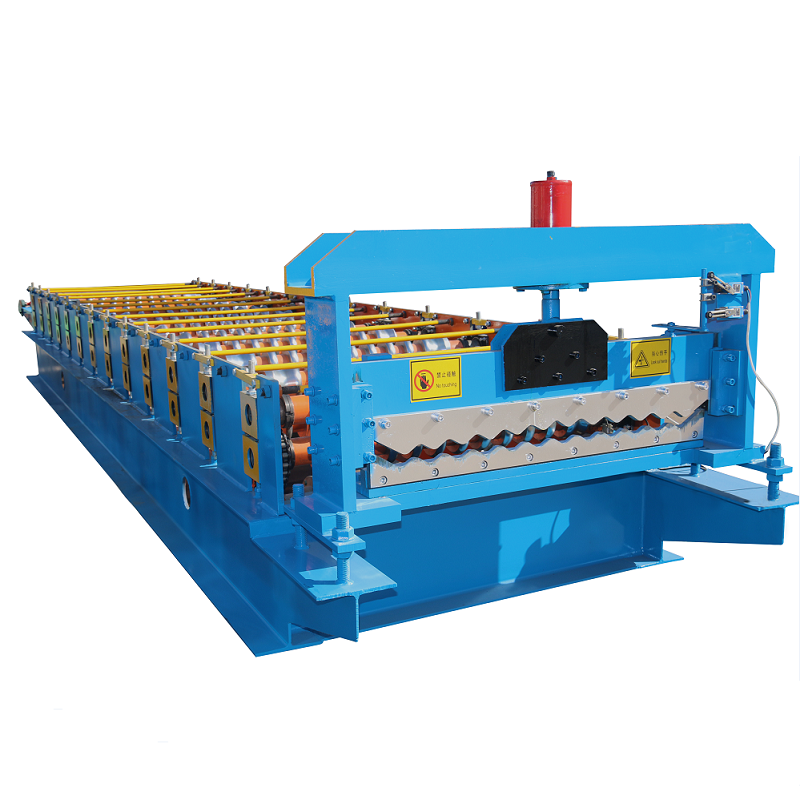

Quality Horizontal Profiled Sheet Forming Equipment for Sale

By:Admin

{} specializes in producing high-quality equipment for the construction and manufacturing sectors, and its Horizontal Profiled Sheet Forming Equipment is no exception. Boasting advanced features and precision engineering, this equipment has been well-received by companies around the world for its ability to streamline the production of profiled sheets while maintaining exceptional quality.

One of the key features of the Horizontal Profiled Sheet Forming Equipment is its versatility. It is capable of forming a wide range of profiled sheets, allowing manufacturers to cater to diverse customer demands without the need for multiple machines. This not only saves on costs but also maximizes efficiency and increases productivity. In addition, the equipment is designed to be user-friendly, with intuitive controls and easy setup, making it a valuable asset for any production facility.

Another noteworthy aspect of {}'s Horizontal Profiled Sheet Forming Equipment is its exceptional precision and consistency. The equipment is engineered to deliver precise and uniform results, ensuring that every profiled sheet meets the highest standards of quality. This level of consistency is essential for construction and manufacturing projects, where even the slightest deviation can lead to inefficiencies and delays.

In addition to its technical prowess, {} is committed to sustainability and environmental responsibility. The Horizontal Profiled Sheet Forming Equipment is designed to minimize waste and energy consumption, aligning with the company's dedication to sustainable manufacturing practices. By prioritizing eco-friendly solutions, {} is setting an example for the industry and contributing to a more sustainable future.

Furthermore, {} offers comprehensive support and maintenance services for its Horizontal Profiled Sheet Forming Equipment, ensuring that customers can rely on their investment for years to come. With a team of skilled technicians and engineers, the company is dedicated to providing prompt assistance and expertise, building long-lasting relationships with its clients.

The success of {}'s Horizontal Profiled Sheet Forming Equipment is a testament to the company's commitment to innovation and excellence. By consistently pushing the boundaries of engineering and manufacturing, {} has established itself as a leader in the industry, earning the trust and admiration of customers worldwide.

