High-Quality Steel Forming Machines for Efficient Production

By:Admin

Founded on the principles of excellence and continuous improvement, Steel Forming Machines has been dedicated to providing top-of-the-line equipment for a variety of applications. Whether it’s for the automotive, aerospace, construction, or energy industries, the company’s products are designed to meet the highest standards of performance and reliability.

One of the key factors that sets Steel Forming Machines apart from its competitors is its focus on research and development. The company has a team of highly skilled engineers and technicians who are constantly working on new innovations and improvements to their existing product line. This commitment to innovation has led to the development of some of the most advanced and efficient steel forming machines on the market.

In addition to its cutting-edge technology, Steel Forming Machines also prides itself on its dedication to customer satisfaction. The company understands that every business has unique needs and challenges, and it strives to provide personalized solutions that meet those specific requirements. Whether it’s through custom equipment design, expert technical support, or comprehensive training programs, Steel Forming Machines is committed to helping its customers succeed.

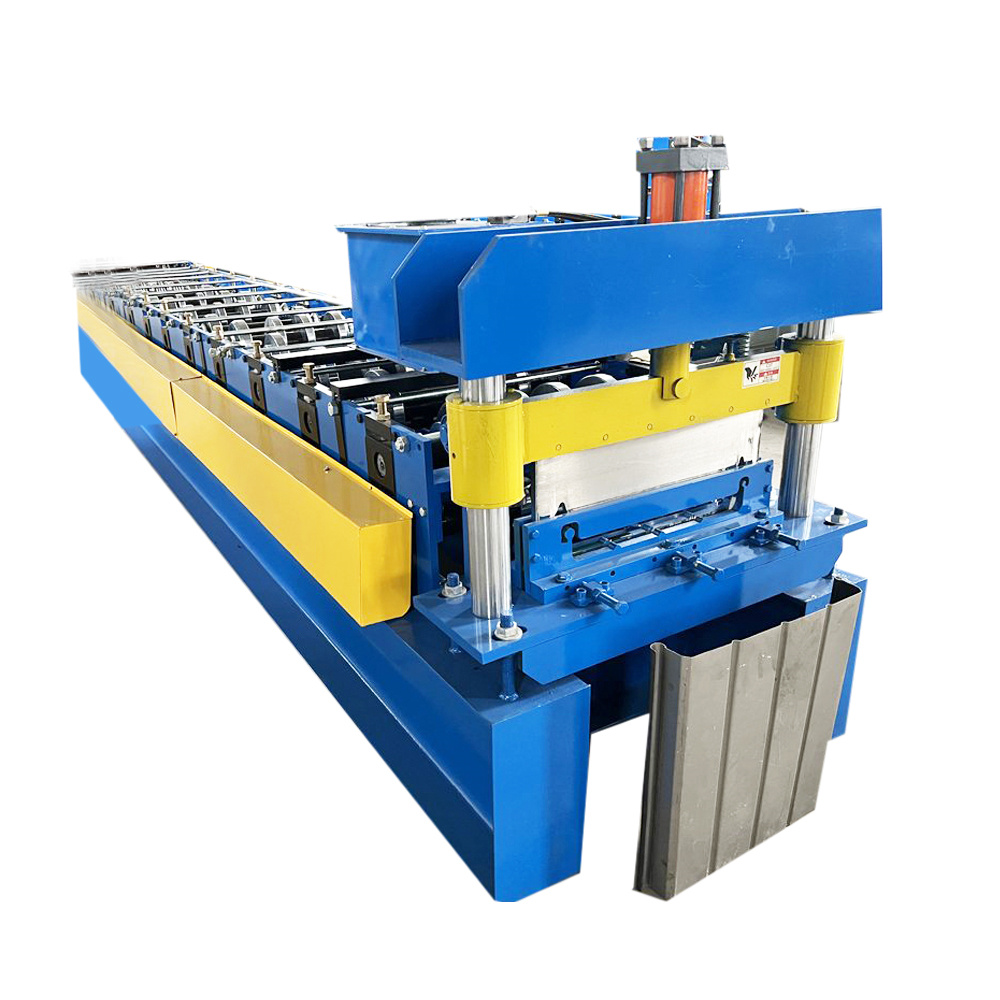

One of the most popular products offered by Steel Forming Machines is its line of roll forming machines. These machines are designed to efficiently produce high-quality metal components with a high degree of accuracy and consistency. From simple shapes to complex profiles, the roll forming machines from Steel Forming Machines are capable of handling a wide range of production requirements. With their advanced control systems and precision tooling, these machines are ideal for businesses looking to streamline their manufacturing processes and increase their productivity.

