High-Quality Standing Seam Roof Panel Machine: All You Need to Know

By:Admin

[Company Name], a leading manufacturer of metal forming and fabrication machinery, is excited to announce the release of their latest innovation, the Standing Seam Roof Panel Machine. This revolutionary new machine is designed to streamline the production of standing seam roof panels, providing a cost-effective and efficient solution for metal roofing manufacturers and contractors.

The Standing Seam Roof Panel Machine is equipped with advanced technology and precision engineering, allowing for the seamless production of high-quality roof panels. The machine features an automated process for feeding, forming, and cutting metal sheets, significantly reducing the time and labor required for panel production. Additionally, the machine is capable of producing a variety of panel profiles and sizes, providing versatility for a range of roofing projects.

With a focus on durability and performance, the Standing Seam Roof Panel Machine is built to withstand the rigors of continuous use in a manufacturing environment. The machine's rugged construction and reliability make it a valuable investment for metal forming businesses looking to enhance their production capabilities.

"We are thrilled to introduce our Standing Seam Roof Panel Machine to the market," said [Company Name] CEO. "This machine represents a significant advancement in metal forming technology, offering unprecedented efficiency and quality for standing seam roof panel production. We believe that this machine will be a game-changer for roofing manufacturers and contractors, allowing them to take their business to the next level."

In addition to its innovative features, the Standing Seam Roof Panel Machine is designed with user-friendly controls and intuitive operation, making it accessible for operators of all skill levels. The machine's easy setup and minimal maintenance requirements further contribute to its appeal as a practical and reliable investment for metal roofing businesses.

As an industry leader in metal forming machinery, [Company Name] has a proven track record of delivering cutting-edge solutions that meet the evolving needs of the market. With a commitment to quality and customer satisfaction, the company's Standing Seam Roof Panel Machine is backed by comprehensive support and service, ensuring that customers can maximize the machine's performance and longevity.

The introduction of the Standing Seam Roof Panel Machine solidifies [Company Name]'s position as a pioneering force in the metal forming industry, with a dedication to innovation and excellence. Metal roofing manufacturers and contractors can now take advantage of this groundbreaking technology to elevate their production capabilities and meet the growing demand for high-quality standing seam roof panels in the construction industry. [Company Name] invites interested parties to learn more about the Standing Seam Roof Panel Machine and explore the possibilities it offers for enhancing their metal roofing operations.

[Company Name] is a leading manufacturer of metal forming and fabrication machinery, specializing in innovative solutions for the production of a wide range of metal components. With a strong focus on quality, performance, and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses across the metal forming industry. The company's diverse portfolio of machinery includes roll forming machines, panel roll formers, and CNC metal forming equipment, all designed to deliver superior results and efficiency for manufacturers and fabricators. Based on a foundation of engineering expertise and a passion for innovation, [Company Name] continues to set the standard for excellence in metal forming technology. For more information about [Company Name]'s Standing Seam Roof Panel Machine and their full range of metal forming machinery, please visit [website].