To learn more about {} and its Horizontal Profiled Sheet Forming Equipment, visit their website or contact their team for personalized assistance. With a track record of exceptional products and a dedication to customer satisfaction, {} is poised to continue driving progress and setting new benchmarks for the industry.

Company News & Blog

Industrial Street Light Pole Machine/Equipment for Manufacturing Lamp Posts from China Manufacturer

Title: China Manufacturer Introduces Cutting-Edge Industrial Street Light Pole Making EquipmentIntroduction:As the demand for efficient and reliable street lighting continues to grow globally, manufacturers are seeking innovative solutions to meet these needs. In a significant development, a leading Chinese manufacturer has unveiled its state-of-the-art Industrial Street Light Pole Making Equipment, revolutionizing the production process for lamp posts. This machinery promises to enhance the quality, efficiency, and durability of light poles, ensuring safer and brighter streets in cities around the world.Innovative Features and Technologies:The newly introduced Industrial Street Light Pole Making Equipment integrates cutting-edge technologies and offers an array of impressive features. Employing advanced manufacturing techniques, the machine boasts enhanced precision and efficacy, guaranteeing superior quality lamp posts every time.One of the key features of this equipment is its automated operation, significantly reducing the risk of human error and improving overall production efficiency. Through the integration of computer-controlled programmable logic systems, the machine ensures precise bending, shaping, and cutting of the street light poles. Moreover, the production line can be easily customized to accommodate various pole designs, ensuring flexibility for diverse urban lighting requirements.With an emphasis on sustainability, the equipment optimizes energy consumption by incorporating smart energy-saving mechanisms. By utilizing energy-efficient motors and minimizing material wastage, this innovative machine helps conserve resources and reduce the project's environmental impact.Quality Assurance and Certification:Recognizing the critical role played by street light poles in ensuring public safety, the manufacturer has prioritized quality in their machinery. Compliance with international quality standards is ensured through rigorous testing and inspections at various stages of the production process.Furthermore, the manufacturer has obtained industry certifications from trusted authorities, highlighting its commitment to delivering reliable and durable products. These certifications serve as an assurance of the machinery's ability to withstand harsh weather conditions and provide long-lasting performance.Employment Opportunities and Local Economy Boost:The introduction of this top-of-the-line industrial equipment is set to stimulate economic growth by generating employment opportunities. The machinery requires skilled operators and technicians to ensure its smooth operation, creating job prospects within the region.Moreover, this venture contributes to the growth of the local economy. With the increased production of lamp posts, there will be a rise in the demand for raw materials and ancillary services. This, in turn, incentivizes local suppliers and service providers, supporting the overall development and prosperity of the region.Global Implications:The release of this Industrial Street Light Pole Making Equipment by a prominent Chinese manufacturer has implications that extend beyond the domestic market. As street lighting remains a crucial aspect of urban infrastructure worldwide, this efficient and cost-effective machine has the potential to revolutionize the industry on a broader scale.Exporting this advanced machinery to international markets allows cities worldwide to adopt high-quality light poles designed for durability, improved energy efficiency, and enhanced public safety. By investing in this innovative solution, municipalities can elevate the standard of their urban lighting infrastructure, positively impacting the quality of life for their citizens.Conclusion:The introduction of the Industrial Street Light Pole Making Equipment by this renowned Chinese manufacturer signifies a major breakthrough, reinforcing China's position as a global leader in industrial machinery. This cutting-edge technology promises to revolutionize the production of light poles worldwide, ensuring safer and brighter streets for urban populations and stimulating economic growth in the process. With its commitment to quality, sustainability, and innovation, this manufacturer is setting new benchmarks in the street lighting industry.

Quality Steel Tile 750 Glazed Steel Profile Roll Forming Machine with PLC Control for Construction

