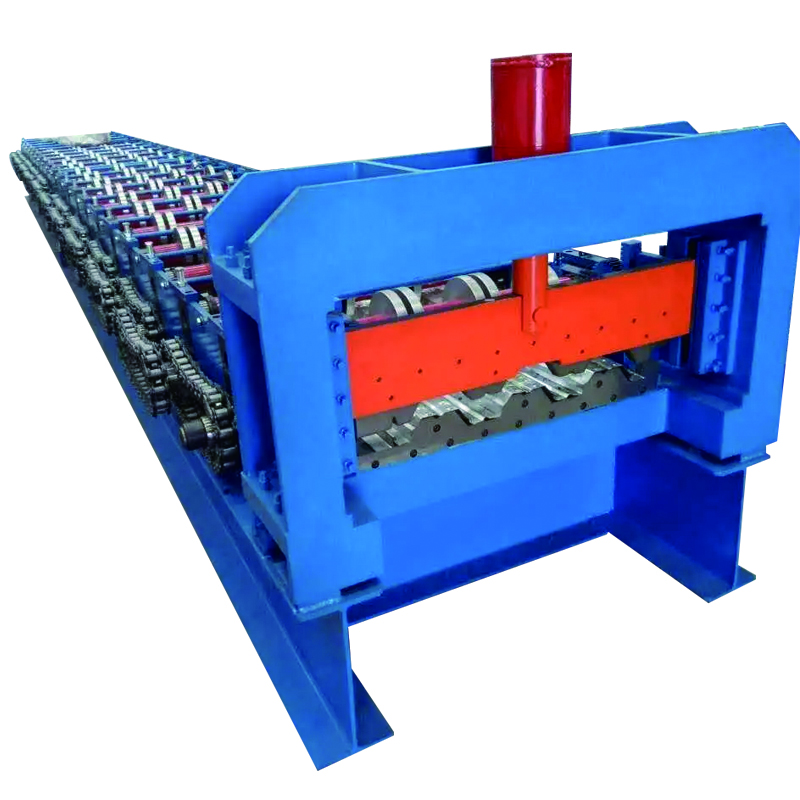

High-Quality Profile Rolling Forming Machine for Efficient Metal Fabrication

By:Admin

The manufacturing industry has always been at the forefront of technological innovation, constantly seeking new ways to increase efficiency and productivity. One of the latest developments in this area is the introduction of the Profile Rolling Forming Machine by [Company Name], a cutting-edge piece of equipment that is revolutionizing the way metal profiles are manufactured.

[Company Name] has been a leader in the manufacturing industry since its inception, providing innovative solutions for metalworking processes. With a reputation for delivering high-quality and reliable machinery, the company has now introduced the Profile Rolling Forming Machine, which is set to have a significant impact on the industry.

The Profile Rolling Forming Machine is a highly versatile piece of equipment that is capable of forming a wide variety of metal profiles with different shapes, sizes, and thicknesses. It utilizes advanced technology and precision engineering to produce consistent and high-quality profiles, making it an invaluable tool for manufacturers across various industries.

One of the key features of the Profile Rolling Forming Machine is its ability to perform multiple operations in a single pass, significantly reducing production time and costs. This is made possible by the machine's innovative design, which allows for the simultaneous forming, bending, and shaping of metal profiles, eliminating the need for multiple machines and manual labor.

In addition to its efficiency, the Profile Rolling Forming Machine also offers a high level of precision and accuracy, ensuring that each profile meets the exact specifications and requirements of the customer. This level of quality control is essential for industries such as automotive, construction, and aerospace, where precision and consistency are critical.

Furthermore, the Profile Rolling Forming Machine is equipped with advanced automation features, including computer numerical control (CNC) technology, which allows for seamless integration into existing manufacturing processes. This not only reduces the risk of human error but also improves overall productivity and output.

The introduction of the Profile Rolling Forming Machine is a testament to [Company Name]'s commitment to innovation and excellence in the manufacturing industry. With a strong focus on research and development, the company continues to push the boundaries of what is possible, providing its customers with the latest advancements in metalworking technology.

