Top-quality Corrugated Roof Sheet Roll Forming Machine for Your Construction Needs

By:Admin

The roofing industry is constantly evolving, and new innovations in technology and machinery are essential for meeting the demands of this dynamic market. One such innovation is the Corrugated Roof Sheet Roll Forming Machine, which has been developed to provide an efficient solution for producing high-quality corrugated roof sheets. This cutting-edge machine is designed to streamline the production process while ensuring precision and consistency in the final product.

The Corrugated Roof Sheet Roll Forming Machine is manufactured by a leading company in the field of machinery and equipment for the construction industry. With decades of experience and a strong commitment to innovation, the company has established itself as a trusted provider of high-quality solutions for various construction needs. The Corrugated Roof Sheet Roll Forming Machine is a testament to the company's dedication to delivering advanced technology that meets the evolving requirements of the roofing industry.

This state-of-the-art machine is equipped with advanced features that make it an ideal choice for producing corrugated roof sheets. Its high-speed production capabilities allow for increased output, making it suitable for large-scale manufacturing operations. The machine's precision engineering ensures that every sheet produced meets the required specifications, with consistent corrugation and straight edges. This level of precision is essential for ensuring the integrity and durability of the finished roof sheets.

In addition to its efficiency and precision, the Corrugated Roof Sheet Roll Forming Machine is also designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make it simple to operate, reducing the need for extensive training and minimizing the potential for errors during production. Furthermore, the machine's robust construction and durable components contribute to its reliability, ensuring minimal downtime and consistent performance.

The Corrugated Roof Sheet Roll Forming Machine is designed to accommodate various material specifications, making it suitable for a wide range of roofing applications. Whether producing sheets from aluminum, steel, or other materials, this versatile machine can adapt to different requirements, providing flexibility for manufacturers and contractors. This adaptability is crucial for meeting the diverse needs of the roofing industry and catering to different project specifications.

The introduction of the Corrugated Roof Sheet Roll Forming Machine represents a significant advancement in the production of corrugated roof sheets. Its combination of efficiency, precision, and versatility makes it a valuable asset for manufacturers and contractors seeking to enhance their capabilities and meet the growing demands of the roofing market. With this innovative machine, businesses can optimize their operations and deliver superior quality roof sheets to their customers.

As the roofing industry continues to evolve, the demand for advanced machinery and equipment will only increase. The Corrugated Roof Sheet Roll Forming Machine stands as a testament to the ongoing innovation in this sector, providing a solution that addresses the industry's evolving needs. With its cutting-edge technology and reliable performance, this machine is poised to make a significant impact on the production of corrugated roof sheets, setting a new standard for efficiency and quality in the roofing industry.

Company News & Blog

High-Quality Roofing Roll Forming Machines for Steel Material

Steel Roofing Roll Forming Machines have become an essential part of the construction and roofing industry, providing a fast and efficient way to produce high-quality metal roofing and cladding panels. These machines are designed to efficiently transform metal coils into perfectly shaped roofing panels, providing a cost-effective and durable solution for a variety of buildings and structures.One of the leading manufacturers of Steel Roofing Roll Forming Machines, {}, has been at the forefront of technological innovation and industry expertise. With a strong focus on research and development, the company has continuously improved and updated its product line to meet the evolving needs of the construction industry.The importance of Steel Roofing Roll Forming Machines in the construction industry cannot be overstated. These machines have revolutionized the way metal roofing and cladding panels are produced, offering a highly efficient and cost-effective solution for roofing contractors and building owners. By using Steel Roofing Roll Forming Machines, manufacturers can produce large quantities of roofing panels with minimal waste and labor, resulting in significant cost savings for their customers.The versatility of Steel Roofing Roll Forming Machines also allows for the production of a wide range of roofing profiles, including standing seam, corrugated, and concealed-fastener panels. This flexibility enables manufacturers to meet the unique design and performance requirements of different building projects, from residential homes to commercial and industrial facilities. Furthermore, the precision and consistency provided by these machines ensure that each panel meets the highest standards of quality and durability.In addition to their efficiency and versatility, Steel Roofing Roll Forming Machines are also known for their durability and low maintenance requirements. Built with high-quality materials and advanced engineering, these machines are designed to withstand the rigors of continuous use in demanding manufacturing environments. This durability ensures that manufacturers can rely on their Steel Roofing Roll Forming Machines to consistently deliver high-quality roofing panels, year after year.Furthermore, {} has established itself as a trusted and reliable partner for manufacturers worldwide. With a strong commitment to customer satisfaction, the company provides comprehensive support and training to ensure that customers can maximize the performance of their Steel Roofing Roll Forming Machines. This includes installation and commissioning services, as well as ongoing technical assistance and spare parts availability.As the construction industry continues to evolve and demand for high-quality, cost-effective roofing solutions grows, Steel Roofing Roll Forming Machines will play a crucial role in meeting these needs. With their ability to efficiently produce a wide range of roofing profiles, while delivering exceptional quality and durability, these machines are well-positioned to remain a key technology in the construction industry for years to come.In conclusion, Steel Roofing Roll Forming Machines have become an indispensable tool for the modern construction industry. With their efficiency, versatility, and durability, these machines enable manufacturers to produce high-quality metal roofing panels in a cost-effective and sustainable manner. As a leading manufacturer of Steel Roofing Roll Forming Machines, {} continues to drive innovation and excellence, ensuring that its customers can meet the evolving demands of the construction industry with confidence and success.