[News Title]: Steel Tile 750 Glazed Steel Profile Roll Forming Machine PLC Control Revolutionizing Construction Industry[News Introduction]:In a remarkable technological breakthrough, top manufacturers and exporters from China have developed the Steel Tile 750 Glazed Steel Profile Roll Forming Machine. This state-of-the-art machinery, with its advanced PLC control system, is set to revolutionize the construction industry by providing unparalleled precision and efficiency in the production of glazed steel tiles. With great anticipation, the machine is set to lead the way in the global market, catering to the ever-growing demands for high-quality construction materials.[Paragraph 1]:The Steel Tile 750 Glazed Steel Profile Roll Forming Machine is a game-changer in the construction sector. Its advanced features and robust design enable it to produce high-quality glazed steel tiles consistently. Utilizing the latest PLC control system, this machine allows for precise and efficient control of the entire manufacturing process, ensuring flawless end products every time. [Paragraph 2]:This cutting-edge roll forming machine is designed to produce glazed steel profiles with a thickness ranging from 0.4mm to 0.8mm and a width of up to 750mm. With its adjustable roller system, operators can effortlessly customize the profile dimensions as per project requirements, making it a versatile tool for construction companies. Moreover, its high-speed production capability of up to 12 meters per minute, coupled with its automatic shearing and cutting functions, ensures maximum productivity and cost-effectiveness.[Paragraph 3]:One of the standout features of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is its user-friendly interface. Equipped with a centralized PLC control system, operators can effortlessly monitor and control the machine's operations, making it ideal for both experienced manufacturing professionals and newcomers alike. The intuitive touch screen display provides real-time data and allows for easy adjustments, reducing the scope for errors and downtime.[Paragraph 4]:In addition to its impressive performance capabilities, this roll forming machine also guarantees exceptional durability and stability in operation. Its robust steel frame and high-quality components ensure longevity, minimizing maintenance requirements and maximizing return on investment. With its energy-efficient design, the machine is also environmentally friendly, aligning with the growing global focus on sustainable construction practices.[Paragraph 5]:With Chinese manufacturers leading the way in technological advancements, the Steel Tile 750 Glazed Steel Profile Roll Forming Machine is poised to take the construction industry by storm. By combining precision engineering with cutting-edge controls, this machinery promises to enhance the capabilities of construction companies worldwide. Additionally, its versatility allows for the production of a wide range of glazed steel profiles, enriching architectural possibilities and providing aesthetically pleasing solutions.[Conclusion]:In conclusion, the launch of the Steel Tile 750 Glazed Steel Profile Roll Forming Machine marks a significant milestone in the construction industry. With its advanced PLC control, exceptional productivity, and versatility, this machine sets a new benchmark for the manufacturing of glazed steel tiles. As demand for high-quality construction materials continues to surge, this game-changing technology will undoubtedly shape the future of the industry, enabling companies to deliver superior quality projects efficiently and cost-effectively.

High-Quality Automatic Cut-To-Length Machine for Precision Cutting

Automatic Cut-To-Length Machine Revolutionizing Production ProcessThe manufacturing industry is continuously evolving with the advancement of technology, and one company at the forefront of this evolution is {}. With a commitment to innovation and efficiency, they have recently introduced their latest addition to their production line – the Automatic Cut-To-Length Machine. This state-of-the-art machine is set to revolutionize the production process, offering precision, speed, and enhanced productivity.The Automatic Cut-To-Length Machine is designed to streamline the process of cutting materials to specific lengths, catering to the diverse needs of various industries such as automotive, construction, and appliances. This machine is equipped with advanced features that enable it to effortlessly cut different materials including metals, plastics, and composites with utmost accuracy and consistency.One of the key highlights of the Automatic Cut-To-Length Machine is its cutting-edge technology that allows for automated operation. This not only reduces the need for manual labor but also minimizes the margin of error, resulting in higher quality output. Additionally, with its rapid cutting speed, the machine significantly increases production efficiency, ultimately leading to cost savings for the company.Furthermore, the Automatic Cut-To-Length Machine is integrated with intelligent software that enables precise customization and optimization of cutting processes. This ensures that the machine can meet the specific requirements of each customer, catering to a wide range of dimensions and tolerances. With such versatility, the machine offers a competitive edge in the market, allowing {} to provide tailored solutions to meet the unique demands of their clients.In addition to its technical capabilities, the Automatic Cut-To-Length Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and ensuring seamless integration into the production line. This not only enhances the overall efficiency of the manufacturing process but also creates a safer working environment for the operators.{} has a long-standing reputation for delivering high-quality, reliable machinery, and the introduction of the Automatic Cut-To-Length Machine is a testament to their commitment to continuous improvement and innovation. With a strong focus on research and development, the company has invested heavily in advancing their technological capabilities, ensuring that they remain at the forefront of the industry.The launch of the Automatic Cut-To-Length Machine underscores {}'s dedication to meeting the evolving needs of their customers. By incorporating cutting-edge technology and automation into their production line, they are not only enhancing their own operational efficiency but also empowering their clients to achieve greater success in their respective industries.Moreover, the introduction of the Automatic Cut-To-Length Machine aligns with {}'s long-term sustainability goals. By optimizing the cutting process and reducing material waste, the machine contributes to a more environmentally friendly manufacturing approach. This reflects {}'s commitment to conducting business in a responsible and ethical manner, prioritizing sustainability and resource efficiency.With the introduction of the Automatic Cut-To-Length Machine, {} is poised to set new standards within the manufacturing industry. By leveraging cutting-edge technology and innovation, they are not just meeting the current demands of the market but also shaping the future of production processes. As the industry continues to evolve, {} remains dedicated to pushing boundaries and redefining what is possible in manufacturing.