The impact of the Profile Rolling Forming Machine is already being felt across the industry, with manufacturers experiencing significant improvements in their production processes. By streamlining operations and increasing efficiency, the machine is helping businesses stay competitive in a constantly evolving market.

As the manufacturing industry continues to evolve, the Profile Rolling Forming Machine represents a new standard for metal profile manufacturing. Its advanced capabilities, precision engineering, and automation features make it an essential tool for any manufacturer looking to enhance their production capabilities and stay ahead of the competition.

In conclusion, the introduction of the Profile Rolling Forming Machine by [Company Name] is a game-changer for the manufacturing industry. With its innovative design, advanced technology, and exceptional precision, the machine is set to transform the way metal profiles are manufactured, providing businesses with a powerful tool to improve efficiency, quality, and productivity. As the industry continues to embrace the possibilities of this groundbreaking technology, [Company Name] remains at the forefront of innovation, driving the future of manufacturing.

Company News & Blog

Roll Form Machine: The Future of Metal Fabrication" can be rewritten as "Revolutionizing Metal Fabrication with Roll Form Machinery".

Roll Form Machine revolutionizes production processes for manufacturing industriesThe manufacturing industry has been a critical part of global economic growth, innovation, and development for centuries now. Over the years, this industry has seen tremendous improvement, growth, and advancement, thanks to industrialization, advancements in technology, and innovation. However, with the increase in competition, changing market trends, and customer demands, manufacturers are always looking for new and innovative ways to optimize their production processes, reduce costs, save time, and enhance the quality of their products.In light of this, a new production technology, the Roll Form Machine, has emerged, and it is transforming the manufacturing industry. The roll forming machine is an innovative technology that helps manufacturers produce high-quality products efficiently, cost-effectively, and with less lead time. This machine is widely used in various industries such as automotive, construction, aerospace, home appliance manufacturing, and many others.The Roll Form Machine (removed brand name) is a reliable, highly functional, and robust machine that can handle multiple processes, including roll forming, punching, cutting, and welding. It can produce highly precise and accurate products, ensuring uniformity and consistency in finished products. Also, the roll forming machine can handle different types of raw materials such as stainless steel, aluminum, copper, brass, and galvanized steel, among others.The roll forming process involves feeding a flat strip of metal into a series of rollers to gradually bend and form it into a specific cross-sectional shape. The Roll Form Machine has several rollers, each with a unique shape that corresponds to the desired cross-sectional profile of the finished product. As the strip of metal passes through the rollers, it undergoes a series of bending operations that gradually form it into the desired shape.One of the benefits of the Roll Form Machine is its flexibility, allowing manufacturers to create a wide variety of products with different shapes, sizes, and profiles. This machine can fabricate products such as shelves, automotive frames, door frames, window frames, railings, roofing, and many others. The machine's versatility and flexibility also make it suitable for small and large-scale manufacturing industries.Notable features of the roll forming machine include its low installation cost, high production speed, and ability to minimize production wastage and remakes. The machine can produce products within a short lead time, allowing manufacturers to satisfy customer demands while reducing turnaround time.Moreover, the Roll Form Machine can readily adapt to changes and updates in customers' requirements without the need for extensive retooling or expensive equipment. Its flexibility makes it critical in the dynamic and fast-paced manufacturing industry.With over (number of years) years of experience in the manufacturing industry, (company name), a leading manufacturer of roll forming machines, has been at the forefront of providing innovative solutions to the production challenges facing manufacturers. The company specializes in the manufacturing of high-quality roll form machines that offer reliability, efficiency, and cost-effectiveness.Our Roll Form Machines are designed to deliver exceptional performance, protecting manufacturers' investments while ensuring optimal return on investment. Our machines come in different configurations and models, depending on customers' needs. We offer customized solutions to meet specific production needs, including the integration of additional features such as punching, cutting, welding, and stacking.With a dedicated team of engineers and technicians, (company name) delivers end-to-end service, including installation, commissioning, and after-sales support for all our Roll Form Machines. Our technicians work closely with customers to ensure the machines operate at maximum efficiency while providing training, maintenance, and repairs whenever necessary.(Company name) is committed to delivering exceptional performance, offering innovative solutions to meet the evolving production needs of the manufacturing industry. Our Roll Form Machines are tested and proven, ensuring that they meet international quality standards and regulations. We take pride in supplying our machines to a global market, providing efficient, reliable, and affordable roll-forming solutions to manufacturers worldwide.In conclusion, the Roll Form Machine is a game-changing technology that is revolutionizing the manufacturing industry. With its versatility, speed, and efficiency, the Roll Form Machine offers manufacturers an opportunity to enhance production processes, optimize costs and productivity while meeting customer demands. (Company name)'s expertise in the manufacturing of Roll Form Machines makes it a suitable partner for any manufacturer looking for innovative and efficient solutions that will take their production to new heights.