Another flagship product from Steel Forming Machines is its line of press brakes. These machines are essential for businesses involved in metal fabrication, as they allow for the precise bending and forming of sheet metal. With options for different tonnages and bed lengths, the press brakes from Steel Forming Machines are versatile enough to handle a wide range of applications. Whether it’s for small-scale custom projects or large-scale industrial production, these machines are designed to deliver consistent, high-quality results.

In addition to its core product line, Steel Forming Machines also offers a variety of auxiliary equipment and accessories to complement its machines. From cut-to-length systems to decoilers and recoilers, the company provides everything businesses need to ensure a seamless and efficient production process. With its comprehensive range of products and solutions, Steel Forming Machines is truly a one-stop shop for all steel forming and fabrication needs.

As the manufacturing industry continues to evolve, businesses are constantly looking for ways to improve their processes and stay ahead of the competition. Steel Forming Machines has been at the forefront of this evolution, providing businesses with the tools and technology they need to succeed. With its commitment to innovation, quality, and customer satisfaction, the company is poised to continue leading the way in the field of steel forming and fabrication equipment for years to come.

Company News & Blog

Roll Form Machine: The Future of Metal Fabrication" can be rewritten as "Revolutionizing Metal Fabrication with Roll Form Machinery".

Roll Form Machine revolutionizes production processes for manufacturing industriesThe manufacturing industry has been a critical part of global economic growth, innovation, and development for centuries now. Over the years, this industry has seen tremendous improvement, growth, and advancement, thanks to industrialization, advancements in technology, and innovation. However, with the increase in competition, changing market trends, and customer demands, manufacturers are always looking for new and innovative ways to optimize their production processes, reduce costs, save time, and enhance the quality of their products.In light of this, a new production technology, the Roll Form Machine, has emerged, and it is transforming the manufacturing industry. The roll forming machine is an innovative technology that helps manufacturers produce high-quality products efficiently, cost-effectively, and with less lead time. This machine is widely used in various industries such as automotive, construction, aerospace, home appliance manufacturing, and many others.The Roll Form Machine (removed brand name) is a reliable, highly functional, and robust machine that can handle multiple processes, including roll forming, punching, cutting, and welding. It can produce highly precise and accurate products, ensuring uniformity and consistency in finished products. Also, the roll forming machine can handle different types of raw materials such as stainless steel, aluminum, copper, brass, and galvanized steel, among others.The roll forming process involves feeding a flat strip of metal into a series of rollers to gradually bend and form it into a specific cross-sectional shape. The Roll Form Machine has several rollers, each with a unique shape that corresponds to the desired cross-sectional profile of the finished product. As the strip of metal passes through the rollers, it undergoes a series of bending operations that gradually form it into the desired shape.One of the benefits of the Roll Form Machine is its flexibility, allowing manufacturers to create a wide variety of products with different shapes, sizes, and profiles. This machine can fabricate products such as shelves, automotive frames, door frames, window frames, railings, roofing, and many others. The machine's versatility and flexibility also make it suitable for small and large-scale manufacturing industries.Notable features of the roll forming machine include its low installation cost, high production speed, and ability to minimize production wastage and remakes. The machine can produce products within a short lead time, allowing manufacturers to satisfy customer demands while reducing turnaround time.Moreover, the Roll Form Machine can readily adapt to changes and updates in customers' requirements without the need for extensive retooling or expensive equipment. Its flexibility makes it critical in the dynamic and fast-paced manufacturing industry.With over (number of years) years of experience in the manufacturing industry, (company name), a leading manufacturer of roll forming machines, has been at the forefront of providing innovative solutions to the production challenges facing manufacturers. The company specializes in the manufacturing of high-quality roll form machines that offer reliability, efficiency, and cost-effectiveness.Our Roll Form Machines are designed to deliver exceptional performance, protecting manufacturers' investments while ensuring optimal return on investment. Our machines come in different configurations and models, depending on customers' needs. We offer customized solutions to meet specific production needs, including the integration of additional features such as punching, cutting, welding, and stacking.With a dedicated team of engineers and technicians, (company name) delivers end-to-end service, including installation, commissioning, and after-sales support for all our Roll Form Machines. Our technicians work closely with customers to ensure the machines operate at maximum efficiency while providing training, maintenance, and repairs whenever necessary.(Company name) is committed to delivering exceptional performance, offering innovative solutions to meet the evolving production needs of the manufacturing industry. Our Roll Form Machines are tested and proven, ensuring that they meet international quality standards and regulations. We take pride in supplying our machines to a global market, providing efficient, reliable, and affordable roll-forming solutions to manufacturers worldwide.In conclusion, the Roll Form Machine is a game-changing technology that is revolutionizing the manufacturing industry. With its versatility, speed, and efficiency, the Roll Form Machine offers manufacturers an opportunity to enhance production processes, optimize costs and productivity while meeting customer demands. (Company name)'s expertise in the manufacturing of Roll Form Machines makes it a suitable partner for any manufacturer looking for innovative and efficient solutions that will take their production to new heights.

