Roof Tiles and IBR Sheeting Making Machinery: A Comprehensive Guide

By:Admin

Founded in {year}, {Company Name} quickly established itself as a pioneer in the field of roofing technology. The company's commitment to research and development has led to the creation of cutting-edge machines that have revolutionized the way roof tiles and IBR sheeting are produced. Their state-of-the-art facilities and team of highly skilled engineers have enabled them to stay ahead of the competition and continuously improve their products.

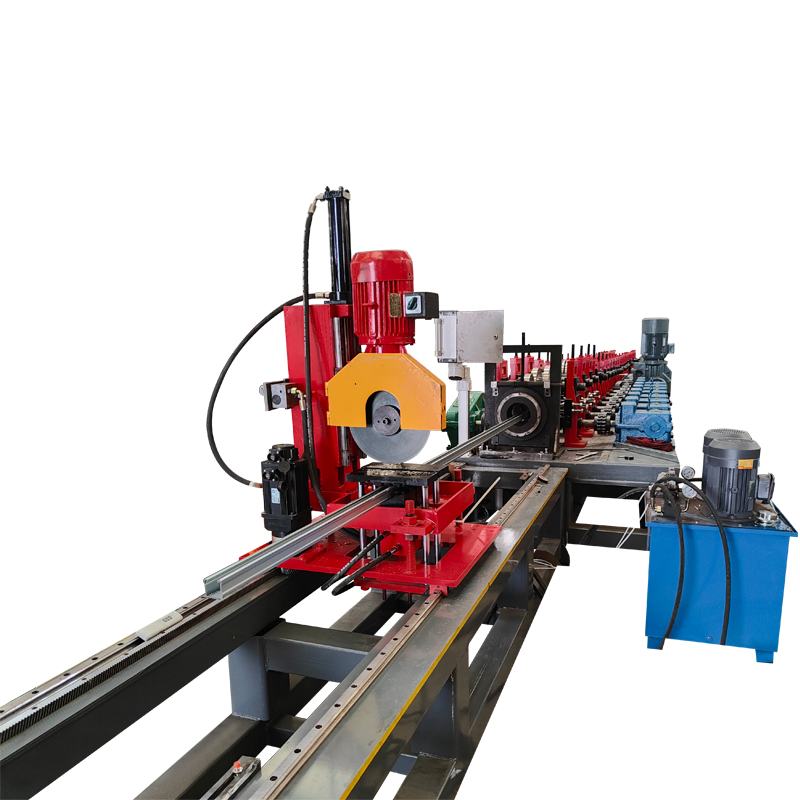

One of {Company Name}'s latest innovations is the Roof Tiles and IBR Sheeting Making Mach, a machine that has been designed to streamline the production process and enhance the overall quality of roof tiles and IBR sheeting. This machine is equipped with advanced features that allow for increased precision and efficiency, ultimately leading to higher output and reduced waste. Whether it's clay roof tiles or metal IBR sheeting, this machine is versatile enough to handle a wide range of materials and designs, making it an essential asset for any roofing manufacturer.

The Roof Tiles and IBR Sheeting Making Mach comes with a user-friendly interface that makes operation easy and straightforward. It is also equipped with safety features to ensure the well-being of the operators. Moreover, it is designed to be energy-efficient and environmentally friendly, aligning with {Company Name}'s commitment to sustainability. By minimizing the use of resources and optimizing the production process, this machine not only benefits the manufacturer but also contributes to a greener and more sustainable future.

In addition to their cutting-edge machines, {Company Name} also provides comprehensive support and services to their clients. From installation and training to maintenance and technical assistance, they are dedicated to ensuring that their customers are equipped to maximize the potential of their machines. This customer-centric approach has earned them a stellar reputation in the industry, with clients trusting {Company Name} to deliver reliable and efficient solutions for their roofing needs.

The Roof Tiles and IBR Sheeting Making Mach is just one example of {Company Name}'s relentless pursuit of excellence. With a strong focus on innovation and a deep understanding of the roofing industry, they continue to push the boundaries of what is possible, setting new standards and raising the bar for the competition. As the demand for high-quality roofing materials continues to grow, {Company Name} remains committed to providing the technology and expertise needed to meet and exceed these expectations.