Economical Design Manual Adjust Roll Forming Machine for Z Purlin Making

, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.In the construction industry, structures like roofs and walls need structural stability and support for them to withstand external forces like wind and snow. The solution to this is adding purlins to the building structure. A purlin is a horizontal structural member that supports the roof or wall. C&Z purlins are common types of purlins used in roofing and wall cladding in steel buildings.To produce these C&Z purlins, the industry has invested in C&Z purlin forming machines. Among the available machines in the market is the Economical Design Z Purlin Making Machine, which is manually adjusted roll forming machine. It is an important machine since it can produce both C&Z purlins with ease, providing design flexibility.The Economical Design Z Purlin Making Machine has several features that make it a preferable choice in the market. One of the key features is its manual adjust roll forming system. This feature helps in adjusting and changing the machine's size manually, making it easy to shift from one design to another, which saves time and cost for contractors.The machine is also user-friendly, thanks to its touch-screen operation. Operators can adjust various aspects of the machine's performance, including the rolling speed, length, and thickness of the purlins produced. This feature allows the purlin making process to be as efficient as possible, while still producing high quality and durable purlins.Another crucial feature in the Economical Design Z Purlin Making Machine is its compact and modern design. This feature makes it easy to install, transport, and maintain, without taking up too much space. The compact design also allows the machine to operate efficiently, thus minimizing energy consumption.To ensure the machine’s longevity, it is made up of quality materials. It has a reinforced steel frame to maintain its structural integrity, ensuring that it can withstand the intended production loads for years to come. This makes the Economical Design Z Purlin Making Machine a cost-effective option, which provides value for money over the long term.In conclusion, the Economical Design Z Purlin Making Machine is a valuable machine in the construction industry. It allows for high-quality purlins to be produced in an efficient and cost-effective manner. Its manual adjust roll forming system, touch screen operation, compact design, and quality materials ensure that it is the best option for contractors seeking to produce high quality and durable purlins for their projects. If you are in the market for a Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, or a Manual Adjust Purlin Making Machine , consider the Economical Design Z Purlin Making Machine since it is a reliable and efficient option.Keywords: Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.