Quality Glazed Tile Roll Forming Machine and Corrugating Equipment for Sale

Glazed Tile Roll Forming And Corrugating Machine is a revolutionary piece of equipment that is set to change the game in the construction industry. This high-tech machine is designed to produce glazed tiles and corrugated sheets with precision and efficiency, making it an indispensable tool for construction companies and contractors all over the world.The Glazed Tile Roll Forming And Corrugating Machine is equipped with advanced technology and a state-of-the-art design that allows for seamless production of high-quality tiles and sheets. It is capable of working with a variety of materials, including steel, aluminum, and copper, making it a versatile choice for any construction project. The machine features a user-friendly interface, allowing operators to easily input their desired specifications and produce custom tiles and sheets with ease.One of the key features of the Glazed Tile Roll Forming And Corrugating Machine is its speed and efficiency. With the ability to produce up to 60 tiles or sheets per minute, this machine can significantly increase productivity and reduce production time, saving construction companies time and money. It also boasts a high degree of accuracy, ensuring that each tile or sheet meets the strictest quality standards.In addition to its impressive performance, the Glazed Tile Roll Forming And Corrugating Machine is also designed with sustainability in mind. It is equipped with energy-efficient components and is built to minimize waste, making it an environmentally-friendly choice for construction projects. This focus on sustainability aligns with our company's commitment to reducing our environmental impact and contributing to a greener future.Our company is a leading manufacturer of construction machinery, known for our innovative designs and commitment to quality. With over 20 years of experience in the industry, we have a proven track record of delivering reliable and efficient equipment that meets the needs of our customers. Our team of engineers and designers are dedicated to staying at the forefront of technological advancements, ensuring that our products are always cutting-edge and able to support the evolving needs of the construction industry.As part of our commitment to customer satisfaction, we offer comprehensive support services for the Glazed Tile Roll Forming And Corrugating Machine. Our team of technicians are available to provide training, technical support, and maintenance services, ensuring that our customers are able to maximize the performance of their equipment and achieve the best possible results. We also offer a range of financing options to make our equipment more accessible to a wider range of customers, allowing them to take advantage of the benefits of our cutting-edge technology.The introduction of the Glazed Tile Roll Forming And Corrugating Machine represents a significant advancement in the construction industry, offering a solution that is both efficient and sustainable. With its speed, precision, and versatility, this machine is set to revolutionize the way that construction companies produce tiles and sheets, allowing them to meet their project requirements with ease. As a leading manufacturer in the industry, we are proud to be at the forefront of this innovation and to continue supporting the success of our customers with our state-of-the-art equipment.