As the global construction and roofing industry continues to evolve, {Company Name} is poised to remain a driving force behind this progress. Through their unwavering dedication to quality, efficiency, and sustainability, they are shaping the future of roofing technology, and the Roof Tiles and IBR Sheeting Making Mach is just the latest example of their commitment to innovation. With a track record of success and a vision for the future, {Company Name} is undoubtedly a name to watch in the world of roofing technology.

Company News & Blog

Efficient Purlin Forming Machine for Strong and Durable Structures

Title: Advanced Purlin Forming Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced construction industry, efficiency and precision are key factors that drive successful projects. Providing solutions to these demands, a cutting-edge Purlin Forming Machine has emerged, enabling construction companies to streamline their processes and deliver outstanding results. This innovative machinery is set to revolutionize the way purlins are produced, enhancing construction efficiency, cost-effectiveness, and overall project quality.Streamlined Purlin Manufacturing Process:The Purlin Forming Machine, developed and manufactured by a leading engineering firm, has been designed with utmost precision and state-of-the-art technology. This machine enables steel purlins to be produced rapidly and accurately, eliminating traditional manual methods that are time-consuming and error-prone.By automating the purlin manufacturing process, the machine ensures consistent quality and eliminates human error, resulting in a more precise and reliable end product. It utilizes sophisticated computer-controlled mechanisms and advanced software to ensure seamless operation, allowing construction companies to meet tight project deadlines with ease.Efficiency and Cost-effectiveness:The innovative Purlin Forming Machine optimizes the use of materials and reduces wastage significantly. Its intelligent design and engineering contribute to a drastic reduction in material costs, resulting in more affordable projects. The machine's automated nature not only increases productivity but also reduces labor costs, enhancing overall project profitability.Moreover, the machine's ability to produce purlins of various sizes and designs offers construction companies unparalleled versatility. It eliminates the need to source purlins from different suppliers, saving time and money, while maintaining consistent quality throughout the project duration.Enhanced Construction Quality:Traditionally, manual purlin production processes are prone to human error and inconsistency, leading to compromised structural integrity. The Purlin Forming Machine tackles this issue by producing purlins with exceptional accuracy, ensuring that they fit seamlessly in the construction framework.The machine's advanced technology and precise measurements guarantee that each purlin manufactured is uniform in size, shape, and strength. Consequently, the overall structural integrity of buildings is vastly improved, minimizing the risk of complications or failures during construction and enhancing the longevity of the completed structures.Environmental Friendly Manufacturing:In addition to its exceptional performance, the Purlin Forming Machine adheres to environmentally friendly manufacturing practices. By optimizing material usage and minimizing waste generation, it contributes to a sustainable construction environment. The machine's energy-efficient operations also reduce energy consumption, making it an eco-conscious choice for construction companies.Future Prospects and Competitiveness:The Purlin Forming Machine presents a significant opportunity for construction companies to enhance their competitiveness. By leveraging this advanced technology, companies can not only expedite their project timelines but also offer superior quality deliverables. This cutting-edge machinery equips construction firms to take on larger projects with improved efficiency and precision, ultimately strengthening their position in the industry.Conclusion:The advanced Purlin Forming Machine has emerged as a game-changer in the construction industry, offering numerous benefits to construction companies. Its ability to automate and streamline the purlin manufacturing process leads to improved efficiency, cost-effectiveness, and construction quality. Alongside its positive environmental impact and contribution to sustainable construction practices, this innovative machinery is poised to revolutionize the industry and shape the future of construction.

