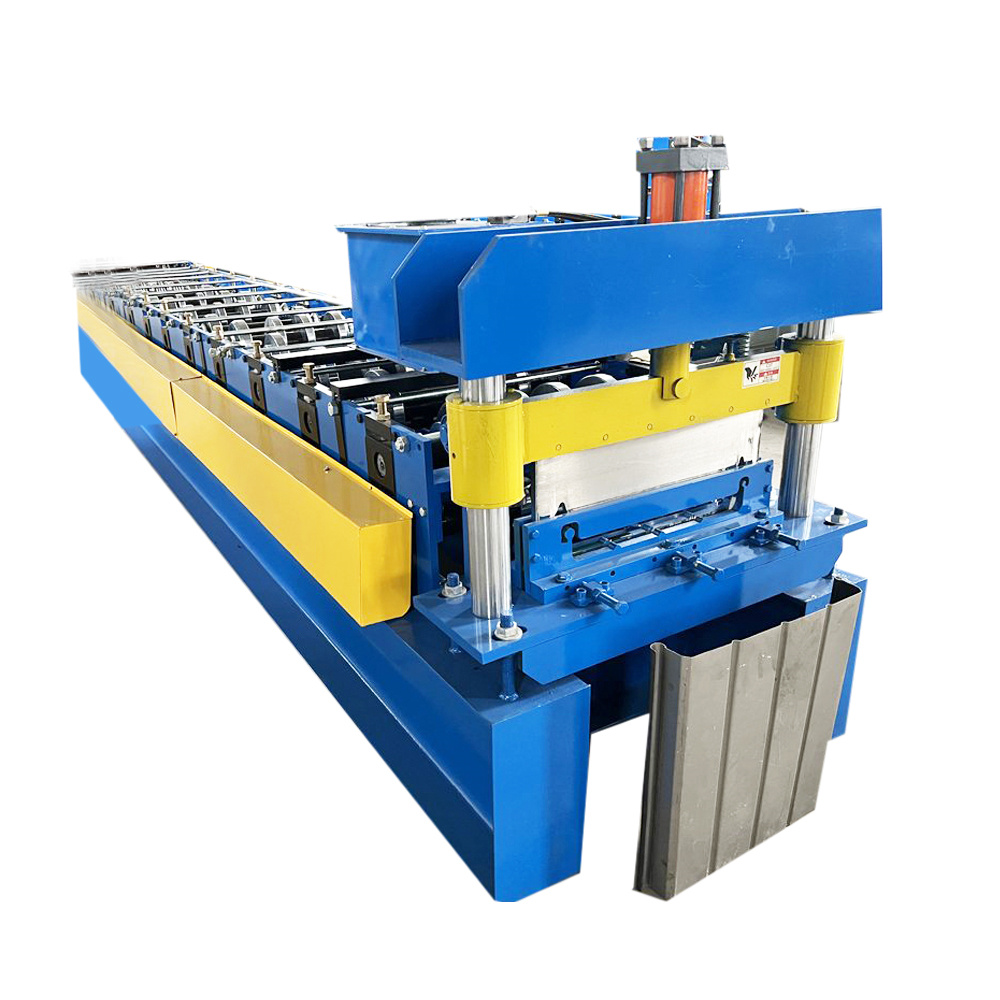

High-quality Roof Sheeting Machine for Efficient Construction

By:Admin

The Roof Sheeting Machine, which has been in development for over two years, is a culmination of extensive research and development efforts by RSMC's team of engineers and industry experts. It boasts a range of advanced features and capabilities that set it apart from traditional roofing sheet manufacturing equipment.

One of the key highlights of the Roof Sheeting Machine is its high-speed production capabilities. It is capable of producing roofing sheets at a rate that is significantly faster than competing machines, without compromising on quality. This will enable RSMC to meet the growing demand for roofing sheets in the market, while ensuring that each sheet meets the highest standards of durability and strength.

