available for Export

Roll forming machines have revolutionized the way we manufacture structural components for construction projects. One such machine which has gained immense popularity in recent years is the Floor Deck Roll Forming Machine. This machine is used to produce high-quality metal decks used for flooring and roofing in various construction projects.The Floor Deck Roll Forming Machine is essentially a series of rollers and tooling which bend and shape metal sheets into the desired profile for the metal deck. With the help of a motor, the metal sheets are slowly fed through the rollers and are bent into the desired shape. The end result is a metal deck that is strong, durable, and can withstand harsh weather conditions.When it comes to manufacturing the Floor Deck Roll Forming Machine, there are many professional and experienced manufacturers available in the market. They specialize in producing a variety of Metal Deck Roll Forming Machines according to your specific requirements. Whether you want a machine to produce metal decks for commercial or residential projects, these manufacturers can deliver you the equipment that meets your needs.The Floor Deck Roll Forming Machine is not only a useful tool for construction projects but is also a profitable investment in the long run. With the demand for metal decking material on the rise, investing in this machine can help you keep up with the competition and cater to your customers' needs.There are various types of metal decks that can be produced with the help of the Floor Deck Roll Forming Machine, such as roof decks, composite floor decks, non-composite floor decks, and more. Each type serves a unique purpose in construction projects and can be custom-made to fit the individual requirements of the project.Metal decks produced by the Floor Deck Roll Forming Machine offer many advantages over traditional construction materials such as timber decking. The metal decks are stronger, more durable, and can withstand harsh weather conditions, making them a popular choice for construction projects of all types.In conclusion, investing in a Floor Deck Roll Forming Machine can be a game-changer for your construction business. It offers a range of benefits such as faster production time, customized solutions, durability, and profitability. Find a reliable and experienced manufacturer of Metal Deck Roll Forming Machines to get started and take your construction business to the next level of success.

High-Quality Cut To Length And Slitting Machine for Efficient Industrial Use

Innovative Machinery Introduces New Cut To Length And Slitting MachineInnovative Machinery, a leading provider of manufacturing solutions, has recently unveiled their latest cutting-edge innovation - the Cut To Length And Slitting Machine. This state-of-the-art machine is designed to revolutionize the metal processing industry by offering unparalleled precision, efficiency, and productivity.The Cut To Length And Slitting Machine is a versatile and high-performance solution for processing metal coils into flat sheets and slitting them into narrow strips with precision and consistency. It is ideal for a wide range of applications, including the production of metal roofing, siding, and automotive components. With its advanced technology and user-friendly design, this machine is set to streamline the manufacturing process for various industries, leading to increased productivity and cost savings.One of the key features of the Cut To Length And Slitting Machine is its ability to handle a wide range of materials, including steel, stainless steel, aluminum, and other non-ferrous metals. This versatility makes it an essential tool for metal processing facilities that require flexibility in their production processes. In addition, the machine can accommodate different coil widths and thicknesses, allowing for customized cutting and slitting operations to meet specific customer requirements.The precision and accuracy of the Cut To Length And Slitting Machine are further enhanced by its advanced control system and cutting-edge technology. The machine is equipped with high-performance servo motors and PLC control to ensure smooth and precise operation, minimizing material waste and maximizing production efficiency. Furthermore, it features automatic tension control and edge guiding systems to deliver consistent and accurate results with minimal setup time and operator intervention.Innovative Machinery has a long-standing reputation for delivering cutting-edge manufacturing solutions to its customers. With a team of highly skilled engineers and technicians, the company is committed to providing innovative and reliable machinery that meets the evolving needs of the metal processing industry. The introduction of the Cut To Length And Slitting Machine is a testament to their dedication to pushing the boundaries of technology and delivering solutions that drive operational excellence for their clients.In addition to its technical capabilities, the Cut To Length And Slitting Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to set up, operate, and maintain, reducing the need for extensive training and minimizing the risk of human error. This, in turn, leads to improved productivity and a safer working environment for the manufacturing workforce.As a company committed to sustainability and environmental responsibility, Innovative Machinery has also incorporated energy-efficient features into the design of the Cut To Length And Slitting Machine. By optimizing power consumption and reducing waste, the machine helps to minimize the environmental impact of metal processing operations, aligning with the industry's growing focus on sustainability and resource efficiency.Overall, the introduction of the Cut To Length And Slitting Machine represents a significant milestone for Innovative Machinery and the metal processing industry as a whole. With its advanced capabilities, versatility, and user-friendly design, this innovative machine is poised to set new standards for precision, efficiency, and productivity in metal processing operations. As the demand for high-quality metal products continues to grow, the Cut To Length And Slitting Machine is positioned to become an indispensable asset for manufacturers looking to stay ahead of the competition and achieve operational excellence.

