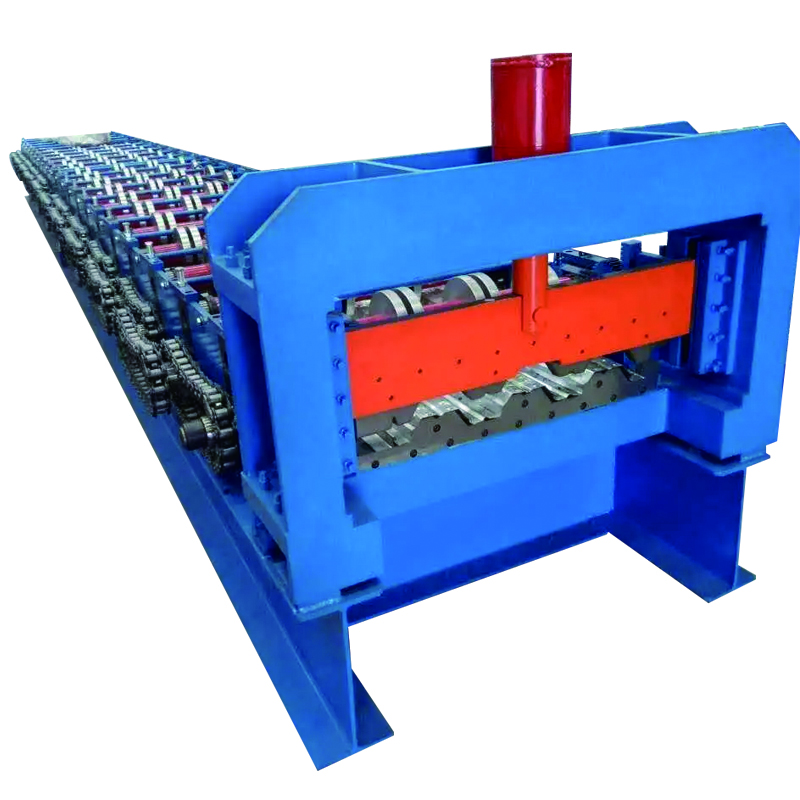

Steel Glazed Tile Forming Machine for Sale - Everything You Need to Know

By:Admin

The CSTFM is the result of years of research and development by a leading manufacturing company in the steel industry. With a strong commitment to innovation and quality, the company has created a machine that is capable of producing glazed tiles that meet the highest industry standards. The machine is also designed to be efficient and easy to operate, allowing for increased production and reduced labor costs.

One of the key features of the CSTFM is its ability to produce a wide range of glazed tiles in different colors and designs. This flexibility allows for greater customization, giving customers the ability to create unique and eye-catching roofing solutions for their homes or buildings. The machine also boasts a high level of precision, ensuring that each glazed tile is produced to exact specifications.

In addition to its impressive performance, the CSTFM is also designed with sustainability in mind. The machine is equipped with advanced energy-saving features and is built to minimize waste and environmental impact. This makes it an ideal choice for companies and individuals who are seeking to reduce their carbon footprint and operate in a more environmentally responsible manner.

The company behind the CSTFM has a long history of producing high quality and innovative products for the steel industry. With a team of experienced engineers and designers, they have been able to stay ahead of the curve and continually push the boundaries of what is possible in steel manufacturing. This dedication to excellence has earned the company a strong reputation in the industry and made them a trusted partner for businesses and individuals alike.

The introduction of the CSTFM is set to have a significant impact on the steel roofing industry. With its advanced technology and superior performance, the machine is expected to become a popular choice for companies looking to enhance their production capabilities and offer a wider range of roofing options to their customers.

The CSTFM is already generating a great deal of interest and excitement within the industry, with many companies expressing a strong desire to incorporate this groundbreaking technology into their operations. With its ability to produce high quality glazed tiles in a wide range of colors and designs, the machine is poised to open up new opportunities for businesses and homeowners alike.

