Standing Seam Former: A Guide to Choosing The Right Option

By:Admin

Established in [year], {} has been a leading manufacturer of roofing and construction equipment, providing high-quality products to contractors and construction companies worldwide. The company's standing seam former is a testament to their commitment to innovation and excellence in the industry.

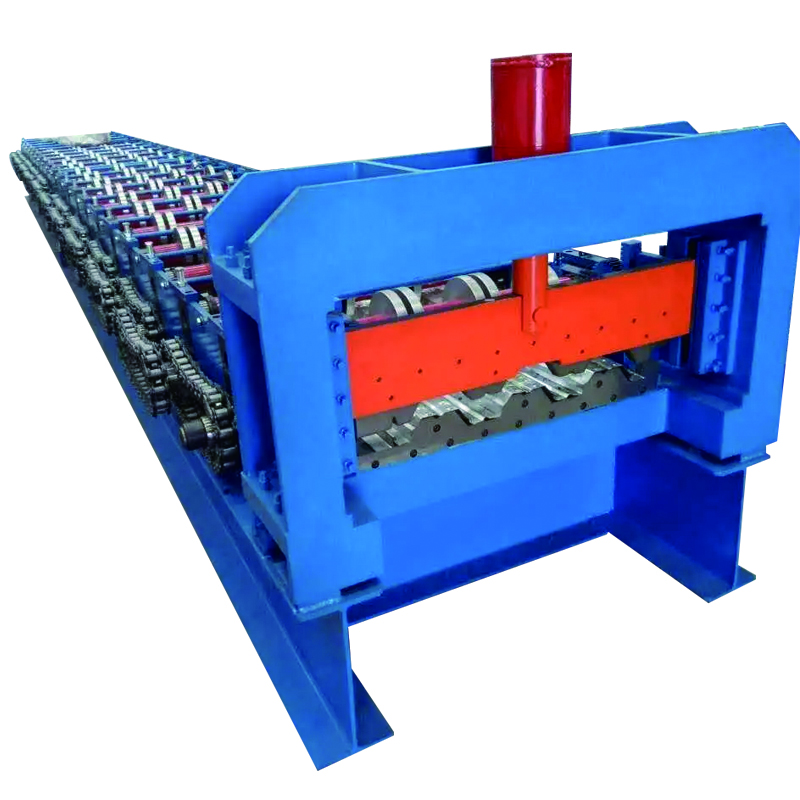

The standing seam former developed by {} is designed to produce high-quality standing seam panels with ease. It is equipped with advanced technology and features that make the process of forming standing seam panels efficient and precise. The machine is capable of producing panels of varying widths and heights, giving contractors the flexibility to meet the specific requirements of their projects.

One of the key features of the {} standing seam former is its user-friendly interface, which allows operators to easily input the specifications for the panels they need to produce. The machine then automates the forming process, resulting in consistent and accurate panels every time. This not only saves time but also minimizes the margin of error, leading to higher quality end products.

In addition to its advanced technology, the {} standing seam former is also built with durability in mind. Constructed with high-quality materials and precision engineering, the machine is designed to withstand the rigors of heavy-duty use in a construction environment. This ensures that contractors can rely on the machine to perform consistently and reliably, project after project.

Furthermore, {} provides comprehensive training and support for their standing seam former, ensuring that contractors are able to maximize its capabilities and fully benefit from its advanced features. The company's team of experts is dedicated to assisting customers in understanding the machine's operation and maintenance, as well as providing any technical support that may be required.

The impact of the {} standing seam former has been felt across the construction industry, with contractors and construction companies praising its efficiency and precision. By streamlining the process of forming standing seam panels, the machine has enabled contractors to increase their productivity while maintaining high standards of quality.

Moreover, the use of the {} standing seam former has resulted in cost savings for contractors, as the machine's efficient operation and consistent output minimize waste and rework. This has allowed contractors to take on more projects and increase their profitability, making the investment in the standing seam former a smart decision for many in the industry.

As the construction industry continues to evolve, innovative solutions like the {} standing seam former will play a crucial role in shaping the way buildings are constructed. With its advanced technology, durability, and comprehensive support, the standing seam former from {} has set a new standard for efficiency and precision in the production of standing seam metal roofs.