Highly Efficient Rolling Forming Machine for Profile Manufacturing

Profile Rolling Forming Machine Revolutionizes the Manufacturing IndustryIn today's fast-paced industrial landscape, the need for efficient and reliable machinery has never been more critical. Companies across various sectors are constantly seeking innovative solutions that not only enhance productivity but also ensure top-notch quality. One such groundbreaking development comes in the form of the Profile Rolling Forming Machine, a technology that has taken the manufacturing industry by storm.Profile Rolling Forming Machine utilizes state-of-the-art techniques to produce high-precision profiles in a cost-effective manner. By employing a unique rolling process, this cutting-edge machine enables the creation of complex profiles from a wide range of materials, including metal, plastic, and composite materials. This revolutionary technology has garnered significant attention and is set to have a major impact on multiple industries.One key advantage of the Profile Rolling Forming Machine lies in its ability to produce profiles with exceptional accuracy and uniformity. Traditionally, manufacturing complex profiles involves various time-consuming and labor-intensive processes, such as casting, cutting, and shaping. However, with the advent of this new technology, these conventional methods are being replaced by a streamlined process that guarantees superior precision.The Profile Rolling Forming Machine's rolling process starts with a specially designed set of rolls that gradually shape the material into the desired profile. This continuous bending and rolling operation not only ensures an impeccable finish but also eliminates the need for excessive material wastage. The precision and efficiency of this process significantly reduce production costs and enhance overall productivity.Additionally, the Profile Rolling Forming Machine offers immense flexibility in terms of profile customization. With its advanced computer-controlled system, users can easily program the machine to produce profiles of various shapes and dimensions, catering to unique design requirements. This versatility has opened up several opportunities for manufacturers, enabling them to manufacture highly intricate profiles that were previously deemed unachievable.Furthermore, this groundbreaking technology excels in both small-scale and large-scale production. The Profile Rolling Forming Machine can efficiently handle both small batches and high-volume production, making it suitable for a wide range of applications. From automotive components to architectural elements, this innovation has the potential to revolutionize numerous industries that rely heavily on complex profile production.Moreover, the Profile Rolling Forming Machine offers enhanced productivity by minimizing downtime and maintenance requirements. The robust design of this machine ensures prolonged usage without compromising on performance. Advanced sensors integrated into the machinery provide real-time data about the process, enabling operators to detect any issues promptly and take corrective measures, thereby reducing production delays.In conclusion, the Profile Rolling Forming Machine represents an exciting breakthrough in the manufacturing industry. With its unmatched precision, flexibility, and scalability, this innovative technology has the power to revolutionize the way complex profiles are produced. As industries strive for greater efficiency and productivity, the Profile Rolling Forming Machine emerges as a game-changer, providing manufacturers with the means to achieve exceptional quality while optimizing costs. Embracing this technology will undoubtedly propel businesses to the forefront of their respective industries, opening new avenues for growth and advancement.

