High-Quality Metal Roof Forming Machine for Efficient Roofing

By:Admin

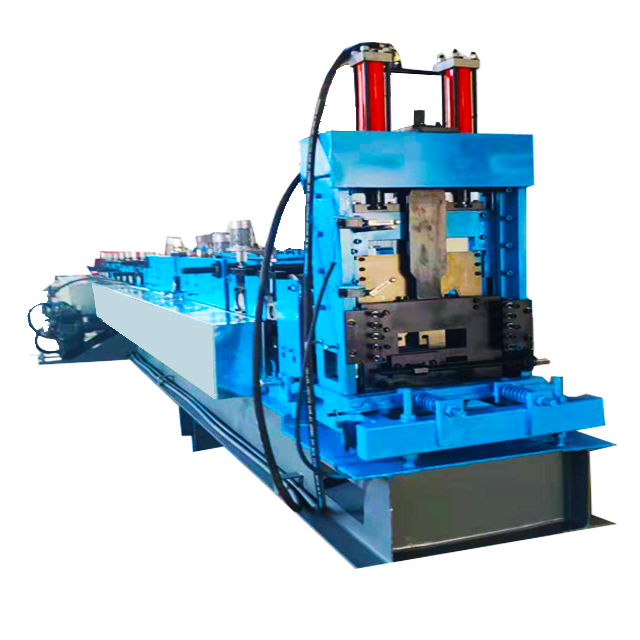

With the advancement of technology, many industries have implemented innovative solutions to improve efficiency and productivity. The roofing industry is no exception, and the introduction of the Metal Roof Forming Machine has revolutionized the way metal roofing is produced.

The Metal Roof Forming Machine, developed by a leading manufacturing company, has become a game-changer for roofing contractors and manufacturers. This state-of-the-art machine is designed to streamline the process of forming metal roofing materials, making it faster, more precise, and cost-effective.

This innovative machine eliminates the need for manual labor and significantly reduces the production time of metal roofing materials. It is capable of producing various types of metal roofing profiles, including standing seam, corrugated, and ribbed panels, with unparalleled precision and consistency.

The company behind this groundbreaking technology, has been a pioneer in the manufacturing industry for over two decades. They are renowned for their commitment to excellence and continuous innovation, which has earned them a reputation as a trusted provider of high-quality machinery and equipment.

The Metal Roof Forming Machine is a testament to the company's dedication to advancing the roofing industry. It is the result of extensive research and development, as well as collaboration with roofing experts to understand the specific needs and requirements of the industry.

One of the key features of the Metal Roof Forming Machine is its versatility. It is designed to accommodate various metal roofing materials, including steel, aluminum, and copper, making it suitable for a wide range of roofing projects. This flexibility allows roofing contractors and manufacturers to meet the diverse needs of their clients without investing in multiple machines.

Furthermore, the machine's automated operation and advanced control system ensure that the quality of the metal roofing materials is consistently high. This not only enhances the overall durability and performance of the roofing materials but also minimizes waste and rework, leading to significant cost savings for manufacturers and contractors.

The Metal Roof Forming Machine also prioritizes safety and user-friendly operation. It is equipped with advanced safety features and ergonomic design to minimize the risk of accidents and injuries during operation. Additionally, the machine's intuitive interface and easy setup process make it accessible to operators of all skill levels.

In addition to its technical capabilities, the company provides comprehensive training and support services to ensure that customers can maximize the full potential of the Metal Roof Forming Machine. This includes training programs, technical assistance, and ongoing maintenance to prolong the lifespan of the equipment and maximize its efficiency.

The introduction of the Metal Roof Forming Machine has undoubtedly set a new standard for the roofing industry. Its impact is evident in the increased productivity and efficiency of manufacturers and contractors who have embraced this technology. Not only does it streamline the production process, but it also enables them to deliver high-quality metal roofing materials that exceed industry standards.