Company News & Blog

New Study Reveals Surprising Findings in the Roll Forming Industry

Total Roll Forming, a leading manufacturer of roll forming and metal shaping solutions, has recently announced the expansion of its operations to meet the increasing demand for its products and services. The company, known for its innovative and high-quality solutions, has a long-standing reputation in the industry for providing reliable and cost-effective roll forming technology.With the expansion of its operations, Total Roll Forming is set to further solidify its position as a top provider of roll forming solutions. The company's state-of-the-art manufacturing facilities, coupled with its team of experienced engineers and technicians, enable it to offer a wide range of roll forming capabilities to meet the needs of diverse industries.Total Roll Forming's roll forming solutions are used in various applications, including automotive, construction, aerospace, and appliance industries. The company's expertise in custom roll forming enables it to cater to the specific needs of its clients, offering tailored solutions that meet the highest standards of quality and precision.Furthermore, Total Roll Forming is committed to sustainability and environmentally friendly manufacturing practices. The company continuously invests in research and development to improve its processes and reduce its environmental footprint. This commitment to sustainability has earned Total Roll Forming a reputation as an industry leader in eco-friendly roll forming solutions.In addition to its manufacturing capabilities, Total Roll Forming provides comprehensive support and services to its clients. From design and engineering to prototyping and production, the company works closely with its customers to ensure that their exact specifications are met. Total Roll Forming's dedication to customer satisfaction has resulted in long-lasting partnerships with some of the most renowned companies in the industry.Total Roll Forming's expansion comes at a time when the demand for roll forming solutions is on the rise. The company's ability to offer custom roll forming solutions that are tailored to the unique requirements of its clients has set it apart from its competitors. As a result, Total Roll Forming has experienced significant growth in recent years and is now well-positioned to capitalize on the increasing demand for its products and services."We are excited to announce the expansion of our operations to better serve our clients and meet the growing demand for our roll forming solutions," said [Company Spokesperson]. "Total Roll Forming is committed to providing innovative, high-quality, and sustainable solutions to our customers, and we believe that our expanded capabilities will enable us to further enhance our offerings and solidify our position as a leader in the industry."Total Roll Forming's expansion is a testament to the company's commitment to excellence and its determination to meet the evolving needs of its clients. With its expanded operations, Total Roll Forming is poised to continue setting the standard for roll forming technology and shaping the future of the industry.

High-quality Roll Forming Machine for B Decking: A Guide

B Decking Roll Forming Machine is a revolutionary piece of machinery that has been making waves in the construction industry. Developed by a leading roll forming machine manufacturer, this cutting-edge piece of equipment has been designed to meet the demands of modern construction projects.With the ability to produce high-quality B deck profiles, this machine offers a fast and efficient solution for creating structural floor and roof decking. Its advanced technology and precise engineering ensure that the profiles are produced accurately and to the highest standards, meeting the requirements of even the most complex construction designs.The B Decking Roll Forming Machine is an essential tool for construction companies, as it enables them to create strong and durable decking systems with ease. The machine's high-speed production capabilities make it ideal for large-scale projects, allowing construction firms to meet tight deadlines and deliver exceptional results.With its user-friendly interface and intelligent control system, the B Decking Roll Forming Machine is easy to operate and requires minimal training. This ensures that construction crews can quickly adapt to using the machine, maximizing productivity and minimizing downtime.In addition to its impressive performance, the B Decking Roll Forming Machine is also designed with sustainability in mind. It is built to minimize waste and optimize material usage, reducing the environmental impact of construction projects.The company behind the B Decking Roll Forming Machine is renowned for its dedication to innovation and quality. With a strong focus on research and development, the company has consistently delivered cutting-edge solutions for the construction industry, earning a reputation as a leading provider of roll forming machinery.The company's commitment to excellence is reflected in the design and construction of the B Decking Roll Forming Machine. Each machine is built to the highest standards using the finest materials and components, ensuring long-lasting durability and reliable performance.Furthermore, the company provides comprehensive technical support and maintenance services for the B Decking Roll Forming Machine, ensuring that construction firms can rely on their equipment to perform at its best for years to come.The B Decking Roll Forming Machine is the result of extensive research and development, as well as a deep understanding of the needs and challenges faced by construction companies. By addressing these needs with innovative solutions, the company has positioned itself as a key player in the roll forming machinery industry.In conclusion, the B Decking Roll Forming Machine is a game-changer for the construction industry, offering a fast, efficient, and sustainable solution for creating structural floor and roof decking. With its advanced technology, user-friendly interface, and commitment to quality, this machine is helping construction companies to achieve exceptional results and meet the demands of modern construction projects.

