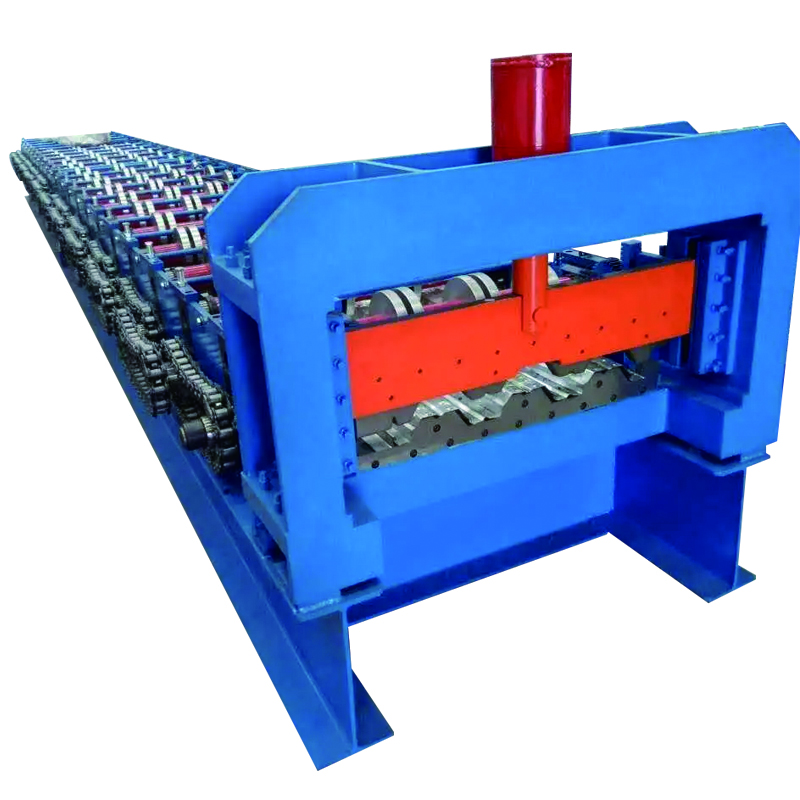

Top Corrugated Steel Sheet Making Machine - Everything You Need to Know

By:Admin

The Corrugated Steel Sheet Making Machine is a result of years of research and development, leveraging the latest technologies to ensure superior quality and performance. The machine is capable of producing corrugated steel sheets with precision and speed, meeting the demands of modern construction projects and manufacturing processes.

One of the key features of the Corrugated Steel Sheet Making Machine is its versatility. It is designed to accommodate a wide range of steel materials, including galvanized steel, pre-painted steel, and aluminum. This flexibility allows our customers to produce a variety of corrugated steel sheets to meet their specific requirements.

In addition to its versatility, the Corrugated Steel Sheet Making Machine is also known for its efficiency. With automated processes and advanced control systems, the machine is able to produce corrugated steel sheets with minimal human intervention, reducing the risk of errors and increasing productivity. This is particularly beneficial for large-scale manufacturing operations where speed and efficiency are of the essence.

Furthermore, the Corrugated Steel Sheet Making Machine is designed with durability in mind. Made from high-quality materials and components, the machine is built to withstand the rigors of heavy-duty use, ensuring a long operational lifespan for our customers. This reliability is a testament to our commitment to providing the best possible solutions for our customers' metal sheet manufacturing needs.

Our dedication to quality and innovation has made [Company Name] a trusted name in the industry. With a track record of delivering cutting-edge solutions to our customers, we are proud to add the Corrugated Steel Sheet Making Machine to our portfolio of products. This machine represents our ongoing commitment to pushing the boundaries of what is possible in metal sheet manufacturing, and we are excited to see the positive impact it will have on our customers' operations.

To support our customers in maximizing the potential of the Corrugated Steel Sheet Making Machine, we also offer comprehensive training and technical support. Our team of experts is available to provide guidance on machine operation, maintenance, and troubleshooting, ensuring that our customers can make the most of this innovative technology.

