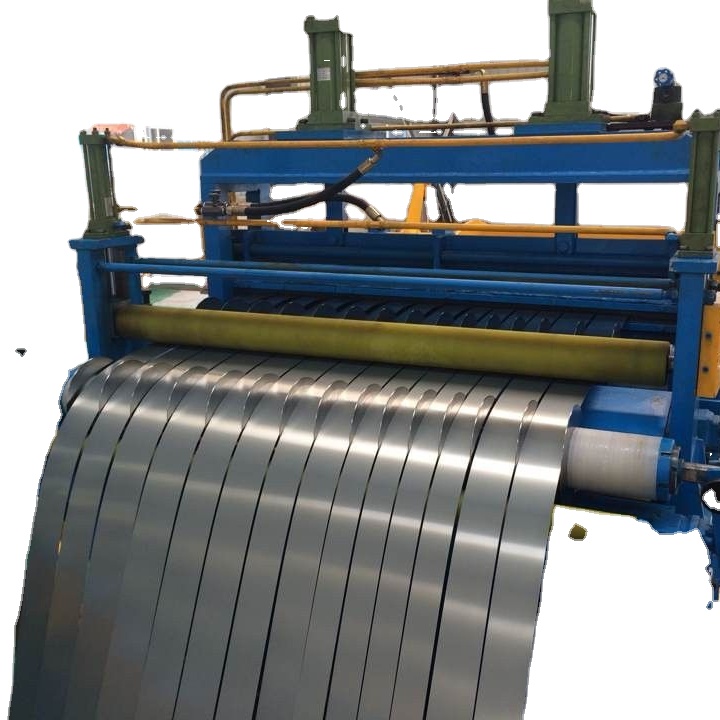

High-Quality Steel Roofing Roll Forming Machines for Efficient Roofing Production

By:Admin

{Company name} is a leading manufacturer of Steel Roofing Roll Forming Machines, specializing in providing high-quality machines that meet the specific requirements of the construction industry. With years of experience and expertise in the field, {Company name} has gained a solid reputation for designing and producing top-notch roll forming machines that ensure efficiency and precision in metal panel production.

The Steel Roofing Roll Forming Machines offered by {Company name} are equipped with advanced technology and ergonomic designs, allowing for easy operation and maintenance. These machines are built to deliver exceptional performance while maintaining high levels of productivity, making them ideal for both small and large-scale production needs.

One of the key features of {Company name}'s Steel Roofing Roll Forming Machines is their versatility in producing a variety of roofing panels. Whether it's standing seam panels, corrugated panels, or any other custom design, these machines can be tailored to meet the specific requirements of each project. This flexibility has made {Company name} a preferred choice for many construction companies looking for reliable roll forming solutions.

In addition to their versatility, the Steel Roofing Roll Forming Machines from {Company name} are known for their durability and long-term performance. The machines are built using high-quality materials and components that are designed to withstand the rigors of continuous use in a demanding construction environment. This ensures that the machines offer a reliable and cost-effective solution for metal panel production, making them a valuable asset for any construction business.

Furthermore, {Company name} takes pride in providing excellent customer support and service to ensure that their clients get the most out of their investment. From installation and training to ongoing technical assistance, the company's team of experts is dedicated to offering comprehensive support to their customers, helping them maximize the efficiency and productivity of their Steel Roofing Roll Forming Machines.

As the construction industry continues to evolve, the demand for high-quality metal roofing panels is expected to rise. With {Company name}'s Steel Roofing Roll Forming Machines, construction companies can stay ahead of the curve by having the capability to produce top-notch roofing panels that meet the highest standards of quality and durability.

In conclusion, {Company name} stands out as a reputable manufacturer of Steel Roofing Roll Forming Machines, offering innovative and reliable solutions for metal panel production. With their commitment to excellence and customer satisfaction, the company has solidified its position as a leading provider of roll forming technology in the construction industry. Whether it's for a new construction project or an upgrade to an existing facility, {Company name}'s Steel Roofing Roll Forming Machines are the ideal choice for efficient and high-quality metal panel production.