Overall, the Color Steel Glazed Tile Forming Machine is a game-changing product that is set to revolutionize the steel roofing industry. With its advanced technology, impressive performance, and commitment to sustainability, it is clear that this machine will become an essential tool for companies looking to stay ahead of the competition and meet the growing demand for high quality glazed tiles. As the machine continues to gain traction in the market, it is expected to become a key driver of innovation and growth in the steel industry for years to come.

Company News & Blog

Cutting-Edge Z Purlin Machine Unveiled - Discover the Latest Advancements in Structural Manufacturing

[Title]: Advanced Z Purlin Machine Revolutionizes Steel Construction Industry[Subtitle]: Leading Manufacturer Announces Groundbreaking Technology for High-Efficiency Z Purlin Production[Date][City, State]In a technological breakthrough that is set to revolutionize the steel construction industry, [Company Name], a renowned leader in the manufacturing of advanced machinery, has unveiled its latest innovation: the cutting-edge Z Purlin Machine. This state-of-the-art equipment boasts an impressive array of features and improvements that promise to enhance efficiency, productivity, and overall quality in steel construction projects.With over [Number] years of experience in the industry, [Company Name] has built a reputation for cutting-edge machinery that meets the evolving needs of the construction sector. The Z Purlin Machine is the latest addition to their portfolio, demonstrating their commitment to innovation and continuous improvement.Designed by a team of highly skilled engineers, the Z Purlin Machine is set to streamline the process of manufacturing Z purlins, an essential component in steel structures. These purlins, with their unique shape, are widely used in buildings, bridges, warehouses, and various other construction projects for providing structural support.Equipped with the latest technology and engineered to perfection, this machine offers a range of unparalleled advantages over traditional methods. The Z Purlin Machine automates every step of the manufacturing process, from material feeding to cutting and shaping, greatly reducing manual labor and associated costs. Its robust design ensures increased productivity, with the ability to produce Z purlins of precise dimensions at an impressive speed of [Number] per minute.Moreover, this groundbreaking machine is meticulously designed to ensure superior quality and accuracy in every produced Z purlin, ultimately enhancing the overall integrity of steel structures. By leveraging advanced control systems, the Z Purlin Machine guarantees consistent and uniform purlin dimensions, eliminating variations that could compromise the structural integrity of buildings.[Company Name]'s commitment to sustainability shines through in the Z Purlin Machine. This state-of-the-art equipment is not only energy-efficient but also minimizes material waste during production. With intelligent programming, the machine optimizes material usage, reducing scrap and enhancing overall resource efficiency.Recognizing the importance of user-friendliness and the need for seamless integration into existing production lines, [Company Name] has ensured that the Z Purlin Machine is easy to operate and maintain. Its user-friendly interface allows operators to quickly master its functionalities, minimizing downtime. Furthermore, [Company Name] offers comprehensive training programs and prompt after-sales support to cater to the evolving needs of its customers.The introduction of the Z Purlin Machine has already evoked immense excitement within the steel construction industry. Renowned architects, engineers, and construction companies have expressed their eagerness to utilize this cutting-edge machinery to elevate the quality and efficiency of their projects. Pre-orders for the Z Purlin Machine have been pouring in from various markets, indicating widespread confidence in [Company Name]'s expertise and the potential of this groundbreaking innovation.In conclusion, [Company Name] has once again proven its commitment to technological advancement and customer satisfaction with the launch of the Z Purlin Machine. By revolutionizing the process of Z purlin production, this innovative equipment promises to transform the steel construction industry, enhancing efficiency, precision, and sustainability. As the global demand for steel structures continues to rise, [Company Name] remains at the forefront of delivering cutting-edge solutions that empower construction professionals to build a better and more prosperous future.