High-Quality Roof Sheet Forming Machines and Roll Forming Machines for Sale in China

Roof Sheet Forming Machine Manufacturer in China: Leading the Industry with Quality ProductsAs the construction industry continues to grow at an unprecedented pace, the demand for high-quality building materials and machinery continues to increase. One of these essential machines is the roof sheet forming machine, which plays a vital role in the production of roofing sheets for various commercial and industrial buildings.Enterprises in China are known for producing top-notch roofing sheet forming machines that ensure quality roofing sheets that meet customer specifications. Among these manufacturers is (remove brand name), which has been at the forefront of producing cutting-edge machinery for sheet metal fabrication, roofing, and cladding.With years of experience in the industry, (remove brand name) has developed into a reliable and trustworthy partner for clients from all over the world. Their roof sheet forming machines are world-class, featuring advanced technology that ensures the production of high-quality roofing sheets and panels that meet or exceed industry standards.The Roof Sheet Forming MachineRoofing sheet forming machines, also known as roof panel roll forming machines, are specialized machines designed for the production of roofing sheets and panels. These machines work by passing strips of metal through a series of rollers, which gradually form the sheet or panel into the desired shape.Roofing sheets produced from these machines are used for a variety of building applications. They are an ideal choice for commercial, industrial, and residential buildings that require lightweight, durable, and flexible roofing materials.Roof sheet forming machines vary in size, capacity, and level of automation. At (remove brand name), the company offers a range of roofing sheet forming machines, including the Step Tile Roof Forming Machine, Corrugated Sheet Forming Machine, and Trapezoidal Sheet Forming Machine.Each of these machines has been designed to provide customers with a unique solution tailored to their needs and preferences. They are constructed using the latest technology, ensuring consistent quality and performance.Company Introduction: (remove brand name)Founded in 2009, (remove brand name) has grown to become one of the leading manufacturers of roofing sheet forming machines in China. Over the past decade, the company has continued to innovate its products, incorporating the latest technology and design features to ensure that their customers receive nothing but the best.At (remove brand name), the focus has always been on providing customers with products that meet and exceed their expectations. The company is committed to delivering quality machinery that is both reliable and cost-effective.The company's production facilities are equipped with state-of-the-art machinery that enables it to produce high-quality roofing sheet forming machines at competitive prices. The team of engineers and technicians at (remove brand name) are highly skilled and knowledgeable, and they work tirelessly to ensure that every machine is manufactured to the highest standards.Quality Assurance and Certifications(Insert company name) is committed to providing its customers with quality products that meet industry standards. The company has implemented a comprehensive quality assurance system that covers every stage of the production process.To ensure that its machines are of the highest quality, (remove brand name) works with accredited and reputable testing and certification agencies. All their machines are rigorously tested to ensure compliance with relevant regulations and certification standards, such as CE, ISO, and SGS.In conclusion, (remove brand name) has established itself as a leading manufacturer of roofing sheet forming machines in China. With a focus on quality, innovation, and customer satisfaction, the company continues to set the standards for the industry. By choosing them as a partner, customers can rest assured that they will receive nothing but the best roofing sheet forming machines.