Company News & Blog

Aluminium Profile Bending and Window Curving Services: Mumbai's Metfab Machines Delivers Expert Solutions

Title: Unlocking Ultimate Precision: Aluminium Extrusion Bending MachineIntroduction:In the world of manufacturing, precision and efficiency are key factors contributing to a successful production process. When it comes to shaping aluminium profiles and sections for various industries, the importance of a reliable bending machine cannot be overstated. Metfab Machines Mumbai, a leading provider of fabrication machinery, offers an exceptional solution - the Aluminium Extrusion Bending Machine. In this blog, we will explore the incredible capabilities of this machine and how it revolutionizes the bending process in the aluminium industry.Section 1: Understanding Aluminium Extrusion BendingAluminium extrusion bending refers to the process of bending aluminium profiles and sections to achieve specific shapes and curves. This bending technique has gained immense popularity due to its versatility and the advantages it offers in terms of aesthetics and functionality.Section 2: The Powerhouse: The Aluminium Extrusion Bending MachineMetfab Machines Mumbai stands out as a provider of high-quality bending machines, specifically designed to handle aluminium extrusion. Their precision-engineered Aluminium Extrusion Bending Machine offers exceptional capabilities, making it an indispensable tool in the aluminium fabrication industry.The machine boasts state-of-the-art features such as:1. Advanced Bending Technology: Metfab Machines Mumbai incorporates cutting-edge bending technology in their Aluminium Extrusion Bending Machine, ensuring precision, accuracy, and consistency in every bend.2. Versatile Bending Capabilities: This machine is designed to handle a wide range of aluminium profiles and sections, allowing manufacturers to create complex shapes, arcs, and curves with ease.3. Adjustable Bending Speed: The machine offers adjustable bending speed, allowing manufacturers to optimize productivity based on the complexity of the job at hand.4. Easy-to-use Controls: Metfab Machines Mumbai understands the importance of efficiency in manufacturing. Hence, their machine comes equipped with user-friendly controls that streamline the bending process, minimizing errors and maximizing output.Section 3: The Advantages of Aluminium Extrusion BendingThe Aluminium Extrusion Bending Machine offered by Metfab Machines Mumbai provides numerous benefits to manufacturers and fabricators. Let's delve into some of the advantages:1. Enhanced Aesthetics: With the ability to create complex curves and shapes, aluminium extrusion bending adds a touch of elegance to various applications such as architectural designs, furniture, and signage.2. Increased Functionality: By bending aluminium profiles and sections, manufacturers can create components that fit unique specifications, optimizing functionality and performance.3. Cost-Effective Solution: Aluminium extrusion bending eliminates the need for joining multiple pieces, resulting in reduced fabrication costs, improved structural integrity, and minimized maintenance.4. Superior Strength and Durability: The bending process does not compromise the strength and durability of aluminium. Metfab Machines Mumbai's Aluminium Extrusion Bending Machine ensures that the original structural integrity of the material remains intact.Section 4: Revolutionizing Aluminium Fabrication IndustryMetfab Machines Mumbai's Aluminium Extrusion Bending Machine is a game-changer for the aluminium fabrication industry. Its exceptional capabilities, user-friendly interface, and ability to deliver precision and accuracy make it an unrivaled choice for manufacturers.Conclusion:The Aluminium Extrusion Bending Machine from Metfab Machines Mumbai shines as a cutting-edge tool in the aluminium fabrication industry. With its advanced bending technology, versatility, and ability to enhance aesthetics and functionality, this machine ensures that manufacturers can produce superior quality curved and shaped aluminium profiles and sections. By investing in this innovative solution, manufacturers unlock the power of precision and efficiency in their production processes, setting new standards in the aluminium industry.