High-Quality CZ Purlin Roll Forming Machine: Made in China

Are you in the construction industry and looking for a reliable and efficient way to manufacture CZ Purlins? Look no further, as HangZhou Roll Forming Machinery Co.,Ltd has the perfect solution for you - their advanced CZ Purlin Roll Forming Machine, which is making waves in the market. In this blog post, we will dive into the details of this remarkable product, exploring its features, benefits, and why it is a game-changer in the steel manufacturing industry.What is a CZ Purlin, you may ask? Well, it is a structural member found in roof trusses and walls to provide support and stability to a building. CZ Purlins are widely used in industrial and commercial construction due to their versatility and strength. With the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd, producing these components becomes a breeze.Now, let's take a closer look at this exceptional machine. Equipped with cutting-edge technology, the CZ Purlin Roll Forming Machine is designed to optimize efficiency and productivity. Its high-speed production capability can churn out CZ Purlins with incredible precision and accuracy, meeting the strictest industry standards. With this machine, you can say goodbye to manual labor-intensive processes and hello to automated precision manufacturing.One of the notable features of the CZ Purlin Roll Forming Machine is its versatility. It can handle various sizes and thicknesses of CZ Purlins, allowing you to cater to different construction needs. This flexibility is a huge advantage, as it eliminates the need to invest in multiple machines for different CZ Purlin specifications. With just one machine, you can produce a wide range of CZ Purlins, saving both space and resources.The CZ Purlin Roll Forming Machine boasts a user-friendly interface, making it accessible to operators of all skill levels. Its intuitive controls and adjustable parameters empower operators to customize output according to specific project requirements. Whether you need CZ Purlins for low-rise or high-rise buildings, this machine can adapt to meet your demands.Durability and reliability are crucial when it comes to machinery, and the CZ Purlin Roll Forming Machine does not disappoint. Built with top-quality materials, it can withstand heavy-duty usage and deliver consistent results over an extended period. This machine is engineered to endure the demands of high-volume production without compromising on its precision and performance.However, the advantages of the CZ Purlin Roll Forming Machine go beyond its features. Investing in this machine can yield significant benefits for your business. Firstly, it eliminates the need for outsourcing CZ Purlin production, saving you time and money. By bringing the manufacturing process in-house, you gain better control over your supply chain, ensuring uninterrupted production and timely delivery.Secondly, the CZ Purlin Roll Forming Machine enhances the overall quality of your CZ Purlins, which boosts customer satisfaction and improves your reputation. With precise dimensions, consistent results, and superior strength, your clients will have confidence in your product. This, in turn, leads to increased customer loyalty and repeat business.Moreover, the CZ Purlin Roll Forming Machine promotes sustainability. By being more energy-efficient and reducing material waste, it aligns with environmental regulations and supports your company's commitment to a greener future. Not only will you benefit from cost savings, but you will also contribute positively to the environment.In conclusion, the CZ Purlin Roll Forming Machine by HangZhou Roll Forming Machinery Co.,Ltd is a game-changer in the steel manufacturing industry. Its advanced technology, versatility, user-friendly interface, durability, and numerous benefits make it a must-have for any construction company. With this machine, you can streamline your production process, enhance your product quality, and position your business for growth and success. Say goodbye to manual labor and inefficiency, and embrace automation and precision with the CZ Purlin Roll Forming Machine.

