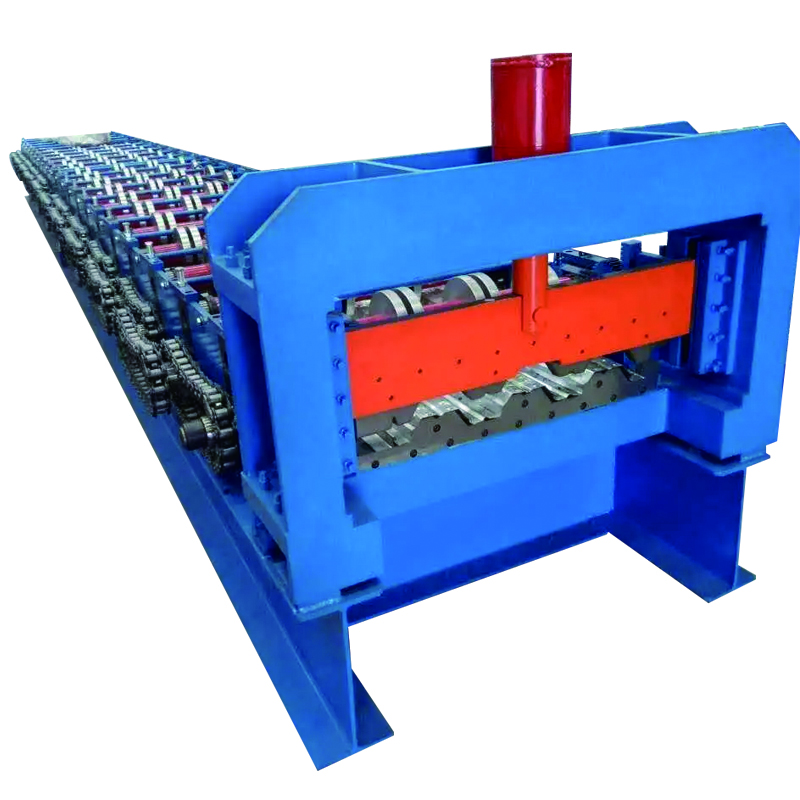

High-Quality Glazed Roofing Sheet Roll Forming Machine for Sale

By:Admin

The Glazed Roofing Sheet Roll Forming Machine is equipped with advanced technology and precision engineering, allowing for efficient and accurate production of glazed roofing sheets. The machine is capable of forming sheets with a variety of profiles and dimensions, making it suitable for a wide range of roofing applications.

One of the key features of the Glazed Roofing Sheet Roll Forming Machine is its high speed and productivity. With the ability to produce large quantities of glazed roofing sheets in a short amount of time, this machine is a valuable asset for manufacturers looking to meet tight deadlines and high demand.

In addition to its speed and productivity, the Glazed Roofing Sheet Roll Forming Machine also offers exceptional quality and precision. The machine is equipped with advanced control systems and cutting-edge technology, ensuring that each sheet produced is of the highest standard. This is essential for meeting the strict quality requirements of the construction industry.

Furthermore, the Glazed Roofing Sheet Roll Forming Machine is designed for ease of use and maintenance. Its user-friendly interface and intuitive controls make it easy for operators to set up and operate the machine, while its modular design allows for quick and convenient maintenance when needed.

[Company Name] has a proven track record of delivering high-quality and reliable roll forming machines to its customers. With a focus on innovation and customer satisfaction, the company prides itself on providing advanced solutions that meet the evolving needs of the construction industry.

In addition to the Glazed Roofing Sheet Roll Forming Machine, [Company Name] offers a comprehensive range of roll forming machines for various applications, including corrugated roofing sheets, IBR sheets, and metal tiles. With a commitment to excellence and continuous improvement, the company continues to invest in research and development to bring new and advanced products to the market.

[Quote from company spokesperson]: "We are excited to introduce the Glazed Roofing Sheet Roll Forming Machine to the market. This new product is a result of our ongoing commitment to innovation and meeting the needs of our customers. We are confident that this machine will set a new standard for the production of glazed roofing sheets, offering unmatched speed, quality, and reliability."

With the launch of the Glazed Roofing Sheet Roll Forming Machine, [Company Name] reaffirms its position as a leader in the roll forming machine industry. The company continues to push the boundaries of technology and engineering, delivering cutting-edge solutions that drive efficiency and quality in the construction sector. As the demand for glazed roofing sheets continues to grow, [Company Name] is well-positioned to meet this demand with its latest innovation.