Universal Milling Machine with Large Table Size 300x1300mm - Metallurgical & Metalworking Machinery - Manufacturing Equipment - Machinery & Parts - Products - Cs-Cx.com

In today's fast-paced manufacturing industry, companies are constantly striving to improve efficiency and productivity. One way they achieve this is by investing in advanced machinery and equipment. Universal vertical and horizontal milling machines are one such example. These machines, with their wide range of capabilities, are essential tools for the metallurgical and metalworking industries.The table of a universal milling machine measures 300x1300mm, offering ample space for a variety of machining operations. This allows for the production of large and complex parts, as well as the ability to work on multiple small parts simultaneously. The size of the table also enables operators to use different types of fixtures and clamps, facilitating precise and secure machining.One of the key features of a universal milling machine is its ability to perform both vertical and horizontal milling operations. This versatility allows manufacturers to tackle various machining tasks, ranging from simple drilling and boring to intricate contouring and threading. By having the option to perform both vertical and horizontal milling, manufacturers can optimize their production processes and eliminate the need for multiple machines, saving time and resources.The bed of a universal milling machine plays a crucial role in ensuring accuracy and stability during machining operations. The bed of this particular model, the TMS6330H from SMAC, is exceptionally wide and features keen box guide ways. These guide ways have been hardened and precision ground, providing superior rigidity and stability. As a result, the machine can withstand heavy cutting forces and vibrations, ensuring precision and repeatability in every operation.To further enhance the durability and wear resistance of the machine, the saddle of the TMS6330H is lined with TF wearable material. This lining ensures smooth movement of the saddle along the guide ways, reducing friction and extending the lifespan of the machine. The combination of the wide bed and the TF wearable material lining makes the TMS6330H a highly reliable and long-lasting milling machine.In addition to its outstanding technical specifications, SMAC is a reputable brand known for its commitment to quality and customer satisfaction. The company specializes in horizontal profiled panel manufacturing equipment, offering innovative solutions for the metalworking industry. With their expertise and experience, SMAC has developed the TMS6330H milling machine to meet the demanding needs of modern manufacturers.By investing in a universal milling machine like the TMS6330H from SMAC, manufacturers can significantly improve their production processes. With its wide bed, high rigidity, and versatile milling capabilities, this machine enables efficient and precise machining of various metal parts. Furthermore, the use of TF wearable material ensures the longevity and reliability of the machine, making it a valuable asset for any metalworking facility.In conclusion, the universal vertical and horizontal milling machine with a table measuring 300x1300mm is an indispensable tool in the metallurgical and metalworking industries. The TMS6330H model from SMAC offers exceptional performance, thanks to its wide bed, hardened guide ways, and TF wearable material lining. By investing in this advanced machinery, manufacturers can optimize their production processes, increase efficiency, and deliver high-quality products to their customers.