Roof Tiles and IBR Sheeting Making Machine: Everything You Need to Know

Roof Tiles And IBR Sheeting Making Machine: Revolutionizing the Roofing IndustryIn today's rapidly evolving construction industry, innovation is the key to staying ahead of the competition. One company that is leading the way in roofing technology is {Company Name}. With a strong commitment to quality and innovation, {Company Name} has introduced a state-of-the-art Roof Tiles And IBR Sheeting Making Machine to revolutionize the roofing industry.This machine is a game changer for the roofing industry as it is capable of producing high-quality roof tiles and IBR sheeting at an incredible speed. The advanced technology and precision engineering of this machine ensure that the finished products are of the highest quality, meeting and exceeding industry standards.The Roof Tiles And IBR Sheeting Making Machine is designed to be versatile and adaptable to various roofing requirements. It can produce a wide range of roof tiles and IBR sheeting in different sizes, shapes, and colors, making it suitable for a diverse range of construction projects. This flexibility is a significant advantage for contractors and builders who are looking for customized roofing solutions.The machine is also equipped with advanced automation features, which increase productivity and efficiency in the manufacturing process. This not only reduces labor costs but also ensures consistent quality and precision in every single tile or sheet produced. With the ability to produce a large volume of roof tiles and IBR sheeting in a short amount of time, the machine is a cost-effective solution for meeting high demands in the roofing market.{Company Name} takes pride in its commitment to sustainability and environmental responsibility. The Roof Tiles And IBR Sheeting Making Machine is designed to minimize waste and optimize resource utilization, making it an eco-friendly choice for roofing manufacturers. The company's dedication to sustainability aligns with the growing demand for environmentally friendly construction solutions.In addition to the cutting-edge technology of the machine, {Company Name} offers comprehensive training and support to its clients. The company's team of experts provides hands-on training and guidance to help clients optimize the operation of the machine and achieve the best results. This level of support is invaluable for companies looking to integrate new technology into their manufacturing processes.The introduction of the Roof Tiles And IBR Sheeting Making Machine is a testament to {Company Name}'s commitment to pushing the boundaries of innovation in the roofing industry. The company's vision is to set new standards for quality, efficiency, and sustainability in roofing manufacturing, and this machine is a significant step in that direction.The market response to the Roof Tiles And IBR Sheeting Making Machine has been overwhelmingly positive, with many companies expressing interest in adopting this cutting-edge technology for their roofing operations. The machine's ability to streamline production, reduce costs, and deliver superior quality products has positioned it as a game changer in the roofing industry.As the construction industry continues to evolve, innovative solutions like the Roof Tiles And IBR Sheeting Making Machine will play a crucial role in shaping the future of roofing manufacturing. With {Company Name} at the forefront of this technological revolution, the possibilities for the roofing industry are limitless.In conclusion, the introduction of the Roof Tiles And IBR Sheeting Making Machine by {Company Name} marks a significant milestone in the roofing industry. This state-of-the-art machine is set to revolutionize the way roof tiles and IBR sheeting are manufactured, setting new standards for quality, efficiency, and sustainability. With its advanced technology, versatility, and environmental responsibility, the machine is poised to become a game changer in the roofing market. {Company Name} is leading the way in innovation, and their commitment to excellence is reshaping the future of roofing manufacturing.

Steel Coil Slitting Line: Streamlining Precision Cutting and Efficiency in the Manufacturing Industry

Steel Coil Slitting Line is one of the most important machines for the steel industry. It is a machine that is used to cut large coils of steel into smaller strips of the required width. This process is necessary for various applications, such as manufacturing of pipes, tubes, metal sheets, and so on. In this regard, machine suppliers, including {brand name removed}, are vital for the steel industry.{Supplier name removed} is a leading supplier of steel processing machines that includes Steel Coil Slitting Line. The company is a prominent entity in the industry and has carved a niche for itself in the international market. It has established a reputation for quality, durability, and reliability, which has made the company a preferred choice for organizations that deal in the manufacture of steel products.The Steel Coil Slitting Line from {supplier name removed} is built to cater to the diverse needs of customers worldwide. It is designed with cutting-edge technology and equipment that makes it highly productive, efficient, and accurate. This machine is easy to operate and requires minimal maintenance, which further enhances its reliability and durability.Furthermore, this Steel Coil Slitting Line is versatile and capable of handling different types of steel coils. It can process various types of steel materials and thicknesses with ease. Its high precision and accuracy ensure that customers are provided with consistent cuts, which is crucial for the successful production of quality steel products.{Supplier name removed} understands the significance of customer satisfaction and strives to provide top-notch products and exceptional after-sales support to its customers. They have a team of experts who are always available to assist their clients, ranging from machine installation, training, maintenance, and upgrades.Steel Coil Slitting Line has numerous benefits that make it a necessary machine for the steel industry. Firstly, it allows for efficient utilization of steel coils, which reduces the cost of production and waste. Secondly, it is flexible and can accommodate different widths and thicknesses of coils, which offers flexibility in production processes. Thirdly, its high precision and accuracy ensure that customers receive products with consistent quality.In conclusion, Steel Coil Slitting Line is a vital machine for the steel industry. It facilitates efficient and consistent production processes, reduces waste, and enhances the overall quality of steel products. {Supplier name removed} is a renowned supplier of high-quality steel processing machines, and their Steel Coil Slitting Line is one of the best in the market. The company's commitment to excellence, reliability, and customer satisfaction makes them a preferred choice for organizations that require the best steel processing machines in the industry. With {supplier name removed}, customers can count on getting the best value for their investment in steel processing machines.