In conclusion, the Corrugated Steel Sheet Making Machine is set to transform the metal sheet manufacturing industry. With its versatility, efficiency, and durability, it promises to be a game-changer for our customers, enabling them to meet the demands of modern construction and manufacturing with ease. At [Company Name], we are proud to continue leading the way in innovation, and we look forward to the positive impact that the Corrugated Steel Sheet Making Machine will have on our customers' businesses.

Company News & Blog

Interchangeable Purlin Roll Forming Machine Offers Versatile Manufacturing Solutions

C Interchangeable Purlin Roll Forming Machine: A Game Changer in the Steel Manufacturing IndustryThe steel manufacturing industry is constantly evolving, with new technologies and innovations shaping the way steel products are produced. One such innovation is the C Interchangeable Purlin Roll Forming Machine, a revolutionary piece of equipment that is changing the game for steel manufacturers worldwide.The C Interchangeable Purlin Roll Forming Machine is the brainchild of a leading machinery manufacturer, known for its cutting-edge solutions for the metal forming industry. The company has a long-standing reputation for delivering high-quality, reliable, and efficient machinery, and the C Interchangeable Purlin Roll Forming Machine is no exception.This advanced piece of equipment is designed to streamline the production of C-shaped purlins, commonly used in the construction industry for structural support in buildings. With its innovative design and versatile capabilities, the C Interchangeable Purlin Roll Forming Machine is a game-changer for steel manufacturers seeking to enhance their production processes.One of the key features of the C Interchangeable Purlin Roll Forming Machine is its ability to produce C-shaped purlins of varying sizes and dimensions with ease. This level of versatility is a major advantage for steel manufacturers, as it allows them to meet the diverse needs of their customers without the need for multiple machines or complex retooling processes.Furthermore, the C Interchangeable Purlin Roll Forming Machine is equipped with state-of-the-art technology that ensures precision and accuracy in the production process. This results in consistently high-quality purlins that meet industry standards and customer specifications, ultimately enhancing the reputation and reliability of the steel manufacturer.In addition to its impressive capabilities, the C Interchangeable Purlin Roll Forming Machine is known for its efficiency and productivity. Its automated operation and rapid production cycle ensure that steel manufacturers can maximize their output while minimizing production time and labor costs. This level of efficiency is a significant advantage in today's competitive market, where speed and cost-effectiveness are essential for success.The C Interchangeable Purlin Roll Forming Machine is also designed with user-friendly features that make it accessible to operators of varying skill levels. Its intuitive controls and straightforward operation allow for seamless integration into existing production processes, without the need for extensive training or reorganization.Overall, the C Interchangeable Purlin Roll Forming Machine is a powerful tool that is transforming the way steel manufacturers approach the production of C-shaped purlins. Its innovative design, versatile capabilities, precision, efficiency, and user-friendly features make it an invaluable asset for companies looking to stay ahead in the fast-paced steel manufacturing industry.As the demand for steel products continues to grow, the C Interchangeable Purlin Roll Forming Machine is poised to play a crucial role in shaping the future of the steel manufacturing industry. With its ability to enhance productivity, quality, and versatility, this groundbreaking piece of equipment is a testament to the ongoing innovation and advancement within the industry.In conclusion, the C Interchangeable Purlin Roll Forming Machine is a true game-changer for steel manufacturers, offering a competitive edge in an ever-evolving market. Its impact on the industry is undeniable, and it is clear that this revolutionary piece of equipment is set to shape the future of steel manufacturing for years to come.