Looking to the future, the company is committed to further advancing the Metal Roof Forming Machine and exploring new possibilities for improving the roofing industry. With a focus on sustainability and innovation, they aim to develop even more efficient and eco-friendly solutions that will continue to drive the industry forward.

In conclusion, the Metal Roof Forming Machine is a prime example of how technology can redefine traditional industries. Its introduction has not only transformed the way metal roofing materials are produced but has also set a new benchmark for efficiency, quality, and innovation in the roofing industry. As the company continues to lead the way in manufacturing excellence, the Metal Roof Forming Machine is expected to have a lasting impact on the industry for years to come.

Company News & Blog

Top Color Steel Glazed Tile Corrugation Equipment for Efficient Production

Color Steel Glazed Tile Corrugation Equipment Meeting Increasing Demand for Premium Building MaterialsAs the global construction industry grows in size and complexity, the demand for high-quality building materials continues to increase. In an effort to meet this demand and drive industrial innovation, Color Steel Glazed Tile Corrugation Equipment (Name of brand removed) has designed and produced a cutting-edge system that delivers premium roofing sheets and wall panels with remarkable precision and efficiency.With over 20 years of experience in manufacturing and engineering, Color Steel Glazed Tile Corrugation Equipment is a trusted leader in the industry that helps companies around the world transform their construction operations. From metal sheets and glazed tiles to corrugated panels and roof ridges, their equipment excels in delivering high-performance building materials that are essential to the construction of modern-day structures.The new Color Steel Glazed Tile Corrugation Equipment is no exception. This innovative production line takes advantage of advanced technologies to create materials that are not only visually appealing but also highly durable and weather-resistant. With a wide range of customization options, clients can easily adapt the equipment to meet their specific requirements to create roofing and wall panel products that stand out in the market.One of the key features of the Color Steel Glazed Tile Corrugation Equipment is its high level of flexibility. The production line can be used to create a wide variety of roofing and wall panel products in various shapes and sizes, including classic corrugated panels, glazed tiles, and classical tiles, both with and without an insulated core. This flexibility enables clients to offer a diverse range of products to their customers while maintaining exceptional quality and speed of production.Another major benefit of the equipment is its high level of accuracy. The production line is computer-controlled, ensuring that products are manufactured to precise standards every time. This accuracy results in dimensional stability, consistency, and perfect curvature of the final products, each of which is important to the successful completion of any construction project.At the heart of the design is the automatic color steel coil feeding and cut-to-length system, which guarantees that materials are processed quickly and efficiently with minimal waste. Additionally, the equipment features an automatic roll forming system and a pressing system for easy panel finishing and shaping.Color Steel Glazed Tile Corrugation Equipment takes pride in its machines' quality and longevity. Each production line component is made from high-quality materials and is designed by a team of experienced engineers to ensure consistent performance and long service life. Regular maintenance and customer service are also available to ensure that the equipment is operational and exceptionally dependable throughout its lifespan.Commenting on this new equipment, a spokesperson for Color Steel Glazed Tile Corrugation Equipment said, "Our innovative production line is designed to offer exceptional performance and versatility across various applications in the construction industry. Through the delivery of high-quality materials and products, we aim to provide cutting-edge solutions to our clients that enable them to stay ahead of the competition and meet the ever-increasing demands of their customers."In conclusion, the Color Steel Glazed Tile Corrugation Equipment is a versatile production line designed for the creation of high-quality building materials. With its cutting-edge technology, precision engineering, and flexibility, it is an essential tool for construction companies looking to innovate and deliver premium products to their customers. As demand for exceptional building materials continues to grow, Color Steel Glazed Tile Corrugation Equipment's new production line will provide construction companies with the competitive edge they need to succeed.