9ct Rose Gold Cubic Zirconia Full Eternity Stacker Ring with Round Brilliant Cut Channel Set

Title: The Allure of the Stacker for the CZ Purline Machine: Enhancing Your Jewelry CollectionIntroduction: Welcome to our blog on the fascinating world of high-quality jewelry. Today, we will be exploring the captivating style and craftsmanship of the Stacker for the CZ Purline Machine. Specifically, we will delve into the stunning 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring and its timeless appeal that resonates with jewelry enthusiasts around the world. Let's dive into this exceptional piece and discover how it can enhance your personal collection.1. Embracing the Stackable Trend:Stackable rings are a growing phenomenon in the world of fashion jewelry. The versatility of these pieces allows wearers to mix and match, creating unique and personalized combinations. The CZ Purline Machine's Stacker Ring is no exception. Its minimalist design flawlessly harmonizes with other rings, making it an ideal choice for those looking to make a statement.2. The Allure of Rose Gold:Rose gold has experienced a significant resurgence in popularity in recent years, captivating the hearts of fashion-forward individuals everywhere. The warm, rosy hue complements a variety of skin tones, adding a touch of elegance and sophistication to any outfit. With its 9ct composition, the Stacker Ring possesses a delicate balance of durability and subtlety.3. The Timeless Brilliance of Cubic Zirconia:Cubic Zirconia (CZ) is renowned for its remarkable similarity to diamonds, boasting an exceptional brilliance and clarity that make it an affordable alternative. The round brilliant-cut CZ stones in the Stacker Ring are meticulously set using the channel setting technique, ensuring maximum light reflection and an intense sparkle that catches the eye.4. Unmatched Elegance of the Full Eternity Design:The full eternity design of the Stacker Ring is nothing short of breathtaking. The channel-set CZ stones encircle the entirety of the band, symbolizing an everlasting bond and adding a touch of luxury. This timeless design is not only visually stunning but also holds significant sentimental value, making it an excellent choice for special occasions, anniversaries, or as a heartfelt gift.5. Crafting Excellence with CZ Purline Machine:The CZ Purline Machine revolutionizes the world of cubic zirconia jewelry, ensuring precise stone placement and meticulous craftsmanship. By utilizing advanced technology, the Stacker Ring is a testament to the manufacturer's dedication to excellence, resulting in a flawlessly executed piece that is sure to turn heads.Conclusion:In conclusion, the 9ct Rose Gold Cubic Zirconia Round Brilliant Cut Channel Set Full Eternity Stacker Ring is an exceptional addition to any jewelry collection. Its stackable nature allows for endless customization and versatility, while the rose gold and sparkling CZ stones offer timeless appeal. The craftsmanship and attention to detail, facilitated by the CZ Purline Machine, make this ring a true masterpiece. Elevate your style and leave a lasting impression with this stunning piece of jewelry.

High-quality Glazed Tile Roll Forming and Corrugating Machine: Everything You Need to Know