Manufacture Machine for Glazed Tiles: Roll Forming and Forming Machines from China

Title: Revolutionizing Tile Manufacturing with the Color Steel Glazed Metal Tile Sheet Corrugation MachineIntroduction:In the dynamic landscape of modern construction, the demand for aesthetically pleasing tiles has surged exponentially. This has prompted the development of innovative manufacturing techniques, such as the Color Steel Glazed Metal Tile Sheet Corrugation Machine from Cangzhou Dixin Roll Forming Machine Co., Ltd (brand name omitted). This groundbreaking machinery has revolutionized the process of producing glazed tiles, offering enhanced efficiency, and superior quality. Let's delve into the features and benefits of this advanced roll forming technology.1. Understanding the Glazed Tiles Making Manufacture Machine:The Color Steel Glazed Metal Tile Sheet Corrugation Machine is a state-of-the-art roll forming machine designed to fabricate glazed tiles efficiently and precisely. This advanced technology is equipped with cutting-edge features that simplify the production process, ensuring the manufacture of high-quality glazed tiles.2. High-Speed Production:One of the key advantages of this machine is its remarkable production speed. By integrating cutting-edge automation and intelligent controls, the machine excels in generating an extensive number of tiles within a short span of time. This high-speed production capability ensures timely completion of construction projects, meeting market demand and helping construction companies achieve cost-effectiveness.3. Superior Tile Quality:The Color Steel Glazed Metal Tile Sheet Corrugation Machine guarantees exceptional tile quality due to its advanced design and precision engineering. The machine ensures accurate dimensions, smooth finishes, and consistent color application. Its innovative technology enables the production of uniformly shaped and visually appealing glazed tiles. These high-quality tiles enhance the overall aesthetics of buildings, elevating their charm and value.4. Flexibility in Design:With the Color Steel Glazed Metal Tile Sheet Corrugation Machine, manufacturers can explore various design options, offering customers an expansive range of glazing patterns, colors, and dimensions. This flexibility in design allows for customization, meeting the diverse requirements of architects and homeowners alike. The machine's adaptability further enables the production of unique and exclusive tile designs, delivering a competitive edge in the market.5. Energy Efficiency:In an era where sustainable practices are gaining prominence, the Color Steel Glazed Metal Tile Sheet Corrugation Machine stands out due to its energy-efficient design. The machine's optimized power consumption and minimal material wastage contribute to the reduction of ecological footprints, making it an eco-friendly choice. By aligning with green building practices, manufacturers using this machine can enhance their brand image and fulfill their corporate social responsibilities.6. Durability and Longevity:With its robust construction and utilization of high-quality materials, this glazed tile manufacturing machine ensures durability and longevity. The machine's reliability minimizes downtime, reduces maintenance costs, and provides consistent performance over an extended period. Manufacturers can rely on this machinery to deliver exceptional results consistently, thereby optimizing their production output and profitability.Conclusion:The introduction of the Color Steel Glazed Metal Tile Sheet Corrugation Machine has revolutionized the realm of glazed tile manufacturing. Its cutting-edge features and advanced technology ensure high-speed production, superior quality tiles, design flexibility, energy efficiency, and longevity. By embracing this innovative machine, manufacturers can streamline their operations, gain a competitive advantage, and cater to the ever-growing demand for glazed tiles in the construction industry.Keywords: Color Steel Glazed Metal Tile Sheet Corrugation Machine, glazed tiles, manufacturing, roll forming machine, sustainable practices, design flexibility, high-speed production, superior tile quality, energy efficiency, durability.