Company News & Blog

Standing Seam Metal Roof Roll Former - A Must-Have for Roofing Professionals

Standing Seam Metal Roof Roll Former Revolutionizes Metal Roofing IndustryMetal roofing has always been a popular choice for commercial and industrial buildings, thanks to its durability and longevity. However, the installation process has often been time-consuming and labor-intensive, requiring skilled labor and a considerable amount of effort. This has caused some builders and property managers to shy away from metal roofing in favor of other materials.However, all of this is about to change with the introduction of the innovative Standing Seam Metal Roof Roll Former from (company name). This revolutionary piece of equipment has the potential to completely transform the metal roofing industry, making the installation process faster, more efficient, and more cost-effective than ever before.The Standing Seam Metal Roof Roll Former is a state-of-the-art machine that is designed to produce standing seam metal roofing panels on-site. This eliminates the need for pre-fabricated panels, which are often costly to transport and can be challenging to maneuver and install. With this roll former, contractors can produce custom metal roofing panels of any length directly at the job site, resulting in a quicker and more streamlined installation process.One of the key features of the Standing Seam Metal Roof Roll Former is its ability to produce panels with precise and consistent dimensions, ensuring a tight and secure fit that minimizes the risk of leaks and other issues. This level of precision is crucial for the long-term performance of the roof, as it helps to maintain the integrity of the building and protect it from water damage.In addition to its efficiency and precision, the Standing Seam Metal Roof Roll Former is also incredibly versatile. It can be used to produce a wide range of panel profiles, allowing contractors to offer their clients a variety of design options. Whether a building owner is looking for a sleek and modern appearance or a more traditional look, this roll former can deliver the perfect solution.Furthermore, the Standing Seam Metal Roof Roll Former from (company name) is designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to a wide range of contractors and roofing professionals. This accessibility opens up new opportunities for smaller companies and contractors who may not have had the resources to invest in traditional metal roofing equipment.The introduction of the Standing Seam Metal Roof Roll Former is a game-changer for the metal roofing industry, and (company name) is proud to be at the forefront of this innovative technology. With this roll former, the company is committed to helping contractors and property owners take advantage of the many benefits of metal roofing, including its durability, energy efficiency, and low maintenance requirements.The company has a long history of providing high-quality metal roofing solutions, and the Standing Seam Metal Roof Roll Former is the latest addition to its lineup of cutting-edge products. With a focus on innovation and customer satisfaction, (company name) is dedicated to pushing the boundaries of what is possible in the metal roofing industry.As the demand for metal roofing continues to grow, the introduction of the Standing Seam Metal Roof Roll Former couldn't have come at a better time. It represents a significant step forward for the industry, making metal roofing more accessible and desirable than ever before. With this innovative technology, the future of metal roofing looks brighter than ever, and (company name) is proud to be leading the way.

Ultimate Guide to Corrugated Color Steel Tile Production Line

The Corrugated Color Steel Tile Production Line is an advanced manufacturing system that has been recently introduced by a leading player in the steel industry. This production line is designed to produce high-quality, durable corrugated color steel tiles that are widely used in the construction and roofing sectors.The company, known for its expertise and innovation in the steel manufacturing sector, has invested heavily in research and development to bring this cutting-edge production line to the market. The Corrugated Color Steel Tile Production Line is equipped with state-of-the-art technology and automation systems, ensuring high efficiency and precision in the manufacturing process.The production line is capable of handling a wide range of steel materials, including galvanized steel, pre-painted steel, and aluminum-zinc coated steel. This versatility allows the company to cater to the diverse needs of its customers, providing them with a wide variety of options in terms of colors, finishes, and coating materials.One of the key features of the Corrugated Color Steel Tile Production Line is its ability to produce custom-designed steel tiles according to the specific requirements of customers. This flexibility is made possible by the advanced software and control systems integrated into the production line, allowing for quick and easy adjustments in the manufacturing process.The company takes pride in its commitment to sustainability and environmental responsibility. The Corrugated Color Steel Tile Production Line is designed with energy efficiency in mind, minimizing waste and emissions during the manufacturing process. Additionally, the production line is equipped with recycling systems to ensure that any scrap materials are effectively reused, further reducing the environmental footprint of the manufacturing operation.In addition to its advanced technology and environmental considerations, the company's production line is also designed with the safety and well-being of its workers in mind. The production line is equipped with safety features and protocols to ensure that all manufacturing processes are carried out with the highest standards of occupational health and safety.The introduction of the Corrugated Color Steel Tile Production Line represents a significant milestone for the company as it continues to strengthen its position as a leading provider of high-quality steel products. With this new manufacturing capability, the company aims to meet the growing demand for durable, visually appealing steel tiles in the construction and roofing sectors, both in domestic and international markets.The company's investment in this advanced production line is also a testament to its long-term vision and commitment to innovation. By continuously investing in research and development, the company is able to stay ahead of the curve in terms of technology and product offerings, ensuring that it remains a preferred partner for customers seeking high-quality steel products.As the construction and roofing industries continue to evolve, the demand for innovative, high-quality steel products is expected to grow. The Corrugated Color Steel Tile Production Line positions the company to meet this demand, offering customers a reliable source for durable and visually appealing steel tiles that meet their specific requirements.In conclusion, the introduction of the Corrugated Color Steel Tile Production Line represents a significant advancement for the company, showcasing its commitment to innovation, sustainability, and customer satisfaction. With its advanced technology, flexible manufacturing capabilities, and commitment to quality, the company is well-poised to meet the evolving needs of the construction and roofing industries, both domestically and internationally.