Metal Steel IBR Roof Panel Roll Forming Machine for Quality Roof Sheets

Title: Enhancing Roofing Quality with the 820 Model Metal Steel IBR Roof Panel Roll Forming MachineIntroduction:Roofing plays a vital role in providing protection and durability to a building structure. One of the key aspects of effective roofing is the manufacturing process, where quality and precision are essential. In this blog, we will explore the revolutionary 820 Model Metal Steel IBR Roof Panel Roll Forming Machine, also known as the Roof Sheet Making Machine. This machine not only ensures precise and efficient production but also guarantees the high-quality roofing sheets needed for long-lasting performance. Let's dive deeper into the features and advantages of this top-notch roll forming machine.1. Advanced Technology and Manufacturing Process:The 820 Model Metal Steel IBR Roof Panel Roll Forming Machine utilizes state-of-the-art technology and an advanced manufacturing process. Combining strength and capacity, this machine is designed to roll form metal sheets into sturdy and reliable IBR roof panels. The integration of cutting-edge technology ensures exceptional accuracy, consistency, and efficiency throughout the entire production process.2. Uncompromising Quality:Reliability and quality assurance are of paramount importance in the roofing industry. This machine guarantees the production of high-quality roofing sheets by employing superior raw materials and precise roll forming techniques. By maintaining consistent panel dimensions and close tolerances, the 820 Model ensures the utmost durability and structural integrity of every roofing panel produced.3. Efficiency and Versatility:Equipped with cutting-edge automation features, the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine ensures high productivity and efficiency. It offers seamless integration with other production processes, such as cutting, bending, and curving, thereby streamlining the overall manufacturing workflow. This versatility allows for customization according to specific roofing requirements, providing customers with a wide range of choices to suit their needs.4. Cost-effective Solution:Investing in the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is a wise choice for long-term cost savings. The machine's exceptional efficiency and precision reduce material waste and labor costs, ultimately maximizing production output. Additionally, the durability and reliability of the roofing sheets produced by this machine minimize the need for frequent repairs or replacements, saving both time and money.5. Durability against Harsh Weather Conditions:Roofing panels manufactured by the 820 Model are designed to withstand the harshest weather conditions. These panels possess exceptional resistance to UV rays, extreme temperatures, moisture, and corrosion. With proper installation and maintenance, roofs utilizing IBR roof panels can provide long-lasting protection and peace of mind.Conclusion:The 820 Model Metal Steel IBR Roof Panel Roll Forming Machine offers an innovative and efficient approach to roofing sheet production. Its advanced technology, quality assurance, efficiency, versatility, and cost-effectiveness make it an ideal choice for businesses in the roofing industry. With this cutting-edge machine, manufacturers can ensure the production of high-quality IBR roofing panels that withstand the test of time and provide unrivaled protection against varying environmental conditions. Invest in the 820 Model and elevate your roofing business to new heights!

High-Quality Metal Roofing Roller Machine for Sale - Get Yours Today!

Metal Roofing Roller Machine Boosts Production and Quality for {Company}{City, State} - {Company}, a leading manufacturer of metal roofing products, has recently invested in state-of-the-art metal roofing roller machine to enhance its production capabilities. The new machine promises to boost production efficiency and improve the quality of the company's metal roofing products, strengthening its position in the competitive roofing industry.The metal roofing roller machine, which was custom-designed and manufactured by a reputable equipment supplier, is equipped with advanced technology and features that enable precise and efficient rolling of metal sheets. This allows {Company} to produce a wide range of metal roofing products with varying profiles and specifications, catering to the diverse needs of its customers.In addition to increasing production capacity, the new machine also provides greater flexibility in terms of customization. {Company} can now quickly adjust the settings of the roller machine to accommodate specific customer requests, such as custom color coating or unique profile designs. This level of flexibility sets {Company} apart from its competitors, as it can offer tailor-made metal roofing solutions to meet the individual requirements of its clients.The metal roofing roller machine also brings significant improvements in product quality. With precise and uniform rolling capabilities, the machine ensures that the metal sheets maintain their structural integrity and uniformity throughout the production process. This results in metal roofing products that are free from defects, such as warping or uneven thickness, ensuring the durability and longevity of the roofs installed by {Company}.The investment in the metal roofing roller machine reflects {Company}'s commitment to innovation and continuous improvement. By integrating advanced technology into its production processes, {Company} aims to stay ahead of the curve in the rapidly evolving roofing industry. The new machine not only enhances the company's capabilities but also demonstrates its dedication to delivering superior metal roofing products to its customers.Furthermore, the introduction of the metal roofing roller machine has had a positive impact on {Company}'s operations. The increased efficiency and productivity have allowed the company to fulfill orders in a timelier manner, leading to greater customer satisfaction and loyalty. With the ability to produce a wider variety of metal roofing products, {Company} has also expanded its market reach and appeal, attracting new clients and opportunities for growth."We are thrilled to announce the addition of the metal roofing roller machine to our production facility," said {Spokesperson}, CEO of {Company}. "This investment represents a significant milestone for {Company} and underlines our dedication to providing high-quality metal roofing solutions to our customers. The new machine will enable us to meet the growing demand for our products while maintaining the highest standards of excellence."{Company} has a strong track record in the metal roofing industry, with a reputation for delivering superior products and exceptional customer service. The investment in the metal roofing roller machine further solidifies the company's position as an industry leader, setting the bar for quality and innovation in the market.With the new metal roofing roller machine in place, {Company} is poised to elevate its production capabilities and set new standards for metal roofing solutions. As the company continues to leverage advanced technology and expertise, customers can expect top-notch metal roofing products that meet their specific needs and exceed their expectations.As {Company} propels forward with its commitment to excellence, the future looks bright for both the company and its customers. The investment in the metal roofing roller machine is a testament to {Company}'s dedication to staying at the forefront of the industry, and as a result, customers can look forward to even more reliable, durable, and aesthetically appealing metal roofing solutions from {Company}.