Standing Seam Metal Roof Roll Former - A Must-Have for Roofing Professionals

Standing Seam Metal Roof Roll Former Revolutionizes Metal Roofing IndustryMetal roofing has always been a popular choice for commercial and industrial buildings, thanks to its durability and longevity. However, the installation process has often been time-consuming and labor-intensive, requiring skilled labor and a considerable amount of effort. This has caused some builders and property managers to shy away from metal roofing in favor of other materials.However, all of this is about to change with the introduction of the innovative Standing Seam Metal Roof Roll Former from (company name). This revolutionary piece of equipment has the potential to completely transform the metal roofing industry, making the installation process faster, more efficient, and more cost-effective than ever before.The Standing Seam Metal Roof Roll Former is a state-of-the-art machine that is designed to produce standing seam metal roofing panels on-site. This eliminates the need for pre-fabricated panels, which are often costly to transport and can be challenging to maneuver and install. With this roll former, contractors can produce custom metal roofing panels of any length directly at the job site, resulting in a quicker and more streamlined installation process.One of the key features of the Standing Seam Metal Roof Roll Former is its ability to produce panels with precise and consistent dimensions, ensuring a tight and secure fit that minimizes the risk of leaks and other issues. This level of precision is crucial for the long-term performance of the roof, as it helps to maintain the integrity of the building and protect it from water damage.In addition to its efficiency and precision, the Standing Seam Metal Roof Roll Former is also incredibly versatile. It can be used to produce a wide range of panel profiles, allowing contractors to offer their clients a variety of design options. Whether a building owner is looking for a sleek and modern appearance or a more traditional look, this roll former can deliver the perfect solution.Furthermore, the Standing Seam Metal Roof Roll Former from (company name) is designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to a wide range of contractors and roofing professionals. This accessibility opens up new opportunities for smaller companies and contractors who may not have had the resources to invest in traditional metal roofing equipment.The introduction of the Standing Seam Metal Roof Roll Former is a game-changer for the metal roofing industry, and (company name) is proud to be at the forefront of this innovative technology. With this roll former, the company is committed to helping contractors and property owners take advantage of the many benefits of metal roofing, including its durability, energy efficiency, and low maintenance requirements.The company has a long history of providing high-quality metal roofing solutions, and the Standing Seam Metal Roof Roll Former is the latest addition to its lineup of cutting-edge products. With a focus on innovation and customer satisfaction, (company name) is dedicated to pushing the boundaries of what is possible in the metal roofing industry.As the demand for metal roofing continues to grow, the introduction of the Standing Seam Metal Roof Roll Former couldn't have come at a better time. It represents a significant step forward for the industry, making metal roofing more accessible and desirable than ever before. With this innovative technology, the future of metal roofing looks brighter than ever, and (company name) is proud to be leading the way.

How an Aluminum Profile Bending Machine Can Benefit Your Business

Aluminum Profile Bending Machine: A Marvel in the Metal Fabrication IndustryMetal fabrication is one of the most important sectors of the manufacturing industry, and its importance cannot be overemphasized. Metal fabrication provides a host of products that are part of our daily lives, from automobiles to household appliances, construction materials, and everything in between. However, metal fabrication is not an easy job. It requires an array of specialized tools and equipment, especially when it comes to bending aluminum profiles. This is where Aluminum Profile Bending Machine comes into play.Aluminum Profile Bending Machine is a revolutionary piece of equipment that has revolutionized the metal fabrication industry. It is designed to bend aluminum profiles with precision and accuracy, creating complex shapes that were once considered impossible. Thanks to this machine, fabricators can now bend aluminum profiles with ease, speed, and efficiency.At its core, an Aluminum Profile Bending Machine utilizes a combination of pressure and heat to bend aluminum profiles into the desired shape. The machine consists of a series of rollers, each of which has a unique shape that corresponds to the desired shape of the end product. The rollers apply pressure to the aluminum profile, gradually bending it into the desired shape.One of the most significant advantages of Aluminum Profile Bending Machines is their versatility. They can bend aluminum profiles in a range of shapes and sizes, from simple curves to complex forms. This machine has made it possible for companies to create custom-designed aluminum profiles that are tailored to their specific needs.The Aluminum Profile Bending Machine is also incredibly efficient. Fabricators can bend numerous profiles with the same machine, which significantly reduces production time and costs. This level of efficiency enables manufacturers to produce high-quality aluminum profiles in large quantities, thereby meeting market demand.One aluminum profile bending machine that stands out from the crowd is the one produced by Rolla-V. Rolla-V is a leading manufacturer of advanced and innovative machines that are used in the metal fabrication industry. Rolla-V's machine is designed to bend aluminum profiles with high precision and speed.Rolla-V's Aluminum Profile Bending Machine is equipped with the latest technology, including hydraulic actuators, an intuitive control panel, and a digital readout system. The hydraulic actuators enable the machine to apply a considerable amount of pressure, which is necessary for bending aluminum profiles. The control panel is user-friendly and allows operators to adjust the settings based on the desired bend angle. The digital readout system is incredibly accurate, ensuring that the aluminum profile is bent to the exact angle specified.Furthermore, Rolla-V's machine is incredibly versatile, capable of bending aluminum profiles in a range of shapes and sizes. The machine's rollers can be changed to accommodate different profiles, making it possible to fabricate custom-designed profiles.Rolla-V's Aluminum Profile Bending Machine is also highly efficient. It can bend numerous profiles in a short amount of time, significantly reducing production costs and increasing profitability. The machine's high level of efficiency has made it a popular choice among fabricators worldwide.In conclusion, the Aluminum Profile Bending Machine is a remarkable piece of equipment that has revolutionized the metal fabrication industry. It has made it possible to bend aluminum profiles with precision, speed, and efficiency, creating complex shapes that were once impossible. Rolla-V's machine is one of the most advanced and innovative machines in the market, providing fabricators with the tools they need to fabricate custom-designed aluminum profiles with ease.