In addition to its impressive speed, the Roof Sheeting Machine also offers a high level of versatility. It is capable of producing roofing sheets in a variety of dimensions, thicknesses, and profiles, allowing RSMC to cater to a diverse range of customer requirements. This flexibility will enable the company to expand its product offerings and target new market segments, further solidifying its position as a leader in the roofing sheet industry.

Moreover, the Roof Sheeting Machine incorporates advanced automation and control systems, which help to streamline the production process and minimize the risk of errors. This will not only improve the overall efficiency of RSMC's manufacturing operations but also ensure that each roofing sheet meets the company's stringent quality standards.

The launch of the Roof Sheeting Machine represents a significant milestone for RSMC, reflecting the company's commitment to innovation and continuous improvement. With this new addition to its manufacturing capabilities, RSMC is poised to further enhance its competitive edge in the market and consolidate its position as a preferred supplier of high-quality roofing sheets.

The Roof Sheeting Machine is part of RSMC's broader strategy to invest in cutting-edge technology and modernize its production facilities. By leveraging the latest advancements in equipment and machinery, the company aims to not only enhance its operational efficiency but also reduce its environmental footprint, in line with its commitment to sustainability.

RSMC's dedication to innovation and quality has earned it a reputation as a trusted and reliable partner in the roofing sheet industry. With the launch of the Roof Sheeting Machine, the company is set to raise the bar even higher and set new standards for excellence in the manufacturing of roofing sheets.

As RSMC continues to expand its production capacity and strengthen its market presence, the Roof Sheeting Machine will play a crucial role in supporting its growth ambitions. With its cutting-edge technology and advanced capabilities, the machine is poised to drive RSMC's success and contribute to its leadership in the roofing sheet industry.

In conclusion, the launch of the Roof Sheeting Machine is a testament to RSMC's unwavering commitment to innovation, quality, and customer satisfaction. With this new addition to its manufacturing capabilities, the company is well-positioned to meet the evolving needs of the market and deliver superior roofing solutions to its customers.

Company News & Blog

High-Quality Z Purlin Making Machine for Efficient Manufacturing

Z Purlin Making Machine Enhances Production Efficiency for Steel Construction CompanyThe steel construction industry has always been a vital part of the global economy, providing the infrastructure for buildings, bridges, and various other structures. As technology continues to advance, there is a growing need for machinery that can streamline the production process and improve efficiency. With this in mind, the introduction of the Z Purlin Making Machine by a leading manufacturing company has brought significant improvements to the production capabilities of steel construction companies around the world.The Z Purlin Making Machine is a state-of-the-art piece of equipment that is designed to produce high-quality Z-shaped steel purlins, which are essential components in the construction of steel buildings. This machine is capable of handling different types of steel coils and can produce Z purlins of various sizes and thicknesses, making it a versatile and practical solution for steel construction companies of all scales.One of the key features of the Z Purlin Making Machine is its ability to automate the production process, which significantly reduces the need for manual labor and minimizes the risk of errors. This level of automation not only improves the overall efficiency of the production line but also enhances the safety of workers, as they are not required to perform repetitive tasks in a high-risk environment.Furthermore, the Z Purlin Making Machine is equipped with advanced technology that allows for precise and accurate manufacturing, resulting in consistent and reliable output. This not only benefits the steel construction company in terms of product quality but also contributes to cost savings by minimizing material wastage and rework.In addition to its technical capabilities, the Z Purlin Making Machine is also designed with user-friendly features that make it easy to operate and maintain. This ensures that steel construction companies can integrate this machine into their production process with minimal disruption and downtime, ultimately leading to a smoother transition towards improved production efficiency.For steel construction companies looking to enhance their production capabilities, the Z Purlin Making Machine offers a compelling solution that can deliver tangible benefits in terms of cost savings, quality improvement, and overall operational efficiency. By investing in this state-of-the-art equipment, companies can position themselves at the forefront of the industry and gain a competitive edge in the market.As a leading manufacturer of the Z Purlin Making Machine, our company is committed to providing innovative solutions that empower steel construction companies to thrive in today's dynamic business environment. With a strong focus on research and development, we have continuously refined our product to meet the evolving needs of our customers, ensuring that they have access to the latest technology that can drive their success.At our company, we understand the critical role that technology plays in the steel construction industry, and we are dedicated to delivering machinery that not only meets industry standards but also exceeds expectations. With the Z Purlin Making Machine, we have brought a new level of efficiency and productivity to steel construction companies, enabling them to achieve their production goals with confidence and precision.In conclusion, the introduction of the Z Purlin Making Machine has brought about a significant improvement in the production capabilities of steel construction companies, offering a combination of advanced technology, automation, and user-friendly features. As the demand for high-quality steel structures continues to grow, this machine serves as a valuable asset for companies seeking to stay competitive and deliver superior quality products to their clients. With our commitment to innovation and customer satisfaction, we are proud to be at the forefront of this technological advancement in the steel construction industry.