High-Quality Steel Sheet Making Machine for Efficient Production

The Steel Sheet Making Machine is a revolutionary piece of equipment that has the ability to transform raw materials into high-quality steel sheets with precision and efficiency. With its advanced technology and innovative design, the machine is set to revolutionize the steel manufacturing industry.The machine, developed by the leading steel manufacturing company, is the result of years of research and development. It incorporates the latest advancements in steel production technology, enabling it to produce steel sheets of superior quality at a faster rate than traditional methods.One of the key features of the Steel Sheet Making Machine is its automation capabilities. The machine is equipped with advanced robotics and control systems that allow it to operate seamlessly and with minimal human intervention. This not only improves production efficiency but also ensures consistent quality in every sheet produced.Furthermore, the machine is designed to be highly customizable, allowing for a wide range of steel sheet specifications to be produced. This versatility makes it an ideal solution for a variety of applications, from construction and automotive manufacturing to consumer goods production.In addition to its technological advancements, the machine also boasts enhanced safety features. With built-in sensors and safety mechanisms, the machine can detect and respond to potential hazards, ensuring a safe working environment for the operators.The company behind the Steel Sheet Making Machine has a long-standing reputation for innovation and excellence in the steel manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in steel production, leading to the development of the highly advanced machine.In addition to its technical expertise, the company also places a strong emphasis on sustainability and environmental responsibility. The Steel Sheet Making Machine is designed to minimize waste and energy consumption, making it a more eco-friendly option compared to traditional steel manufacturing methods.Moreover, the company is committed to providing comprehensive support and maintenance services for the machine, ensuring that it continues to operate at its full potential throughout its lifespan.The introduction of the Steel Sheet Making Machine marks a significant advancement in the steel manufacturing industry. With its cutting-edge technology, high efficiency, and commitment to sustainability, the machine is set to redefine the way steel sheets are produced.As the demand for steel continues to grow across various industries, the Steel Sheet Making Machine offers a solution that is not only capable of meeting this demand but also of doing so in a way that is more efficient, reliable, and sustainable.The company is confident that the machine will have a significant impact on the steel manufacturing industry, providing manufacturers with a competitive edge in the market. With its advanced capabilities and commitment to excellence, the Steel Sheet Making Machine is poised to become a game-changer in the industry, setting new standards for quality and efficiency in steel production.In conclusion, the Steel Sheet Making Machine represents a major step forward in the steel manufacturing industry. With its advanced technology, customizable capabilities, and commitment to sustainability, the machine is poised to revolutionize the way steel sheets are produced, setting new benchmarks for quality, efficiency, and environmental responsibility. The company's dedication to innovation and excellence has culminated in the development of a truly groundbreaking machine that is set to shape the future of steel manufacturing.