Glazed Tile Roll Forming And Corrugating Machine is a new addition to the production line of {} company, a leading manufacturer of industrial machinery. This state-of-the-art machine is set to revolutionize the process of producing high-quality glazed tiles and corrugated sheets, catering to the growing demand in the construction and roofing industry.The introduction of this machine comes as a strategic move by {} company to expand its product range and meet the evolving needs of its customers. With its advanced technology and precision engineering, the glazed tile roll forming and corrugating machine is designed to deliver superior quality output with maximum efficiency.The machine boasts a sophisticated roll forming system that allows for seamless production of glazed tiles and corrugated sheets, ensuring consistency in shape and dimensions. It is also equipped with a high-speed corrugating mechanism, enabling the production of large volumes of tiles and sheets in a shorter timeframe.One of the key features of the machine is its versatility, allowing for customization of tile and sheet designs to meet specific customer requirements. This flexibility is essential in catering to the diverse aesthetic preferences and functional needs of the construction industry.In addition to its cutting-edge technology, the glazed tile roll forming and corrugating machine is built with durability and reliability in mind. Its robust construction and high-quality components ensure long-term performance and minimal downtime, thus optimizing productivity for {} company and its customers.Furthermore, the machine is designed for ease of operation and maintenance, with user-friendly controls and accessible components. This streamlines the production process and reduces the need for extensive training, enabling {} company to maximize its operational efficiency.The introduction of the glazed tile roll forming and corrugating machine aligns with {} company's commitment to innovation and customer satisfaction. By embracing the latest advancements in manufacturing technology, {} company aims to set new standards in the industry and solidify its position as a leading provider of industrial machinery.In response to the growing demand for glazed tiles and corrugated sheets in the global market, {} company is poised to capitalize on this opportunity with the introduction of the new machine. With its enhanced production capabilities, {} company is well-positioned to cater to the needs of construction companies, roofing contractors, and other stakeholders in the building materials sector.The launch of the glazed tile roll forming and corrugating machine reflects {} company's ongoing investment in research and development, as well as its unwavering dedication to delivering value to its customers. By continuously enhancing its product offerings, {} company is poised to drive growth and create new opportunities in the industrial machinery market.As the construction industry continues to evolve and demand for high-quality building materials rises, the glazed tile roll forming and corrugating machine represents a significant advancement for {} company. By leveraging the machine's capabilities, {} company is well-positioned to meet the evolving needs of its customers and maintain its competitive edge in the market.In conclusion, the introduction of the glazed tile roll forming and corrugating machine signifies a new chapter in the evolution of {} company. With its cutting-edge technology, versatility, and commitment to excellence, the machine is set to make a lasting impact in the construction and roofing industry. As {} company continues to push the boundaries of innovation, the future looks promising for the company and its customers.

Efficient and High-Speed Automatic Slitter for Precision Cutting

Automatic Slitter: Revolutionize the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking innovative solutions to improve production efficiency and maximize output. The introduction of automatic slitter has taken the industry by storm, offering a cutting-edge solution to streamline the slitting process and significantly enhance productivity. This groundbreaking technology has revolutionized the way companies approach their manufacturing operations, setting new standards for precision and speed.The automatic slitter, developed by [Company Name], is a state-of-the-art machine that is designed to automate the slitting process, allowing for seamless and precise cutting of various materials such as paper, film, fabric, and metal. The machine is equipped with advanced sensors and cutting blades, which are capable of performing high-speed and accurate cuts with minimal human intervention. This level of automation not only reduces the chances of human error but also increases the overall efficiency of the manufacturing process.One of the key benefits of the automatic slitter is its ability to handle a wide range of materials with different thickness and properties. This versatility makes it an ideal solution for companies operating in diverse industries, including packaging, textiles, and automotive. Furthermore, the machine's adjustable cutting parameters and user-friendly interface provide operators with the flexibility to customize the cutting process according to specific requirements, ensuring superior quality and consistency in the finished products.The introduction of automatic slitter has not only transformed the manufacturing landscape but has also had a significant impact on the bottom line for many companies. By eliminating the need for manual intervention and reducing material wastage, the machine has helped companies achieve substantial cost savings while also boosting their overall production capacity. This has allowed businesses to meet the growing demands of the market and stay ahead of the competition.In addition to its operational benefits, the automatic slitter also contributes to a safer working environment for operators. The machine's advanced safety features, such as automatic blade guards and emergency stop mechanisms, mitigate the risks associated with manual cutting processes, ensuring a secure and productive working environment.[Company Name]'s automatic slitter has already garnered attention from industry leaders and has been well-received by manufacturing companies worldwide. Its cutting-edge technology and superior performance have positioned it as a game-changer in the industry, setting new standards for efficiency and precision in the manufacturing process.The company's commitment to innovation and continuous improvement has played a pivotal role in the development of this groundbreaking technology. With a team of experienced engineers and experts in the field of manufacturing, [Company Name] has been able to push the boundaries of what is possible and deliver a solution that truly makes a difference for its customers.Looking ahead, [Company Name] is dedicated to further enhancing the capabilities of the automatic slitter and exploring new opportunities to apply its technology in different manufacturing processes. The company is also focused on providing comprehensive training and support to its customers, ensuring they can maximize the benefits of the machine and stay ahead in the rapidly evolving manufacturing landscape.As the demand for efficient and cost-effective manufacturing solutions continues to rise, automatic slitter is poised to play a crucial role in shaping the future of the industry. With its advanced technology, versatility, and operational benefits, the automatic slitter has undoubtedly established itself as a game-changer, offering a compelling case for companies to embrace automation and drive their manufacturing operations to new heights.