High-Quality Sheet Metal Forming Rollers for Efficient Manufacturing

[Company Name] is a leading manufacturer of sheet metal forming rollers and has been serving the industry for over two decades. The company takes pride in its innovative approach to sheet metal forming technology and is known for providing high-quality, durable, and reliable products to its customers.The latest addition to [Company Name]'s line of sheet metal forming rollers is set to revolutionize the industry. With a focus on precision engineering and advanced materials, the new rollers promise to deliver superior performance and efficiency for a wide range of applications.The development of these new rollers is a result of [Company Name]'s commitment to investing in research and development. By leveraging the latest technologies and engineering expertise, the company has been able to create a product that meets the ever-evolving needs of the sheet metal forming industry."We are thrilled to introduce our latest sheet metal forming rollers to the market," said [Company Name]'s CEO. "These rollers are the culmination of years of hard work, dedication, and a relentless pursuit of excellence. We believe that they will set a new standard for performance and reliability in the industry."The new rollers have been designed to offer a number of key benefits to their users. They are made from high-quality materials that are engineered to withstand the rigors of sheet metal forming processes. This ensures that they will have a long service life and require minimal maintenance, ultimately lowering the total cost of ownership for customers.In addition to their durability, the new rollers also offer improved precision and accuracy. This is essential for ensuring that the formed sheet metal meets the required specifications, which is particularly important in industries such as automotive manufacturing and aerospace.The design of the rollers also takes into account the need for flexibility. They are compatible with a wide range of sheet metal forming equipment, making them suitable for use in various manufacturing environments. This versatility ensures that [Company Name]'s customers can maximize the value they get from their investment in the new rollers.To support the launch of the new rollers, [Company Name] is also providing comprehensive technical support and training to its customers. This includes on-site assistance with installation and setup, as well as ongoing maintenance and troubleshooting support. This is part of the company's commitment to ensuring that its customers get the maximum benefit from their investment in its products.The introduction of the new sheet metal forming rollers represents a significant milestone for [Company Name]. It is a testament to the company's dedication to pushing the boundaries of what is possible in the sheet metal forming industry. With these new rollers, [Company Name] is poised to continue its leadership in the market and provide its customers with the tools they need to succeed.In conclusion, [Company Name]'s new sheet metal forming rollers represent a significant advancement in the industry. With their focus on durability, precision, and flexibility, these rollers are set to become an essential tool for manufacturers looking to optimize their sheet metal forming processes. As [Company Name] continues to innovate and invest in new technologies, it is clear that the company will remain at the forefront of the sheet metal forming industry for years to come.