How Drip Edge Roll Forming Machines are Advancing Construction Technology

Drip Edge Roll Forming Machine: Innovating the Construction IndustryThe construction industry has seen a significant transformation over the years, and the introduction of advanced machinery has revolutionized the way buildings are constructed. One such innovative piece of equipment is the Drip Edge Roll Forming Machine, which has been making waves in the construction sector. This state-of-the-art machinery is designed to streamline the process of manufacturing drip edge profiles, offering a range of benefits including efficiency, precision, and cost-effectiveness.The Drip Edge Roll Forming Machine is the brainchild of a leading manufacturing company that specializes in producing a wide range of roll forming machinery for various industries. With years of expertise and a strong focus on research and development, the company has established itself as a pioneer in the field of roll forming technology. Their commitment to delivering high-quality, innovative solutions has earned them a stellar reputation among their clients and peers.The Drip Edge Roll Forming Machine is a testament to the company's dedication to continuous improvement and innovation. It is designed to meet the growing demand for high-quality drip edge profiles in the construction industry. The machine features a cutting-edge design that allows for the efficient and precise forming of drip edge profiles, ensuring consistent quality and seamless integration into building structures.One of the key highlights of the Drip Edge Roll Forming Machine is its advanced automation capabilities. The machine is equipped with a user-friendly interface and programmable controls, allowing for easy operation and customization of drip edge profiles. This level of automation not only enhances operational efficiency but also minimizes the risk of errors, resulting in higher productivity and cost savings for construction companies.In addition to its automation features, the Drip Edge Roll Forming Machine is also known for its versatility. It is capable of producing a wide range of drip edge profiles, accommodating various design requirements and specifications. This flexibility makes it an ideal solution for construction projects of all scales, from residential buildings to commercial complexes.Furthermore, the Drip Edge Roll Forming Machine is designed with durability and longevity in mind. It is built using high-quality materials and components, ensuring robustness and reliability even under heavy usage. This durability, combined with the company's excellent after-sales support, provides clients with peace of mind and a solid return on investment.The introduction of the Drip Edge Roll Forming Machine has had a significant impact on the construction industry. It has empowered construction companies to elevate the quality of their buildings while reducing production costs and lead times. By integrating this advanced machinery into their operations, construction firms can stay ahead of the competition and meet the evolving demands of the market.In conclusion, the Drip Edge Roll Forming Machine represents a significant advancement in the construction industry. Its innovative design, advanced automation capabilities, versatility, and durability have set a new standard for manufacturing drip edge profiles. With a strong focus on delivering value and excellence, the company behind this remarkable machinery continues to drive progress in the field of roll forming technology. As the construction sector continues to evolve, the Drip Edge Roll Forming Machine stands as a beacon of innovation, propelling the industry towards a more efficient and sustainable future.