In conclusion, {} has cemented its position as a leader in the industry with its cutting-edge standing seam former. The company's commitment to excellence and innovation has propelled them to the forefront of the construction equipment market, and the impact of their standing seam former is sure to be felt for years to come.

Company News & Blog

High-Quality Standing Seam Machine for Double Lock Construction

In the world of construction and roofing, the demand for high-quality and efficient standing seam machines is ever-growing. One company that has been at the forefront of providing top-notch standing seam machines is [company name]. With their latest innovation, the Double Lock Standing Seam Machine, they have once again proven their commitment to excellence in the industry.[Company name] has been a leader in the manufacturing of roofing and construction machinery for over two decades. Their dedication to providing cutting-edge solutions for their customers has earned them a stellar reputation in the industry. The company prides itself on producing reliable, durable, and high-performance machines that meet the ever-evolving needs of their clients.The Double Lock Standing Seam Machine is the latest addition to [company name]'s impressive lineup of equipment. This machine is designed to streamline the process of creating standing seam panels, which are widely used in the construction of roofs, walls, and other architectural applications. With its innovative features and robust construction, the Double Lock Standing Seam Machine is set to revolutionize the way standing seam panels are produced.One of the key features of the Double Lock Standing Seam Machine is its dual profile capabilities. This means that the machine is capable of producing two different types of standing seam panels, offering versatility and flexibility to the user. This feature is particularly valuable for contractors and construction companies that work on a variety of projects with different design requirements.Additionally, the Double Lock Standing Seam Machine boasts a quick and easy tooling changeover, allowing for seamless transitions between different profiles. This not only saves time but also enhances overall productivity, making it an ideal choice for businesses looking to maximize efficiency.Another notable feature of the Double Lock Standing Seam Machine is its high-speed production capabilities. The machine is capable of producing standing seam panels at an impressive rate, ensuring that projects can be completed in a timely manner without compromising on quality. This speed and efficiency make the machine a valuable asset for companies looking to meet tight deadlines and deliver exceptional results.Furthermore, the Double Lock Standing Seam Machine is designed for ease of use and maintenance. Its user-friendly interface and robust construction make it an ideal choice for both seasoned professionals and those new to the industry. The machine is also built to withstand the rigors of heavy-duty use, providing long-term reliability and performance.With the introduction of the Double Lock Standing Seam Machine, [company name] has once again demonstrated its commitment to innovation and customer satisfaction. The machine's advanced features, high-speed production capabilities, and user-friendly design make it a standout choice in the market.In conclusion, the Double Lock Standing Seam Machine from [company name] is a game-changer for the construction and roofing industry. Its innovative features, reliable performance, and ease of use make it a valuable asset for any business looking to enhance their standing seam panel production capabilities. With a proven track record of delivering high-quality machinery, [company name] continues to set the standard for excellence in the industry.

High-quality Glazed Tile Profiling Equipment for Precise and Efficient Results

In a bid to revolutionize the glazed tile industry, the renowned machinery manufacturing company {} has introduced its latest technological marvel - the Glazed Tile Profiling Equipment. This cutting-edge equipment is set to redefine the way glazed tiles are produced, making the process more efficient and precise than ever before.With a legacy of excellence in the manufacturing industry, {} has consistently delivered state-of-the-art machinery that has set new benchmarks for quality and innovation. The Glazed Tile Profiling Equipment is no exception, as it promises to be a game-changer for tile manufacturers globally.One of the key features of the Glazed Tile Profiling Equipment is its advanced profiling capabilities. This equipment is designed to create intricate and precise profiles on glazed tiles, giving them a unique and aesthetically appealing look. This level of precision is unprecedented in the industry and is set to elevate the quality of glazed tiles to new heights.Furthermore, the Glazed Tile Profiling Equipment boasts a high level of automation, which significantly reduces the need for manual intervention in the production process. This not only increases efficiency but also minimizes the margin for error, resulting in superior quality glazed tiles that meet the highest standards.In addition to its technical capabilities, the Glazed Tile Profiling Equipment is also designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, ensuring a seamless production process. This not only streamlines operations but also reduces the need for extensive training, making it a cost-effective solution for manufacturers.The introduction of the Glazed Tile Profiling Equipment is a testament to {}'s commitment to innovation and excellence. With a track record of delivering cutting-edge machinery that meets the evolving needs of the manufacturing industry, {} has once again raised the bar with this latest offering.In a statement, a spokesperson for {} commented, "We are thrilled to introduce the Glazed Tile Profiling Equipment to the market. We believe that this equipment will revolutionize the way glazed tiles are produced, offering unprecedented levels of precision and efficiency. As a company, we are dedicated to pushing the boundaries of technology and setting new standards for quality, and we are confident that the Glazed Tile Profiling Equipment will further solidify our position as a leader in the machinery manufacturing industry."The introduction of the Glazed Tile Profiling Equipment comes at a time when the demand for high-quality glazed tiles is at an all-time high. With this innovative equipment, manufacturers can now produce tiles that not only meet but exceed consumer expectations, giving them a competitive edge in the market.As the glazed tile industry continues to evolve, the introduction of advanced machinery such as the Glazed Tile Profiling Equipment is a clear indication of the direction in which the industry is headed. With {} at the forefront of this technological revolution, the future of glazed tile production looks brighter than ever.