Optimize Your Production Efficiency with the Latest Roll Form Machine

[Publication Name] – [Date]Roll Form Machine: Shaping the Future of ManufacturingIn today's ever-evolving industrial landscape, precision and efficiency in manufacturing processes are paramount. Companies across various sectors constantly seek innovative solutions to enhance production quality and reduce costs. [Company Name], a leading player in the manufacturing industry, remains at the forefront of this drive for cutting-edge technology.With their groundbreaking development – the Roll Form Machine – [Company Name] has revolutionized the way industries shape metal sheets, opening new doors of opportunity for businesses worldwide. This state-of-the-art machinery combines advanced engineering and groundbreaking automation, resulting in unmatched precision, speed, and versatility.The Roll Form Machine developed by [Company Name] has garnered significant attention due to its ability to transform flat pieces of metal into complex profiles and shapes with remarkable precision. The machine utilizes a continuous process where the metal sheet is fed into the machine, and through a series of carefully designed rolling dies, it is gradually formed into the desired shape.One of the key advantages of the Roll Form Machine lies in its flexibility. With interchangeable rolling dies and adjustable settings, the machine can easily adapt to produce a wide range of profiles and shapes. This versatility eliminates the need for multiple specialized machines, streamlining production processes and reducing costs for manufacturers.Furthermore, the Roll Form Machine boasts a rapid production speed that sets it apart from traditional manufacturing methods. By utilizing automated processes, [Company Name] has significantly enhanced the efficiency of roll forming, enabling manufacturers to achieve higher volumes and faster turnarounds. This advantage becomes particularly crucial for industries with high production demands, such as automotive, construction, and appliance manufacturing.Additionally, the Roll Form Machine ensures exceptional precision and accuracy throughout the entire production process. With advanced sensors and feedback systems, [Company Name] has implemented stringent quality control measures to meet the most demanding industry standards. The machine's ability to consistently deliver high-quality products with minimized defects has garnered praise from manufacturers seeking to maintain an edge in an increasingly competitive market.[Company Name], renowned for its commitment to innovation, has integrated cutting-edge automation technologies into the Roll Form Machine. Through the use of sophisticated software and control systems, the machine enables seamless integration into existing manufacturing setups. This seamless integration allows for centralized control, simplifies maintenance, and optimizes production schedules, empowering manufacturers to achieve higher productivity and reduce downtime.Moreover, the Roll Form Machine prioritizes safety, addressing a critical concern in the manufacturing industry. [Company Name] has invested in comprehensive safety measures, including emergency stop mechanisms, safety guards, and employee training, ensuring a secure and user-friendly operating environment. By prioritizing safety, the company aims to minimize accidents, protect its workers, and bolster customer trust in their products.The Roll Form Machine has already gained recognition and adoption within the manufacturing industry, with prominent companies across various sectors embracing its capabilities. Its impact has been particularly notable in the construction sector, as it allows for the rapid production of complex and customized profiles required for modern architectural designs.[Company Name] remains committed to research and development, continuously improving and expanding the capabilities of the Roll Form Machine. By working closely with their customers, the company seeks to understand the ever-changing needs of the industry and develop tailored solutions that propel manufacturing processes into the future.As the industrial landscape advances towards automation and precision, the Roll Form Machine developed by [Company Name] emerges as a game-changer, revolutionizing the way manufacturers shape metal sheets. With its remarkable flexibility, speed, precision, and safety features, this cutting-edge machinery promises to reshape industries and unlock new possibilities for businesses worldwide.###[Word Count: 649]

High-Quality Glazed Metal Tile Roll Forming Machine for Efficient Roofing Solutions