High-Quality Storage Rack Roll Forming Machine for Efficient Warehouse Organization

Storage Rack Roll Forming Machine Revolutionizes Storage SolutionsIn today's fast-paced world, the demand for efficient and cost-effective storage solutions is higher than ever. The industrial sector, in particular, is constantly seeking innovative technologies to optimize their storage processes. This is where the innovative Storage Rack Roll Forming Machine, from {}, comes into play. This revolutionary machine has the potential to transform the way storage racks are fabricated, providing a quicker, more efficient, and more cost-effective solution for businesses around the world.{}, the company behind this cutting-edge technology, is a leading manufacturer of roll forming machines. With over 20 years of experience in the industry, they have consistently delivered high-quality, reliable, and efficient roll forming solutions to their global clientele. Their commitment to innovation, product quality, and customer satisfaction has positioned them as a trusted and respected name in the roll forming machinery industry.The Storage Rack Roll Forming Machine, developed by {}, is a state-of-the-art piece of equipment designed to fabricate storage racks with unparalleled precision and efficiency. This machine is capable of producing storage racks of various sizes and configurations, catering to the diverse needs of industries such as logistics, warehousing, manufacturing, and retail.One of the key features of the Storage Rack Roll Forming Machine is its flexibility. The machine can be easily adjusted to accommodate different types of materials, including steel, aluminum, and other alloys. This flexibility allows businesses to customize their storage racks according to their specific requirements, without the need for additional machinery or extensive retooling.Furthermore, the Storage Rack Roll Forming Machine is equipped with advanced automation and control systems, enabling seamless operation and minimizing the risk of errors or defects in the final product. This not only improves the overall production efficiency but also ensures the consistency and quality of the storage racks being manufactured.In addition to its technical capabilities, the Storage Rack Roll Forming Machine is also designed with the operator in mind. The user-friendly interface and intuitive controls make it easy for operators to set up, operate, and maintain the machine, reducing the need for extensive training and minimizing the risk of human error.By implementing the Storage Rack Roll Forming Machine into their production processes, businesses can expect to see a significant increase in productivity and cost savings. The machine's high-speed operation and efficient material utilization translate to shorter lead times and reduced production costs, ultimately leading to improved profitability for the end-user.In a highly competitive market, where efficiency and cost-effectiveness are crucial factors for success, the Storage Rack Roll Forming Machine from {} offers a competitive edge to businesses seeking to streamline their storage rack manufacturing processes. Its ability to deliver consistent, high-quality results in a fast and efficient manner positions it as a game-changer in the industry.With a strong track record of delivering innovative and reliable roll forming solutions, {} is well-equipped to meet the growing demand for the Storage Rack Roll Forming Machine. Their dedication to customer satisfaction and their commitment to excellence make them a trusted partner for businesses looking to enhance their storage solutions.In conclusion, the Storage Rack Roll Forming Machine from {} represents a significant advancement in the field of storage rack manufacturing. Its innovative technology, coupled with {}'s expertise and reputation for excellence, makes it a compelling choice for businesses seeking to optimize their production processes and stay ahead of the competition. As the demand for efficient and cost-effective storage solutions continues to grow, the Storage Rack Roll Forming Machine is poised to make a lasting impact on the industry.