High-quality Pultrusion Machine for FRP Cable Trays

The FRP Cable Tray Pultrusion Machine is a cutting-edge piece of equipment that is being hailed as a game changer in the manufacturing industry. This innovative machine, which is manufactured by an industry-leading company, is designed to produce high-quality FRP cable trays with enhanced durability and strength.The pultrusion process is a manufacturing method that involves pulling and shaping continuous fiber reinforcements through a liquid resin bath. This process results in a high-strength, lightweight, and corrosion-resistant product that is ideal for a wide range of industrial applications. The FRP Cable Tray Pultrusion Machine utilizes advanced technology to precisely control the pultrusion process, ensuring that the resulting cable trays meet the highest quality standards.With the growing demand for durable and corrosion-resistant cable management systems, the FRP Cable Tray Pultrusion Machine is poised to revolutionize the industry. The machine is capable of producing a wide range of cable tray profiles, including ladder, perforated, and solid-bottom designs, to accommodate various installation requirements. Additionally, the machine can be customized to produce cable trays in different widths, depths, and load capacities, making it a versatile solution for diverse project specifications.The company behind the FRP Cable Tray Pultrusion Machine is a renowned industry leader with a proven track record of delivering innovative solutions for the composite manufacturing sector. With years of experience and expertise in pultrusion technology, the company has earned a reputation for producing high-quality machinery that meets the evolving needs of the market.In addition to the FRP Cable Tray Pultrusion Machine, the company offers a comprehensive range of pultrusion equipment and systems for various applications, including structural profiles, grating, rods, and tubes. The company's commitment to research and development has led to the continual advancement of its pultrusion machinery, ensuring that customers receive state-of-the-art solutions that deliver superior performance and reliability.The FRP Cable Tray Pultrusion Machine is equipped with advanced features that enhance productivity and efficiency. Its automated control system allows for precise monitoring and adjustment of the pultrusion parameters, ensuring consistent product quality and dimensional accuracy. The machine's robust construction and durable components contribute to its reliability and long-term performance, making it a valuable investment for manufacturers seeking to streamline their production processes.Moreover, the company provides comprehensive technical support and training services to assist customers in maximizing the potential of the FRP Cable Tray Pultrusion Machine. From installation and commissioning to maintenance and troubleshooting, the company's team of experts is dedicated to ensuring that customers achieve optimal results with their pultrusion equipment.As the demand for high-performance cable management solutions continues to grow, the FRP Cable Tray Pultrusion Machine is poised to be a valuable asset for manufacturers looking to stay ahead in the market. Its ability to deliver superior quality, flexibility, and efficiency makes it a standout solution for producing FRP cable trays that meet the stringent requirements of modern industrial and commercial projects.In conclusion, the FRP Cable Tray Pultrusion Machine represents a significant advancement in pultrusion technology, offering manufacturers a competitive edge in producing high-quality and durable cable management systems. With the backing of a leading industry player, this innovative machine is set to make a lasting impact on the composite manufacturing sector, driving efficiency and excellence in cable tray production.

Guide to Choosing a Metal Roof Forming Machine

Metal Roof Forming Machine Innovates the Roofing IndustryAs the roofing industry continues to evolve, the demand for high-quality, durable, and efficient metal roofing materials has seen a significant rise in recent years. With this increasing demand, companies like [Company Name] have stepped up to the plate to provide cutting-edge solutions to meet the industry's needs. [Company Name] has recently unveiled their latest innovation – the Metal Roof Forming Machine, a technology that is set to revolutionize the way metal roofing materials are manufactured.The Metal Roof Forming Machine is a state-of-the-art piece of equipment that is designed to streamline the process of forming metal roofing materials. This machine boasts a number of advanced features that set it apart from traditional metal forming equipment, making it an indispensable tool for roofing manufacturers looking to improve their production processes.One of the standout features of the Metal Roof Forming Machine is its high level of automation. This machine is equipped with advanced computerized controls that allow for precise and efficient metal forming, reducing the margin of error and ensuring consistently high-quality finished products. This level of automation also means that the machine requires minimal human intervention, resulting in lower labor costs and a more efficient production line overall.In addition to its automation capabilities, the Metal Roof Forming Machine also offers a high level of flexibility. This machine is capable of producing a wide range of metal roofing materials, including panels of different sizes, shapes, and profiles. This versatility allows manufacturers to meet the diverse needs of their customers without having to invest in multiple pieces of equipment, making it a cost-effective solution for businesses of all sizes.Furthermore, the Metal Roof Forming Machine is designed with the end user in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and oversee the metal forming process, reducing the need for extensive training or specialized expertise. This accessibility ensures that manufacturers can quickly integrate the machine into their existing production line, minimizing downtime and maximizing productivity.With the introduction of the Metal Roof Forming Machine, [Company Name] has solidified its position as a leader in the roofing industry. This innovative technology is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing of roofing materials, and represents a significant step forward for the industry as a whole.In addition to its cutting-edge technology, [Company Name] also prides itself on its commitment to sustainability and environmental responsibility. The Metal Roof Forming Machine is designed to minimize material waste and energy consumption, making it a greener alternative to traditional metal forming methods. By reducing the environmental impact of the manufacturing process, [Company Name] is demonstrating its dedication to developing solutions that are not only efficient and cost-effective but also environmentally friendly.The Metal Roof Forming Machine is already making waves in the roofing industry and has garnered significant interest from manufacturers looking to improve their production processes. With its advanced features, flexibility, and commitment to sustainability, this technology is set to redefine the way metal roofing materials are manufactured, setting a new standard for the industry as a whole.In conclusion, the Metal Roof Forming Machine from [Company Name] represents a significant leap forward for the roofing industry. With its advanced technology, efficiency, and sustainability, this innovation is set to revolutionize the way metal roofing materials are manufactured, providing manufacturers with a cost-effective, user-friendly, and environmentally responsible solution. As the demand for metal roofing continues to grow, the Metal Roof Forming Machine is poised to play a pivotal role in shaping the future of the industry.