How Forming Machines Revolutionize Production Processes

article:As automation and technology continue to revolutionize the manufacturing industry, the demand for advanced forming machines has never been greater. A leading company in the industry has recently introduced a state-of-the-art forming machine, which promises to greatly increase efficiency and accuracy in the production of metal parts and components. Let's take a closer look at this exciting development.The new forming machine, which has been designed and engineered to the highest standards, offers a number of advanced features and capabilities that set it apart from other machines on the market. Its advanced servo technology ensures consistent and precise forming, while its flexible and user-friendly controls allow for easy programming and customization. The machine can handle a wide variety of materials, including steel, aluminum, titanium, and even composites, making it a versatile and essential tool for any metalworking operation.The company behind the new forming machine is a well-established and highly respected name in the manufacturing industry. With a long history of innovation and expertise in precision engineering, the company is perfectly positioned to deliver high-quality and reliable forming solutions to its clients worldwide. Its commitment to excellence is reflected in every aspect of the new machine, from its design and construction to its operation and maintenance.But what truly sets this forming machine apart is its ability to integrate seamlessly with other systems and technologies. The machine is equipped with advanced sensors and communication protocols that allow it to exchange data and coordinate with other machines, robots, and software programs. This means that it can be easily integrated into an existing production line or used as part of a larger automation system, increasing efficiency and productivity across the entire manufacturing process.The benefits of this new forming machine are numerous, and will be felt by manufacturers across a wide range of industries. Its advanced technology and customization options will enable companies to produce parts and components that are more precise, consistent, and reliable than ever before. This will lead to higher quality products and increased customer satisfaction, which will ultimately drive growth and profitability. Additionally, the machine's integration capabilities will enable companies to streamline their operations and reduce costs, by eliminating the need for manual labor and reducing the risk of errors and defects.In conclusion, the introduction of this new forming machine is a major development in the manufacturing industry, and one that is sure to have a lasting impact on businesses around the world. The combination of advanced technology, expert engineering, and seamless integration capabilities make this machine a must-have for any company that values efficiency, quality, and innovation. As automation continues to shape and transform the manufacturing industry, it is exciting to see what new innovations and solutions will emerge, and how they will help to shape the future of manufacturing.

Cold Roll Forming Machine for Steel Processing Equipment

If you are in the market for a purlin roll forming machine, then look no further than our CZ interchange purlin roll forming machine. As a professional manufacturer, we have exported our machines to various countries, including India and Dubai. With our machine, you can expect excellent quality at a low price.One of the advantages of our CZ interchange purlin roll forming machine is its versatility. It can handle different thickness materials, ranging from 1.5mm to 3.0mm. Additionally, it can produce both C and Z shape purlins, with the size ranging from 80mm to 300mm. This flexibility allows you to meet the requirements of various projects.Another key feature of our CZ interchange purlin roll forming machine is its ability to easily switch between C and Z types. This means that you can efficiently produce different types of purlins without the need for significant adjustments or additional equipment. This feature adds convenience and saves you time and effort.To ensure the stability and durability of our machine, we have opted for an iron cast structure. This robust design guarantees the machine's longevity and provides a stable platform for producing high-quality purlins. You can rely on our machine to consistently deliver excellent results.When it comes to applications, our CZ interchange purlin roll forming machine is ideal for steel processing. Whether you are involved in construction, manufacturing, or any other industry that requires purlins, our machine can meet your needs. It is capable of efficiently producing purlins of various shapes and sizes, making it a versatile tool for your business.In conclusion, our CZ interchange purlin roll forming machine offers numerous advantages that make it a top choice for individuals and businesses in need of a reliable and versatile purlin forming machine. With its ability to handle different thickness materials, produce various shapes and sizes, and easily switch between C and Z types, our machine provides the flexibility and convenience you require. Additionally, its iron cast structure ensures stability and durability. Invest in our CZ interchange purlin roll forming machine and take your production capabilities to the next level.