Highly Efficient Rolling Forming Machine for Studs

Stud Rolling Forming Machine Revolutionizes the Construction IndustryThe construction industry is constantly evolving, with new technologies and innovations aimed at improving efficiency and productivity. One such innovation that is making waves in the industry is the Stud Rolling Forming Machine, a state-of-the-art equipment that is changing the way construction projects are executed.The Stud Rolling Forming Machine, developed by a leading machinery company, is designed to streamline the process of forming studs, which are an essential component in the construction of various structures, from residential buildings to commercial establishments. Traditionally, forming studs required extensive manual labor and a significant amount of time, leading to delays and increased labor costs. However, with the introduction of the Stud Rolling Forming Machine, this process has been revolutionized, enabling construction companies to significantly improve their efficiency and productivity.The machine's advanced technology and precision engineering allow for the seamless and rapid production of studs, eliminating the need for manual labor and reducing the likelihood of errors. This not only leads to cost savings for construction companies but also ensures that the quality of the studs produced is consistently high, ultimately contributing to the overall safety and stability of the structures being built.Furthermore, the Stud Rolling Forming Machine is versatile and adaptable, capable of producing studs in various sizes and specifications to cater to the specific requirements of different construction projects. This flexibility makes it an invaluable asset for construction companies, as it enables them to effectively meet the diverse needs of their clients without compromising on quality or efficiency.In addition to its technical capabilities, the Stud Rolling Forming Machine is also designed with user-friendliness in mind, featuring intuitive controls and interface that make it easy for operators to understand and operate the machine effectively. This ensures that construction companies can seamlessly integrate the machine into their existing operations without the need for extensive training or retooling, further contributing to its appeal and practicality.The company behind the Stud Rolling Forming Machine has a long-standing reputation for excellence in manufacturing and engineering, with a track record of developing cutting-edge machinery that has significantly impacted various industries. Their commitment to innovation and quality is reflected in the design and performance of the Stud Rolling Forming Machine, which has quickly gained recognition and acclaim within the construction industry.With a focus on continuous improvement and customer satisfaction, the company has invested significant resources into research and development, ensuring that the Stud Rolling Forming Machine remains at the forefront of technological advancements and is poised to meet the evolving needs of the construction industry.In response to the overwhelmingly positive reception of the Stud Rolling Forming Machine, the company has also established a comprehensive support infrastructure, providing training, maintenance, and technical assistance to ensure that construction companies can fully maximize the potential of the machine and achieve optimal results in their projects. This commitment to customer service further underscores the company's dedication to driving positive change and progress within the construction industry.As the construction industry continues to evolve and embrace new technologies, the Stud Rolling Forming Machine stands out as a game-changer that is reshaping the way studs are formed and utilized in construction projects. With its innovative design, efficiency, and performance, it has quickly become an indispensable tool for construction companies seeking to enhance their operations and deliver superior results to their clients.In conclusion, the Stud Rolling Forming Machine represents a significant milestone in the advancement of construction technology, and its impact on the industry is set to be long-lasting and transformative. As more construction companies recognize the benefits and advantages it offers, its adoption is expected to become increasingly widespread, further solidifying its status as a game-changing innovation that is revolutionizing the construction industry.