How Drip Edge Roll Forming Machines are Advancing Construction Technology

Drip Edge Roll Forming Machine: Innovating the Construction IndustryThe construction industry has seen a significant transformation over the years, and the introduction of advanced machinery has revolutionized the way buildings are constructed. One such innovative piece of equipment is the Drip Edge Roll Forming Machine, which has been making waves in the construction sector. This state-of-the-art machinery is designed to streamline the process of manufacturing drip edge profiles, offering a range of benefits including efficiency, precision, and cost-effectiveness.The Drip Edge Roll Forming Machine is the brainchild of a leading manufacturing company that specializes in producing a wide range of roll forming machinery for various industries. With years of expertise and a strong focus on research and development, the company has established itself as a pioneer in the field of roll forming technology. Their commitment to delivering high-quality, innovative solutions has earned them a stellar reputation among their clients and peers.The Drip Edge Roll Forming Machine is a testament to the company's dedication to continuous improvement and innovation. It is designed to meet the growing demand for high-quality drip edge profiles in the construction industry. The machine features a cutting-edge design that allows for the efficient and precise forming of drip edge profiles, ensuring consistent quality and seamless integration into building structures.One of the key highlights of the Drip Edge Roll Forming Machine is its advanced automation capabilities. The machine is equipped with a user-friendly interface and programmable controls, allowing for easy operation and customization of drip edge profiles. This level of automation not only enhances operational efficiency but also minimizes the risk of errors, resulting in higher productivity and cost savings for construction companies.In addition to its automation features, the Drip Edge Roll Forming Machine is also known for its versatility. It is capable of producing a wide range of drip edge profiles, accommodating various design requirements and specifications. This flexibility makes it an ideal solution for construction projects of all scales, from residential buildings to commercial complexes.Furthermore, the Drip Edge Roll Forming Machine is designed with durability and longevity in mind. It is built using high-quality materials and components, ensuring robustness and reliability even under heavy usage. This durability, combined with the company's excellent after-sales support, provides clients with peace of mind and a solid return on investment.The introduction of the Drip Edge Roll Forming Machine has had a significant impact on the construction industry. It has empowered construction companies to elevate the quality of their buildings while reducing production costs and lead times. By integrating this advanced machinery into their operations, construction firms can stay ahead of the competition and meet the evolving demands of the market.In conclusion, the Drip Edge Roll Forming Machine represents a significant advancement in the construction industry. Its innovative design, advanced automation capabilities, versatility, and durability have set a new standard for manufacturing drip edge profiles. With a strong focus on delivering value and excellence, the company behind this remarkable machinery continues to drive progress in the field of roll forming technology. As the construction sector continues to evolve, the Drip Edge Roll Forming Machine stands as a beacon of innovation, propelling the industry towards a more efficient and sustainable future.

High-quality Steel Profile Manufacturing Machine for Your Business Needs

Color Steel Profile Manufacturing Machine, a leading manufacturer of steel profile manufacturing machinery, has announced the launch of a new series of cutting-edge machines that are set to revolutionize the industry.With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market."We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.