High-Quality Portable Roll Forming Machine for Sale

Portable Roll Forming Machine Provides Efficient Solution for On-site Metal Fabrication[Company Name], a leading provider of innovative metal forming solutions, has introduced a state-of-the-art portable roll forming machine that is designed to revolutionize on-site metal fabrication processes. This cutting-edge machine offers unparalleled flexibility and efficiency, allowing contractors and builders to streamline their operations and achieve superior results in metal roofing, siding, and other construction applications.The portable roll forming machine is the latest addition to [Company Name]'s comprehensive lineup of metal forming equipment, and it is set to redefine the way metal products are fabricated in the field. With its advanced technology and user-friendly design, this machine enables operators to produce custom metal profiles directly at the job site, eliminating the need for transportation and reducing material waste. This not only saves time and money, but also minimizes the environmental impact of metal fabrication processes.One of the key advantages of the portable roll forming machine is its ability to handle a wide variety of metal materials, including steel, aluminum, and copper. This versatility allows contractors to take on a diverse range of projects without the need for multiple machines, making it an invaluable asset for construction firms of all sizes. In addition, the machine's compact size and lightweight construction make it easy to transport and set up, further enhancing its appeal for on-site fabrication applications.In terms of performance, the portable roll forming machine is engineered to deliver exceptional accuracy and consistency in metal profiling. Its precision roller system and automated controls ensure that each profile meets the exact specifications, resulting in high-quality finished products that meet or exceed industry standards. Furthermore, the machine's adjustable speed and feed settings enable operators to optimize production efficiency and adapt to different material thicknesses with ease.To support users in maximizing the capabilities of the portable roll forming machine, [Company Name] provides comprehensive training and technical support services. Their team of experienced metal forming specialists is on hand to offer guidance on machine setup, operation, and maintenance, ensuring that customers can make the most of their investment and achieve superior results in their metal fabrication projects. This commitment to customer satisfaction is a cornerstone of [Company Name]'s business philosophy, and it has helped them build a reputation as a trusted partner in the metal forming industry."We are thrilled to introduce our portable roll forming machine to the market, as we believe it represents a major breakthrough in on-site metal fabrication technology," said [Spokesperson Name], the CEO of [Company Name]. "This machine is the result of years of research and development, and we are confident that it will empower our customers to take their metal forming capabilities to the next level. From its portable design to its advanced performance features, every aspect of this machine has been engineered with the needs of on-site fabricators in mind."With the introduction of the portable roll forming machine, [Company Name] is poised to set a new standard for on-site metal fabrication efficiency and quality. As construction and renovation projects continue to demand faster turnaround times and superior craftsmanship, this innovative machine is expected to become an indispensable tool for contractors, builders, and metal fabricators seeking to stay ahead of the curve in the industry. [Company Name] remains committed to driving the advancement of metal forming technology, and their portable roll forming machine is a testament to their dedication to innovation and excellence.

Quality Corrugation Sheet Steel Tile Roll Forming Machine: Manufacturer and Exporter from China