Roll Former for Drip Edge Production: A Complete Guide

In the competitive world of construction and roofing, precision and efficiency are paramount. That's why the introduction of the Drip Edge Roll Former by [Company Name] has been creating a significant buzz in the industry. With its advanced technology and innovative design, this roll former is set to revolutionize the way drip edges are produced for roofing projects.Firstly, let's take a closer look at [Company Name]. With over 20 years of experience in the field of roll forming machinery, [Company Name] has established itself as a trusted and reliable provider of high-quality equipment for the construction and roofing industry. The company's commitment to innovation and customer satisfaction has driven it to develop cutting-edge solutions for various challenges faced by contractors and builders.The Drip Edge Roll Former is a prime example of [Company Name]'s dedication to delivering top-of-the-line equipment that meets the evolving needs of the industry. This roll former is designed to streamline the production process of drip edges, which are an essential component of roofing systems as they effectively direct water away from the structure, preventing potential water damage.So, what sets the Drip Edge Roll Former apart from traditional methods of producing drip edges? The answer lies in its state-of-the-art features and capabilities. This roll former is equipped with precision-driven rollers that can efficiently shape metal strips into uniform and high-quality drip edges. By utilizing this advanced machinery, contractors and manufacturers can produce drip edges with consistent dimensions and flawless finishes, ensuring the utmost reliability and durability for roofing projects.Furthermore, the Drip Edge Roll Former boasts an intuitive control system that allows for easy customization of drip edge specifications, such as width, length, and thickness. This level of flexibility enables users to cater to the specific requirements of their projects, whether it's a small-scale residential roofing job or a large commercial construction endeavor. The ability to tailor drip edges to exact specifications is a game-changer for the industry, as it enhances productivity and reduces material waste.In addition to its precision and customization capabilities, the Drip Edge Roll Former is engineered for speed and efficiency. It can produce a high volume of drip edges in a relatively short amount of time, making it ideal for meeting tight project deadlines and demand. The seamless operation of this roll former allows for continuous production without compromising on quality, ultimately optimizing production processes and boosting overall project efficiency.The impact of the Drip Edge Roll Former extends beyond its technical prowess – it also signifies [Company Name]'s commitment to sustainability and cost-effectiveness. By streamlining the production of drip edges, this roll former minimizes material waste and energy consumption, aligning with the industry's push for eco-friendly practices. Moreover, the efficiency and consistency of drip edge production contribute to cost savings for contractors and manufacturers, making it a financially sound investment for businesses of all sizes.As the construction and roofing industry continues to evolve, the introduction of the Drip Edge Roll Former by [Company Name] marks a significant milestone in advancing the production of essential roofing components. Its cutting-edge technology, precision engineering, and cost-effective benefits position it as a valuable asset for those seeking to elevate their operations and deliver superior results.In conclusion, the Drip Edge Roll Former stands as a testament to [Company Name]'s unwavering dedication to innovation and excellence. With its game-changing capabilities, this roll former is set to redefine the standards of drip edge production and set a new benchmark for efficiency and quality in the roofing industry.With the Drip Edge Roll Former, [Company Name] continues to solidify its position as a leader in providing advanced solutions that empower businesses to thrive in the competitive construction and roofing landscape. As the industry embraces the next generation of technology, the Drip Edge Roll Former is poised to make a lasting impact on how drip edges are manufactured and utilized, driving progress and success for those who harness its potential.