High-precision Slitting Line for Efficient Metal Processing

Cr Slitting Line, a cutting-edge technology used in the manufacturing industry, has recently been installed at the premises of [Company Name]. This new addition to the company's production facilities is expected to enhance the efficiency and precision of the cutting process for various materials, including steel, aluminum, and other metal alloys. The Cr Slitting Line is specifically designed to handle coils of varying widths and thicknesses, allowing for greater flexibility in the manufacturing process. It is equipped with state-of-the-art automation and control systems, ensuring consistent and accurate cutting results. The line also boasts high-speed capabilities, enabling fast and efficient processing of materials.With the installation of the Cr Slitting Line, [Company Name] aims to further improve its production capabilities and meet the growing demand for high-quality cut-to-length products. The company has a strong reputation for delivering precision-engineered metal components to a wide range of industries, including automotive, construction, and manufacturing. The addition of this advanced cutting technology underscores [Company Name]'s commitment to staying at the forefront of innovation in the industry.The Cr Slitting Line is set to revolutionize the cutting process at [Company Name] by enabling faster turnaround times, increased productivity, and improved material utilization. This cutting-edge technology will allow the company to offer a broader range of customized cutting solutions to its diverse customer base, catering to their specific requirements with unparalleled precision and quality.In addition to the technical capabilities of the Cr Slitting Line, [Company Name] is also committed to ensuring the highest standards of safety and environmental responsibility in its operations. The company has implemented rigorous safety protocols and measures to safeguard the well-being of its employees and minimize the environmental impact of its manufacturing processes.The installation of the Cr Slitting Line is a strategic investment for [Company Name] as it positions the company for future growth and expansion in the market. By incorporating this advanced cutting technology into its production facilities, the company is poised to enhance its competitive edge and solidify its position as a leading provider of cut-to-length solutions.The news of the installation of the Cr Slitting Line at [Company Name] has been met with excitement and anticipation within the industry. Customers, suppliers, and industry professionals alike have expressed their confidence in the company's ability to leverage this new technology to deliver even greater value and quality to its stakeholders.In summary, the installation of the Cr Slitting Line at [Company Name] represents a significant milestone in the company's ongoing commitment to innovation and excellence in manufacturing. This cutting-edge technology is set to redefine the company's cutting capabilities and propel it to new heights of success in the industry. With its unparalleled precision, speed, and efficiency, the Cr Slitting Line is poised to transform the way [Company Name] delivers cutting solutions to its customers, setting new standards for quality and performance in the manufacturing sector.

High-Quality Profile Rolling Forming Machine for Efficient Metal Fabrication

Profile Rolling Forming Machine Revolutionizes Manufacturing IndustryThe manufacturing industry has always been at the forefront of technological innovation, constantly seeking new ways to increase efficiency and productivity. One of the latest developments in this area is the introduction of the Profile Rolling Forming Machine by [Company Name], a cutting-edge piece of equipment that is revolutionizing the way metal profiles are manufactured.[Company Name] has been a leader in the manufacturing industry since its inception, providing innovative solutions for metalworking processes. With a reputation for delivering high-quality and reliable machinery, the company has now introduced the Profile Rolling Forming Machine, which is set to have a significant impact on the industry.The Profile Rolling Forming Machine is a highly versatile piece of equipment that is capable of forming a wide variety of metal profiles with different shapes, sizes, and thicknesses. It utilizes advanced technology and precision engineering to produce consistent and high-quality profiles, making it an invaluable tool for manufacturers across various industries.One of the key features of the Profile Rolling Forming Machine is its ability to perform multiple operations in a single pass, significantly reducing production time and costs. This is made possible by the machine's innovative design, which allows for the simultaneous forming, bending, and shaping of metal profiles, eliminating the need for multiple machines and manual labor.In addition to its efficiency, the Profile Rolling Forming Machine also offers a high level of precision and accuracy, ensuring that each profile meets the exact specifications and requirements of the customer. This level of quality control is essential for industries such as automotive, construction, and aerospace, where precision and consistency are critical.Furthermore, the Profile Rolling Forming Machine is equipped with advanced automation features, including computer numerical control (CNC) technology, which allows for seamless integration into existing manufacturing processes. This not only reduces the risk of human error but also improves overall productivity and output.The introduction of the Profile Rolling Forming Machine is a testament to [Company Name]'s commitment to innovation and excellence in the manufacturing industry. With a strong focus on research and development, the company continues to push the boundaries of what is possible, providing its customers with the latest advancements in metalworking technology.The impact of the Profile Rolling Forming Machine is already being felt across the industry, with manufacturers experiencing significant improvements in their production processes. By streamlining operations and increasing efficiency, the machine is helping businesses stay competitive in a constantly evolving market.As the manufacturing industry continues to evolve, the Profile Rolling Forming Machine represents a new standard for metal profile manufacturing. Its advanced capabilities, precision engineering, and automation features make it an essential tool for any manufacturer looking to enhance their production capabilities and stay ahead of the competition.In conclusion, the introduction of the Profile Rolling Forming Machine by [Company Name] is a game-changer for the manufacturing industry. With its innovative design, advanced technology, and exceptional precision, the machine is set to transform the way metal profiles are manufactured, providing businesses with a powerful tool to improve efficiency, quality, and productivity. As the industry continues to embrace the possibilities of this groundbreaking technology, [Company Name] remains at the forefront of innovation, driving the future of manufacturing.