High-quality Tile Forming Machine for Efficient Production

In today's rapidly evolving construction industry, the demand for efficient and innovative machinery has never been higher. This is why the introduction of the new Tile Forming Machine by [Company Name] is a game-changer. This cutting-edge piece of equipment promises to revolutionize the way tile forming is carried out, providing a higher level of precision, speed, and reliability.[Company Name] has been a leading manufacturer of construction machinery for many years, consistently setting the bar for quality and performance in the industry. Their dedication to innovation and customer satisfaction has earned them a reputation as a trusted and reliable brand, with a strong presence in both domestic and international markets.The new Tile Forming Machine is a testament to [Company Name]'s commitment to pushing the boundaries of what is possible in construction machinery. The machine is designed to streamline the tile forming process, offering a level of efficiency and accuracy that was previously unimaginable. This is achieved through advanced technology and engineering, combined with the company's extensive experience and expertise in the field.One of the key features of the Tile Forming Machine is its ability to handle a wide range of tile sizes and materials with ease. This versatility is a major selling point for contractors and construction companies, allowing them to adapt to different project requirements without the need for multiple machines. In addition, the machine's precision ensures that each tile is formed to exact specifications, reducing the margin for error and waste.Another standout feature of the Tile Forming Machine is its speed and productivity. With rapid forming and cutting capabilities, the machine is able to significantly increase output, saving valuable time and resources for users. This is particularly important in today's fast-paced construction environment, where deadlines are tight and efficiency is a top priority.In addition to its performance benefits, the Tile Forming Machine also prioritizes user-friendly operation and maintenance. A simple and intuitive interface makes it easy for operators to control and monitor the machine, while its robust build ensures durability and longevity. This focus on practicality and convenience reflects [Company Name]'s understanding of the needs and challenges faced by their customers.Furthermore, the Tile Forming Machine is designed with sustainability in mind, incorporating energy-efficient components and processes. This aligns with [Company Name]'s commitment to environmental responsibility, aiming to minimize the carbon footprint of their machinery while maximizing its positive impact on the construction industry.As with all [Company Name] products, the Tile Forming Machine is backed by comprehensive customer support and after-sales service. This includes training, maintenance, and technical assistance, ensuring that customers can make the most of their investment and experience minimal downtime.The introduction of the Tile Forming Machine marks a significant milestone for [Company Name], reaffirming their position as a driving force in the construction machinery market. With its impressive capabilities and customer-centric approach, the machine is expected to be a popular choice for construction professionals looking to elevate their operations.In conclusion, the new Tile Forming Machine by [Company Name] represents a leap forward in tile forming technology. Its combination of precision, efficiency, versatility, and sustainability sets a new standard for the industry, offering significant benefits for construction projects of all scales. With their proven track record and steadfast commitment to innovation, [Company Name] is set to make a lasting impact with this latest addition to their product lineup.