High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Sale

Glazed Tile Panel Roll Forming And Corrugation Machine (Name Removed) has become a popular choice among construction professionals for its ability to efficiently produce high-quality glazed tile panels and corrugated metal sheets. The machine is designed to meet the growing demand for durable and aesthetically pleasing roofing and cladding materials, particularly in the residential and commercial sectors.The roll forming and corrugation machine from (Name Removed) is known for its precision and reliability, making it an essential tool for manufacturers and contractors looking to meet tight production deadlines without compromising on quality. With its advanced technology and user-friendly interface, the machine has quickly become the go-to solution for businesses looking to streamline their production processes and maximize their output.One of the key features of the (Name Removed) roll forming and corrugation machine is its versatility. It is capable of producing a wide range of glazed tile panels and corrugated metal sheets, allowing businesses to cater to diverse customer requirements. Whether it's a traditional or modern design, the machine can effortlessly produce panels and sheets that meet industry standards and exceed customer expectations.In addition to its flexibility, the (Name Removed) roll forming and corrugation machine is also praised for its efficiency. The machine is designed to minimize material waste and maximize production yield, helping businesses optimize their resources and reduce production costs. This not only benefits the bottom line but also contributes to sustainability efforts by reducing the environmental impact of manufacturing processes.Moreover, the roll forming and corrugation machine is equipped with state-of-the-art safety features to ensure a secure working environment for operators. This includes built-in safeguards and emergency stop mechanisms that prioritize the well-being of workers and prevent accidents from occurring during operation.The (Name Removed) roll forming and corrugation machine is the result of years of research and development by a company that is dedicated to delivering innovative solutions for the construction industry. With a strong commitment to quality and performance, the company has established itself as a leader in the manufacturing of roll forming and corrugation machinery, earning the trust and loyalty of customers worldwide.Founded (Year Established), (Company Name) has continually invested in cutting-edge technology and engineering expertise to develop a wide range of industrial machinery. The company's dedication to research and development has led to the creation of innovative solutions that have redefined industry standards and empowered businesses to achieve new levels of success.In addition to its commitment to product excellence, (Company Name) is also known for its customer-centric approach. The company takes pride in providing exceptional service and support to its customers, offering comprehensive training programs and technical assistance to ensure that businesses can fully leverage the capabilities of their machinery.Furthermore, (Company Name) operates with a strong focus on sustainability and corporate social responsibility. The company adheres to rigorous environmental standards and implements eco-friendly practices in its manufacturing processes, demonstrating its dedication to minimizing its carbon footprint and contributing to a greener future.As the construction industry continues to evolve, the demand for high-performance roll forming and corrugation machinery is expected to grow. With its superior capabilities and unwavering commitment to customer satisfaction and sustainability, (Name Removed) and (Company Name) are well-positioned to meet the needs of businesses operating in this dynamic sector.In conclusion, the glazed tile panel roll forming and corrugation machine from (Name Removed) is revolutionizing the production of roofing and cladding materials, offering businesses the tools they need to thrive in a competitive market. With its advanced technology, versatility, efficiency, and commitment to excellence, the machine is set to play a pivotal role in shaping the future of the construction industry.

Roll Forming Machine for Light Gauge Steel Trusses

Light Gauge Steel Truss Roll Forming Machine Revolutionizes Construction IndustryThe construction industry has undergone a significant transformation with the introduction of the Light Gauge Steel Truss Roll Forming Machine, a state-of-the-art technology that is set to change the way we build. This innovative machine has been designed to produce high-quality steel trusses more efficiently than traditional methods, effectively reducing construction time and costs.The foundation stone of this technology was laid by a leading manufacturing company that has been serving the construction industry for many years. This modern machine is not only revolutionary but also green, making it a perfect fit for environmentally conscious construction projects.The process of manufacturing steel trusses with the Light Gauge Steel Truss Roll Forming Machine starts with a roll of steel. This roll is then fed into the machine where it undergoes several processes to form the truss. The machine uses a series of precision tools to shape the steel to the desired specifications, producing trusses that are ready for installation without further modifications.The Light Gauge Steel Truss Roll Forming Machine can produce a wide range of truss designs including king post, queen post, and double pitch trusses. The machine is highly customizable, making it easy for the manufacturer to produce trusses of different sizes and shapes. This feature makes it suitable for both simple residential construction projects and large-scale commercial developments.One of the significant advantages of using the Light Gauge Steel Truss Roll Forming Machine is its speed. Traditional methods of producing steel trusses can be time-consuming, and the quality can vary greatly. The modern machine, however, can produce high-quality trusses at a speed of up to 60 meters per minute, reducing production time by up to 50%.In addition to its speed, the Light Gauge Steel Truss Roll Forming Machine is highly accurate. The precision tools used in the manufacturing process produce trusses with consistent dimensions, ensuring that they fit perfectly in the building without the need for modifications.Furthermore, the Light Gauge Steel Truss Roll Forming Machine is eco-friendly, emitting minimal pollutants during operation. Its low carbon footprint makes it an ideal choice for green construction projects where sustainability is a priority.The Light Gauge Steel Truss Roll Forming Machine eliminates the need for welding and other heavy-duty tasks, which reduces the health and safety risks associated with traditional methods. This feature significantly improves the safety of the workers and reduces the risk of on-site accidents.The Light Gauge Steel Truss Roll Forming Machine is easy to operate, ensuring that manufacturers require minimal training. The machine's user-friendly interface allows for easy adjustments, reducing downtime and ensuring that production remains optimal.In conclusion, the introduction of the Light Gauge Steel Truss Roll Forming Machine has significantly transformed the construction industry. This innovative technology is cost-effective, eco-friendly, and capable of producing high-quality steel trusses at incredible speeds. It has made construction safer, more efficient, and more sustainable. Its versatility in producing a wide range of truss designs makes it suitable for both small and large-scale construction projects. The Light Gauge Steel Truss Roll Forming Machine is undoubtedly the future of steel truss production and the construction industry as a whole.