High-Quality Glazed Tile Roll Forming Machine Supplier in China - Extensive Product Range

Title: Enhancing Roof Aesthetics with Color Steel Glazed Tile Roof Panel Roll FormerIntroductionWith the growing popularity of glazed tile roofing panels, both in residential and commercial buildings, the demand for efficient and reliable machinery that can manufacture them is on the rise. In this blog post, we will explore the benefits and features of a Color Steel Glazed Tile Roof Panel Roll Former, which is a leading product in the market. This advanced roll forming machine allows manufacturers to produce high-quality glazed tile roof panels with ease. Section 1: Understanding Glazed Tile Roll Forming MachineA Glazed Tile Roll Forming Machine is a specialized equipment designed to transform raw materials, typically color steel, into glazed tile roof panels. This roll forming process involves feeding the steel sheet through a series of rollers that gradually shape and form the desired profile. The result is a strong, aesthetically pleasing, and weather-resistant tile, perfect for enhancing the overall appearance of any building.Section 2: Key Features and Advantages2.1. Precision Manufacturing: The Color Steel Glazed Tile Roof Panel Roll Former ensures precise molding and sizing of glazed tile panels, thanks to its innovative design and cutting-edge technology. The machine guarantees consistent panel quality, reducing the chances of any defects or inconsistencies.2.2. Versatility: This roll forming machine can manufacture various styles and profiles of glazed tiles, catering to the diverse needs of customers. From traditional curved designs to modern flat styles, the machine offers exceptional flexibility and customization options.2.3. Efficiency and Speed: With the ability to operate at high speeds, the roll former significantly increases productivity, allowing manufacturers to meet tight production deadlines. The fast and efficient production process helps minimize labor costs and maximize overall output.2.4. Durability: The construction of the Color Steel Glazed Tile Roof Panel Roll Former is robust and durable, ensuring a longer lifespan. Its strong framework and high-quality components enable continuous and reliable operation, reducing downtimes and maintenance requirements.Section 3: Benefits for Manufacturers3.1. Cost-Effective Solution: Investing in a Glazed Tile Roll Forming Machine eliminates the need for outsourcing tile manufacturing, resulting in substantial cost savings for manufacturers in the long run. The machine's high efficiency and minimal material wastage contribute to further economic advantages.3.2. High-Quality Output: The precision and consistency offered by the roll former ensure that every glazed tile produced is of superior quality. Manufacturers can deliver a premium product that meets the market's high standards, enhancing their reputation and customer satisfaction.3.3. Customization Possibilities: The versatility of the machine enables manufacturers to cater to specific customer requirements. From different colors to various tile sizes and profiles, customization options are limitless, allowing for greater market competitiveness.3.4. Reduced Carbon Footprint: As the Color Steel Glazed Tile Roof Panel Roll Former operates based on energy-efficient principles, it helps reduce the overall carbon footprint of manufacturers. This commitment to sustainability aligns with the growing demand for eco-friendly construction materials and practices.ConclusionInvesting in a Color Steel Glazed Tile Roof Panel Roll Former is a wise choice for manufacturers aiming to expand their product offerings, increase productivity, and enhance the overall quality of their glazed tile roof panels. With its precision manufacturing, versatility, efficiency, and durability, this robust machinery can take roofing aesthetics and functionality to new heights. By embracing modern roll forming technology, manufacturers can stay ahead of the competition and meet the ever-growing demand for glazed tile roofing products.