High-Quality C/Z Purlin Roll Forming Machine for Sale - Complete Guide

C/Z Purlin Roll Forming Machine: Revolutionizing the Construction IndustryIn recent years, there has been a significant shift in the construction industry towards more efficient and cost-effective building materials and methods. One of the key innovations that has emerged to meet this demand is the C/Z Purlin Roll Forming Machine. This machine is revolutionizing the way that steel purlins are manufactured, offering a faster, more accurate, and more cost-effective method for producing these essential building components.The C/Z Purlin Roll Forming Machine, manufactured by {company name}, is designed to produce high-quality steel purlins with incredible speed and efficiency. The machine is capable of forming both C and Z shaped purlins, which are essential components in the construction of steel-framed buildings. These purlins are used to provide structural support and stability to the building, making them a critical component in the construction process.The traditional method of manufacturing steel purlins involved cutting and punching individual pieces of steel, which was a time-consuming and labor-intensive process. However, the C/Z Purlin Roll Forming Machine has completely transformed this process. The machine uses a continuous rolling process to form the steel into the desired shape, eliminating the need for cutting and punching individual pieces. This not only speeds up the manufacturing process but also results in a more accurate and consistent product.Additionally, the C/Z Purlin Roll Forming Machine is highly versatile, capable of producing purlins in a wide range of sizes and thicknesses. This makes it suitable for a variety of construction projects, from small-scale residential buildings to large industrial structures. The machine can also be easily adjusted to accommodate changes in production requirements, making it a highly adaptable and efficient tool for any construction project.One of the key advantages of the C/Z Purlin Roll Forming Machine is its cost-effectiveness. By streamlining the manufacturing process and reducing the amount of labor required, the machine significantly lowers the production costs associated with steel purlins. This not only benefits the manufacturers but also makes steel-framed construction more affordable for builders and developers. As a result, the machine is helping to make steel-framed construction more accessible and attractive to a wider range of customers.{Company name} has gained a strong reputation as a leading manufacturer of roll forming machines, with a commitment to innovation and quality. The company's C/Z Purlin Roll Forming Machine is a testament to their dedication to developing cutting-edge technology that meets the evolving needs of the construction industry. With a focus on precision engineering and high-quality components, {company name} has positioned itself as a trusted partner for construction companies looking to improve their manufacturing processes.The C/Z Purlin Roll Forming Machine is not only revolutionizing the way steel purlins are manufactured but is also contributing to the overall advancement of the construction industry. By offering a more efficient, cost-effective, and versatile method for producing these essential building components, the machine is helping to drive innovation and progress in the field of construction.In conclusion, the C/Z Purlin Roll Forming Machine is a game-changer for the construction industry. Its speed, efficiency, versatility, and cost-effectiveness are revolutionizing the way steel purlins are manufactured, making steel-framed construction more accessible and attractive to a wider range of customers. As a leading manufacturer of roll forming machines, {company name} is at the forefront of this transformation, with a commitment to delivering cutting-edge technology that meets the evolving needs of the construction industry. With the C/Z Purlin Roll Forming Machine, {company name} is not just shaping steel, it's shaping the future of construction.

High-Quality Metal Roof Panel Machine for Sale - Find Out More!

Metal Roof Panel Machine Revolutionizes Manufacturing ProcessMetal roofing has become an increasingly popular option for commercial and industrial buildings, thanks to its durability, energy efficiency, and low maintenance requirements. However, up until now, the manufacturing process for metal roof panels has been a time-consuming and labor-intensive task.Enter the Metal Roof Panel Machine, a revolutionary piece of equipment that is set to transform the industry. Developed by a leading machinery manufacturer, this state-of-the-art machine streamlines the production of metal roof panels, making the process faster, more efficient, and cost-effective.With the Metal Roof Panel Machine, companies can now produce high-quality metal roof panels in a fraction of the time it takes using traditional methods. This not only increases productivity and reduces labor costs but also allows for quicker turnaround times, enabling manufacturers to meet the growing demand for metal roofing products.The machine is equipped with advanced technology that allows for precise shaping and cutting of metal sheets, ensuring consistent quality and accuracy in every panel produced. Its automated features and user-friendly interface make it easy to operate, requiring minimal training for operators.In addition, the Metal Roof Panel Machine is designed to be versatile, capable of producing a wide range of metal roof panel profiles to meet the unique needs of different projects. Whether it's a standing seam, corrugated, or ribbed panel, this machine can handle it all, giving manufacturers the flexibility to cater to diverse customer requirements.The company behind this groundbreaking innovation, {}, has been a leader in the manufacturing and distribution of machinery for the metal construction industry for over 30 years. With a strong focus on research and development, they have consistently introduced cutting-edge solutions that have transformed the way metal buildings are constructed.{}’s commitment to innovation and excellence is reflected in the Metal Roof Panel Machine, which sets a new standard for metal roof panel production. By integrating the latest technologies and engineering expertise, they have created a game-changing solution that is poised to revolutionize the manufacturing process for metal roofing.As the demand for metal roofing continues to rise, the Metal Roof Panel Machine comes at a crucial time for the industry. With its ability to significantly increase production capacity and improve efficiency, it will enable manufacturers to keep up with the growing market demand and stay competitive in the industry.Furthermore, the machine's energy-efficient design and reduced material waste contribute to sustainability, aligning with the industry's push for eco-friendly and sustainable building solutions. By minimizing the environmental impact of metal roof panel production, it also positions manufacturers as responsible stewards of the environment.In conclusion, the Metal Roof Panel Machine is a game-changer for the metal construction industry. With its ability to streamline production, increase efficiency, and improve quality, it represents a significant leap forward in the manufacturing of metal roof panels. As the industry continues to evolve, this innovative solution from {} is set to play a pivotal role in shaping the future of metal roofing.