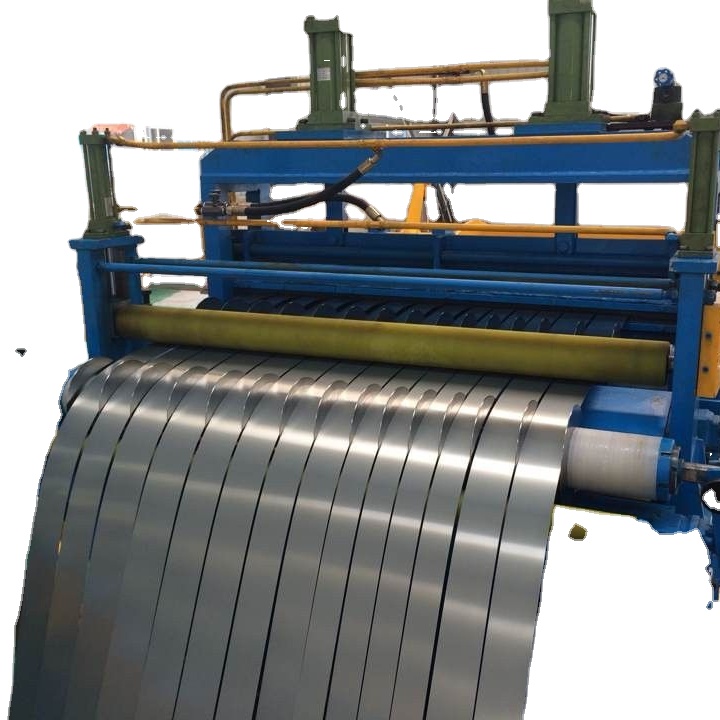

High-Quality Metal Coil Slitting Machine for Efficient Production

Metal Coil Slitting Machine: A New Addition to {Company's Name} State-of-the-Art Manufacturing Facility{Company's Name} has recently enhanced its manufacturing capabilities with the addition of a state-of-the-art Metal Coil Slitting Machine. This new machine is set to significantly improve the efficiency and precision of the company's metal processing operations, further solidifying {Company's Name} as a leader in the industry.The Metal Coil Slitting Machine is designed to precisely cut large coils of metal into narrower strips, enabling {Company's Name} to meet the specific size requirements of its customers. This advanced piece of equipment is equipped with high-speed blades and cutting-edge technology, ensuring that each strip is cut with utmost accuracy and consistency.The addition of the Metal Coil Slitting Machine is a testament to {Company's Name}'s commitment to investing in cutting-edge technology to deliver the highest quality products to its customers. With this new machine, the company will be able to effectively process a variety of metal coils, including steel, aluminum, and stainless steel, offering greater flexibility and versatility in its manufacturing capabilities.In addition to its precision cutting capabilities, the Metal Coil Slitting Machine is equipped with advanced safety features and automation technology, allowing for seamless operation and minimizing the risk of human error. This not only ensures the safety of {Company's Name}'s employees but also contributes to the overall efficiency of the manufacturing process.{Company's Name} takes great pride in its ability to provide customized solutions to its customers, and the addition of the Metal Coil Slitting Machine further strengthens this commitment. With the ability to process metal coils into precise strips of varying sizes, the company will be able to meet the specific requirements of each customer, catering to a wide range of industries such as automotive, construction, and manufacturing.Furthermore, the Metal Coil Slitting Machine will enable {Company's Name} to streamline its production processes, reduce lead times, and improve overall productivity. This will ultimately result in enhanced customer satisfaction and a competitive edge in the market.The investment in the Metal Coil Slitting Machine also aligns with {Company's Name}'s dedication to sustainability and environmental responsibility. By optimizing its manufacturing processes, the company will be able to minimize material waste and energy consumption, contributing to a more sustainable operation.{Company's Name} has always been at the forefront of innovation, and the addition of the Metal Coil Slitting Machine is a testament to its commitment to staying ahead of industry trends. By continuously investing in advanced technology and equipment, the company aims to maintain its position as a leading provider of metal processing solutions.The Metal Coil Slitting Machine has already been integrated into {Company's Name}'s manufacturing facility and is fully operational. The company is excited about the opportunities this new addition brings and is looking forward to delivering even greater value to its customers.As {Company's Name} continues to expand and evolve, the addition of the Metal Coil Slitting Machine underscores its dedication to excellence, innovation, and customer satisfaction. With this new state-of-the-art equipment, the company is well-positioned to further elevate its capabilities and maintain its leadership in the industry.

New Aluminum Profile Polishing Machine Unveiled to Enhance Finishing Quality