New Study Reveals Surprising Findings in the Roll Forming Industry

Total Roll Forming, a leading manufacturer of roll forming and metal shaping solutions, has recently announced the expansion of its operations to meet the increasing demand for its products and services. The company, known for its innovative and high-quality solutions, has a long-standing reputation in the industry for providing reliable and cost-effective roll forming technology.With the expansion of its operations, Total Roll Forming is set to further solidify its position as a top provider of roll forming solutions. The company's state-of-the-art manufacturing facilities, coupled with its team of experienced engineers and technicians, enable it to offer a wide range of roll forming capabilities to meet the needs of diverse industries.Total Roll Forming's roll forming solutions are used in various applications, including automotive, construction, aerospace, and appliance industries. The company's expertise in custom roll forming enables it to cater to the specific needs of its clients, offering tailored solutions that meet the highest standards of quality and precision.Furthermore, Total Roll Forming is committed to sustainability and environmentally friendly manufacturing practices. The company continuously invests in research and development to improve its processes and reduce its environmental footprint. This commitment to sustainability has earned Total Roll Forming a reputation as an industry leader in eco-friendly roll forming solutions.In addition to its manufacturing capabilities, Total Roll Forming provides comprehensive support and services to its clients. From design and engineering to prototyping and production, the company works closely with its customers to ensure that their exact specifications are met. Total Roll Forming's dedication to customer satisfaction has resulted in long-lasting partnerships with some of the most renowned companies in the industry.Total Roll Forming's expansion comes at a time when the demand for roll forming solutions is on the rise. The company's ability to offer custom roll forming solutions that are tailored to the unique requirements of its clients has set it apart from its competitors. As a result, Total Roll Forming has experienced significant growth in recent years and is now well-positioned to capitalize on the increasing demand for its products and services."We are excited to announce the expansion of our operations to better serve our clients and meet the growing demand for our roll forming solutions," said [Company Spokesperson]. "Total Roll Forming is committed to providing innovative, high-quality, and sustainable solutions to our customers, and we believe that our expanded capabilities will enable us to further enhance our offerings and solidify our position as a leader in the industry."Total Roll Forming's expansion is a testament to the company's commitment to excellence and its determination to meet the evolving needs of its clients. With its expanded operations, Total Roll Forming is poised to continue setting the standard for roll forming technology and shaping the future of the industry.

High-Quality Glazed Tile Panel Roll Forming and Corrugation Machine for Efficient Production