High-Quality Metal Roof Making Machine for Sale: Find Out More

Metal Roof Making Machine Revolutionizes Roofing IndustryThe roofing industry is constantly evolving and innovating, and one of the latest advancements that is revolutionizing the way roofs are made is the Metal Roof Making Machine. This state-of-the-art machine, manufactured by a leading company in the industry, is changing the game for roofing contractors and manufacturers.With the ability to produce high-quality metal roofing panels at a fraction of the time and cost of traditional methods, this machine is a game-changer for the industry. The Metal Roof Making Machine is designed to streamline the production process, allowing for faster and more efficient manufacturing of metal roofing panels. This means that roofing contractors can now meet tight deadlines and take on more projects, ultimately increasing their bottom line.The Metal Roof Making Machine is equipped with cutting-edge technology that allows for precision and accuracy in panel production. This means that each panel is of the highest quality, ensuring that the end result is a durable and long-lasting roof. Additionally, the machine is versatile and can produce a wide variety of panel designs and sizes, giving contractors and manufacturers the flexibility to meet the unique needs of each project.In addition to its production capabilities, the Metal Roof Making Machine is also designed with ease of use in mind. Its user-friendly interface and intuitive controls make it easy for operators to quickly learn and master the machine, minimizing the need for extensive training and reducing the chances of errors in production. This allows for a seamless and efficient manufacturing process, further reducing costs and increasing productivity.The company behind the Metal Roof Making Machine has a long-standing reputation for excellence in the industry. With a commitment to quality and innovation, they have been at the forefront of developing cutting-edge solutions for the roofing industry. Their team of experts and engineers have worked tirelessly to design and manufacture a machine that not only meets the needs of the industry but exceeds expectations.With a focus on customer satisfaction, the company provides comprehensive support and training for their machines, ensuring that their clients are equipped with the knowledge and resources they need to succeed. This dedication to service and support has earned them the trust and loyalty of countless roofing contractors and manufacturers around the world.The Metal Roof Making Machine is already making waves in the industry, with many contractors and manufacturers adopting this new technology to improve their production processes. The machine has been praised for its speed, efficiency, and quality, and is quickly becoming a staple in the toolset of roofing professionals.As the roofing industry continues to evolve, the Metal Roof Making Machine is leading the way in transforming the way roofs are made. With its advanced technology, ease of use, and commitment to quality, this machine is sure to have a lasting impact on the industry for years to come. Its ability to streamline production, improve quality, and reduce costs is a testament to the innovation and dedication of the company behind it. In conclusion, the Metal Roof Making Machine is a game-changer for the roofing industry. Its advanced technology, ease of use, and commitment to quality are setting a new standard for metal roofing production. With the support and expertise of the company behind it, contractors and manufacturers can now take their production processes to new heights. This revolutionary machine is paving the way for the future of roofing, and it's clear that the industry will never be the same.

Trapezoid Profile Metal Roofing Sheet Machine: Everything You Need to Know

Metal Roofing Sheet Trapezoid Profile Machine is a revolutionary piece of equipment that is set to transform the roofing industry. This state-of-the-art machine is designed to produce high-quality trapezoid profile metal roofing sheets, which are known for their durability and aesthetic appeal. With the ability to create custom trapezoid profile sheets in a variety of sizes and materials, this machine is expected to be a game-changer for roofing contractors and businesses.The technology behind the Metal Roofing Sheet Trapezoid Profile Machine is truly innovative, allowing for precise and efficient production of trapezoid profile sheets. The machine is equipped with advanced automated features that ensure consistent quality and accuracy in each sheet that is produced. This is crucial for ensuring that the roofing sheets are a perfect fit and provide excellent protection against the elements.One of the key benefits of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It is capable of working with a wide range of materials, including steel, aluminum, and other metals commonly used in roofing. This means that roofing contractors and businesses can easily adapt to different project requirements and client preferences without having to invest in multiple machines.In addition to its versatility, the Metal Roofing Sheet Trapezoid Profile Machine is also designed for speed and efficiency. The machine has a high production capacity, allowing for quick turnaround times on orders. This is essential for meeting tight project deadlines and maximizing productivity for businesses in the roofing industry.Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, reducing the need for extensive training and streamlining the production process. This is particularly beneficial for businesses looking to optimize their efficiency and minimize production costs.As a leading provider of innovative roofing solutions, {} is proud to introduce the Metal Roofing Sheet Trapezoid Profile Machine to the market. With decades of experience in the industry, the company has a strong track record of delivering high-quality roofing products and machinery. The introduction of this advanced machine is a testament to the company's commitment to staying at the forefront of technological advancements in the roofing sector.In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {} offers a comprehensive range of roofing materials and equipment to meet the needs of residential, commercial, and industrial projects. The company's dedication to quality, reliability, and customer satisfaction has established them as a trusted partner for roofing professionals and businesses.With the introduction of the Metal Roofing Sheet Trapezoid Profile Machine, {} is poised to empower roofing contractors and businesses with the tools they need to elevate their capabilities and deliver exceptional results. The machine's ability to produce high-quality trapezoid profile sheets with speed and precision is set to have a significant impact on the roofing industry, setting a new standard for efficiency and excellence.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine represents a major leap forward for the roofing industry. Its innovative technology, versatility, and efficiency make it a valuable asset for roofing contractors and businesses looking to enhance their capabilities and deliver superior results. With the backing of {}'s expertise and reputation for quality, the machine is set to become a game-changing tool for the production of trapezoid profile metal roofing sheets.