Aluminum Profile Polishing Machine: The Future of Aluminum FinishingIn recent years, aluminum has become one of the most commonly used materials in various industries. This versatile metal has excellent properties that make it useful in diverse applications, such as construction, transportation, electronics, and aerospace. However, achieving a high-quality finish on aluminum surfaces can be challenging, especially for manufacturers who need to meet strict customer demands and industry standards. That's why the Aluminum Profile Polishing Machine (APP) has emerged as a game-changer in aluminum finishing processes.APP is a state-of-the-art machine that uses advanced technology to polish and buff aluminum profiles with precision, speed, and consistency. The machine's design and functionality are tailored to meet the specific needs of the aluminum industry, where the demand for high-performance products and cost-effective solutions is high.One of the key benefits of APP is that it can handle a wide range of aluminum profiles, from simple shapes to complex geometries, such as extrusions, tubes, angles, and channels. Thanks to its modular and versatile setup, the machine can be adapted to different production requirements, ensuring maximum efficiency and productivity.Another advantage of APP is its excellent polishing performance, which results in a mirror-like finish on aluminum surfaces. With the help of state-of-the-art abrasives and polishing agents, APP can remove scratches, corrosion, and any other surface imperfections, leaving a smooth and shiny surface that meets the most demanding quality standards.Moreover, APP is easy to operate and maintain, thanks to its user-friendly interface and robust construction. The machine can be controlled through a touch screen, which allows operators to adjust polishing parameters, such as speed, pressure, and angle, in real-time. Additionally, APP's modular design allows for easy access and cleaning of its components, reducing downtime and minimizing maintenance costs.The Aluminum Profile Polishing Machine is also environmentally friendly, as it uses water-based polishing agents that are free of harmful chemicals and VOCs. This makes APP a sustainable solution that meets the growing demand for eco-friendly manufacturing practices and regulations.APP is a product of [Omitted for Privacy], a leading manufacturer of aluminum processing machinery. With over [Omitted for Privacy] years of experience, the company has become a trusted partner of many aluminum companies worldwide, providing them with innovative and reliable solutions that improve their efficiency and profitability.According to [Omitted for Privacy], the Aluminum Profile Polishing Machine is the result of extensive research and development, aiming to address the growing challenges in the aluminum finishing industry. The company's team of experts has worked hard to ensure that APP meets the highest quality standards and customer expectations."[Omitted for Privacy] is committed to delivering cutting-edge technology that enables our customers to stay ahead in the market. We believe that the Aluminum Profile Polishing Machine is a game-changer in the aluminum finishing industry, as it offers unparalleled performance, versatility, and sustainability," said [Omitted for Privacy], CEO of [Omitted for Privacy].In conclusion, the Aluminum Profile Polishing Machine is a revolutionary solution that unlocks new possibilities for aluminum manufacturers. With its advanced technology, exceptional performance, and user-friendly design, APP can help companies achieve faster and more reliable results, while reducing costs and improving sustainability. As the demand for high-quality aluminum products continues to increase, APP is poised to become the future of aluminum finishing.