Barrel Vault Panel Bending Machine: The Ultimate Guide

Global Machinery Company Introduces Innovative Horizontal Barrel Vault Panel Bending MachineNew York, NY - Global Machinery Company, a leading manufacturer of advanced machinery equipment, is proud to introduce its latest innovative product, the Horizontal Barrel Vault Panel Bending Machine. This cutting-edge machine is designed to meet the increasing demand for a high-quality and efficient solution for bending and shaping panel materials.The Horizontal Barrel Vault Panel Bending Machine is a state-of-the-art equipment that offers precision and accuracy in bending various types of panels. It is suitable for a wide range of applications including architectural, automotive, aerospace, and manufacturing industries. The machine is capable of bending materials such as aluminum, steel, and other alloys with ease, making it a versatile and reliable solution for modern manufacturing processes.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its advanced technology that ensures consistent and uniform bending results. The machine is equipped with a sophisticated control system that allows for precise adjustment of the bending parameters, ensuring that each panel is bent to the exact specifications required. This level of precision is crucial in industries where product quality and integrity are of utmost importance.Furthermore, the Horizontal Barrel Vault Panel Bending Machine boasts a robust and durable construction, making it a long-term investment for businesses. The machine is designed to withstand heavy-duty usage and can withstand the rigors of a demanding manufacturing environment. Its efficient design also allows for easy maintenance and service, reducing downtime and ensuring continuous operation.In addition to its advanced features, the Horizontal Barrel Vault Panel Bending Machine is also designed with user-friendliness in mind. The machine is equipped with an intuitive interface that allows operators to easily program and control the bending process. This ensures that even inexperienced users can operate the machine with confidence and produce high-quality results.“We are excited to introduce the Horizontal Barrel Vault Panel Bending Machine to the market,” said the spokesperson for Global Machinery Company. “This machine represents the next level of innovation in panel bending technology, and we believe it will revolutionize the way industries approach panel bending processes. Its advanced features and user-friendly design make it a valuable addition to any manufacturing facility.”Global Machinery Company has built a solid reputation for delivering cutting-edge machinery equipment to industries around the world. With a focus on innovation and quality, the company has consistently developed products that meet the evolving needs of modern manufacturing processes. The introduction of the Horizontal Barrel Vault Panel Bending Machine is a testament to the company's commitment to providing advanced solutions to its customers.The Horizontal Barrel Vault Panel Bending Machine is now available for purchase through Global Machinery Company's authorized distributors and partners worldwide. The company also offers comprehensive training and support services to ensure that customers can maximize the potential of this innovative machine.As industries continue to evolve and demand higher standards of quality and efficiency, the introduction of the Horizontal Barrel Vault Panel Bending Machine from Global Machinery Company is a timely and welcome addition to the manufacturing landscape. With its advanced technology, durability, and user-friendly design, this machine is set to become a game-changer in the field of panel bending, offering a powerful solution for businesses looking to stay ahead in a competitive market.