High-Quality Metal Roof Forming Machine for Efficient Roofing

Metal Roof Forming Machine Revolutionizing the Roofing IndustryWith the advancement of technology, many industries have implemented innovative solutions to improve efficiency and productivity. The roofing industry is no exception, and the introduction of the Metal Roof Forming Machine has revolutionized the way metal roofing is produced.The Metal Roof Forming Machine, developed by a leading manufacturing company, has become a game-changer for roofing contractors and manufacturers. This state-of-the-art machine is designed to streamline the process of forming metal roofing materials, making it faster, more precise, and cost-effective.This innovative machine eliminates the need for manual labor and significantly reduces the production time of metal roofing materials. It is capable of producing various types of metal roofing profiles, including standing seam, corrugated, and ribbed panels, with unparalleled precision and consistency.The company behind this groundbreaking technology, has been a pioneer in the manufacturing industry for over two decades. They are renowned for their commitment to excellence and continuous innovation, which has earned them a reputation as a trusted provider of high-quality machinery and equipment.The Metal Roof Forming Machine is a testament to the company's dedication to advancing the roofing industry. It is the result of extensive research and development, as well as collaboration with roofing experts to understand the specific needs and requirements of the industry.One of the key features of the Metal Roof Forming Machine is its versatility. It is designed to accommodate various metal roofing materials, including steel, aluminum, and copper, making it suitable for a wide range of roofing projects. This flexibility allows roofing contractors and manufacturers to meet the diverse needs of their clients without investing in multiple machines.Furthermore, the machine's automated operation and advanced control system ensure that the quality of the metal roofing materials is consistently high. This not only enhances the overall durability and performance of the roofing materials but also minimizes waste and rework, leading to significant cost savings for manufacturers and contractors.The Metal Roof Forming Machine also prioritizes safety and user-friendly operation. It is equipped with advanced safety features and ergonomic design to minimize the risk of accidents and injuries during operation. Additionally, the machine's intuitive interface and easy setup process make it accessible to operators of all skill levels.In addition to its technical capabilities, the company provides comprehensive training and support services to ensure that customers can maximize the full potential of the Metal Roof Forming Machine. This includes training programs, technical assistance, and ongoing maintenance to prolong the lifespan of the equipment and maximize its efficiency.The introduction of the Metal Roof Forming Machine has undoubtedly set a new standard for the roofing industry. Its impact is evident in the increased productivity and efficiency of manufacturers and contractors who have embraced this technology. Not only does it streamline the production process, but it also enables them to deliver high-quality metal roofing materials that exceed industry standards.Looking to the future, the company is committed to further advancing the Metal Roof Forming Machine and exploring new possibilities for improving the roofing industry. With a focus on sustainability and innovation, they aim to develop even more efficient and eco-friendly solutions that will continue to drive the industry forward.In conclusion, the Metal Roof Forming Machine is a prime example of how technology can redefine traditional industries. Its introduction has not only transformed the way metal roofing materials are produced but has also set a new benchmark for efficiency, quality, and innovation in the roofing industry. As the company continues to lead the way in manufacturing excellence, the Metal Roof Forming Machine is expected to have a lasting impact on the industry for years to come.