Highway Guardrail Roll Forming Machine: A Guide to a Essential Equipment

The highway guardrail roll forming machine has been making waves in the construction industry with its innovative technology and efficient production capabilities. This machine is capable of producing durable and high-quality guardrails for highways, ensuring the safety of millions of drivers and passengers each day.The company behind this cutting-edge technology is a leading manufacturer in the field of roll forming machinery. With years of experience and expertise in the industry, they have been at the forefront of technological advancements, constantly striving to improve and innovate their products.The highway guardrail roll forming machine is a testament to their dedication to quality and efficiency. It is designed to produce guardrails that meet the highest standards of safety and durability, ensuring that they can withstand the wear and tear of heavy traffic and harsh weather conditions.One of the key features of this machine is its advanced roll forming technology, which allows for the precise and efficient production of guardrails. This technology ensures that each guardrail is consistently formed to the exact specifications, resulting in a uniform and high-quality end product.Another key advantage of this machine is its high production capacity. It is capable of producing a large volume of guardrails in a relatively short amount of time, making it ideal for large-scale construction projects. This not only saves time and labor costs but also ensures that there is a steady supply of guardrails for the ongoing maintenance and expansion of highways.Furthermore, the machine is designed for ease of operation and maintenance. It is equipped with user-friendly controls and features that allow for seamless operation and quick changeovers between different guardrail profiles. This not only increases efficiency but also reduces downtime and production costs.In addition to its technological advancements, the company also prides itself on its commitment to sustainability. The highway guardrail roll forming machine is designed with energy-efficient features that minimize power consumption and reduce the environmental impact of production. This aligns with the company's dedication to responsible and sustainable manufacturing practices.The positive impact of the highway guardrail roll forming machine is already being felt in the construction industry. It has enabled construction companies to streamline their production processes, reduce costs, and improve the overall quality of guardrails. This, in turn, has contributed to the safety and reliability of highway infrastructure, benefiting countless drivers and passengers.As the demand for high-quality guardrails continues to grow, the highway guardrail roll forming machine is poised to play a pivotal role in meeting this demand. With its cutting-edge technology, high production capacity, and commitment to sustainability, it is set to revolutionize the way guardrails are manufactured and contribute to the ongoing safety and efficiency of highway systems.In conclusion, the highway guardrail roll forming machine is a testament to the innovative and forward-thinking approach of the company behind it. It represents a significant advancement in the field of roll forming machinery and has the potential to make a lasting impact on the construction industry. As the company continues to push the boundaries of technological innovation, it is clear that they are committed to driving positive change and delivering high-quality solutions for the future of highway infrastructure.

Durable Light Gauge Steel Roll Forming Machine for Efficient Construction

Title: Leading the Industry in Light Gauge Steel Roll Forming MachinesIn recent years, the construction industry has been undergoing a significant transformation with the increasing use of light gauge steel in modern building design. As a result, there has been a growing demand for advanced manufacturing technology, such as the Light Gauge Steel Roll Forming Machine, to cater to this evolving industry need. One company that has been at the forefront of this technological innovation is {}.{} has been a leader in the manufacturing and supply of advanced roll forming machines for various industries, including the construction sector. With a strong focus on research and development, the company has continuously adapted its technology to meet the changing demands of the market, especially in the realm of light gauge steel roll forming.The Light Gauge Steel Roll Forming Machine developed by {} is a state-of-the-art equipment designed to efficiently produce high-quality light gauge steel products. The machine is equipped with advanced features such as precision rollers, automated control systems, and quick-change tooling, allowing for seamless and accurate production of a wide range of steel profiles. This level of precision and reliability has positioned {} as a trusted partner for companies looking to enhance their manufacturing capabilities in the light gauge steel sector.One of the key advantages of the {} Light Gauge Steel Roll Forming Machine is its versatility. With the capability to produce a diverse range of profiles, including studs, tracks, furring channels, and wall panels, the machine offers unparalleled flexibility to meet the unique requirements of different construction projects. This adaptability has made {} a preferred choice for manufacturers and contractors seeking a comprehensive solution for their light gauge steel forming needs.In addition to its cutting-edge technology, {} is also known for its commitment to quality and customer satisfaction. The company places a strong emphasis on rigorous quality control measures throughout the manufacturing process, ensuring that each roll forming machine meets the highest standards of performance and reliability. Furthermore, {} provides comprehensive training and technical support to its customers, empowering them to maximize the potential of the equipment and achieve optimal production efficiency.With a global presence, {} has established itself as a leading provider of light gauge steel roll forming solutions, serving a diverse clientele across different regions. The company's dedication to innovation and customer-centric approach has earned it a solid reputation in the industry, setting it apart as a trusted and dependable partner for businesses looking to invest in advanced roll forming technology.As the construction industry continues to evolve, the demand for advanced manufacturing solutions such as the Light Gauge Steel Roll Forming Machine is expected to grow significantly. In response to this trend, {} remains at the forefront of technological development, consistently updating and enhancing its equipment to meet the evolving needs of the market. By leveraging its expertise and industry knowledge, {} is well-positioned to continue leading the industry in the realm of light gauge steel roll forming machines.In conclusion, {} has solidified its position as a leading provider of light gauge steel roll forming machines, offering advanced technology, versatility, and unparalleled customer support to its global clientele. With a strong commitment to innovation and quality, the company is poised to play a pivotal role in shaping the future of the construction industry through its cutting-edge manufacturing solutions.