Best Metal Roof Forming Machines for Efficient Roof Installation

Introducing Innovative Metal Roof Forming Machine Revolutionizing the Construction IndustryThe construction industry has seen numerous technological advancements in recent years, and one of the most impactful innovations is the development of Metal Roof Forming Machine. This state-of-the-art equipment, designed and manufactured by a leading company in the construction machinery industry, has revolutionized the way metal roofs are fabricated, making it faster, more efficient, and cost-effective.With the increasing demand for durable and long-lasting roofing solutions, the Metal Roof Forming Machine has become an indispensable tool for roofing contractors and construction companies. This advanced machinery has the capability to fabricate metal roofs of various designs and specifications, allowing for greater flexibility and customization to meet the specific requirements of individual projects.The Metal Roof Forming Machine is equipped with cutting-edge technology and precision engineering, ensuring the production of high-quality metal roofing panels with consistent dimensions and flawless finishes. This level of precision and accuracy has significantly reduced material wastage and labor costs, making metal roofing more affordable and environmentally sustainable.Furthermore, the Metal Roof Forming Machine is designed for ease of use and user-friendly operation, allowing operators to quickly set up and produce metal roofing panels with minimal training and expertise. This has streamlined the manufacturing process and increased productivity, enabling construction companies to meet tight project deadlines and deliver exceptional results to their clients.In addition to its efficiency and cost-effectiveness, the Metal Roof Forming Machine also boasts a high level of durability and reliability, ensuring continuous and uninterrupted operation even in the most challenging work environments. This has made it a preferred choice for construction companies seeking equipment that can withstand the rigors of heavy-duty use and deliver consistent performance over an extended period.The company behind the Metal Roof Forming Machine has a strong track record of excellence in the construction machinery industry, with a reputation for delivering innovative and reliable solutions to meet the evolving needs of the market. With a focus on research and development, the company continues to invest in cutting-edge technologies and engineering expertise to stay ahead of the competition and provide its customers with the best-in-class products and services.In addition to its commitment to innovation, the company also places a strong emphasis on customer satisfaction and after-sales support, offering comprehensive training programs, technical assistance, and maintenance services to ensure the optimal performance and longevity of its machinery. This dedication to customer care has earned the company a loyal customer base and a reputation for being a trusted partner in the construction industry.As the construction industry continues to evolve and demand for high-quality roofing solutions grows, the Metal Roof Forming Machine stands poised to play a pivotal role in shaping the future of construction practices. Its ability to deliver superior quality, efficiency, and cost-effectiveness has already made it a game-changer in the industry, and its potential for further advancements and applications is limitless.In conclusion, the Metal Roof Forming Machine represents a significant advancement in the construction machinery industry, offering unparalleled efficiency, precision, and durability in the fabrication of metal roofing panels. With its innovative design and reliable performance, this state-of-the-art equipment is set to redefine the standards of excellence in metal roofing fabrication and contribute to the advancement of the construction industry as a whole.

Ultimate Guide to Roofing Sheet Profiling Machines

Roofing Sheet Profiling Machine Revolutionizes Manufacturing IndustryThe manufacturing industry is constantly evolving with new technologies and innovations. One such innovation making waves in the industry is the Roofing Sheet Profiling Machine, which has the potential to revolutionize the way roofing sheets are produced. This cutting-edge machine, developed and manufactured by the industry-leading company {}, is set to transform the manufacturing process for roofing sheets.The Roofing Sheet Profiling Machine is a state-of-the-art piece of equipment designed to streamline the production of roofing sheets. Using advanced profiling technology, this machine is capable of producing high-quality roofing sheets with precision and efficiency. Its innovative design allows for the customization of roofing sheets according to specific requirements, making it a versatile and indispensable tool for manufacturers in the roofing industry.Incorporating the latest advancements in technology, the Roofing Sheet Profiling Machine is equipped with automated features that enhance productivity and accuracy. Its user-friendly interface and intuitive controls make it easy to operate, resulting in increased efficiency and reduced labor costs. This machine is also designed for durability and reliability, ensuring consistent performance over an extended period of time.The company behind this groundbreaking innovation, {}, is a leading manufacturer of industrial machinery with a proven track record of delivering high-quality, cutting-edge equipment to various industries. With a focus on innovation and customer satisfaction, {} has established itself as a trusted name in the manufacturing industry. The Roofing Sheet Profiling Machine is a testament to the company's commitment to providing innovative solutions that meet the evolving needs of its customers.The Roofing Sheet Profiling Machine has already garnered significant attention within the manufacturing industry, with many companies recognizing its potential to revolutionize the production of roofing sheets. By significantly reducing lead times and material waste, this machine offers manufacturers a cost-effective and sustainable solution for producing high-quality roofing sheets. Its ability to produce customized profiles further enhances its appeal, allowing manufacturers to cater to specific customer needs and market demands.In addition to its technological advancements, the Roofing Sheet Profiling Machine also prioritizes safety and environmental considerations. It is designed to meet stringent safety standards, ensuring a secure working environment for operators. Furthermore, its efficient use of materials and energy aligns with the industry's growing focus on sustainability and environmental responsibility.The introduction of the Roofing Sheet Profiling Machine marks a significant milestone in the manufacturing industry, particularly within the roofing sector. Its potential to reshape the production process for roofing sheets is poised to generate considerable interest and adoption among manufacturers looking to stay ahead in a competitive market. With its advanced features, user-friendly operation, and commitment to safety and sustainability, this machine represents a game-changing innovation that is set to redefine the manufacturing landscape.As the industry continues to embrace technological advancements, the Roofing Sheet Profiling Machine stands out as a prime example of how innovation can drive efficiency, quality, and sustainability in manufacturing. With its potential to revolutionize the production of roofing sheets, this machine is well-positioned to shape the future of the industry and set new standards for excellence. As manufacturers increasingly seek solutions that deliver greater value and performance, the Roofing Sheet Profiling Machine emerges as an indispensable asset that embodies the spirit of progress and innovation in manufacturing.