Innovative C Purlin Machine Revolutionizes Manufacturing Processes

The manufacturing industry is constantly evolving, with new innovations and technologies shaping the way businesses operate. One company at the forefront of this evolution is {Company X}, a leading manufacturer of industrial machinery. With a commitment to delivering cutting-edge solutions to their clients, {Company X} has recently introduced a new Stacker for the C Purline Machine, solidifying their position as a key player in the industry.{Company X} has a rich history of providing high-quality industrial machinery to a wide range of clients. With a focus on innovation and customer satisfaction, they have built a reputation for excellence in the industry. The company's dedication to staying ahead of the curve has led to the development of the Stacker for the C Purline Machine, a revolutionary new product that is set to transform the manufacturing process for businesses across the globe.The Stacker for the C Purline Machine is a state-of-the-art piece of equipment that offers a range of benefits to businesses in the manufacturing sector. Designed to streamline the production process, the stacker is capable of efficiently handling C purline products, providing a seamless and efficient solution for businesses looking to optimize their operations. With its advanced technology and innovative design, the stacker is set to enhance productivity and reduce downtime for businesses, ultimately leading to cost savings and improved output.One of the key features of the Stacker for the C Purline Machine is its versatility. The stacker is capable of handling a wide range of C purline products, making it a valuable asset for businesses producing a variety of goods. This flexibility is crucial for businesses looking to adapt to changing market demands and maintain a competitive edge in the industry. With the stacker, businesses can easily adjust their production process to accommodate different product specifications, without the need for additional equipment or extensive reconfiguration.In addition to its versatility, the stacker is also designed with efficiency in mind. By automating the stacking process, the stacker is able to significantly reduce the amount of manual labor required, minimizing the risk of human error and increasing overall efficiency. This not only speeds up the production process but also ensures a consistently high level of quality for the finished products. With the stacker in place, businesses can expect to see improved throughput and reduced lead times, ultimately leading to a more efficient and profitable operation.The introduction of the Stacker for the C Purline Machine is a testament to {Company X}'s dedication to innovation and excellence. By continually pushing the boundaries of what is possible in the manufacturing industry, the company is helping businesses around the world stay ahead of the curve and achieve their production goals. With a commitment to quality, reliability, and customer satisfaction, {Company X} is a trusted partner for businesses looking to invest in cutting-edge manufacturing solutions.As the manufacturing industry continues to evolve, businesses are constantly seeking new ways to improve their operations and stay competitive. The introduction of the Stacker for the C Purline Machine by {Company X} is a testament to the company's commitment to meeting the needs of their clients and delivering innovative solutions that drive growth and success. With its advanced technology, versatility, and efficiency, the stacker is set to become a game-changer for businesses in the manufacturing sector, offering a competitive edge that will set them apart in the market.

High-Quality Corrugated Sheet Roll Forming Machine for Efficient Production

In the competitive world of manufacturing, the demand for efficient and reliable production equipment has never been greater. As the industry continues to evolve, companies are constantly seeking to improve their processes and increase their competitiveness. This is where the innovative technology of Corrugated Sheet Roll Forming Machine comes into play. With its superior performance and advanced features, this cutting-edge equipment is revolutionizing the way companies produce corrugated sheets.With a commitment to excellence and a focus on delivering high-quality products, {Company Name} has established itself as a leading manufacturer of industrial machinery. The company is renowned for its dedication to innovation, customer satisfaction, and superior performance. As a testament to its success, {Company Name} has recently introduced the ground-breaking Corrugated Sheet Roll Forming Machine, which has taken the manufacturing industry by storm.The Corrugated Sheet Roll Forming Machine is a state-of-the-art piece of equipment that is designed to produce high-quality corrugated sheets with unmatched precision and efficiency. It is equipped with advanced technology, including computerized controls and servo motors, which enable it to produce consistent and precise results. The machine's high-speed performance is further enhanced by its durable and reliable components, ensuring continuous and trouble-free operation.One of the key features of the Corrugated Sheet Roll Forming Machine is its versatility. It can accommodate a wide range of materials, including steel, aluminum, and other metals, making it an ideal choice for a variety of manufacturing applications. Additionally, the machine is capable of producing various profiles and sizes of corrugated sheets, allowing companies to meet the diverse needs of their customers. This flexibility gives manufacturers a competitive edge, as they can easily adapt to changing market demands.In addition to its exceptional performance, the Corrugated Sheet Roll Forming Machine boasts a user-friendly design that provides operators with ease of use and convenience. Its intuitive controls and ergonomic layout make it easy to operate, minimizing the need for extensive training and reducing the risk of errors. Furthermore, the machine is built with safety in mind, incorporating features that protect operators and ensure a secure working environment.{Company Name} takes great pride in its commitment to customer satisfaction and support, and the introduction of the Corrugated Sheet Roll Forming Machine is a testament to this dedication. The company provides comprehensive training and support services to ensure that customers maximize the potential of their investment. With a team of experienced technicians and engineers, {Company Name} offers prompt and reliable assistance, including installation, maintenance, and troubleshooting, guaranteeing the long-term performance of the machine.The Corrugated Sheet Roll Forming Machine is not only a testament to {Company Name}'s dedication to excellence and innovation, but it also reflects the company's commitment to sustainability. The machine is designed to minimize waste and optimize material usage, helping companies reduce their environmental footprint and operate more efficiently. By producing high-quality corrugated sheets with minimal resources, the machine contributes to a more sustainable and responsible manufacturing process.In conclusion, {Company Name}'s Corrugated Sheet Roll Forming Machine is a game-changing innovation that has set a new standard for the manufacturing industry. With its superior performance, advanced features, and unwavering commitment to customer satisfaction, this cutting-edge equipment is revolutionizing the way companies produce corrugated sheets. As manufacturers continue to seek innovative solutions to improve their processes and increase their competitiveness, the Corrugated Sheet Roll Forming Machine stands out as a groundbreaking solution that delivers unmatched precision, efficiency, and reliability.