Introducing the Latest Glazed Tile Panel Roll Forming And Corrugation Machine from Industry LeaderIn today's rapidly evolving construction industry, the demand for efficient and high-quality manufacturing equipment is at an all-time high. With the need for faster production and higher precision, companies are constantly seeking the latest technology to stay ahead of the curve. That's where the new Glazed Tile Panel Roll Forming And Corrugation Machine from {Company Name} comes in.With a rich history of serving the construction industry with top-notch machinery, {Company Name} is proud to introduce the latest addition to their lineup - the Glazed Tile Panel Roll Forming And Corrugation Machine. This state-of-the-art machine is designed to revolutionize the manufacturing process for glazed tile panels, offering unparalleled precision and efficiency.The machine is equipped with advanced roll forming and corrugation technology, allowing for seamless production of glazed tile panels with consistent quality and precise measurements. This innovative technology not only streamlines the manufacturing process but also ensures that every panel produced meets the highest industry standards.One of the key features of the Glazed Tile Panel Roll Forming And Corrugation Machine is its versatility. With the ability to produce a wide range of panel sizes and shapes, this machine can cater to the diverse needs of the construction industry. Whether it's for residential, commercial, or industrial applications, the machine can adapt to various requirements, making it a valuable asset for manufacturers.In addition to its impressive capabilities, the Glazed Tile Panel Roll Forming And Corrugation Machine also prioritizes user-friendly operation. With intuitive controls and a user-friendly interface, operators can easily navigate through the machine's functions, ensuring smooth and hassle-free production. This not only saves time but also minimizes the risk of errors, resulting in a more efficient manufacturing process.Furthermore, {Company Name} is committed to providing exceptional after-sales support for their customers. From installation and training to maintenance and troubleshooting, their team of experts is dedicated to ensuring that the Glazed Tile Panel Roll Forming And Corrugation Machine operates at its best, maximizing productivity and minimizing downtime.{Company Name} has a long-standing reputation for delivering cutting-edge machinery to the construction industry, and the Glazed Tile Panel Roll Forming And Corrugation Machine is a testament to their commitment to innovation. By investing in this state-of-the-art equipment, manufacturers can expect to elevate their production capabilities and stay ahead of the competition.With the introduction of the Glazed Tile Panel Roll Forming And Corrugation Machine, {Company Name} continues to be at the forefront of providing advanced solutions to the construction industry. Their dedication to excellence and customer satisfaction sets them apart as a trusted partner for manufacturers seeking the best-in-class machinery.In conclusion, the Glazed Tile Panel Roll Forming And Corrugation Machine from {Company Name} is set to make a significant impact on the manufacturing process for glazed tile panels. Its advanced technology, versatility, user-friendly operation, and exceptional support make it a must-have investment for construction industry manufacturers. As the industry continues to evolve, {Company Name} remains a reliable source for innovative solutions, empowering manufacturers to achieve new heights of success.

Highly Efficient Steel Sheet Roller Forming Machine for Automated Production

Automatic Steel Sheet Roller Forming MachineIn the world of industrial machinery, the demand for efficiency and precision is constantly increasing. This has led to the development of advanced technology that can streamline production processes and improve the overall quality of output. One such advancement is the Automatic Steel Sheet Roller Forming Machine, which has been making waves in the manufacturing industry for its ability to produce high-quality steel sheet products with unparalleled accuracy and speed.The Automatic Steel Sheet Roller Forming Machine, developed by [Company Name], is a cutting-edge piece of equipment that is designed to revolutionize the way steel sheets are manufactured. With its advanced automation and precise control systems, this machine is capable of processing steel sheets with utmost precision and consistency, delivering products of superior quality while minimizing human error.The machine is equipped with a set of rollers that are designed to bend and shape steel sheets with extreme precision. These rollers are powered by a high-performance motor and are controlled by a sophisticated computer system that ensures every bend and fold is executed with utmost accuracy. This level of precision allows for the creation of complex and intricate steel sheet products that meet the highest standards of quality and craftsmanship.In addition to its precision, the Automatic Steel Sheet Roller Forming Machine is also designed for efficiency. Its advanced automation capabilities allow for seamless operations, reducing the need for manual intervention and increasing productivity. This means that manufacturers can produce a higher volume of steel sheet products in a shorter amount of time, ultimately improving their overall output and profitability.To further enhance its efficiency, the machine is also equipped with a user-friendly interface that allows operators to easily program and control its operations. This intuitive interface simplifies the machine's setup and operation, making it accessible to a wide range of operators with varying levels of experience and expertise.Moreover, the Automatic Steel Sheet Roller Forming Machine is also designed for versatility. It is capable of producing a wide range of steel sheet products, from simple bends and folds to more intricate and complex designs. This flexibility allows manufacturers to meet the diverse needs of their customers and expand their product offerings, ultimately enhancing their competitiveness in the market.[Company Name] is a leading manufacturer of industrial machinery, with a strong focus on innovation and quality. With a track record of delivering cutting-edge solutions to the manufacturing industry, [Company Name] has established itself as a trusted partner for businesses seeking to enhance their production processes and streamline their operations.The development of the Automatic Steel Sheet Roller Forming Machine is a testament to [Company Name]'s commitment to driving innovation in the manufacturing industry. By leveraging its expertise in industrial machinery and technology, [Company Name] has succeeded in developing a state-of-the-art solution that is set to redefine the way steel sheet products are manufactured.With its precision, efficiency, and versatility, the Automatic Steel Sheet Roller Forming Machine represents a significant leap forward in the manufacturing industry. It promises to revolutionize the production of steel sheet products, offering manufacturers a competitive edge in delivering high-quality products with unparalleled precision and speed.As the demand for high-quality steel sheet products continues to grow, the Automatic Steel Sheet Roller Forming Machine is poised to become an indispensable tool for manufacturers seeking to meet the evolving needs of the market. With its advanced technology and cutting-edge capabilities, this machine is set to transform the way steel sheets are manufactured, setting new standards for quality, efficiency, and productivity in the industry.