Efficient Roof Roll Forming Machine Boosts Productivity and Quality

Title: Revolutionary Roof Roll Forming Machine Revolutionizes the Roofing IndustryIntroduction:In a bid to revolutionize the roofing industry, a leading machinery manufacturing company has introduced an innovative Roof Roll Forming Machine. This state-of-the-art machine is set to transform the way roofs are manufactured, increasing efficiency, reducing costs, and enhancing the overall quality of roofing materials.The Roof Roll Forming Machine, manufactured by a renowned machinery company, incorporates cutting-edge technology, advanced production techniques, and a commitment to sustainability. Its introduction marks a significant milestone in the roofing industry, meeting the demands of increased production while ensuring quality and durability.Efficiency and Speed:The Roof Roll Forming Machine establishes new benchmarks for efficiency and speed in the production of roofing materials. By automating the manufacturing process, it eliminates manual labor, reducing production time and increasing output. The machine's sophisticated design includes precise roll forming tools that shape flat metal coils into desired roof profiles, ensuring uniformity and accuracy in every single piece of roofing material produced.Additionally, the machine's automated control system guarantees consistent quality throughout the production process. This not only ensures reliability but also reduces material waste, making the Roof Roll Forming Machine highly cost-effective and environmentally sustainable.Versatility and Customization:Recognizing the growing demand for diverse roof designs, the Roof Roll Forming Machine offers exceptional versatility, enabling the production of a wide range of roof profiles. From traditional shingles to modern standing seam and corrugated roofs, this machine can adapt to meet any architectural requirement. This versatility ensures that architects, contractors, and homeowners have access to custom roof designs that suit their preferences and project specifications.Superior Material Quality:The Roof Roll Forming Machine incorporates advanced technology that guarantees the highest level of quality in every roof produced. The machine utilizes premium-grade metal coils, ensuring exceptional durability and longevity of the roofing materials. The precise roll forming process ensures that each piece of roofing material is free from defects, providing superior resistance against weather elements and guaranteeing a long-lasting roof.Furthermore, the Roof Roll Forming Machine allows for the integration of additional features such as insulation, coatings, and ventilation systems, ensuring enhanced thermal insulation, weatherproofing, and energy efficiency. These features contribute to creating sustainable and comfortable living spaces while reducing energy consumption and utility bills.Transformation of the Roofing Industry:The introduction of the Roof Roll Forming Machine is expected to have a transformative impact on the entire roofing industry. With its ability to streamline the production process, reduce costs, and enhance product quality, this innovative machine empowers manufacturers to meet the ever-increasing demand for efficient and sustainable roofing solutions.Moreover, the machine's versatility and customization options allow for the creation of unique and aesthetically pleasing roof designs, further fueling architectural innovation and creativity. Contractors and homeowners can now choose from an extensive range of roofing options, ensuring their projects align with their individual preferences and overall design concepts.Conclusion:The Roof Roll Forming Machine has emerged as a game-changer in the roofing industry, optimizing the production process, improving material quality, and allowing for unparalleled customization. Consequently, this innovative machine not only meets the evolving needs of the industry but also contributes to sustainable construction practices.As this Roof Roll Forming Machine continues to gain traction, it is expected to revolutionize the way roofing materials are produced, providing architects, contractors, and homeowners with efficient, durable, and aesthetically pleasing roofing solutions for years to come.