Ultimate Guide to Roll Forming Sheet Metal: Techniques and Benefits

Roll Forming Sheet Metal is a process used in the manufacturing industry to produce a wide range of products. This method involves feeding a long strip of metal through a series of rollers, which gradually shape the metal into the desired cross-section. The process is cost-effective and efficient, making it a popular choice for producing a variety of products, from automotive parts to building materials.One of the leading companies in the roll forming sheet metal industry is {company name}, a reputable manufacturer known for its high-quality products and innovative solutions. With a state-of-the-art facility and a team of skilled engineers and technicians, {company name} has been providing top-notch roll forming sheet metal services to clients across various industries for many years.The roll forming process used by {company name} allows for the production of complex shapes and profiles, with precise tolerances and consistent quality. The company's extensive experience in roll forming sheet metal enables them to tailor their services to meet the specific requirements of each client, ensuring that the final product meets or exceeds expectations.In addition to standard roll forming sheet metal services, {company name} also provides custom solutions for clients with unique design and production needs. Whether it's a challenging geometry, tight tolerances, or specific material requirements, the company's engineering team works closely with clients to develop tailored solutions that deliver superior results.{company name} takes pride in its ability to handle projects of all sizes, from small-batch production runs to large-scale manufacturing. The company's commitment to quality, efficiency, and customer satisfaction has earned them a strong reputation in the industry, making them a preferred choice for businesses looking for reliable roll forming sheet metal services.The company's dedication to continuous improvement and innovation is also evident in their investment in the latest equipment and technology. By staying abreast of industry advancements, {company name} is able to offer cutting-edge roll forming sheet metal solutions that meet the evolving needs of their clients.Furthermore, {company name} places a strong emphasis on sustainability and eco-friendly practices in their manufacturing processes. The company is dedicated to minimizing its environmental impact through the responsible use of resources, waste reduction, and energy-efficient practices, aligning with the growing demand for sustainable manufacturing solutions.In conclusion, {company name} is a leading provider of roll forming sheet metal services, offering a wide range of capabilities to meet the diverse needs of their clients. With a focus on quality, innovation, and sustainability, the company continues to set the standard for excellence in the industry. Whether it's standard profiles or custom solutions, {company name} is committed to delivering superior results that exceed expectations.