Advanced High-Speed Cut-To-Length Machines Revolutionize Industrial Operations

Title: Innovative High-Speed Cut-to-Length Machine Revolutionizes Industrial AutomationIntroduction:In today's ever-evolving manufacturing landscape, efficiency and precision are of paramount importance. As companies strive to optimize their production processes, a groundbreaking solution has emerged – the High-Speed Cut-to-Length Machine (CCLM) – a technological marvel that is set to revolutionize the industrial automation sector. Developed by an industry-leading manufacturer, this state-of-the-art machine combines cutting-edge technologies with a focus on speed, accuracy, and versatility. By improving productivity and ensuring higher quality outputs, the High-Speed CCLM promises to bring about a new era in manufacturing.[Paragraph 1: Background and Importance of Industrial Automation]Automation has long been a key imperative in the manufacturing sector, as it offers numerous benefits such as improved productivity, reduced labor costs, and enhanced product quality. However, until now, the cut-to-length process has remained a bottleneck for many industries. Traditional machinery often falls short in terms of accuracy, speed, and flexibility. The introduction of the High-Speed CCLM aims to address these limitations, enhancing efficiency while maintaining a high level of precision.[Paragraph 2: Overview of the High-Speed Cut-to-Length Machine]Developed by a leading manufacturer with a rich history of innovation, the High-Speed CCLM is a game-changer in the field of industrial automation. Boasting a combination of advanced technologies, meticulous engineering, and comprehensive user-centric design, this machine is capable of processing various materials at an unprecedented pace and accuracy. By seamlessly integrating automation features, such as robotic arms and powerful AI algorithms, the High-Speed CCLM is capable of precisely cutting and shaping an array of materials including metals, plastics, and composites.[Paragraph 3: Key Features and Advantages]The High-Speed CCLM differentiates itself from conventional machinery through several standout features that elevate it to a league of its own. First and foremost, this machine allows for rapid changeovers, enabling manufacturers to seamlessly transition between different types and sizes of materials. Furthermore, its high-speed operation significantly reduces manufacturing cycle times, leading to increased productivity and throughput. The use of advanced laser-guided technology ensures exceptional accuracy, while the incorporation of AI algorithms enables predictive maintenance, reducing downtime and maintenance costs.[Paragraph 4: Impact on Manufacturing Industry]The advent of the High-Speed CCLM is set to revolutionize the manufacturing industry as a whole. By streamlining the cut-to-length process, this machine eliminates the need for multiple manual interventions, thereby minimizing the risk of errors and accidents. Additionally, its high-speed capabilities enable manufacturers to meet ever-growing customer demands and tight production schedules efficiently. The automation features of the High-Speed CCLM also allow for simpler and more cost-effective scaling of operations, facilitating the growth of small-scale enterprises.[Paragraph 5: Case Studies and Customer Testimonials]Numerous businesses across various industries have already integrated the High-Speed CCLM into their manufacturing processes, yielding remarkable results. Companies that have implemented this innovative machine have reported significant improvements in productivity, waste reduction, and overall quality control. Customer testimonials highlight how the High-Speed CCLM has transformed their operations, saving them time and resources, while simultaneously enhancing their competitiveness in the market.[Paragraph 6: Conclusion]In conclusion, the introduction of the High-Speed Cut-to-Length Machine represents a significant milestone in the automation revolution within the manufacturing industry. With its advanced features, exceptional speed, and unmatched precision, this innovative machine is poised to redefine the way materials are cut and shaped, driving efficiency, and enhancing competitiveness for businesses across the globe. As industrial automation continues to evolve, the High-Speed CCLM sets a new benchmark for excellence, consolidating its position as a game-changer in the field.