Highly Efficient Coil Slitter Unveils Cutting-Edge Technology for Enhanced Productivity

[Headline]Leading Coil Slitter Company Innovates to Enhance Productivity and Efficiency in the Manufacturing Industry[Subheading]New Technologies and Cutting-edge Automation Solutions Set to Revolutionize Coil Slitting Process[Date][City, State] - Coil Slitter (need remove brand name) has established itself as a global leader in the manufacturing sector, specializing in coil slitting machines that deliver exceptional precision and efficiency. With a commitment to continuous innovation, the company has recently introduced a range of new technologies and cutting-edge automation solutions that promise to revolutionize the coil slitting process.Taking advantage of the latest advancements in robotics, artificial intelligence, and connectivity, Coil Slitter aims to streamline coil processing operations, helping manufacturers maximize productivity and eliminate production bottlenecks. Through this commitment to innovation, the company aims to position itself as the go-to provider for coil slitting solutions globally.Coil Slitter’s state-of-the-art machines boast advanced features designed to meet the diverse needs of manufacturing companies across various industries. The company’s coil slitting machines enable automatic and precise longitudinal cutting of coils, reducing processing time and ensuring consistent width and quality of the finished materials.In an effort to optimize production processes as well as save time and costs, Coil Slitter has implemented smart automation systems across its product line. Real-time data collection, advanced analytics, and machine learning algorithms form the backbone of these systems, allowing manufacturers to monitor and improve their coil slitting operations effectively. These cutting-edge solutions assist manufacturers in identifying and addressing potential issues before they impact product quality or disrupt production schedules.Of particular importance in today's manufacturing landscape is the need for eco-friendly practices. Recognizing this, Coil Slitter has incorporated sustainable features into its machines. Precision control systems in the machines reduce material wastage, resulting in a significant impact on environmental footprints. Furthermore, the company has minimized the energy consumption of its machines, contributing to reduced carbon emissions and operating costs.Coil Slitter places great emphasis on working closely with its clients to understand their specific requirements and challenges. By developing custom solutions, the company ensures optimal performance and flexibility in different manufacturing environments. Combining comprehensive expertise and dedication to customer satisfaction, Coil Slitter has earned a stellar reputation for delivering high-quality, reliable coil slitting machines."Keeping up with technological advancements is crucial to stay ahead of the competition in today's fast-paced manufacturing industry," says John Smith, CEO of Coil Slitter. "Coil Slitter has always been committed to innovation, and our latest range of coil slitting machines and automation solutions represent the next frontier in the industry. We aim to empower manufacturers to increase their productivity, improve their bottom line, and contribute to a sustainable future."Coil Slitter’s coil slitting machines have been successfully implemented in numerous manufacturing facilities worldwide, providing tangible benefits to businesses across the globe. The company's commitment to ongoing research and development ensures that its customers always have access to cutting-edge solutions that keep them ahead of the curve.As the manufacturing industry continues to evolve, Coil Slitter remains dedicated to maintaining its position as a global leader in the coil slitting sector. With an unwavering focus on innovation, customer satisfaction, and sustainability, the company is set to shape the future of coil slitting and enhance the efficiency of the manufacturing industry as a whole.About Coil Slitter:Coil Slitter is a global leader in the manufacturing sector, specializing in coil slitting machines that offer exceptional precision, efficiency, and sustainability. With a commitment to innovation and customer satisfaction, the company delivers cutting-edge coil slitting solutions to manufacturers worldwide. By incorporating state-of-the-art technologies and automation systems, Coil Slitter aims to revolutionize the manufacturing process and drive industry growth.###Note: The brand name mentioned in the template has been removed to comply with the user's request.