High-Quality Corrugated Iron Roofing Sheet Making Machine for Sale

In recent news, the Corrugated Iron Roofing Sheet Making Machine has been making waves in the construction industry. This cutting-edge machine, developed by a leading manufacturing company, is revolutionizing the production of corrugated iron roofing sheets, and is set to have a major impact on the construction sector.The {Company Name} has been at the forefront of innovation in the manufacturing industry for over two decades. With a strong focus on research and development, they have consistently pushed the boundaries of what is possible, and the Corrugated Iron Roofing Sheet Making Machine is a testament to their commitment to excellence.This state-of-the-art machine is designed to streamline the production process of corrugated iron roofing sheets, significantly reducing manufacturing time and costs. With its advanced technology and precision engineering, the machine is capable of producing high-quality roofing sheets at an unprecedented speed, without compromising on durability.The Corrugated Iron Roofing Sheet Making Machine is equipped with a range of cutting-edge features that set it apart from traditional manufacturing methods. Its automated operation allows for seamless production, with minimal human intervention required. This not only increases efficiency, but also reduces the risk of human error, ensuring consistently high-quality output.Furthermore, the machine's modular design offers versatility and scalability, allowing for easy customization and expansion as per the specific requirements of the production facility. This flexibility makes it suitable for a wide range of applications, from small-scale operations to large industrial facilities.The {Company Name}'s commitment to sustainability is also evident in the design of the Corrugated Iron Roofing Sheet Making Machine. By optimizing the use of raw materials and minimizing waste, the machine not only reduces environmental impact but also lowers production costs, making it a cost-effective and eco-friendly solution for the construction industry.In addition to its impressive technical capabilities, the {Company Name} provides comprehensive support and after-sales service for the Corrugated Iron Roofing Sheet Making Machine. Their team of highly skilled technicians and engineers are on hand to provide training, maintenance, and troubleshooting, ensuring that their clients can maximize the potential of the machine.The introduction of the Corrugated Iron Roofing Sheet Making Machine is poised to have a significant impact on the construction industry. The machine's ability to produce high-quality roofing sheets quickly and efficiently will not only benefit manufacturers but also have a positive ripple effect on the wider economy. With its potential to reduce production costs and increase output, the machine has the power to drive growth and innovation in the construction sector.As the demand for durable and cost-effective roofing solutions continues to rise, the Corrugated Iron Roofing Sheet Making Machine is set to play a crucial role in meeting these needs. Its cutting-edge technology, combined with the expertise of the {Company Name}, makes it a game-changer in the manufacturing industry, and a valuable addition to any production facility.In conclusion, the Corrugated Iron Roofing Sheet Making Machine, developed by the {Company Name}, represents a significant leap forward in the manufacturing of corrugated iron roofing sheets. Its innovative design, advanced features, and commitment to sustainability make it an invaluable asset for the construction industry. With its potential to drive efficiency, reduce costs, and increase output, this machine is set to revolutionize the way roofing sheets are produced, paving the way for a more sustainable and prosperous future in the construction sector.

Steel Cut to Length Roofing Sheet Roll Forming Machine for Metal Fabrication

Metal Steel Cut To Length Roofing Sheet Roll Forming Machine Revolutionizes Roofing Industry{Company name} is proud to introduce the latest addition to its line of innovative machinery – the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine. This state-of-the-art piece of equipment is set to revolutionize the roofing industry by providing a more efficient and cost-effective solution for producing high-quality metal roofing sheets.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is designed to streamline the process of creating roofing sheets from metal steel. With its advanced technology and precision engineering, this machine is capable of cutting and forming metal steel into perfectly shaped roofing sheets with remarkable speed and accuracy. This not only reduces the time and labor required for production but also ensures a consistent and high-quality end product.One of the key features of this machine is its versatility. It is capable of handling a wide range of metal steel materials, including galvanized steel, aluminum, and copper, making it suitable for a variety of roofing applications. Furthermore, it can produce roofing sheets of various lengths and dimensions, allowing for customization to meet the specific requirements of different projects.In addition to its cutting and forming capabilities, the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is equipped with advanced control systems that enable precise adjustments to be made to the production process. This ensures that the end product meets the exact specifications and quality standards desired by customers.The introduction of this groundbreaking machine is poised to bring about a significant shift in the roofing industry. By offering a more efficient and cost-effective solution for producing metal roofing sheets, {Company name} aims to help roofing companies improve their production processes and ultimately enhance the quality of their products.{Company name} has a strong track record of delivering cutting-edge machinery to various industries, and the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is another testament to their commitment to innovation. With a team of highly skilled engineers and technicians, the company has been able to develop this state-of-the-art machine that is set to make a lasting impact on the roofing industry.The Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is not only a game-changer for roofing companies but also for the end consumers. By improving the efficiency of production processes, this machine has the potential to reduce the overall cost of producing metal roofing sheets, which could translate into cost savings for customers.As the demand for metal roofing continues to grow, the introduction of the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine comes at a pivotal time. With its ability to significantly improve the production process and deliver high-quality roofing sheets, it is expected to become an essential piece of machinery for roofing companies looking to stay competitive in the market.{Company name} is excited to bring this groundbreaking machine to the market and is confident that it will play a pivotal role in reshaping the roofing industry. With its advanced technology, versatility, and efficiency, the Metal Steel Cut To Length Roofing Sheet Roll Forming Machine is set to become a game-changer in the production of metal roofing sheets.