How to Build a Sheet Metal Barn in 6 Simple Steps

Title: How to Build a Sheet Metal Barn in 6 Easy StepsIntroduction:Sheet metal barns provide an excellent solution for storage and shelter needs. Not only are they durable and cost-effective, but they can also be constructed relatively easily. In this article, we will outline a step-by-step guide on how to build a sheet metal barn in six simple steps. Whether you have experience in construction or are a DIY enthusiast, this guide will help you create your very own sheet metal barn.Step 1: Planning and PreparationBefore starting any project, careful planning is essential. Determine the size and design of your barn based on your requirements. Take measurements of the desired area and sketch out the barn's layout. Consult local building codes and acquire any necessary permits. Once you have a clear plan, gather the required materials.Step 2: Foundation and Frame ConstructionCreate a solid foundation for your sheet metal barn. Excavate the area, level the ground, and lay a sturdy foundation using concrete or treated wood. Next, construct the frame using the plywood pallets. Cut them to the desired size and connect them securely using screws and nuts, ensuring stability and durability.Step 3: Installing RoofingSelect the appropriate sheet metal for the roofing of your barn. Galvanized sheet metal provides excellent protection against rust and corrosion. Measure and cut the sheet metal to fit the roof frame, leaving a slight overhang for drainage. Secure the roofing sheets to the frame using screws or nails, ensuring proper alignment and sealing.Step 4: Wall ConstructionMeasure and cut additional plywood panels to serve as walls for your sheet metal barn. Attach them securely to the frame, leaving space for doors and windows as needed. Ensure tight joints and smooth surfaces for a professional finish.Step 5: Doors and WindowsInstall suitable doors and windows into the wall structure. Depending on your requirements, you can choose ready-made options or customize your own. Ensure proper insulation and weatherproofing to protect your belongings from the elements.Step 6: Finishing TouchesTake time to inspect your sheet metal barn for any loose screws or nails. Replace or tighten them as necessary. Consider adding ventilation systems, gutters, or additional storage options such as shelves or hooks. Apply a protective finish, such as paint or weather-resistant coatings, to increase the longevity and aesthetics of your barn.Conclusion:Building a sheet metal barn is a satisfying project that offers both functionality and durability. By following these six easy steps, you can construct your own barn and enjoy the benefits of efficient storage and shelter. Whether you are a DIY enthusiast or a seasoned builder, creating a sheet metal barn can be achieved with the right materials, tools, and patience. Embrace your creativity and get started on your own sheet metal barn project today!

Efficient Sheet Roll Forming Solutions for Your Business

The Sheet Roll Forming Process: A Revolution in Metal FabricationMetal fabrication has long been an essential part of the manufacturing industry, with various methods and technologies continually evolving to meet the increasing demands of modern production. One such innovation is the sheet roll forming process, a highly efficient and versatile method that has revolutionized the way metal sheets are manipulated and shaped.Sheet roll forming involves feeding a metal sheet through a series of roll forming stations, where it is gradually bent, shaped, and formed into the desired profile. Unlike traditional metal fabrication methods such as cutting, stamping, or punching, sheet roll forming allows for continuous and precise shaping of the metal, resulting in a superior quality of the finished product.The process begins with a flat metal sheet being fed into the first set of rolls, where it is gradually bent and formed into the desired shape. As the sheet progresses through each roll forming station, additional features such as holes, slots, and flanges can be added, resulting in a fully formed and customized metal component. The entire process is controlled by a series of precision-engineered rollers and dies, ensuring that the final product meets the exact specifications of the design.The advantages of sheet roll forming are numerous, making it an indispensable tool for a wide range of industries. Due to its ability to produce complex and intricate shapes with minimal waste, sheet roll forming is highly cost-effective and can significantly reduce manufacturing time and labor costs. Additionally, the process allows for the use of a variety of metals, including steel, aluminum, and copper, further expanding its applicability across different industries.The benefits of sheet roll forming are not lost on the manufacturing industry, prompting companies to invest in state-of-the-art roll forming equipment to capitalize on its advantages. One such company that has embraced sheet roll forming is {}, a leading provider of metal fabrication solutions. With a strong focus on innovation and technology, {} has integrated sheet roll forming into its manufacturing processes, allowing for the production of highly intricate and customized metal components.{}'s sheet roll forming capabilities have enabled the company to expand its product offerings and cater to a wider range of industries, including automotive, construction, and aerospace. By leveraging the efficiency and precision of sheet roll forming, {} has been able to meet the exacting requirements of its customers, delivering high-quality metal components that meet or exceed industry standards.In addition to its manufacturing capabilities, {} has also invested in research and development to further enhance its sheet roll forming processes. By staying at the forefront of technological advancements, {} continues to push the boundaries of metal fabrication, offering innovative solutions that address the evolving needs of the industry.As the demand for complex and customized metal components continues to grow, sheet roll forming is poised to play a pivotal role in shaping the future of metal fabrication. With its ability to produce high-quality, intricate, and cost-effective metal components, sheet roll forming has become an indispensable tool for manufacturers seeking to stay ahead in a competitive marketplace.In conclusion, sheet roll forming represents a significant advancement in metal fabrication, offering unparalleled efficiency, precision, and versatility. With companies like {} at the forefront of this technology, the future of metal fabrication looks promising, as sheet roll forming continues to drive innovation and excellence in manufacturing.