High-Quality Steel Rollforming Machines for Sale: Find the Best Deals Now

Steel rollforming machines are revolutionizing the construction industry with their ability to efficiently produce high-quality metal profiles for various applications. The advancements in technology have made it possible to manufacture these machines with precision and reliability, leading to increased productivity and cost savings for companies around the world. One company that has been at the forefront of this innovation is [Company Name], a leading manufacturer of steel rollforming machines.[Company Name] has been in the business of designing and manufacturing rollforming machines for over 20 years. Their commitment to excellence and continuous improvement has made them a trusted partner for companies in the construction industry. With a team of experienced engineers and technicians, [Company Name] has been able to develop advanced rollforming machines that meet the specific needs of their customers.The company's rollforming machines are designed to produce a wide range of metal profiles, including roof panels, wall cladding, and custom profiles. These machines are equipped with state-of-the-art technology that allows for precise forming of metal sheets, resulting in accurate and consistent profiles. The use of advanced control systems ensures that the machines operate with high efficiency and minimal material waste, leading to cost savings for the customers.One of the key features of [Company Name]'s rollforming machines is their flexibility and versatility. The machines can be customized to meet the unique requirements of different projects, allowing for the production of a wide variety of metal profiles. This flexibility is essential for companies that need to adapt to changing market demands and offer a diverse range of products to their customers.In addition to their technical capabilities, [Company Name] prides itself on providing excellent customer service and support. The company works closely with its customers to understand their specific needs and provide tailored solutions that meet their requirements. From the initial consultation to the installation and commissioning of the machines, [Company Name] ensures that its customers receive the support they need to maximize the performance of the rollforming machines.The rollforming machines manufactured by [Company Name] are also known for their durability and reliability. The use of high-quality materials and components, along with rigorous quality control processes, ensures that the machines are built to last. This reliability is essential for companies that rely on the continuous operation of their rollforming machines to meet their production targets.As the construction industry continues to evolve, the demand for efficient and reliable rollforming machines will only grow. Companies that invest in advanced rollforming technology will be well-positioned to capitalize on the opportunities in the market and stay ahead of the competition. With its commitment to innovation and customer satisfaction, [Company Name] is poised to remain a leader in the industry and continue to provide cutting-edge solutions for its customers.In conclusion, steel rollforming machines have become an essential tool for companies in the construction industry, and [Company Name] has established itself as a leading manufacturer of these machines. With a focus on innovation, quality, and customer satisfaction, the company has been able to deliver advanced rollforming solutions that meet the specific needs of its customers. As the industry continues to evolve, [Company Name] is well-positioned to continue its success and be a trusted partner for companies looking to enhance their production capabilities.

Highly Efficient Glazed Sheet Roll Forming Machine Revolutionizes Production Process

Glazed Sheet Roll Forming Machine Revolutionizing the Construction IndustryIn response to the growing demand for efficient and high-quality construction materials, the development of advanced machinery has become crucial. One such groundbreaking innovation is the Glazed Sheet Roll Forming Machine. This state-of-the-art technology has the potential to revolutionize the construction industry, paving the way for faster and more cost-effective building processes.The Glazed Sheet Roll Forming Machine is a versatile piece of equipment that specializes in the production of glazed sheets used in roofing and cladding applications. This machine utilizes a roll forming technique, where a continuous strip of metal is passed through multiple sets of rolls to gradually shape the material into the desired profile. With the ability to produce sheets of various sizes, thicknesses, and profiles, this machine offers unparalleled flexibility for construction firms.The key advantage of the Glazed Sheet Roll Forming Machine is its ability to produce high-quality glazed sheets with precision and consistency. By eliminating manual labor and human error, this automated technology ensures that each sheet meets the desired specifications, resulting in superior product quality. Additionally, the roll forming process reduces material waste, optimizing resources and reducing costs for construction companies.One of the cutting-edge manufacturers of this revolutionary machinery is [Company Name]. Led by a team of experienced engineers and industry experts, [Company Name] has gained recognition for its commitment to innovation and excellence. With a global presence and a customer-centric approach, [Company Name] has successfully supplied its Glazed Sheet Roll Forming Machines to construction businesses worldwide.The Glazed Sheet Roll Forming Machine developed by [Company Name] combines advanced technology with exceptional design. Its robust construction ensures durability, enabling uninterrupted production even in demanding manufacturing environments. Equipped with a user-friendly interface, this machine allows operators to easily adjust settings and monitor the production process, enhancing efficiency and productivity.Moreover, [Company Name]'s Glazed Sheet Roll Forming Machine is equipped with cutting-edge safety features, prioritizing the well-being of its operators. These features include emergency stop buttons, safety interlocks, and protective covers, adhering to strict industry regulations. By investing in worker safety, [Company Name] sets itself apart as a responsible and reliable machinery provider.The benefits of the Glazed Sheet Roll Forming Machine extend beyond its manufacturing capabilities. As an environmentally conscious solution, this machine contributes to sustainable practices within the construction industry. By optimizing material usage and reducing waste, it promotes resource efficiency, aligning with global efforts to combat climate change and reduce carbon emissions.The Glazed Sheet Roll Forming Machine is set to transform the construction industry, streamlining processes and driving innovation. By investing in this efficient technology, construction companies can significantly reduce project timelines and costs, positioning themselves at the forefront of the industry. Moreover, the superior quality of glazed sheets produced by this machine ensures long-lasting and aesthetically pleasing structures, satisfying the demands of clients and end-users alike.In conclusion, the Glazed Sheet Roll Forming Machine represents a major breakthrough in the construction industry. With its automated and precise manufacturing capabilities, this machine has the potential to redefine the way buildings are constructed. Companies like [Company Name] are leading the way by investing in cutting-edge technology and delivering high-quality machinery to businesses around the world. As the demand for efficient and sustainable construction materials continues to grow, the Glazed Sheet Roll Forming Machine remains at the forefront, revolutionizing the industry one sheet at a time.