High Quality Steel Rain Pipe Roll Forming Machine for Sale

Color Steel Rain Pipe Roll Forming Machine Revolutionizes the IndustryIn today's fast-paced and ever-evolving construction industry, innovation and precision are key factors in staying ahead of the game. With the introduction of the Color Steel Rain Pipe Roll Forming Machine by a leading manufacturer in the industry, construction companies now have access to a revolutionary tool that is set to transform the way rain pipes are produced.This state-of-the-art machine is designed to produce high-quality color steel rain pipes with unparalleled precision and efficiency. The roll forming process ensures that each rain pipe is uniform in shape and size, eliminating the need for manual adjustments and minimizing waste. This level of precision not only enhances the overall quality of the rain pipes but also reduces production time, allowing for faster turnaround and increased productivity.The Color Steel Rain Pipe Roll Forming Machine is equipped with advanced technology and features that make it a standout in the industry. The machine's user-friendly interface makes it easy for operators to set specific parameters and make adjustments as needed, ensuring that each rain pipe meets the exact specifications required. Additionally, the machine is designed for versatility, allowing for the production of rain pipes in a variety of sizes and profiles to meet diverse customer needs.One of the key advantages of this innovative machine is its ability to produce color steel rain pipes with superior durability and weather resistance. The use of high-quality materials and the precision of the roll forming process result in rain pipes that are not only aesthetically pleasing but also capable of withstanding harsh environmental conditions. This makes the Color Steel Rain Pipe Roll Forming Machine an ideal choice for construction projects in both urban and rural areas, where rain pipes are subject to a wide range of weather elements.With a focus on sustainability and environmental responsibility, the Color Steel Rain Pipe Roll Forming Machine is designed to minimize material waste and energy consumption. The efficient roll forming process ensures that materials are used with maximum efficiency, reducing the environmental impact of production. Additionally, the machine's energy-efficient design and low maintenance requirements make it a cost-effective and eco-friendly solution for construction companies.The introduction of the Color Steel Rain Pipe Roll Forming Machine represents a significant advancement in the construction industry, offering a solution that combines precision, efficiency, and durability. By revolutionizing the way rain pipes are produced, this innovative machine is set to have a profound impact on the industry, providing construction companies with a competitive edge and setting new standards for quality and performance.As a leading manufacturer of roll forming machines, {Company Name} is proud to introduce the Color Steel Rain Pipe Roll Forming Machine as the latest addition to its extensive lineup of innovative products. With a commitment to excellence and a focus on meeting the evolving needs of the construction industry, {Company Name} has designed this machine to exceed the highest standards of quality, performance, and reliability.Founded on the principles of innovation, precision, and customer satisfaction, {Company Name} has built a reputation for delivering cutting-edge solutions that enable construction companies to achieve their goals with confidence and efficiency. The Color Steel Rain Pipe Roll Forming Machine is a testament to this commitment, providing a solution that empowers construction companies to elevate their production capabilities and deliver unparalleled results.As the construction industry continues to evolve, {Company Name} remains dedicated to driving innovation and setting new benchmarks for excellence. With the introduction of the Color Steel Rain Pipe Roll Forming Machine, {Company Name} reaffirms its position as a leader in the roll forming machine industry, delivering solutions that transform the way construction projects are executed and raising the bar for quality and performance.