Quality Steel Roll Forming Machine Manufacturer: Find the Best Deals Now

Color Steel Roll Forming Machine Factory, a leading manufacturer of roll forming machines in the industry, has been delivering high-quality products and services to its customers for over 15 years. Specializing in the production of roll forming machines for color steel, the factory has gained a strong reputation for its reliability, efficiency, and technological innovation.The company takes pride in its state-of-the-art manufacturing facility, equipped with advanced machinery and a highly skilled workforce. This combination allows Color Steel Roll Forming Machine Factory to produce a wide range of roll forming machines that meet the diverse needs of its customers. Whether it's for roofing, wall cladding, or other construction purposes, the factory's machines are designed to deliver precision and performance.In addition to its impressive manufacturing capabilities, Color Steel Roll Forming Machine Factory places a strong emphasis on research and development. The company continuously invests in new technologies and processes to improve the quality and functionality of its products. This commitment to innovation has enabled the factory to stay ahead of the competition and offer cutting-edge solutions to its customers.Furthermore, the factory is dedicated to providing exceptional customer service. With a team of experienced engineers and technicians, Color Steel Roll Forming Machine Factory offers comprehensive support to its clients, from the initial consultation to after-sales service. The company's customer-centric approach has resulted in long-term partnerships with many businesses in the construction industry.One of the key factors that set Color Steel Roll Forming Machine Factory apart from its competitors is its strict adherence to quality control. From the sourcing of raw materials to the final inspection of finished products, the factory maintains rigorous standards to ensure the reliability and durability of its roll forming machines. This commitment to quality has earned the company the trust and loyalty of its customers.In recent years, Color Steel Roll Forming Machine Factory has expanded its market reach beyond its home country, and it now exports its products to various countries around the world. This global expansion is a testament to the factory's growing reputation and the increasing demand for its high-quality roll forming machines.Looking ahead, Color Steel Roll Forming Machine Factory is poised to continue its success and maintain its position as a leading manufacturer in the industry. The company remains focused on innovation, quality, and customer satisfaction, and it is committed to providing the best solutions for the evolving needs of the construction sector.In conclusion, Color Steel Roll Forming Machine Factory is a trailblazer in the roll forming machine industry, known for its technological expertise, dedication to quality, and commitment to customer service. With a strong track record and a global presence, the factory is well positioned to lead the way in shaping the future of roll forming technology.

Efficient Cut-To-Length Machine Revolutionizes Fabric Industry

Title: Cutting-edge Fabric Cut-to-Length Machine Revolutionizes Textile IndustryIntroduction:The fabric cut-to-length machine, a groundbreaking innovation in the textile industry, is set to transform the way fabrics are processed and cut. Developed by a leading company in textile machinery (), this cutting-edge technology promises to enhance efficiency, precision, and productivity in fabric manufacturing while reducing waste and operational costs. By focusing on revolutionary design and incorporating advanced features, this machine is poised to revolutionize fabric cutting processes globally.Paragraph 1:Manufacturers in the textile industry have long been facing challenges relating to efficient and accurate fabric cutting. Traditional cutting methods often result in time-consuming, labor-intensive processes that lead to inconsistencies and inaccuracies. The introduction of the fabric cut-to-length machine aims to overcome these hindrances and provide an automated solution that streamlines the entire cutting process.Paragraph 2:The fabric cut-to-length machine utilizes state-of-the-art technology to deliver high precision cutting, reducing material waste and optimizing fabric utilization. With programmable settings and a user-friendly interface, the machine enables manufacturers to achieve precise dimensions consistently. This innovation not only saves time but also eliminates errors, ensuring uniformity throughout the production process.Paragraph 3:One of the key features of this machine is its ability to accommodate a wide variety of fabric types. Whether it is delicate silk, robust denim, or intricate lace, the machine's advanced cutting mechanisms deliver clean, accurate cuts without compromising the integrity of the fabric. Such versatility enables fabric manufacturers to expand their product lines and cater to diverse customer needs, significantly enhancing their competitiveness in the market.Paragraph 4:In addition to its cutting precision, the fabric cut-to-length machine incorporates efficiency-enhancing mechanisms, such as conveyor systems and automated fabric feeders. These features enable continuous processing and seamless integration with other textile machinery, minimizing downtime and maximizing productivity. Furthermore, its intuitive control panel allows operators to monitor and adjust settings easily, fostering a smoother workflow.Paragraph 5:Environmental sustainability is a growing concern in the textile industry. The fabric cut-to-length machine tackles this issue through material optimization, reducing fabric wastage significantly. By eliminating manual errors and ensuring efficient use of fabric, the machine helps manufacturers reduce their carbon footprint and minimize the environmental impact of fabric production.Paragraph 6:The impact of the fabric cut-to-length machine extends beyond the manufacturing floor, as it also positively influences the bottom line. By reducing fabric waste and increasing productivity, manufacturers can experience significant cost savings over time. Additionally, the machine's longevity and durability contribute to its cost-effectiveness, making it a valuable investment for textile companies seeking to optimize their operations in the long run.Paragraph 7:The introduction of this innovative fabric cut-to-length machine marks a new era in the textile industry, establishing new standards of quality, efficiency, and sustainability. Through its intelligent design, versatility, and ability to streamline fabric cutting processes, manufacturers are now empowered to meet the growing demands of customers while staying competitive in a rapidly evolving market.Conclusion:The fabric cut-to-length machine developed by () is poised to revolutionize the textile industry, simplifying and automating the fabric cutting process. With its precision, versatility, and cost-effectiveness, this cutting-edge technology has the potential to reshape the fabric manufacturing landscape, enabling manufacturers to optimize their operations and meet the ever-growing demands of the market. As the textile industry continues to evolve, the fabric cut-to-length machine will empower companies to embrace change, improve efficiency, and remain at the forefront of innovation.