Corrugation Sheet Steel Tile Roll Forming Machine - A Game-Changer in the Manufacturing IndustryChina is a leader in the manufacturing industry, and one of the key drivers of this success is innovation. Roll forming machines are a prime example of this innovation. The Corrugation Sheet Steel Tile Roll Forming Machine is one such machine that is making waves in the manufacturing sector with its ability to create tiles of various shapes, sizes, and designs.The Corrugation Sheet Steel Tile Roll Forming Machine is developed by a leading Chinese manufacturer of roll forming machines. The company has a long-standing reputation for its high-quality equipment and its commitment to innovation. This new machine is a testament to their commitment to providing customers with the latest and most innovative equipment.The Sheet Corrugation Machine company has been in operation for several years and has established itself as a leading provider of roll forming machines. The company's machines are highly efficient, durable, and versatile, making them ideal for use in a wide range of manufacturing applications.The Corrugation Sheet Steel Tile Roll Forming Machine is designed with high precision to ensure that it produces tiles of unmatched quality. The machine uses advanced technology and automation to produce tiles of various shapes and sizes with high accuracy. The machine has a fully computerized control system that allows operators to set the parameters of the machine to achieve the desired results.One of the key advantages of the Corrugation Sheet Steel Tile Roll Forming Machine is its speed. The machine can produce tiles at high speed, ensuring that manufacturers can meet their production targets and deadlines. This speed is achieved through a combination of advanced technology and the machine's design.The Corrugation Sheet Steel Tile Roll Forming Machine is also highly efficient, which means that it consumes less energy and produces less waste compared to traditional production methods. This efficiency helps manufacturers to reduce their production costs while improving the quality of their products.Another advantage of the Corrugation Sheet Steel Tile Roll Forming Machine is its versatility. The machine can be used to produce tiles of various shapes, sizes, and designs, giving manufacturers the flexibility to meet the requirements of different customers. This versatility makes the machine an ideal option for small and large-scale manufacturers alike.In summary, the Corrugation Sheet Steel Tile Roll Forming Machine is a game-changer in the manufacturing industry. Its advanced technology, speed, efficiency, and versatility make it an ideal option for manufacturers who want to improve the quality of their products while reducing their production costs. The machine's development is a testament to the innovation and commitment to excellence of the Sheet Corrugation Machine company. With this machine, manufacturers can take their production capabilities to the next level and stay ahead of the competition.

High-Quality Z Purlin Making Machine for Efficient Manufacturing

Z Purlin Making Machine Enhances Production Efficiency for Steel Construction CompanyThe steel construction industry has always been a vital part of the global economy, providing the infrastructure for buildings, bridges, and various other structures. As technology continues to advance, there is a growing need for machinery that can streamline the production process and improve efficiency. With this in mind, the introduction of the Z Purlin Making Machine by a leading manufacturing company has brought significant improvements to the production capabilities of steel construction companies around the world.The Z Purlin Making Machine is a state-of-the-art piece of equipment that is designed to produce high-quality Z-shaped steel purlins, which are essential components in the construction of steel buildings. This machine is capable of handling different types of steel coils and can produce Z purlins of various sizes and thicknesses, making it a versatile and practical solution for steel construction companies of all scales.One of the key features of the Z Purlin Making Machine is its ability to automate the production process, which significantly reduces the need for manual labor and minimizes the risk of errors. This level of automation not only improves the overall efficiency of the production line but also enhances the safety of workers, as they are not required to perform repetitive tasks in a high-risk environment.Furthermore, the Z Purlin Making Machine is equipped with advanced technology that allows for precise and accurate manufacturing, resulting in consistent and reliable output. This not only benefits the steel construction company in terms of product quality but also contributes to cost savings by minimizing material wastage and rework.In addition to its technical capabilities, the Z Purlin Making Machine is also designed with user-friendly features that make it easy to operate and maintain. This ensures that steel construction companies can integrate this machine into their production process with minimal disruption and downtime, ultimately leading to a smoother transition towards improved production efficiency.For steel construction companies looking to enhance their production capabilities, the Z Purlin Making Machine offers a compelling solution that can deliver tangible benefits in terms of cost savings, quality improvement, and overall operational efficiency. By investing in this state-of-the-art equipment, companies can position themselves at the forefront of the industry and gain a competitive edge in the market.As a leading manufacturer of the Z Purlin Making Machine, our company is committed to providing innovative solutions that empower steel construction companies to thrive in today's dynamic business environment. With a strong focus on research and development, we have continuously refined our product to meet the evolving needs of our customers, ensuring that they have access to the latest technology that can drive their success.At our company, we understand the critical role that technology plays in the steel construction industry, and we are dedicated to delivering machinery that not only meets industry standards but also exceeds expectations. With the Z Purlin Making Machine, we have brought a new level of efficiency and productivity to steel construction companies, enabling them to achieve their production goals with confidence and precision.In conclusion, the introduction of the Z Purlin Making Machine has brought about a significant improvement in the production capabilities of steel construction companies, offering a combination of advanced technology, automation, and user-friendly features. As the demand for high-quality steel structures continues to grow, this machine serves as a valuable asset for companies seeking to stay competitive and deliver superior quality products to their clients. With our commitment to innovation and customer satisfaction, we are proud to be at the forefront of this technological advancement in the steel construction industry.