Glazed Metal Tile Roll Forming Machine Revolutionizes the Roofing IndustryThe roofing industry has just been revolutionized with the launch of the latest Glazed Metal Tile Roll Forming Machine. This state-of-the-art machine is designed to produce high-quality metal tiles that are not only durable and long-lasting but also have a visually appealing glazed finish. With its advanced technology and precision engineering, this machine is set to raise the bar for roofing materials and provide a cost-effective solution for both commercial and residential projects.The Glazed Metal Tile Roll Forming Machine is the brainchild of a leading manufacturer of roll forming machines, with a reputation for innovation and excellence in the industry. By combining their expertise with cutting-edge technology, they have created a machine that is set to disrupt the traditional methods of producing metal tiles for roofing applications. With its automated processes and user-friendly interface, this machine is set to streamline the production process, reduce labor costs, and increase overall efficiency for roofing companies.The Glazed Metal Tile Roll Forming Machine boasts a range of innovative features that set it apart from other roll forming machines on the market. One of its key highlights is its ability to produce metal tiles with a glazed finish, which enhances the aesthetic appeal of the tiles and adds a layer of protection against the elements. Additionally, the machine is designed to accommodate a wide range of metal materials, ensuring versatility and flexibility for different roofing projects. It also comes equipped with advanced control systems that allow for precise adjustments and consistent output quality.In addition to its advanced features, the Glazed Metal Tile Roll Forming Machine is also notable for its speed and efficiency. With its high production capacity and fast processing times, it is capable of meeting the demands of even the most time-sensitive projects. This makes it an ideal choice for roofing contractors who need to deliver high-quality metal tiles within tight deadlines.Furthermore, the Glazed Metal Tile Roll Forming Machine is built with durability and reliability in mind. Its robust construction and high-quality components ensure that it can withstand the demands of continuous operation, making it a sound investment for roofing companies looking for long-term value. Additionally, the machine is backed by comprehensive technical support and after-sales service, providing customers with peace of mind and confidence in their purchase.With the launch of the Glazed Metal Tile Roll Forming Machine, the roofing industry is set to experience a significant shift towards more advanced and efficient methods of producing metal tiles. This machine is poised to set new standards for quality, durability, and aesthetics, offering a competitive edge to roofing companies that adopt it into their production processes.In conclusion, the Glazed Metal Tile Roll Forming Machine is a game-changer for the roofing industry, offering a combination of advanced technology, efficiency, and quality that is unmatched by traditional roll forming machines. With its ability to produce visually appealing glazed metal tiles, it is set to elevate the standard for roofing materials and provide a cost-effective solution for both commercial and residential projects. As roofing projects continue to demand high-quality and durable materials, this machine is positioned to meet those needs and drive innovation in the industry. For any roofing company looking to stay ahead of the curve, the Glazed Metal Tile Roll Forming Machine is a must-have investment that promises to deliver long-term value and a competitive advantage.

Roll Forming Machine for Light Gauge Steel Trusses

Light Gauge Steel Truss Roll Forming Machine Revolutionizes Construction IndustryThe construction industry has undergone a significant transformation with the introduction of the Light Gauge Steel Truss Roll Forming Machine, a state-of-the-art technology that is set to change the way we build. This innovative machine has been designed to produce high-quality steel trusses more efficiently than traditional methods, effectively reducing construction time and costs.The foundation stone of this technology was laid by a leading manufacturing company that has been serving the construction industry for many years. This modern machine is not only revolutionary but also green, making it a perfect fit for environmentally conscious construction projects.The process of manufacturing steel trusses with the Light Gauge Steel Truss Roll Forming Machine starts with a roll of steel. This roll is then fed into the machine where it undergoes several processes to form the truss. The machine uses a series of precision tools to shape the steel to the desired specifications, producing trusses that are ready for installation without further modifications.The Light Gauge Steel Truss Roll Forming Machine can produce a wide range of truss designs including king post, queen post, and double pitch trusses. The machine is highly customizable, making it easy for the manufacturer to produce trusses of different sizes and shapes. This feature makes it suitable for both simple residential construction projects and large-scale commercial developments.One of the significant advantages of using the Light Gauge Steel Truss Roll Forming Machine is its speed. Traditional methods of producing steel trusses can be time-consuming, and the quality can vary greatly. The modern machine, however, can produce high-quality trusses at a speed of up to 60 meters per minute, reducing production time by up to 50%.In addition to its speed, the Light Gauge Steel Truss Roll Forming Machine is highly accurate. The precision tools used in the manufacturing process produce trusses with consistent dimensions, ensuring that they fit perfectly in the building without the need for modifications.Furthermore, the Light Gauge Steel Truss Roll Forming Machine is eco-friendly, emitting minimal pollutants during operation. Its low carbon footprint makes it an ideal choice for green construction projects where sustainability is a priority.The Light Gauge Steel Truss Roll Forming Machine eliminates the need for welding and other heavy-duty tasks, which reduces the health and safety risks associated with traditional methods. This feature significantly improves the safety of the workers and reduces the risk of on-site accidents.The Light Gauge Steel Truss Roll Forming Machine is easy to operate, ensuring that manufacturers require minimal training. The machine's user-friendly interface allows for easy adjustments, reducing downtime and ensuring that production remains optimal.In conclusion, the introduction of the Light Gauge Steel Truss Roll Forming Machine has significantly transformed the construction industry. This innovative technology is cost-effective, eco-friendly, and capable of producing high-quality steel trusses at incredible speeds. It has made construction safer, more efficient, and more sustainable. Its versatility in producing a wide range of truss designs makes it suitable for both small and large-scale construction projects. The Light Gauge Steel Truss Roll Forming Machine is undoubtedly the future of steel truss production and the construction industry as a whole.