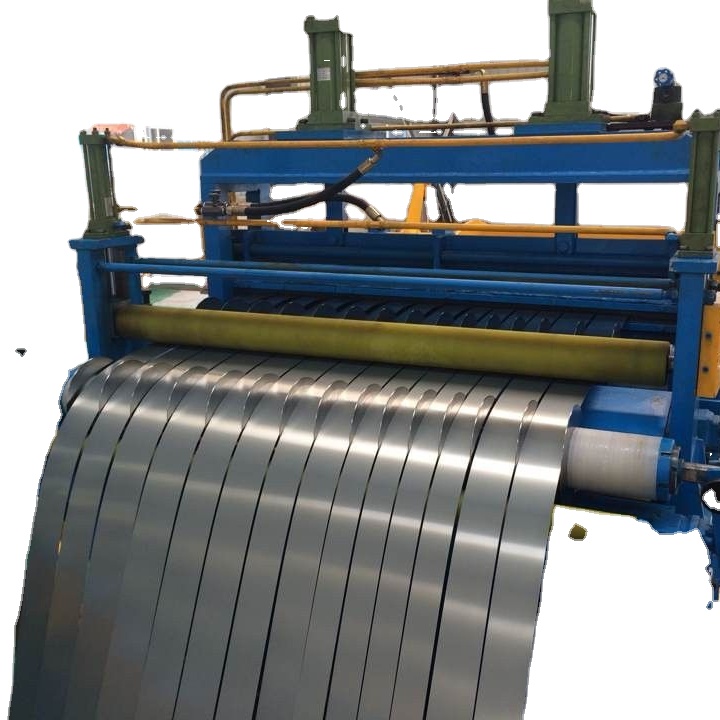

High Precision Cut To Length Machine for Efficient Coil Processing

The Coil Cut To Length Machine, produced by an industry-leading manufacturing company, is revolutionizing the metal fabrication process with its cutting-edge technology and precision engineering. This advanced machine is designed to efficiently cut and straighten coiled steel, aluminum, and other metals to the desired length, providing a high level of accuracy and consistency in the manufacturing process.The company behind this innovative machine has been a prominent player in the metal fabrication industry for over 20 years. They have established a solid reputation for delivering high-quality, reliable equipment that meets the evolving needs of their clients. With a strong focus on research and development, the company has continued to push the boundaries of technological advancement in the field of metal fabrication, and the Coil Cut To Length Machine is a testament to their commitment to innovation.One of the key features of the Coil Cut To Length Machine is its ability to handle a wide range of coil widths and thicknesses, making it a versatile and adaptable solution for a variety of metal fabrication requirements. The machine is equipped with state-of-the-art automation and control systems, allowing for precise adjustments to be made with ease, and ensuring that each cut is made with the highest level of accuracy.In addition to its cutting capabilities, the Coil Cut To Length Machine also incorporates a straightening process that ensures the finished metal is perfectly flat and free from any distortions. This is essential for ensuring the quality and integrity of the final product, and the machine's advanced straightening technology is able to achieve this with exceptional efficiency and reliability.Furthermore, the Coil Cut To Length Machine is designed with a focus on operator safety and ease of use. The machine is equipped with advanced safety features and intuitive controls, ensuring that operators can work with confidence and efficiency. This emphasis on safety and usability reflects the company's commitment to providing not only cutting-edge technology, but also equipment that prioritizes the well-being and efficiency of its users.The introduction of the Coil Cut To Length Machine represents a significant advancement in the field of metal fabrication. Its ability to streamline the manufacturing process, improve accuracy, and enhance overall efficiency is a game-changer for the industry. As demand for high-quality, precision-cut metal products continues to grow, this advanced machine is well-positioned to meet the needs of manufacturers looking to stay ahead of the curve.The company's dedication to innovation and excellence has made them a trusted partner for businesses in the metal fabrication industry, and the introduction of the Coil Cut To Length Machine further solidifies their position as a leader in the field. With a track record of delivering cutting-edge solutions that exceed customer expectations, this company is poised to continue driving the industry forward with their commitment to quality, reliability, and technological advancement.In conclusion, the introduction of the Coil Cut To Length Machine represents a significant milestone for the metal fabrication industry. With its advanced technology, precision engineering, and focus on operator safety and usability, this machine is set to redefine the way metal is cut and straightened for a wide range of manufacturing applications. As the company behind this innovative equipment continues to set new standards for excellence, they are well-positioned to lead the industry into a new era of efficiency and precision in metal fabrication.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.