Cut to Length Machine: A Complete Guide for Steel Cutting Operations

Steel Cut To Length Machine revolutionizing the metalworking industryIn the world of metalworking, precision and efficiency are key components of success. The Steel Cut To Length Machine, produced by a leading manufacturer in the industry, is revolutionizing the way steel is processed and cut. This state-of-the-art machine combines cutting-edge technology with the company's expertise and dedication to excellence, making it a game-changer for businesses in the metalworking sector.With a strong commitment to innovation and quality, {company name} has established itself as a leader in the manufacturing of metalworking machinery. The Steel Cut To Length Machine is a testament to the company's dedication to providing cutting-edge solutions to its customers. With a focus on precision and efficiency, this machine is designed to streamline the process of cutting steel, providing businesses with a cost-effective and reliable solution for their metalworking needs.One of the key features of the Steel Cut To Length Machine is its advanced cutting technology. Equipped with high-precision blades and state-of-the-art automation, this machine is capable of cutting steel with unparalleled accuracy and speed. This precision cutting technology ensures that businesses can produce high-quality steel products with minimal waste, saving both time and money in the production process.Another notable feature of the Steel Cut To Length Machine is its versatility. This machine is designed to handle a wide range of steel thicknesses and widths, making it suitable for a variety of metalworking applications. Whether businesses are working with thin-gauge steel or heavy-duty materials, this machine is capable of delivering consistent and precise cuts, ensuring that the finished products meet the highest standards of quality.In addition to its cutting-edge technology and versatility, the Steel Cut To Length Machine is also designed with user-friendliness in mind. The machine's intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, streamlining the production process and minimizing the potential for errors. This user-friendly design is a testament to {company name}'s commitment to providing its customers with practical and efficient solutions for their metalworking needs.For businesses in the metalworking industry, investing in the Steel Cut To Length Machine represents a step forward in achieving greater productivity and efficiency. By incorporating this cutting-edge machine into their operations, businesses can optimize their production processes, reduce waste, and ultimately improve their bottom line. With the support of {company name}'s expertise and commitment to excellence, the Steel Cut To Length Machine is helping businesses in the metalworking sector stay ahead of the competition.In conclusion, the Steel Cut To Length Machine, produced by {company name}, is transforming the metalworking industry with its cutting-edge technology, versatility, and user-friendly design. With a focus on precision and efficiency, this machine is empowering businesses to achieve greater productivity and cost-effectiveness in their operations. As the demand for high-quality steel products continues to grow, the Steel Cut To Length Machine is positioning businesses in the metalworking sector for success, driving innovation and progress in an ever-evolving industry.

Revolutionizing the Metal Roofing Industry: Innovative Roofing Machines For A Faster Installation Process

Metal Roofing Machines Expands to Meet Growing Demands for Quality Roofing SolutionsWith the growing demand for durable and energy-efficient roofing solutions, Metal Roofing Machines has expanded its manufacturing capabilities, offering high-quality and dependable metal roofing machines for contractors and builders across the United States.Metal Roofing Machines is a family-owned and operated business that has been in the roofing industry for over two decades. The company has established a reputation for producing state-of-the-art metal roofing machines that are designed to meet the needs of contractors and builders of all sizes.The company's metal roofing machines are manufactured to the highest standards of quality and durability, using only top-grade materials and cutting-edge technology. Metal Roofing Machines' products are designed to offer maximum longevity and performance, while ensuring that they are easy to operate and maintain."We understand the importance of having access to reliable and efficient metal roofing machines," says the company spokesperson. "Our products are designed to meet the needs of the modern roofing industry, where time and efficiency are critical factors."Metal Roofing Machines' range of products includes portable roll formers, standing seam roll formers, roofing panel roll formers, gutter machines, and other specialty machines for the metal roofing industry. The company's machines are suitable for use in a variety of applications, including residential roofing, commercial roofing, and agricultural roofing.The standing seam roll former is the most popular machine distributed by Metal Roofing Machines. This machine is designed to produce standing seam roofing panels, which are popular for their clean, modern look and superior weather resistance. This machine is capable of producing high-quality panels quickly, ensuring that contractors are able to complete their roofing projects efficiently.In addition to manufacturing and distributing metal roofing machines, Metal Roofing Machines also provides education and training to contractors and builders who want to learn more about the metal roofing industry. The company offers a range of resources, including online tutorials, webinars, and in-person training sessions, designed to help contractors and builders improve their skills and stay up-to-date with the latest trends and technologies."We are committed to providing our customers with the best possible support," says the company spokesperson. "We believe that by educating our customers and providing them with the resources they need to succeed, we can help them grow their businesses and provide top-quality roofing solutions to their clients."Metal Roofing Machines has established itself as a leader in the metal roofing industry, thanks to its commitment to quality, innovation, and customer support. With its expanded manufacturing capabilities and growing range of products, the company is well-positioned to meet the demand for high-quality and reliable metal roofing solutions in the years to come.