High-Quality Glazed Tile Roll Forming Machine for Metal Roofing Production

Are you in need of a high-quality glazed tile roll forming machine for your metal roofing production? Look no further than the Color Steel Glazed Metal Tile Roll Forming Machine from Dahezb.Designed for producing metal roof tiles in thicknesses ranging from 0.3-0.6mm, this machine specializes in creating aluminum roofing step tile and glazed tiles for roofing sheets. Using advanced automatic technology, it ensures fast and efficient production with consistent results, making it the perfect choice for industrial settings.One of the key advantages of the Color Steel Glazed Metal Tile Roll Forming Machine is its versatility. It can be used with a wide range of raw materials, including color steel, galvanized steel, and aluminum, giving you greater flexibility in your production processes. Additionally, it boasts a high level of precision, thanks to its advanced integrated control system that ensures every tile is made to exacting standards.Another benefit of this glazed tile roll forming machine is its ease of use. With a simple and easy-to-follow interface, it can be operated by personnel with minimal training, reducing the learning curve and saving you time and money. Its compact design also makes it ideal for smaller facilities, and it can be easily transported between locations.Finally, the Color Steel Glazed Metal Tile Roll Forming Machine is built to last. It is constructed from durable materials that can withstand heavy use, and its high-quality components ensure that it requires minimal maintenance over its lifetime. This translates to a lower total cost of ownership and a higher return on investment for your business.In conclusion, if you're looking for a reliable, efficient, and user-friendly glazed tile roll forming machine for your metal roofing production, the Color Steel Glazed Metal Tile Roll Forming Machine from Dahezb is an excellent choice. With its advanced technology, precision, versatility, and durability, it will help you take your business to the next level and meet even the most demanding production requirements.