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

Efficient and Versatile Roll Forming Machine for Tiles Unveiled in Recent News

Title: Advanced Tile Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:The global roofing industry has experienced a significant boost in efficiency and productivity with the introduction of the cutting-edge Tile Roll Forming Machine. Developed by a leading industry player, this innovative machine has revolutionized the process of manufacturing and installing roof tiles, simplifying and accelerating operations for companies worldwide. This article explores the key features and benefits of the Tile Roll Forming Machine that have made it the go-to solution for roof tile production.Enhanced Efficiency and Production Capacity:The Tile Roll Forming Machine incorporates advanced technology that streamlines the traditional process of manufacturing roof tiles. With precise control systems and automated operations, the machine offers unrivaled efficiency and an exceptional production capacity. The entire process, from feeding the raw material to the final tile roll formation, is seamlessly integrated, ensuring a continuous and uninterrupted assembly line that significantly reduces production time.Versatile Functionality:The Tile Roll Forming Machine is highly adaptable to various roof tile profiles and designs. Its customizable features allow manufacturers to produce an extensive range of tile shapes, sizes, and styles, catering to the diverse needs of customers. From conventional clay and concrete tiles to more innovative materials, such as metal and composite, the machine effortlessly creates highly durable and aesthetically pleasing tiles that meet the highest industry standards.Precision and Consistency:One of the standout features of the Tile Roll Forming Machine is its ability to ensure precise dimensions and consistent quality of every tile produced. The machine utilizes advanced robotics and computer-controlled mechanisms that meticulously shape the tiles, guaranteeing uniformity and accuracy throughout the production process. This not only enhances the visual appeal of the end product but also improves installation efficiency by eliminating the need for manual adjustments during the roofing process.Cost-Effectiveness and Sustainability:By investing in the Tile Roll Forming Machine, roofing companies benefit from significant cost savings in the long run. The machine's high production capacity and reduced labor requirements minimize operational expenses and improve overall profitability. Furthermore, its automated functions and seamless integration allow for minimal material wastage, making it an environmentally friendly solution that aligns with sustainability goals.User-Friendly Interface and Maintenance:Designed with user convenience in mind, the Tile Roll Forming Machine features an intuitive interface that allows operators of varying expertise to navigate seamlessly through the production process. Clear instructions and easily accessible controls enable quick setup and efficient production without the need for extensive training. Additionally, the machine's durable construction and easy-to-maintain components ensure long-term reliability and minimal downtime, contributing to improved operational efficiency.Market Impact and Customer Satisfaction:Since its introduction, the Tile Roll Forming Machine has gained immense popularity in the roofing industry, with companies worldwide actively adopting this advanced technology. Manufacturers have reported increased production output, reduced operational costs, and improved product quality. Moreover, customers benefit from the availability of a wide range of high-quality and precisely formed roof tiles at competitive prices, ultimately enhancing their satisfaction and overall experience.Conclusion:The Tile Roll Forming Machine has emerged as a game-changer, revolutionizing the roofing industry by offering enhanced efficiency, increased production capacity, and exceptional quality control. The combination of advanced technology, versatility, and user-friendly features has made this machine an indispensable asset to roofing companies globally. With its positive impact on operational efficiency, cost-effectiveness, and customer satisfaction, the Tile Roll Forming Machine continues to shape the future of roof tile production and installation.

Highly Efficient Glazed Sheet Roll Forming Machine Revolutionizes Production Process