Europe Washing Machine Installation Manual: Easy-to-Follow User Guide for Efficient Operation and Maintenance

Title: Manual Shape C Purlin Punching Holes Making Machine: A Must-Have for European Standard Construction ProjectsIntroductionIn the ever-evolving world of construction, the need for efficient and precise manufacturing processes is paramount. One such process that has gained considerable popularity in recent years is the use of manual shape C purlin punching holes making machines. Designed to meet European standard requirements, these machines have revolutionized the way purlins are manufactured, ensuring enhanced structural integrity and cost-effectiveness. In this blog post, we will explore the key features and advantages of manual shape C purlin punching holes making machines, focusing on their relevance and impact in the European construction industry.What Are Manual Shape C Purlin Punching Holes Making Machines?Manual shape C purlin punching holes making machines are advanced manufacturing systems specifically designed for producing top-quality C purlins in compliance with European construction standards. These machines utilize cutting-edge technology and are equipped with cutting, punching, and forming tools, enabling the precise fabrication of complex purlin shapes to exact specifications.Key Features and Advantages1. Enhanced Precision: The manual shape C purlin punching holes making machines are engineered to deliver exceptional precision in forming and punching holes, ensuring accurate purlin dimensions and consistent hole alignment. This level of precision guarantees optimum installation compatibility, reducing the risk of structural errors and enabling smoother construction processes.2. Versatility: These machines offer a wide range of customization options, allowing for the production of various C purlin sizes and shapes according to project-specific requirements. Whether it's the flange width, thickness, or hole patterns, the manual shape C purlin punching holes making machine provides immense flexibility, ensuring compatibility with diverse construction designs.3. European Standard Compliance: Manual shape C purlin punching holes making machines are specifically engineered to adhere to European construction standards. These standards are known for their stringent quality requirements, ensuring that structures are built to withstand extreme weather conditions and offer exceptional durability. By using machines designed for European standards, construction projects can benefit from the highest level of quality assurance.4. Cost-Effectiveness: Implementing manual shape C purlin punching holes making machines can significantly reduce labor costs and material wastage. The machines' automated and precise manufacturing processes eliminate the need for time-consuming manual labor, resulting in faster production rates and reduced human error. Additionally, the optimization of material usage helps minimize waste, leading to cost savings for both manufacturers and end-users.ConclusionThe emergence of manual shape C purlin punching holes making machines has brought a new level of efficiency and quality assurance to the European construction industry. From increased precision and versatility to compliance with rigorous European standards, these machines are a game-changer for fabricators and construction companies alike. As the demand for sustainable and cost-effective construction practices rises, investing in manual shape C purlin punching holes making machines becomes an essential step towards success in the ever-evolving European construction landscape.

High-quality Steel Profile Manufacturing Machine for Your Business Needs

Color Steel Profile Manufacturing Machine, a leading manufacturer of steel profile manufacturing machinery, has announced the launch of a new series of cutting-edge machines that are set to revolutionize the industry.With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market."We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.