High Quality Roof Tin Making Machine for Sale - Find Out More Here!

Roof Tin Making Machine Revolutionizes the Manufacturing IndustryRoofing has long been an essential component of construction, and the demand for high-quality roofing materials continues to grow. In response to this increasing demand, (Company Name) unveils its latest innovation - a state-of-the-art Roof Tin Making Machine.With over 20 years of experience in the manufacturing industry, (Company Name) has established itself as a leading provider of machinery and equipment for the construction and building materials sector. The company's commitment to innovation and quality has made it a trusted partner for businesses around the world.The Roof Tin Making Machine is the latest addition to (Company Name)'s impressive portfolio of products. This cutting-edge machine is designed to streamline the production process for roofing materials, significantly increasing efficiency and reducing labor costs. By investing in this advanced technology, businesses can expect to see a significant improvement in their bottom line.The Roof Tin Making Machine is equipped with the latest features and functionalities to ensure precision and consistency in the production of roof tins. Its automated operation minimizes the risk of human error, resulting in high-quality end products that meet industry standards. Additionally, the machine is built to be durable and long-lasting, making it a valuable asset for any manufacturing facility.One of the most notable features of the Roof Tin Making Machine is its versatility. It is capable of producing a wide range of roof tin profiles, allowing businesses to cater to diverse customer needs without the need for multiple machines. This flexibility not only saves space but also reduces the initial investment required for setting up a production line.Furthermore, the Roof Tin Making Machine is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels. This ensures that businesses can maximize the potential of the machine without the need for extensive training or specialized expertise.In addition to its impressive technical capabilities, (Company Name) understands the importance of providing exceptional customer support. The company's team of experienced professionals is dedicated to assisting clients every step of the way, from the initial inquiry to after-sales service. This commitment to customer satisfaction sets (Company Name) apart from its competitors and has earned it a reputation for reliability and trustworthiness.The introduction of the Roof Tin Making Machine marks a significant milestone for (Company Name) and the manufacturing industry as a whole. As the demand for roofing materials continues to grow, businesses are constantly seeking ways to improve their production processes and stay ahead of the competition. The Roof Tin Making Machine offers a solution that not only meets but exceeds these expectations, setting a new standard for efficiency and quality in roof tin manufacturing.Looking ahead, (Company Name) remains dedicated to pushing the boundaries of innovation and delivering cutting-edge solutions to its clients. With its unwavering commitment to excellence, the company is poised to continue making a positive impact on the manufacturing industry and beyond.In conclusion, the Roof Tin Making Machine represents a game-changing innovation for the manufacturing industry. Its advanced capabilities, combined with (Company Name)'s commitment to customer satisfaction, make it a valuable asset for businesses looking to elevate their production processes. As the demand for high-quality roofing materials continues to increase, the Roof Tin Making Machine is poised to revolutionize the way roof tins are manufactured, setting new standards for efficiency, quality, and reliability.