High-Speed Corrugated Roll Forming Machine with Hydraulic Cutting - Ideal for 914mm and 1220mm Coil Width

Corrugated Sheet Forming Machine: A Revolutionary Solution for Modern BuildingBuilding construction is a vital industry that contributes significantly to the economy. Architects, builders, and property owners strive to create structures that are resilient and aesthetically appealing. However, the process requires heavy investment, and it's vital to use the best materials and tools. One crucial material is the corrugated sheet, which has become popular due to its durability, cost-effectiveness, and versatility. This is where the Corrugated Sheet Forming Machine comes in.The Corrugated Sheet Forming Machine is an innovative solution that has revolutionized the modern building industry. It is a machine designed to transform flat metal sheets into corrugated sheets, which are widely used for roofing, siding, and cladding applications. The machine uses a series of roller dies to create the corrugated profile, which can be customized to different shapes and sizes. It is a fast, efficient, and highly accurate way to produce high-quality corrugated sheets.One of the most important features of the Corrugated Sheet Forming Machine is its motorized cutting and fast drive system. This system allows for quick and easy processing of metal sheets, reducing the time and effort required to create corrugated sheets. Additionally, the hydraulic cutting system ensures precise cutting and minimal waste, further enhancing the machine's efficiency. The machine's 836 type, lengthened design, and 1220 mm coil width make it suitable for producing large volumes of sheets, making it ideal for commercial applications.The Corrugated Sheet Forming Machine is also highly customizable, allowing operators to create different corrugated profiles. This flexibility allows architects and builders to create unique designs that match their clients' preferences. The machine's versatility is further improved by its ability to process different metals, including galvanized steel, aluminum, and copper. This means that users can choose the material that best fits their project requirements, depending on factors such as durability, cost, and aesthetics.In conclusion, the Corrugated Sheet Forming Machine is an essential tool for the modern building industry. Its speed, accuracy, and versatility make it ideal for producing high-quality corrugated sheets for various applications. Whether you are constructing a commercial building, a residential house, or a metal structure, this machine can help you achieve your goals. If you are looking for a reliable and cost-effective way to produce corrugated sheets, the Corrugated Sheet Forming Machine is the perfect solution.

High-Quality Metal Roofing Sheet Roll Forming Machine for Sale

Metal Roofing Sheet Roll Forming Machine is an innovative and advanced technology that has been introduced by a leading manufacturing company based in China. This machine is designed to efficiently and effectively produce metal roofing sheets with high precision and quality. The company has been a pioneer in the manufacturing industry and has been at the forefront of introducing cutting-edge machinery for various industrial applications.The Metal Roofing Sheet Roll Forming Machine is a state-of-the-art equipment that is designed to cater to the growing demand for high-quality metal roofing sheets. With its advanced features and capabilities, this machine is set to revolutionize the metal roofing industry and provide a cost-effective solution for producing durable and reliable roofing materials.This innovative machine is capable of producing metal roofing sheets in various sizes and shapes, catering to the diverse needs of the construction industry. It is equipped with advanced technology that ensures accurate and precise roll forming, resulting in high-quality roofing sheets that meet industry standards.The company behind this pioneering technology has a proven track record of delivering high-quality machinery for the manufacturing industry. With a strong focus on research and development, the company has consistently introduced innovative solutions to meet the evolving needs of the industry. They have a team of highly skilled engineers and technicians who are dedicated to designing and manufacturing advanced machinery that delivers outstanding performance and reliability.The Metal Roofing Sheet Roll Forming Machine is a testament to the company's commitment to excellence and its ability to stay ahead of the curve in the manufacturing industry. This machine is a result of extensive research and development, and the company is proud to introduce it to the market as a game-changing technology for the metal roofing industry.In addition to its advanced technical capabilities, the Metal Roofing Sheet Roll Forming Machine is also designed with user-friendly features that make it easy to operate and maintain. The company provides comprehensive training and support to ensure that customers can fully leverage the capabilities of this machine and achieve optimal results in their production processes.The introduction of this innovative machine is set to significantly impact the metal roofing industry, offering manufacturers a cost-effective and efficient solution for producing high-quality roofing materials. With its advanced technology and precision engineering, this machine is expected to set new benchmarks for quality and reliability in metal roofing sheet production.The company is confident that the Metal Roofing Sheet Roll Forming Machine will be well-received in the market, and they are committed to supporting their customers in adopting this cutting-edge technology. They have a strong sales and support network that ensures prompt delivery, installation, and after-sales service for their customers around the world.In conclusion, the Metal Roofing Sheet Roll Forming Machine is a groundbreaking technology that is set to reshape the metal roofing industry. With its advanced features, precision engineering, and user-friendly design, this machine is a testament to the company's commitment to delivering innovative solutions for the manufacturing industry. As the demand for high-quality metal roofing sheets continues to grow, this machine is well-positioned to meet the needs of manufacturers and contribute to the advancement of the construction industry.