Top Corrugated Roof Sheet Roll Forming Machine Unveiled: A Comprehensive Review

Title: State-of-the-Art Corrugated Roof Sheet Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:In a breakthrough development for the roofing industry, an innovative Corrugated Roof Sheet Roll Forming Machine has been launched, promising to streamline the manufacturing process while meeting the growing demand for high-quality roofing materials. This state-of-the-art machine combines cutting-edge technology, precision engineering, and advanced automation to produce corrugated roof sheets that cater to a wide range of architectural and construction requirements. The introduction of this machine marks a significant turning point for the industry, bringing forth numerous benefits for manufacturers, customers, and the environment.Streamlining the Manufacturing Process:The Corrugated Roof Sheet Roll Forming Machine utilizes a highly efficient and automated process, significantly reducing the time and effort required for sheet production. With its precise and seamless roll forming mechanism, the machine produces uniformly shaped and dimensionally accurate roof sheets, eliminating common manufacturing defects. This technology ensures that each sheet is produced to exact specifications, resulting in a consistent and reliable end product. The machine's speed and efficiency enhance productivity, allowing manufacturers to meet market demands without compromising quality.Unparalleled Versatility:One of the key advantages of the Corrugated Roof Sheet Roll Forming Machine is its versatility in producing a wide range of corrugated roof sheets. Whether it be for residential, commercial, or industrial applications, the machine can tailor the shape, size, and design of the sheets to meet specific customer requirements. Its flexibility enables manufacturers to meet diverse architectural needs, catering to multiple roofing styles and materials. This advanced machine empowers architects and builders with the ability to achieve their desired aesthetic while maintaining structural integrity.High-Quality and Durable Roofing Materials:The precision-driven design and manufacturing process of the Corrugated Roof Sheet Roll Forming Machine ensure exceptional quality and durability in every sheet produced. By using high-quality materials, combined with advanced engineering techniques, the machine outputs roof sheets that are resistant to extreme weather conditions, corrosion, and pests. This superior durability not only enhances the structural integrity of buildings but also provides long-lasting protection for homeowners, reducing maintenance costs over time.Efficiency and Cost-Effectiveness:The advanced automation incorporated in the Corrugated Roof Sheet Roll Forming Machine significantly reduces human labor, improving efficiency, and lowering production costs. By eliminating the need for manual intervention, the machine minimizes human error, leading to improved overall quality and decreased material wastage. This automation also enhances the safety of workers by reducing their exposure to potentially hazardous situations. The cost-effectiveness of the machine translates into competitive pricing for customers, making high-quality roofing materials more accessible than ever before.Eco-Friendly Roofing Solutions:In today's demanding environmental landscape, sustainable practices are of utmost importance. The Corrugated Roof Sheet Roll Forming Machine aligns with the global push for eco-friendly solutions through its manufacturing process. By utilizing precise measurements and automated technology, the machine significantly reduces material wastage, conserving valuable resources. Moreover, the high-quality and durable roofing materials produced by the machine contribute to energy efficiency in buildings, reducing reliance on heating and cooling systems.Conclusion:The introduction of the innovative Corrugated Roof Sheet Roll Forming Machine represents a significant advancement in the roofing industry. Its state-of-the-art technology, streamlined manufacturing process, and unparalleled versatility make it a game-changer for manufacturers and customers alike. Through its precision-engineered design, the machine delivers high-quality and durable roofing materials that meet architectural and construction needs while prioritizing sustainability. Embracing these cutting-edge machines will not only revolutionize the roofing industry but also contribute to a more sustainable future.