Steel Sheet Roll Forming Machine for Sale - High-Quality and Affordable Options Available

Machines have revolutionized the way we produce or manufacture various products. They have made our lives easier, faster, and more efficient. One such machine that has had a significant impact in the construction industry is the Steel Sheet Roll Forming Machine. This incredible piece of equipment has changed the game when it comes to creating high-quality steel sheet products.The Roll Forming Machine is an essential tool in the manufacturing process of steel sheets. It is designed to transform coils of metal into uniform and seamless sheets with the desired shape and dimensions. This machine works by gradually bending the metal strip through a series of rollers, all positioned in a vertical or horizontal arrangement. With each pass through the rollers, the metal strip takes on the desired shape until it becomes a fully formed steel sheet.One of the primary advantages of using a Steel Sheet Roll Forming Machine is its ability to produce sheets with consistent thickness and shape. This ensures that the end product is of high quality and meets the required standards. The machine's precision and accuracy guarantee uniformity in every single piece, making it the ideal choice for various construction applications.Another benefit of the Steel Sheet Roll Forming Machine is its versatility. It can create an array of steel sheet products, including roofing panels, wall cladding, ceiling panels, and much more. The machine's flexibility allows it to adapt to different architectural designs and construction requirements, making it a valuable asset in any steel fabrication facility.Purchasing a Steel Sheet Roll Forming Machine can be a wise investment for any construction or manufacturing company. Not only does it provide better control over the production process, but it also streamlines operations and increases efficiency. Having this machine onsite eliminates the need for outsourcing sheet metal fabrication, reducing costs and saving time.When buying a Steel Sheet Roll Forming Machine, it is crucial to consider the quality of the machine itself. Look for a reliable supplier that offers durable and high-performance machines. One reputable source for Steel Sheet Roll Forming Machines is (remove brand name). They specialize in providing top-notch machines that have gained a reputation for their excellent performance and reliability.In addition to Steel Sheet Roll Forming Machines, (remove brand name) also offers Light Keel Roll Forming Machines. These machines are specifically designed to create lightweight steel framing systems commonly used in modern construction. The Light Keel Roll Forming Machines from (remove brand name) are known for their precision, productivity, and ease of use.Investing in a Steel Sheet Roll Forming Machine or a Light Keel Roll Forming Machine from (remove brand name) is a smart choice for any construction company. These machines will undoubtedly enhance productivity, reduce costs, and deliver consistent, high-quality steel sheet products.To summarize,- Steel Sheet Roll Forming Machines are invaluable tools in the construction industry.- They offer consistent thickness and shape for high-quality end products.- The versatility of these machines allows for various steel sheet applications.- Investing in a Steel Sheet Roll Forming Machine or Light Keel Roll Forming Machine is a wise choice.- Quality machines from (remove brand name) ensure reliable performance and durability.Incorporating the keywords "Steel Roll Forming" into the content is essential for SEO purposes. By highlighting the advantages and applications of Steel Sheet Roll Forming Machines, this blog aims to provide valuable information to potential buyers interested in purchasing one.