Boost Your Steel Coil Cutting Efficiency with a Cutting-Edge Slitting Line

Steel Coil Slitting Line Boosts Production Efficiency in Metal IndustryIn the ever-evolving metal industry, optimizing production processes has become essential for businesses to stay competitive. With the need for precise cuts and efficient operations, manufacturers are constantly seeking innovative solutions to streamline their processes and improve overall productivity. One such solution is the introduction of the Steel Coil Slitting Line, a cutting-edge machinery that has revolutionized the metal slitting process.Developed by a leading industry player, the Steel Coil Slitting Line has garnered attention for its advanced features and superior performance. This state-of-the-art equipment is designed to precisely cut and slit large steel coils into narrower strips, catering to the diverse needs of various industries such as automotive, construction, and manufacturing. By adapting this technology, companies can significantly enhance their operational efficiency and achieve higher output levels.The Steel Coil Slitting Line is fitted with cutting-edge automation systems and employs cutting-edge technology. It incorporates advanced sensors and control mechanisms to ensure precise and accurate cutting measurements, eliminating human error and guaranteeing consistent strip sizes. The automated feeding and rewinding systems further contribute to uninterrupted production, resulting in improved overall productivity.The technology's efficiency is complemented by its versatility, allowing businesses to handle a wide range of materials and thicknesses. From hot-rolled coils to stainless steel sheets, the Steel Coil Slitting Line caters to diverse metal requirements seamlessly. This versatility translates into greater flexibility for manufacturers, enabling them to meet the demands of their customers more effectively.Moreover, the Steel Coil Slitting Line's rapid setup and changeover times enable businesses to switch between different coil sizes and specifications quickly. This feature proves invaluable in today's fast-paced market, where quick turnaround times and adaptability often determine a company's success. With reduced downtime for adjustments, businesses can maximize their production capabilities and enjoy a competitive edge.By incorporating the Steel Coil Slitting Line into their operations, companies can also expect significant cost savings. The machinery's cutting-edge technology reduces material wastage, as it utilizes precise cutting measurements, minimizing the leftover scraps. Additionally, the improved production efficiency translates into higher output levels, allowing businesses to meet the market demands without having to invest in additional machinery or workforce.The Steel Coil Slitting Line's installation not only brings advantages to individual companies but also positively impacts the industry as a whole. With increased production efficiency, the lead times for delivering metal products are reduced. This, in turn, contributes to smoother supply chain management, benefiting customers who rely on timely deliveries for their projects.Furthermore, the utilization of advanced technology, such as the Steel Coil Slitting Line, showcases the industry's commitment to sustainability. By significantly reducing material wastage and increasing production capabilities, businesses can minimize their environmental footprint, promoting a greener approach to manufacturing.In conclusion, the introduction of the Steel Coil Slitting Line has undoubtedly raised the bar for production efficiency in the metal industry. With its advanced features, including precise cutting measurements, versatility, rapid changeover times, and cost-saving benefits, the technology proves to be invaluable for businesses seeking to optimize their operations and stay ahead in a highly competitive market. By embracing this cutting-edge machinery, manufacturers can elevate their productivity, reduce waste, and contribute to a more sustainable industrial landscape.