Efficient and Time-saving Automatic Roll Slitter Revolutionizes Industrial Cutting Process

In today's fast-paced world, automation has become a key factor in increasing efficiency and productivity, especially in manufacturing and industrial operations. When it comes to cutting and slitting rolls of materials, such as paper, film, and textile, traditional manual methods are no longer effective nor efficient. Instead, the Automatic Roll Slitter, offered by a leading provider of industrial equipment, has gained global recognition for its advanced technology and superior performance.The Automatic Roll Slitter is a state-of-the-art machine that utilizes high-speed rotary knives to slit rolls of materials into precise widths. With its user-friendly interface, users can easily adjust the cutting speed, knife angle, and feed rate to meet their specific needs. The machine is designed for high-volume production, and can handle a variety of roll widths, weights, and types of materials, including non-woven fabrics, foam, and vinyl, among others.Despite its advanced technology and automated features, the Automatic Roll Slitter is designed to be safe and reliable, with a sturdy frame and safety shields to prevent accidents. It also comes with a range of accessories, such as laser sensors, edge guides, and static eliminators, to further enhance its precision and efficiency.According to the company's President, the Automatic Roll Slitter has been a game-changer in the industrial equipment market. "We are proud to offer this cutting-edge product that has revolutionized the way companies handle rolls of materials. The Automatic Roll Slitter is not only faster and more accurate than manual methods, but it also saves time, reduces waste, and lowers production costs."The company's mission is to provide its clients with the highest quality equipment and solutions, backed by excellent customer service and technical support. Its team of experts works closely with clients to understand their unique requirements and help them find the best solutions to optimize their operations.Recently, the Automatic Roll Slitter was used by a leading producer of medical garments to increase their production capacity and improve product quality. The company had been struggling with the limitations of their manual slitting process, which was prone to errors and inconsistencies. After implementing the Automatic Roll Slitter, they were able to achieve a higher yield of usable materials, reduce scrap and rework, and improve their overall output.The Automatic Roll Slitter has also been adopted by companies in various industries, such as packaging, automotive, and electronics, among others. Its versatility and adaptability make it an ideal choice for processing a wide range of materials, from foam tapes to flexible circuits.In addition to its superior performance, the Automatic Roll Slitter is also environmentally friendly, with features such as energy-efficient motors and reduced waste. Its precision cutting also results in less material waste, which contributes to a more sustainable manufacturing process.As the demand for automation and efficient production methods continues to grow, the Automatic Roll Slitter remains a top choice for companies looking to improve their operations and stay ahead of the competition. With its advanced technology, reliability, and excellent customer support, it is no wonder why it has become a preferred choice for many industries worldwide.