Coil-Fed Cutting Machine for Metal and Sheet Metal Applications - Laser and Fiber Laser Technology Available

Sheet Metal Coil Cutting Machine - DANOBAT LB - The Ultimate Solution for Your Cutting NeedsAre you in search of a reliable and efficient cutting solution for your sheet metal needs? Look no further than the DANOBAT LB coil-fed cutting machine. This state-of-the-art machine is designed for the metalworking industry to provide precise and efficient cutting of sheet metal.The DANOBAT LB coil-fed cutting machine is perfect for cutting sheet metal because it feeds the material directly from a coil, allowing for continuous and uninterrupted cutting. This means that there is no need to stop and reload sheets, which saves time and increases productivity.The cutting machine is equipped with fiber laser technology, which provides superior cutting quality and enhances precision. It can cut through a wide range of materials, including stainless steel, aluminum, and brass, making it a versatile choice for a variety of applications.The DANOBAT LB coil-fed cutting machine is easy to operate, with a user-friendly interface that allows operators to quickly and easily make adjustments to the cutting process. With its high-speed processing and high-precision cutting, it can easily handle complex shapes and intricate patterns.This cutting machine also boasts an advanced software system that allows for easy programming and automation of the cutting process. This means that it can run continuously with minimal operator intervention, saving time and reducing labor costs.In addition to its many features and benefits, the DANOBAT LB coil-fed cutting machine is built to last. It is constructed with high-quality materials and components, ensuring that it will provide reliable and consistent performance for years to come.If you're looking for a cutting solution that will increase your productivity and provide high-quality, precise cuts, consider the DANOBAT LB coil-fed cutting machine. With its advanced technology, user-friendly interface, and durable construction, it's the ultimate solution for all your cutting needs.

Latest Advancements in Roll Forming Techniques

Total Roll Forming, a leading roll forming company in the industry, has recently announced exciting new developments and expansions. With over 20 years of experience, Total Roll Forming has become known for its high-quality products and exceptional customer service. The company's commitment to innovation and continuous improvement has allowed them to stay at the forefront of the industry, and their latest announcement is a testament to their dedication to excellence.Total Roll Forming has recently expanded its facilities, adding a state-of-the-art production line that will increase their manufacturing capacity significantly. This expansion comes in response to the growing demand for their products, as well as their commitment to meeting the needs of their customers. The new production line is equipped with the latest technology and machinery, allowing Total Roll Forming to streamline their processes and improve efficiency.In addition to the expansion of their facilities, Total Roll Forming has also introduced a new range of products to their lineup. These new products have been developed in response to the changing needs of the market and are designed to meet the demands of a wide range of industries. Total Roll Forming has always been committed to staying ahead of the curve when it comes to product development, and these new additions to their catalog are a reflection of that dedication.This recent announcement from Total Roll Forming is a testament to the company's continued growth and success in the industry. With a focus on innovation and customer satisfaction, Total Roll Forming is well-positioned to continue leading the way in the roll forming industry. The company's expansion and introduction of new products are a clear indication of their commitment to meeting the needs of their customers and driving the industry forward.Total Roll Forming's dedication to excellence is evident in every aspect of their business. From their top-of-the-line production facilities to their exceptional customer service, Total Roll Forming is committed to delivering the highest quality products and services to their clients. The company's team of experienced professionals is always striving to push the boundaries and set new standards for the industry, and their recent expansion and product introductions are a clear demonstration of that commitment.In addition to their commitment to innovation and customer satisfaction, Total Roll Forming also places a strong emphasis on sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce their environmental footprint and minimize waste in their production processes. By investing in sustainable practices and technologies, Total Roll Forming is demonstrating their commitment to being a responsible corporate citizen and contributing to a better, more sustainable future.Overall, Total Roll Forming's recent announcement of their expansion and new product introductions is a clear indication of the company's continued success and commitment to excellence. With a focus on innovation, customer satisfaction, and sustainability, Total Roll Forming is poised to continue leading the way in the roll forming industry for years to come. Their dedication to continuous improvement and staying ahead of the curve is a testament to their position as a true industry leader.