Purlin Profiles Cold Roll Forming Lines for CZ Profiles

Purlins are an important component in construction, providing structural support to the roof and walls of buildings. As the demand for purlin profiles continues to grow, the need for advanced manufacturing solutions has become increasingly apparent. In response to this demand, [Company Name] has developed a state-of-the-art cold roll forming line specifically designed for the production of high-quality purlin profiles.[Company Name] has established itself as a leading provider of roll forming solutions for the construction industry. With years of experience and a commitment to innovation, [Company Name] has earned a reputation for delivering cutting-edge production technology to its global customer base. The company's expertise in cold roll forming has positioned it as a trusted partner for companies looking to enhance their manufacturing capabilities.The new cold roll forming line for purlin profiles represents the latest advancement in [Company Name]'s product portfolio. Designed to meet the specific requirements of purlin production, the line integrates advanced technology to deliver superior performance and precision. With a focus on efficiency and quality, the line is capable of producing a wide range of purlin profiles with tight tolerances and consistent dimensions.One of the key features of the new cold roll forming line is its flexibility. The line is able to accommodate different material thicknesses and widths, allowing for greater versatility in purlin profile production. This flexibility is essential for meeting the diverse needs of customers and adapting to changing market demands. By offering a customizable solution, [Company Name] is able to provide its customers with a competitive edge in the purlin profile market.In addition to its flexibility, the cold roll forming line is also designed for seamless integration into existing production processes. With user-friendly controls and automated functions, the line is easy to operate and maintain, minimizing downtime and maximizing productivity. This level of automation also enhances the safety of the production environment, creating a reliable and efficient manufacturing system.The new cold roll forming line is a testament to [Company Name]'s commitment to continuous improvement and customer satisfaction. By investing in research and development, [Company Name] has been able to stay ahead of the curve in roll forming technology, offering innovative solutions that address the evolving needs of the construction industry. The company's dedication to quality and reliability has earned it the trust of customers around the world, cementing its position as a leader in the roll forming sector.As the demand for purlin profiles continues to grow, [Company Name] is well-positioned to support the industry with its advanced cold roll forming solutions. By leveraging its expertise and technical capabilities, the company is able to provide tailored production lines that meet the highest standards of performance and efficiency. With a focus on innovation and customer collaboration, [Company Name] is driving the future of purlin profile manufacturing.In conclusion, the launch of [Company Name]'s new cold roll forming line for purlin profiles represents a significant advancement in the roll forming industry. With its cutting-edge technology and commitment to customer satisfaction, [Company Name] is poised to make a lasting impact on the production of purlin profiles, offering a reliable and efficient solution for manufacturers worldwide.