High-Quality and Efficient Forming Machine for Guardrails

Location: [Company Name]'s headquartersDate: [Current Date][Company Name], a leading manufacturer of construction machinery, has recently introduced a new and advanced Guardrail Forming Machine. This state-of-the-art machine is designed to revolutionize the process of guardrail production, making it faster, more efficient, and cost-effective.The Guardrail Forming Machine is equipped with cutting-edge technology and features a high level of automation, reducing the need for manual labor and increasing productivity. This machine is suitable for producing guardrails of various sizes and specifications, making it versatile and adaptable to different project requirements.The innovative design of the Guardrail Forming Machine allows for easy and quick setup, minimizing downtime and maximizing production output. Its precision and accuracy ensure that the guardrails produced meet the highest quality standards, providing a reliable and durable safety barrier for roads and highways.In addition to its cutting-edge technology, the Guardrail Forming Machine is also designed with safety and convenience in mind. With its user-friendly interface and intuitive controls, operators can easily manage and monitor the production process, ensuring smooth and efficient operation.[Company Name] has established itself as a trusted and reputable manufacturer in the construction machinery industry. With a strong focus on research and development, the company continuously strives to innovate and improve its products, meeting the ever-changing demands of the market.The introduction of the Guardrail Forming Machine is a testament to [Company Name]'s commitment to providing innovative solutions that enhance the efficiency and quality of construction projects. By offering this advanced machine, the company aims to support its customers in achieving their project goals while maintaining high standards of safety and reliability.As a company with a global presence, [Company Name] is dedicated to providing its customers with exceptional service and support. The installation and commissioning of the Guardrail Forming Machine are carried out by a team of experienced technicians, ensuring a seamless and hassle-free experience for customers.The launch of the Guardrail Forming Machine is set to make a significant impact on the construction industry, offering a solution that addresses the challenges of guardrail production and installation. With its advanced technology, precision engineering, and commitment to quality, [Company Name] is poised to set a new standard in the manufacturing of guardrails.As the construction industry continues to evolve, [Company Name] remains at the forefront, delivering cutting-edge solutions that empower construction companies to meet their project needs efficiently and effectively. The Guardrail Forming Machine is a testament to the company's dedication to innovation, quality, and customer satisfaction.With the introduction of the Guardrail Forming Machine, [Company Name] is poised to make a lasting impact on the construction industry. This advanced machine is set to revolutionize the production of guardrails, offering a solution that combines innovation, efficiency, and reliability.For more information about [Company Name]'s Guardrail Forming Machine, you can visit their official website or contact their sales representatives. [Company Name] is committed to supporting its customers with cutting-edge solutions that meet the ever-changing demands of the construction industry.