Promotional Corrugated Pipe Machine for PC Solid and Transparent Sheet Manufacturing Line

Title: Enhancing Productivity with Advanced Corrugated Sheet Manufacturing MachineIntroduction:In this era of rapid industrialization and infrastructure development, the demand for high-quality and efficient manufacturing machines is skyrocketing. One such revolutionary machine gaining popularity is the Corrugated Sheet Manufacturing Machine. Let's delve into the technical specifications and product features that make this machine a game-changer.Technical Specifications:The Corrugated Sheet Manufacturing Machine offered by JEEBO Machinery is a state-of-the-art unit designed to produce various types of corrugated sheets. With a width capacity of up to 30000mm and a thickness range of 0.8-15mm, this machine ensures unparalleled flexibility in meeting diverse industry requirements.Product Features and Applications:1. PC.PMMA.PS Optical Transparent Plate:The first impressive feature of this machine is its ability to manufacture optical transparent plates made from PC (Polycarbonate), PMMA (Polymethyl Methacrylate), and PS (Polystyrene). These durable and visually appealing plates find applications in screens, advertising materials, and article lenses. By offering a wide range of options in terms of width and thickness, this machine caters to the specific needs of various industries.2. PC Everlasting Plate PMMA PS Color and Carved:Another remarkable aspect is the machine's capability to produce everlasting plates using PC, PMMA, and PS materials. These plates are known for their long-lasting and robust qualities, making them suitable for applications in advertising materials, architectural elements, and many more. Moreover, the machine can create color and carved plates, adding a decorative aspect to the finished products.3. Enhanced Productivity:The Corrugated Sheet Manufacturing Machine by JEEBO Machinery not only delivers superior quality but also ensures high productivity. Equipped with cutting-edge technology, this machine streamlines the manufacturing process, enabling faster production cycles. The efficiency provided by this machine helps meet demanding deadlines and enhances overall productivity.4. Easy Operation and Maintenance:JEEBO Machinery understands the importance of user-friendliness. Hence, the Corrugated Sheet Manufacturing Machine is designed for easy operation and maintenance. The machine's intuitive control panel allows operators to adjust settings and parameters effortlessly. Additionally, routine maintenance tasks are simplified, ensuring smooth and uninterrupted production operations.Conclusion:In today's competitive market, having the right manufacturing equipment is vital for business success. The Corrugated Sheet Manufacturing Machine from JEEBO Machinery has emerged as a reliable and efficient solution in the industry. With its impressive technical specifications and versatile applications, this machine enables manufacturers to meet diverse demands while enhancing productivity. Investing in this cutting-edge machine will undoubtedly boost manufacturing capabilities and position businesses for long-term growth.Keywords: Corrugated Sheet Manufacturing Machine, PC Transparent Plate, PMMA Plate, PS Plate, everlasting plate, color plate, carved plate, productivity, manufacturing equipment, JEEBO Machinery.

Leading Supplier of Roll Forming Machines: China's Top Manufacturer for Roll Forming Machine Products