Revolutionary Cold Formed Steel Machine Disrupts Construction Industry

Cold Formed Steel Machine: Paving the Way to Innovative Steel ConstructionInvented over a century ago, cold forming is a manufacturing process that has evolved to revolutionize the steel construction industry. Cold formed steel (CFS) offers significant advantages over wood and traditional hot-rolled steel, including durability, sustainability, and adaptability. It's also more cost-effective and easier to install, making it an ideal choice for framing, roofing, and wall panels in commercial and residential buildings.Today, the trend towards offsite construction and modular building is driving the demand for high-quality, precision cold formed steel machines that can deliver the desired outputs in a timely and cost-effective manner. One company that has stepped up to the challenge is [Brand name], a leading supplier of cold formed steel machines and roll forming systems worldwide.With over 20 years' experience in the industry, [Brand name] has gained a reputation for excellence through its innovative and reliable solutions for the production of CFS sections. From stud and track roll forming machines to roof panel and purlin roll forming machines, [Brand name]'s offerings provide the flexibility, accuracy, and speed required to meet various customers' needs.One of [Brand name]'s most popular machines is its patented roll forming system for cold-formed steel frames. This innovative system uses patented software and advanced technologies to produce customized CFS studs, tracks, and joists with precision and efficiency. Unlike traditional roll forming machines, which may require significant setup time and adjustments, [Brand name]'s system can be programmed to produce various sizes and shapes of CFS sections, making it ideal for low-volume, high-mix production runs.Moreover, [Brand name]'s cold formed steel machines are designed with the operator's safety and ease of use in mind. The company's engineers have developed advanced control systems that allow operators to have real-time remote access to the machine's status and performance, minimizing downtime and enhancing productivity. In addition, the machines are equipped with easy-to-use touchscreen interfaces that simplify the setup and configuration process.But what sets [Brand name]'s cold formed steel machines apart from the competition is the company's customer-centric approach that emphasizes collaboration, reliability, and flexibility. When customers choose [Brand name], they don't just get a machine — they get a team of highly qualified engineers and technicians who work closely with them to identify their needs, provide tailored solutions, and ensure the machines meet or exceed their expectations.At [Brand name], customer satisfaction is paramount. That's why the company provides excellent technical support via on-site training, remote assistance, and maintenance services to help customers get the most out of their investment. [Brand name]'s team of experts is also available to provide expert advice on the design, installation, and operation of the machines, as well as the most appropriate materials and accessories to use.As a testament to its commitment to quality and innovation, [Brand name] has received numerous accolades and recognitions over the years. For instance, the company was awarded the prestigious "National Key High-Tech Enterprise" and "Innovative Enterprise" titles by the Chinese government in 2020. These awards recognize [Brand name]'s contributions to the development of the cold formed steel industry and its commitment to advancing the latest technologies and techniques.In summary, the cold formed steel industry is poised for significant growth in the coming years, driven by the need for fast, efficient, and sustainable construction solutions. With its cutting-edge cold formed steel machines and its unwavering dedication to customer service, [Brand name] is well-positioned to help customers unlock the full potential of cold formed steel and to lead the industry forward.