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

High-Quality Steel Coil Slitting Line for Efficient Production

Steel Coil Slitting LineA slitting line is a crucial piece of equipment in the steel industry which is used to cut a wide coil of steel into narrower coils. This process requires precision, speed, and efficiency to meet the demands of the market. {Company Name}, a leading manufacturer of industrial equipment, has recently introduced its latest Steel Coil Slitting Line that promises to revolutionize the steel processing industry.The new Steel Coil Slitting Line from {Company Name} has been designed with cutting-edge technology and innovation to provide unparalleled performance and reliability. With a focus on meeting the diverse needs of the market, this slitting line is capable of processing a wide range of steel coils with speed and accuracy. The state-of-the-art design and engineering ensure that the slitting line can handle different types of steel, including hot-rolled, cold-rolled, and galvanized coils with ease.One of the standout features of the Steel Coil Slitting Line is its precision slitting capability. The line is equipped with high-precision slitter heads that can make clean and accurate cuts, ensuring that the finished coils meet the required specifications. In addition, the slitting line is also equipped with advanced edge guiding systems and tension control mechanisms to maintain the quality of the slit coils throughout the process.Another key aspect of the Steel Coil Slitting Line is its efficiency and productivity. The line is designed to operate at high speeds while maintaining the quality of the slit coils. This enables steel processors to increase their throughput and meet the demands of their customers in a timely manner. The automation and control systems integrated into the slitting line further enhance its efficiency, allowing for seamless operation and minimal downtime.In addition to its performance and capabilities, the Steel Coil Slitting Line from {Company Name} also prioritizes safety and operational ease. The line is equipped with advanced safety features and interlocks to ensure the protection of the operators and the integrity of the process. Furthermore, the user-friendly interface and control systems make it easy for operators to set up and monitor the slitting process, reducing the risk of errors and ensuring consistent quality.{Company Name} has a proven track record in providing high-quality industrial equipment to the steel processing industry. With decades of experience and expertise in engineering and manufacturing, the company is known for its commitment to innovation and customer satisfaction. The introduction of the Steel Coil Slitting Line is a testament to {Company Name}'s dedication to meeting the evolving needs of the steel industry and driving progress through technology.The Steel Coil Slitting Line from {Company Name} is set to make a significant impact on the steel processing industry, offering a new standard of performance, quality, and efficiency. With its advanced features and robust design, the slitting line is poised to empower steel processors to enhance their operations and meet the demands of the market with confidence and reliability.In conclusion, the introduction of the Steel Coil Slitting Line from {Company Name} represents a major advancement in the steel processing industry. With its cutting-edge technology, precision slitting capability, efficiency, and safety features, the slitting line is set to redefine the standards of performance and quality in steel coil processing. As {Company Name} continues to lead the way in industrial equipment manufacturing, the Steel Coil Slitting Line stands as a testament to the company's commitment to innovation and excellence.

Automatic Reinforcement Iron Bar Making Machine: Everything You Need to Know

Ibr Making Machine: Revolutionizing the Roofing IndustryIn the world of construction and roofing, innovation and technology play a vital role in improving efficiency and quality of work. One such innovation that has recently been making waves in the industry is the Ibr Making Machine. This state-of-the-art machine is changing the way roofing materials are manufactured and is set to revolutionize the roofing industry as we know it.The Ibr Making Machine, produced by a leading manufacturing company in the field of construction machinery, is a fully automated, high-speed machine that is capable of producing a wide range of roofing materials with precision and efficiency. From galvanized steel to aluminum, the machine can effortlessly handle various materials, ensuring versatility and high quality in the final products.One of the key features of this machine is its ability to produce IBR (Inverted Box Rib) profiles, a popular choice for roofing material due to its strength and durability. The machine's precision rollers and cutting mechanisms ensure that each sheet produced is of consistent quality and precise dimensions, meeting the highest standards in the industry. This consistency is crucial for roofing projects, as it ensures a seamless and watertight installation, ultimately leading to greater customer satisfaction and long-lasting roofs.Furthermore, the Ibr Making Machine is equipped with advanced technology that allows for seamless customization of roofing materials. This means that contractors and builders can easily adjust the dimensions, thickness, and even colors of the roofing sheets to suit the specific requirements of each project. This level of customization not only provides flexibility but also reduces material waste, ultimately leading to cost savings for the roofing companies and their clients.The company behind the Ibr Making Machine prides itself on its commitment to innovation and quality. With a team of experienced engineers and technicians, the company has dedicated extensive resources to research and development, ensuring that their machines are at the forefront of technological advancements in the industry. In addition, the company places great emphasis on customer service and support, ensuring that their clients are well-trained and supported in the operation and maintenance of the machines.The impact of the Ibr Making Machine on the roofing industry has been profound. Many roofing companies that have adopted this technology have reported significant improvements in their production processes, from faster turnaround times to higher quality products. The machine's efficiency has also allowed these companies to take on larger and more complex projects, expanding their business and ultimately improving their bottom line.Moreover, the Ibr Making Machine has had a positive environmental impact as well. By reducing material waste and energy consumption, the machine contributes to sustainable and eco-friendly manufacturing practices, aligning with the global push for greener and more sustainable construction methods.As the demand for high-quality roofing materials continues to grow, the Ibr Making Machine is poised to become an indispensable asset for roofing companies around the world. Its ability to produce top-notch roofing materials with speed, efficiency, and customization capabilities make it a game-changer in the industry. With the backing of a reputable and innovative manufacturing company, the Ibr Making Machine is set to shape the future of roofing, providing solutions that meet the evolving needs of the construction industry.