Modern day life is fast, and with the increase in population, the number of vehicles on the road has multiplied immensely. This has made the need for a highway guardrail forming machine inevitable. Apart from providing safety for vehicles against accidents, the highway guardrail system also ensures the safety of road workers and pedestrians.Manufacturing highway guardrails is a highly specialized process that involves the use of standard machines. In recent years, the evolution of the roll forming machine has made it possible to produce highway guardrails more efficiently and inexpensively. The highway guardrail forming machine is a new technology that ensures the production of high-quality and reliable guardrails, which are crucial for the safety of all road users.The highway guardrail forming machine is designed to produce a variety of guardrail profiles and shapes. It is made of several components that work in tandem to deliver the desired results. The machine is highly versatile and can be used to produce different types of guardrails, including steel guardrails, W beam guardrails, and thrie beam guardrails.The process of manufacturing highway guardrails using roll forming machines is simpler and faster than traditional methods. The use of the highway guardrail forming machine eliminates the need for welding, which is a time-consuming and costly process. The machine forms the guardrails by passing the materials through a set of rollers that bend the material into the desired shape. This process ensures that the material is not distorted or weakened, ensuring the quality and strength of the completed guardrails.The highway guardrail forming machine's efficiency and cost-effectiveness have made it the primary choice for most guardrail manufacturers. It allows manufacturers to produce guardrails at a faster pace, with greater accuracy, and at a lower cost. This has resulted in an increase in production volumes, leading to faster project completion times and increased customer satisfaction.Apart from increased productivity and lower production costs, the use of the highway guardrail forming machine has other benefits. The machine guarantees a uniform quality of the guardrails produced, eliminating the human error that could lead to inconsistencies and reduced strength. Additionally, the machine is eco-friendly, eliminating the need for excessive energy usage and the production of waste.In conclusion, the highway guardrail forming machine is a significant technological advancement in the production of highway guardrails. It has revolutionized the manufacturing process, making it faster, more efficient, and cost-effective. Manufacturers who use this machine can produce high-quality guardrails that meet the highest safety requirements while reducing wastage, cost, and environmental impact. The highway guardrail forming machine is a crucial component in building safer roads and ensuring the safety of all road users, making it an essential technology for the modern-day world.

High-Quality Single Layer Color Steel Roll Forming Machine at Competitive Prices

Introducing a New and Advanced Single Layer Color Steel Roll Forming MachineAs technology continues to advance, the roll forming industry is also experiencing significant transformation. In line with this, the renowned company {}, a leading manufacturer of roll forming machines, is pleased to announce the launch of their latest innovation - the Single Layer Color Steel Roll Forming Machine. This advanced machine is set to revolutionize the manufacturing process for color steel products, offering enhanced efficiency and superior quality.The Single Layer Color Steel Roll Forming Machine is designed to meet the growing demand for color steel products in various industries such as construction, automotive, and household appliances. With its advanced features and innovative technology, this machine sets a new standard for roll forming equipment.One of the key features of this machine is its ability to produce single layer color steel products with exceptional precision and consistency. This is made possible through the use of high-quality materials and advanced manufacturing techniques, ensuring that the end products meet the highest standards of quality and durability.In addition, the Single Layer Color Steel Roll Forming Machine is designed for versatility, allowing for the production of a wide range of color steel products such as roofing panels, wall cladding, and decking sheets. This flexibility makes it an ideal solution for manufacturers looking to expand their product offerings and meet the diverse needs of their customers.Furthermore, this machine is equipped with advanced control systems and automation technology, enabling seamless operation and minimizing the need for manual intervention. This not only increases productivity but also ensures consistent product quality, reducing the risk of errors and defects.The company {} has a long-standing reputation for delivering high-quality roll forming machines, backed by their commitment to innovation and customer satisfaction. With the introduction of the Single Layer Color Steel Roll Forming Machine, they continue to uphold this tradition by providing manufacturers with a cutting-edge solution that will help them stay ahead in a competitive market.In addition to its innovative products, {} offers comprehensive technical support and maintenance services to ensure that their customers can maximize the performance and lifespan of their machines. This commitment to customer service sets them apart as a trusted partner for manufacturers in the roll forming industry.As a company with a global presence, {} is dedicated to meeting the needs of their diverse customer base, providing tailored solutions to address unique manufacturing challenges. With the launch of the Single Layer Color Steel Roll Forming Machine, they are poised to further strengthen their position as a leading provider of roll forming equipment worldwide.In conclusion, the Single Layer Color Steel Roll Forming Machine from {} represents a significant advancement in roll forming technology, offering unparalleled precision, efficiency, and versatility. With its cutting-edge features and industry-leading performance, this machine is set to make a lasting impact on the manufacturing of color steel products. As the roll forming industry continues to evolve, {} remains at the forefront, driving innovation and delivering solutions that empower manufacturers to thrive in a dynamic market.