Ultimate Guide to Standing Seam Machines

[Company Introduction]Established in 1995, our company has been a pioneer in the manufacturing of roofing and construction equipment. Our commitment to quality, innovation, and customer satisfaction has propelled us to the forefront of the industry. With state-of-the-art facilities and a team of highly skilled professionals, we have been able to consistently deliver high-quality products to our clients.[News Content]The latest addition to our range of cutting-edge equipment is the Standing Seam Machine. With its innovative design and advanced features, this machine is set to revolutionize the roofing industry. The Standing Seam Machine is a versatile and efficient tool that is capable of producing high-quality standing seam panels for a variety of roofing applications.One of the key features of the Standing Seam Machine is its ability to produce panels with precision and speed. Equipped with advanced technology, the machine is able to accurately create standing seam panels of varying widths and lengths, all while maintaining a smooth and seamless finish. This level of precision is essential in ensuring the durability and performance of the roofing panels.Additionally, the Standing Seam Machine is designed for ease of use and convenience. Its user-friendly interface and intuitive controls make it simple for operators to set up and start producing panels quickly and efficiently. This not only saves time and labor costs but also enhances overall productivity.Furthermore, the Standing Seam Machine is built to withstand the rigors of heavy-duty use. Constructed from high-quality materials, the machine is durable and reliable, able to consistently deliver excellent results even in challenging working environments. This robust construction ensures that the machine will provide years of dependable service to its users.In addition to its technical capabilities, the Standing Seam Machine is also designed with safety in mind. With built-in safety features and compliance with industry standards, operators can have peace of mind knowing that they can work with the machine safely and securely.Our company is proud to offer the Standing Seam Machine to our clients, and we are confident that it will meet and exceed their expectations. As with all of our products, the Standing Seam Machine has undergone rigorous testing and quality assurance processes to ensure that it meets our high standards of excellence.As a leading provider of roofing and construction equipment, our company is committed to delivering solutions that empower our clients to achieve success. The addition of the Standing Seam Machine to our product portfolio reinforces our dedication to innovation and our ongoing efforts to provide our customers with the best tools and equipment available in the market.In conclusion, the introduction of the Standing Seam Machine represents a significant milestone for our company and the roofing industry as a whole. With its exceptional performance, user-friendly design, and unwavering reliability, the machine is poised to set a new standard for standing seam panel production. We look forward to bringing this groundbreaking equipment to our clients and contributing to the advancement of the roofing industry.

High-Quality Automatic Cut-To-Length Machine for Precision Cutting

Automatic Cut-To-Length Machine Revolutionizing Production ProcessThe manufacturing industry is continuously evolving with the advancement of technology, and one company at the forefront of this evolution is {}. With a commitment to innovation and efficiency, they have recently introduced their latest addition to their production line – the Automatic Cut-To-Length Machine. This state-of-the-art machine is set to revolutionize the production process, offering precision, speed, and enhanced productivity.The Automatic Cut-To-Length Machine is designed to streamline the process of cutting materials to specific lengths, catering to the diverse needs of various industries such as automotive, construction, and appliances. This machine is equipped with advanced features that enable it to effortlessly cut different materials including metals, plastics, and composites with utmost accuracy and consistency.One of the key highlights of the Automatic Cut-To-Length Machine is its cutting-edge technology that allows for automated operation. This not only reduces the need for manual labor but also minimizes the margin of error, resulting in higher quality output. Additionally, with its rapid cutting speed, the machine significantly increases production efficiency, ultimately leading to cost savings for the company.Furthermore, the Automatic Cut-To-Length Machine is integrated with intelligent software that enables precise customization and optimization of cutting processes. This ensures that the machine can meet the specific requirements of each customer, catering to a wide range of dimensions and tolerances. With such versatility, the machine offers a competitive edge in the market, allowing {} to provide tailored solutions to meet the unique demands of their clients.In addition to its technical capabilities, the Automatic Cut-To-Length Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and ensuring seamless integration into the production line. This not only enhances the overall efficiency of the manufacturing process but also creates a safer working environment for the operators.{} has a long-standing reputation for delivering high-quality, reliable machinery, and the introduction of the Automatic Cut-To-Length Machine is a testament to their commitment to continuous improvement and innovation. With a strong focus on research and development, the company has invested heavily in advancing their technological capabilities, ensuring that they remain at the forefront of the industry.The launch of the Automatic Cut-To-Length Machine underscores {}'s dedication to meeting the evolving needs of their customers. By incorporating cutting-edge technology and automation into their production line, they are not only enhancing their own operational efficiency but also empowering their clients to achieve greater success in their respective industries.Moreover, the introduction of the Automatic Cut-To-Length Machine aligns with {}'s long-term sustainability goals. By optimizing the cutting process and reducing material waste, the machine contributes to a more environmentally friendly manufacturing approach. This reflects {}'s commitment to conducting business in a responsible and ethical manner, prioritizing sustainability and resource efficiency.With the introduction of the Automatic Cut-To-Length Machine, {} is poised to set new standards within the manufacturing industry. By leveraging cutting-edge technology and innovation, they are not just meeting the current demands of the market but also shaping the future of production processes. As the industry continues to evolve, {} remains dedicated to pushing boundaries and redefining what is possible in manufacturing.