High-quality Coil Slitting Machine for HR Coils: Everything You Need to Know

Hr Coil Slitting Machine: Revolutionizing the Steel IndustryIn recent years, the steel industry has witnessed tremendous growth and technological advancements. One such innovation that has revolutionized the steel processing sector is the Hr Coil Slitting Machine. This state-of-the-art equipment has significantly enhanced the efficiency and productivity of steel processing operations, making it an indispensable tool for manufacturers around the world.{Company name}, a leading manufacturer of industrial machinery, has been at the forefront of this technological revolution. With a strong focus on research and development, {Company name} has introduced a range of cutting-edge slitting machines designed to meet the diverse needs of the steel industry.The Hr Coil Slitting Machine manufactured by {Company name} is a versatile and efficient tool that is used for cutting large coils of steel into smaller, more manageable strips. This machine is equipped with advanced features that ensure precision cutting, high-speed operation, and minimal material wastage. These capabilities make it an ideal choice for steel processing facilities looking to optimize their production processes.One of the key advantages of the Hr Coil Slitting Machine is its ability to handle a wide range of materials, including hot-rolled coils, cold-rolled coils, and galvanized coils. This versatility enables manufacturers to process different types of steel with ease, thereby increasing their operational flexibility.Furthermore, the Hr Coil Slitting Machine is equipped with state-of-the-art automation technology, including programmable logic controllers (PLCs) and advanced software systems. This automation allows for seamless integration with other equipment in the production line, leading to improved overall efficiency and reduced downtime.In addition to its cutting-edge technology, the Hr Coil Slitting Machine from {Company name} is also designed with operator safety and convenience in mind. The machine is equipped with various safety features and ergonomic controls, ensuring a safe and comfortable working environment for the operators.{Company name} has gained a strong reputation for its commitment to quality and customer satisfaction. The Hr Coil Slitting Machine is a testament to this commitment, as it is designed and manufactured to the highest industry standards, ensuring long-term reliability and performance.With a strong emphasis on customer support and after-sales service, {Company name} provides comprehensive training and technical assistance to its clients, ensuring that they are able to fully utilize the capabilities of the Hr Coil Slitting Machine and maximize its potential in their operations.The impact of the Hr Coil Slitting Machine on the steel industry has been nothing short of transformative. By improving operational efficiency, reducing material wastage, and enhancing overall productivity, this innovative equipment has become an essential asset for steel manufacturers worldwide.As the demand for high-quality steel products continues to rise, the need for advanced processing equipment such as the Hr Coil Slitting Machine will only grow. With its cutting-edge technology, versatility, and reliability, the Hr Coil Slitting Machine from {Company name} is poised to play a crucial role in shaping the future of the steel industry.

Quality Horizontal Profiled Sheet Forming Equipment for Sale

Horizontal Profiled Sheet Forming Equipment is continuing to make waves in the industry and set new standards for engineering and innovation. With its sleek design and cutting-edge technology, the equipment is revolutionizing the way profiled sheet forming is done. The company behind this groundbreaking technology, {}, is at the forefront of the manufacturing industry, consistently delivering top-notch products and driving progress through its dedication to excellence.{} specializes in producing high-quality equipment for the construction and manufacturing sectors, and its Horizontal Profiled Sheet Forming Equipment is no exception. Boasting advanced features and precision engineering, this equipment has been well-received by companies around the world for its ability to streamline the production of profiled sheets while maintaining exceptional quality.One of the key features of the Horizontal Profiled Sheet Forming Equipment is its versatility. It is capable of forming a wide range of profiled sheets, allowing manufacturers to cater to diverse customer demands without the need for multiple machines. This not only saves on costs but also maximizes efficiency and increases productivity. In addition, the equipment is designed to be user-friendly, with intuitive controls and easy setup, making it a valuable asset for any production facility.Another noteworthy aspect of {}'s Horizontal Profiled Sheet Forming Equipment is its exceptional precision and consistency. The equipment is engineered to deliver precise and uniform results, ensuring that every profiled sheet meets the highest standards of quality. This level of consistency is essential for construction and manufacturing projects, where even the slightest deviation can lead to inefficiencies and delays.In addition to its technical prowess, {} is committed to sustainability and environmental responsibility. The Horizontal Profiled Sheet Forming Equipment is designed to minimize waste and energy consumption, aligning with the company's dedication to sustainable manufacturing practices. By prioritizing eco-friendly solutions, {} is setting an example for the industry and contributing to a more sustainable future.Furthermore, {} offers comprehensive support and maintenance services for its Horizontal Profiled Sheet Forming Equipment, ensuring that customers can rely on their investment for years to come. With a team of skilled technicians and engineers, the company is dedicated to providing prompt assistance and expertise, building long-lasting relationships with its clients.The success of {}'s Horizontal Profiled Sheet Forming Equipment is a testament to the company's commitment to innovation and excellence. By consistently pushing the boundaries of engineering and manufacturing, {} has established itself as a leader in the industry, earning the trust and admiration of customers worldwide.To learn more about {} and its Horizontal Profiled Sheet Forming Equipment, visit their website or contact their team for personalized assistance. With a track record of exceptional products and a dedication to customer satisfaction, {} is poised to continue driving progress and setting new benchmarks for the industry.