Durable Light Gauge Steel Roll Forming Machine for Efficient Construction

Title: Leading the Industry in Light Gauge Steel Roll Forming MachinesIn recent years, the construction industry has been undergoing a significant transformation with the increasing use of light gauge steel in modern building design. As a result, there has been a growing demand for advanced manufacturing technology, such as the Light Gauge Steel Roll Forming Machine, to cater to this evolving industry need. One company that has been at the forefront of this technological innovation is {}.{} has been a leader in the manufacturing and supply of advanced roll forming machines for various industries, including the construction sector. With a strong focus on research and development, the company has continuously adapted its technology to meet the changing demands of the market, especially in the realm of light gauge steel roll forming.The Light Gauge Steel Roll Forming Machine developed by {} is a state-of-the-art equipment designed to efficiently produce high-quality light gauge steel products. The machine is equipped with advanced features such as precision rollers, automated control systems, and quick-change tooling, allowing for seamless and accurate production of a wide range of steel profiles. This level of precision and reliability has positioned {} as a trusted partner for companies looking to enhance their manufacturing capabilities in the light gauge steel sector.One of the key advantages of the {} Light Gauge Steel Roll Forming Machine is its versatility. With the capability to produce a diverse range of profiles, including studs, tracks, furring channels, and wall panels, the machine offers unparalleled flexibility to meet the unique requirements of different construction projects. This adaptability has made {} a preferred choice for manufacturers and contractors seeking a comprehensive solution for their light gauge steel forming needs.In addition to its cutting-edge technology, {} is also known for its commitment to quality and customer satisfaction. The company places a strong emphasis on rigorous quality control measures throughout the manufacturing process, ensuring that each roll forming machine meets the highest standards of performance and reliability. Furthermore, {} provides comprehensive training and technical support to its customers, empowering them to maximize the potential of the equipment and achieve optimal production efficiency.With a global presence, {} has established itself as a leading provider of light gauge steel roll forming solutions, serving a diverse clientele across different regions. The company's dedication to innovation and customer-centric approach has earned it a solid reputation in the industry, setting it apart as a trusted and dependable partner for businesses looking to invest in advanced roll forming technology.As the construction industry continues to evolve, the demand for advanced manufacturing solutions such as the Light Gauge Steel Roll Forming Machine is expected to grow significantly. In response to this trend, {} remains at the forefront of technological development, consistently updating and enhancing its equipment to meet the evolving needs of the market. By leveraging its expertise and industry knowledge, {} is well-positioned to continue leading the industry in the realm of light gauge steel roll forming machines.In conclusion, {} has solidified its position as a leading provider of light gauge steel roll forming machines, offering advanced technology, versatility, and unparalleled customer support to its global clientele. With a strong commitment to innovation and quality, the company is poised to play a pivotal role in shaping the future of the construction industry through its cutting-edge manufacturing solutions.