High-Quality Corrugated Metal Roof Panel Roll Forming Machine for Sale

Corrugated Metal Roof Panel Roll Forming Machine has recently been introduced by a leading manufacturing company in the field of construction equipment. This advanced roll forming machine is designed to revolutionize the process of creating high-quality corrugated metal roof panels, offering a wide range of benefits to construction companies and builders.The new Corrugated Metal Roof Panel Roll Forming Machine is equipped with state-of-the-art technology, allowing for precision and efficiency in the production of metal roof panels. The machine features a series of rollers and tools that are programmed to create precise corrugations and shapes in the metal, resulting in uniform and high-quality roof panels.One of the key advantages of this roll forming machine is its ability to create corrugated metal roof panels of varying sizes and shapes, making it suitable for a wide range of construction projects. Whether it's a large commercial building or a residential property, this machine can cater to the specific requirements of the project, providing flexibility and versatility to construction companies.In addition, the Corrugated Metal Roof Panel Roll Forming Machine is designed for high-speed production, allowing for increased output and efficiency. This means that construction companies can save time and labor costs when using this machine, ultimately leading to higher profitability and quicker project completion.Furthermore, the roll forming machine is equipped with advanced safety features, ensuring the protection of workers and maintaining a safe working environment. With its user-friendly interface and easy-to-use controls, operators can efficiently operate the machine with minimal training, reducing the risk of accidents and errors in production.The company behind this innovative roll forming machine is known for its commitment to quality and innovation in the construction equipment industry. With decades of experience and expertise in manufacturing machinery for the construction sector, they have established themselves as a trusted name in the market.Their dedication to research and development has led to the creation of the Corrugated Metal Roof Panel Roll Forming Machine, a product that reflects their ongoing efforts to meet the evolving needs of the construction industry. By combining cutting-edge technology with practical design, they have succeeded in delivering a machine that sets new standards for efficiency and performance in the production of metal roof panels.Furthermore, the company's customer-centric approach ensures that they provide comprehensive support and service to their clients, assisting them in integrating the roll forming machine into their production processes and addressing any maintenance or technical issues that may arise.Overall, the introduction of the Corrugated Metal Roof Panel Roll Forming Machine represents a significant advancement in the construction equipment industry, offering a solution that enhances productivity, quality, and safety in the production of metal roof panels. With the backing of a reputable and innovative company, this machine is set to make a positive impact on construction projects and the industry as a whole.

High-quality Double Layers Color Steel Roll Forming Machine for Sale - Latest Technology

Double Layers Color Steel Roll Forming Machine Revolutionizes the Manufacturing IndustryAs technology continues to advance, the manufacturing industry is constantly on the lookout for innovative and efficient solutions to improve productivity and quality. Keeping this in mind, {Company Name}, a leading manufacturer in the industry, has introduced the Double Layers Color Steel Roll Forming Machine, a cutting-edge solution that is set to revolutionize the way color steel is produced.The Double Layers Color Steel Roll Forming Machine is designed to streamline the production process while ensuring top-notch quality and accuracy. It is a versatile machine that can accommodate a wide range of color steel materials, making it a valuable addition to any manufacturing setup. With the ability to form two different profiles in one machine, it offers flexibility and efficiency that is unparalleled in the industry.The machine is equipped with advanced technology that allows for precise and consistent forming of color steel, ensuring that each product meets the highest standards. It also comes with a user-friendly interface, making it easy for operators to control and monitor the entire process. This not only reduces the risk of errors but also increases overall productivity.One of the key features of the Double Layers Color Steel Roll Forming Machine is its ability to produce color steel with a smooth, flawless finish. This is crucial in the manufacturing of various products, such as roofing and cladding materials, where the aesthetics of the final product are of utmost importance. With this machine, manufacturers can achieve a consistent and high-quality finish, thereby enhancing the value of their products.Furthermore, the machine is designed with efficiency in mind, ensuring that the production process is streamlined and cost-effective. By reducing manual labor and optimizing material usage, manufacturers can significantly lower their production costs while increasing output. This not only improves their bottom line but also gives them a competitive edge in the market.{Company Name} has a long-standing reputation for delivering top-of-the-line manufacturing solutions, and the introduction of the Double Layers Color Steel Roll Forming Machine further solidifies its position as a leader in the industry. The company is committed to providing innovative and reliable equipment that meets the evolving needs of manufacturers, and this new machine is a testament to that commitment.In addition to the Double Layers Color Steel Roll Forming Machine, {Company Name} offers a comprehensive range of manufacturing equipment and solutions, making it a one-stop destination for all manufacturing needs. Whether it's roll forming, cutting, or packaging equipment, the company has the expertise and resources to cater to the diverse requirements of its clients.With a strong focus on research and development, {Company Name} is continuously pushing the boundaries of innovation in the manufacturing industry. The company invests heavily in developing cutting-edge technology and refining its existing products to ensure that it stays ahead of the curve. This commitment to excellence has earned {Company Name} a reputation for delivering quality and reliability, making it a trusted partner for manufacturers around the world.The introduction of the Double Layers Color Steel Roll Forming Machine is a significant milestone for {Company Name}, and it is set to make a lasting impact on the industry. With its advanced features and capabilities, the machine is poised to set a new standard in color steel production, offering manufacturers a competitive advantage that is unmatched.In conclusion, the Double Layers Color Steel Roll Forming Machine is a game-changer for the manufacturing industry, and {Company Name} is at the forefront of this innovation. With its commitment to excellence and track record of delivering top-notch solutions, the company continues to shape the future of manufacturing, driving efficiency, quality, and productivity to new heights. Whether it's the Double Layers Color Steel Roll Forming Machine or any other product in its portfolio, {Company Name} remains a beacon of innovation and reliability in the industry.