High-Quality Metal Roof Making Machine: Here's What You Need to Know

Metal Roof Making Machines have revolutionized the process of fabricating high-quality metal roofing products. These state-of-the-art machines have significantly improved the efficiency and precision of metal roof manufacturing, making them an essential tool for companies in the roofing industry.One company that has been at the forefront of this innovation is {}. With over 20 years of experience in the metal roofing business, they have established themselves as a leading manufacturer of metal roof making machines. Their dedication to quality and innovation has made them a trusted supplier for roofing companies worldwide.The Metal Roof Making Machine developed by {} is designed to streamline the production process, allowing manufacturers to produce metal roofing products with unmatched speed and accuracy. This advanced machinery is equipped with cutting-edge technology that enables precise bending, cutting, and shaping of metal sheets, resulting in roofing products of exceptional quality.The machine is also designed for versatility, capable of producing a wide range of metal roofing products, including standing seam panels, corrugated panels, and more. This flexibility makes it an ideal solution for roofing companies with diverse product offerings, allowing them to meet the specific needs of their customers with ease.In addition to its impressive capabilities, the Metal Roof Making Machine from {} is also known for its user-friendly design. It is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up the machine and monitor the production process. This ease of use not only improves efficiency but also reduces the need for extensive training, allowing manufacturers to get up and running quickly.Furthermore, {} offers comprehensive support and service for their Metal Roof Making Machines, ensuring that their customers can maximize the performance and lifespan of their equipment. From installation and training to ongoing maintenance and technical support, they are committed to delivering a seamless experience for their clients.The impact of {}'s Metal Roof Making Machines on the metal roofing industry has been profound. Many roofing companies have reported significant improvements in their production processes, with the machines enabling them to increase their output while maintaining the highest standards of quality. This has not only resulted in improved efficiency and profitability for these companies but has also raised the bar for the entire industry.Looking ahead, {} remains dedicated to pushing the boundaries of metal roof manufacturing technology. They continue to invest in research and development, seeking out new innovations that will further enhance the performance and capabilities of their Metal Roof Making Machines. With a relentless commitment to excellence, they are poised to lead the industry into a new era of metal roof manufacturing.In conclusion, the Metal Roof Making Machine from {} has set a new standard for metal roof manufacturing. Its precision, versatility, and user-friendly design have made it an indispensable tool for roofing companies around the world. As the industry continues to evolve, {} is well-positioned to remain at the forefront of innovation, driving the advancement of metal roof manufacturing technology for years to come.

Innovative Purlin Machine Revolutionizes Metal Fabrication Processes

The latest technological advancement from the renowned steel processing machinery company, known for its innovative solutions and top-quality equipment, has sparked interest and excitement in the industry. The unveiling of the Stacker for the CZ Purline Machine has created a buzz among manufacturers and steel processing experts worldwide.The CZ Purline Machine, developed by the company, has been widely praised for its efficiency, precision, and reliability in producing high-quality CZ purlins for a variety of construction and industrial applications. With the addition of the Stacker, the entire process of CZ purlin manufacturing is set to become even more streamlined and productive.The Stacker for the CZ Purline Machine is designed to automate the stacking of finished CZ purlins, eliminating the need for manual handling and significantly reducing production time. This innovative addition is equipped with advanced technology that allows for seamless integration with the CZ Purline Machine, ensuring smooth and uninterrupted operation.The company's commitment to pushing the boundaries of steel processing technology is evident in the development of the Stacker. By addressing the need for increased automation and efficiency in the production process, the company continues to set new standards in the industry and solidify its position as a leading force in steel manufacturing machinery.With a proven track record of delivering high-performance equipment and cutting-edge solutions, the company has gained the trust and confidence of manufacturers and steel processors around the globe. The introduction of the Stacker for the CZ Purline Machine further cements the company's reputation for excellence and innovation.In addition to its dedication to providing top-quality machinery, the company is also known for its exceptional customer service and support. The team of experts at the company is committed to assisting clients in optimizing their production processes and achieving maximum efficiency and productivity.The company's state-of-the-art manufacturing facilities and research and development capabilities have enabled it to consistently deliver groundbreaking solutions that meet the evolving needs of the steel processing industry. The Stacker for the CZ Purline Machine is a testament to the company's unwavering commitment to innovation and technological advancement.As the demand for high-quality steel products continues to grow, the company remains at the forefront of the industry, providing manufacturers with the tools they need to stay ahead in a competitive market. The Stacker for the CZ Purline Machine is poised to revolutionize the production of CZ purlins, offering manufacturers a powerful tool to enhance their operations and meet the increasing demands of their customers.In conclusion, the unveiling of the Stacker for the CZ Purline Machine represents a significant milestone for the company and the steel processing industry as a whole. With its cutting-edge technology, seamless integration, and potential for increased efficiency, the Stacker is set to transform the way CZ purlins are manufactured. As the company continues to lead the way in steel processing machinery, manufacturers can look forward to more groundbreaking innovations that will shape the future of the industry.