Glazed Sheet Roll Forming Machine Revolutionizing the Construction IndustryIn response to the growing demand for efficient and high-quality construction materials, the development of advanced machinery has become crucial. One such groundbreaking innovation is the Glazed Sheet Roll Forming Machine. This state-of-the-art technology has the potential to revolutionize the construction industry, paving the way for faster and more cost-effective building processes.The Glazed Sheet Roll Forming Machine is a versatile piece of equipment that specializes in the production of glazed sheets used in roofing and cladding applications. This machine utilizes a roll forming technique, where a continuous strip of metal is passed through multiple sets of rolls to gradually shape the material into the desired profile. With the ability to produce sheets of various sizes, thicknesses, and profiles, this machine offers unparalleled flexibility for construction firms.The key advantage of the Glazed Sheet Roll Forming Machine is its ability to produce high-quality glazed sheets with precision and consistency. By eliminating manual labor and human error, this automated technology ensures that each sheet meets the desired specifications, resulting in superior product quality. Additionally, the roll forming process reduces material waste, optimizing resources and reducing costs for construction companies.One of the cutting-edge manufacturers of this revolutionary machinery is [Company Name]. Led by a team of experienced engineers and industry experts, [Company Name] has gained recognition for its commitment to innovation and excellence. With a global presence and a customer-centric approach, [Company Name] has successfully supplied its Glazed Sheet Roll Forming Machines to construction businesses worldwide.The Glazed Sheet Roll Forming Machine developed by [Company Name] combines advanced technology with exceptional design. Its robust construction ensures durability, enabling uninterrupted production even in demanding manufacturing environments. Equipped with a user-friendly interface, this machine allows operators to easily adjust settings and monitor the production process, enhancing efficiency and productivity.Moreover, [Company Name]'s Glazed Sheet Roll Forming Machine is equipped with cutting-edge safety features, prioritizing the well-being of its operators. These features include emergency stop buttons, safety interlocks, and protective covers, adhering to strict industry regulations. By investing in worker safety, [Company Name] sets itself apart as a responsible and reliable machinery provider.The benefits of the Glazed Sheet Roll Forming Machine extend beyond its manufacturing capabilities. As an environmentally conscious solution, this machine contributes to sustainable practices within the construction industry. By optimizing material usage and reducing waste, it promotes resource efficiency, aligning with global efforts to combat climate change and reduce carbon emissions.The Glazed Sheet Roll Forming Machine is set to transform the construction industry, streamlining processes and driving innovation. By investing in this efficient technology, construction companies can significantly reduce project timelines and costs, positioning themselves at the forefront of the industry. Moreover, the superior quality of glazed sheets produced by this machine ensures long-lasting and aesthetically pleasing structures, satisfying the demands of clients and end-users alike.In conclusion, the Glazed Sheet Roll Forming Machine represents a major breakthrough in the construction industry. With its automated and precise manufacturing capabilities, this machine has the potential to redefine the way buildings are constructed. Companies like [Company Name] are leading the way by investing in cutting-edge technology and delivering high-quality machinery to businesses around the world. As the demand for efficient and sustainable construction materials continues to grow, the Glazed Sheet Roll Forming Machine remains at the forefront, revolutionizing the industry one sheet at a time.

Cold Rolling Forming Machines for Automated Production of Various Roofing Sheets

and IBR sheet making machine.Roof Sheet Making Machines - An OverviewRoof sheet making machines are modern-day machines that utilize the cold roll forming principle to produce roofing sheets in bulk. These machines are also known as IBR sheet making machines or color steel roll forming machines. They are fully automatic and designed to produce sheets in a variety of designs and dimensions. They are robust, reliable, and highly efficient, capable of producing high-quality roofing sheets that can be used for AD boards, wall panels, and other applications.The Working Principle of Roof Sheet Making MachinesRoof sheet making machines use a series of rollers to form different shapes and designs on flat metal sheets. The process begins when the metal sheet passes through the first set of rollers, which bend it into a curve. The sheet then moves through several sets of rollers, each producing a different shape and size until the final product is produced. The rollers on these machines are designed to be adjustable, allowing operators to create different designs, dimensions, and shapes.Advantages of Roof Sheet Making MachinesRoof sheet making machines offer several benefits, including:1. High efficiency - Roof sheet making machines are fully automatic and can produce large quantities of roofing sheets in a short period. This makes them ideal for mass production.2. Customization - With the adjustable rollers, roof sheet making machines make it possible to create unique designs and shapes that meet specific customer requirements.3. Low maintenance - These machines are designed to be low maintenance, reducing the overall cost of operation.4. High-quality output - Roof sheet making machines produce high-quality roofing sheets that are durable, robust, and weather-resistant.Applications of Roof Sheet Making MachinesRoof sheet making machines find broad applications in the construction industry, particularly in roofing. The roofing sheets produced by these machines are used for:1. Residential roofing - The roofing sheets are used to create attractive, durable, and weather-resistant roofs for homes.2. Commercial roofing - Roof sheet making machines produce roofing sheets that are ideal for commercial buildings such as warehouses, factories, and workshops.3. Agricultural roofing - The roofing sheets are ideal for agricultural use since they are weather-resistant, durable, and low maintenance.ConclusionRoof sheet making machines are versatile, efficient, and affordable pieces of equipment that make the production of high-quality roofing sheets possible. They offer several benefits over other manufacturing methods, including low maintenance, high output, and customization options. With ongoing technological advancements, the market for roof sheet making machines is expected to grow, driving innovation and leading to even greater efficiency and customization options.