High-quality Glazed Tile Roll Forming and Corrugating Machine: Everything You Need to Know

Glazed Tile Roll Forming And Corrugating Machine is a new addition to the production line of {} company, a leading manufacturer of industrial machinery. This state-of-the-art machine is set to revolutionize the process of producing high-quality glazed tiles and corrugated sheets, catering to the growing demand in the construction and roofing industry.The introduction of this machine comes as a strategic move by {} company to expand its product range and meet the evolving needs of its customers. With its advanced technology and precision engineering, the glazed tile roll forming and corrugating machine is designed to deliver superior quality output with maximum efficiency.The machine boasts a sophisticated roll forming system that allows for seamless production of glazed tiles and corrugated sheets, ensuring consistency in shape and dimensions. It is also equipped with a high-speed corrugating mechanism, enabling the production of large volumes of tiles and sheets in a shorter timeframe.One of the key features of the machine is its versatility, allowing for customization of tile and sheet designs to meet specific customer requirements. This flexibility is essential in catering to the diverse aesthetic preferences and functional needs of the construction industry.In addition to its cutting-edge technology, the glazed tile roll forming and corrugating machine is built with durability and reliability in mind. Its robust construction and high-quality components ensure long-term performance and minimal downtime, thus optimizing productivity for {} company and its customers.Furthermore, the machine is designed for ease of operation and maintenance, with user-friendly controls and accessible components. This streamlines the production process and reduces the need for extensive training, enabling {} company to maximize its operational efficiency.The introduction of the glazed tile roll forming and corrugating machine aligns with {} company's commitment to innovation and customer satisfaction. By embracing the latest advancements in manufacturing technology, {} company aims to set new standards in the industry and solidify its position as a leading provider of industrial machinery.In response to the growing demand for glazed tiles and corrugated sheets in the global market, {} company is poised to capitalize on this opportunity with the introduction of the new machine. With its enhanced production capabilities, {} company is well-positioned to cater to the needs of construction companies, roofing contractors, and other stakeholders in the building materials sector.The launch of the glazed tile roll forming and corrugating machine reflects {} company's ongoing investment in research and development, as well as its unwavering dedication to delivering value to its customers. By continuously enhancing its product offerings, {} company is poised to drive growth and create new opportunities in the industrial machinery market.As the construction industry continues to evolve and demand for high-quality building materials rises, the glazed tile roll forming and corrugating machine represents a significant advancement for {} company. By leveraging the machine's capabilities, {} company is well-positioned to meet the evolving needs of its customers and maintain its competitive edge in the market.In conclusion, the introduction of the glazed tile roll forming and corrugating machine signifies a new chapter in the evolution of {} company. With its cutting-edge technology, versatility, and commitment to excellence, the machine is set to make a lasting impact in the construction and roofing industry. As {} company continues to push the boundaries of innovation, the future looks promising for the company and its customers.