Cut to Length Machine: A Complete Guide for Steel Cutting Operations

Steel Cut To Length Machine revolutionizing the metalworking industryIn the world of metalworking, precision and efficiency are key components of success. The Steel Cut To Length Machine, produced by a leading manufacturer in the industry, is revolutionizing the way steel is processed and cut. This state-of-the-art machine combines cutting-edge technology with the company's expertise and dedication to excellence, making it a game-changer for businesses in the metalworking sector.With a strong commitment to innovation and quality, {company name} has established itself as a leader in the manufacturing of metalworking machinery. The Steel Cut To Length Machine is a testament to the company's dedication to providing cutting-edge solutions to its customers. With a focus on precision and efficiency, this machine is designed to streamline the process of cutting steel, providing businesses with a cost-effective and reliable solution for their metalworking needs.One of the key features of the Steel Cut To Length Machine is its advanced cutting technology. Equipped with high-precision blades and state-of-the-art automation, this machine is capable of cutting steel with unparalleled accuracy and speed. This precision cutting technology ensures that businesses can produce high-quality steel products with minimal waste, saving both time and money in the production process.Another notable feature of the Steel Cut To Length Machine is its versatility. This machine is designed to handle a wide range of steel thicknesses and widths, making it suitable for a variety of metalworking applications. Whether businesses are working with thin-gauge steel or heavy-duty materials, this machine is capable of delivering consistent and precise cuts, ensuring that the finished products meet the highest standards of quality.In addition to its cutting-edge technology and versatility, the Steel Cut To Length Machine is also designed with user-friendliness in mind. The machine's intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, streamlining the production process and minimizing the potential for errors. This user-friendly design is a testament to {company name}'s commitment to providing its customers with practical and efficient solutions for their metalworking needs.For businesses in the metalworking industry, investing in the Steel Cut To Length Machine represents a step forward in achieving greater productivity and efficiency. By incorporating this cutting-edge machine into their operations, businesses can optimize their production processes, reduce waste, and ultimately improve their bottom line. With the support of {company name}'s expertise and commitment to excellence, the Steel Cut To Length Machine is helping businesses in the metalworking sector stay ahead of the competition.In conclusion, the Steel Cut To Length Machine, produced by {company name}, is transforming the metalworking industry with its cutting-edge technology, versatility, and user-friendly design. With a focus on precision and efficiency, this machine is empowering businesses to achieve greater productivity and cost-effectiveness in their operations. As the demand for high-quality steel products continues to grow, the Steel Cut To Length Machine is positioning businesses in the metalworking sector for success, driving innovation and progress in an ever-evolving industry.

High-quality Steel Profile Manufacturing Machine for Your Business Needs

Color Steel Profile Manufacturing Machine, a leading manufacturer of steel profile manufacturing machinery, has announced the launch of a new series of cutting-edge machines that are set to revolutionize the industry.With over 20 years of experience in the industry, Color Steel Profile Manufacturing Machine has built a solid reputation for delivering high-quality, innovative solutions to meet the evolving needs of the steel profile manufacturing sector. The company prides itself on its commitment to excellence, attention to detail, and dedication to customer satisfaction.The new series of machines leverages the latest advancements in technology to offer state-of-the-art features and capabilities. From precision engineering to seamless integration with existing manufacturing processes, these machines are designed to optimize productivity, improve efficiency, and reduce manufacturing costs.One of the key highlights of the new series is its enhanced automation capabilities. These machines are equipped with advanced automation systems that enable seamless operation, minimal human intervention, and improved safety. This not only streamlines the manufacturing process but also reduces the risk of errors and enhances overall product quality.In addition to automation, the new series also boasts advanced control systems that provide real-time monitoring and adjustment of key parameters. This enables operators to fine-tune the machines for optimal performance, resulting in higher yields and better quality products.Furthermore, the new series is engineered for versatility, with the ability to produce a wide range of steel profiles with varying specifications, dimensions, and finishes. This flexibility allows manufacturers to cater to a diverse array of customer requirements and market demands, without the need for multiple machines or extensive retooling.Another notable feature of the new series is its energy-efficient design. With a focus on sustainability and cost-effectiveness, the machines are engineered to minimize energy consumption without compromising performance. This not only benefits the environment but also offers significant cost savings for manufacturers in the long run.Color Steel Profile Manufacturing Machine understands the importance of ongoing support and service, which is why the new series comes with comprehensive training, technical support, and aftersales services. This ensures that customers can maximize the value of their investment and operate the machines with confidence and peace of mind.As the steel profile manufacturing industry continues to evolve and grow, the launch of the new series from Color Steel Profile Manufacturing Machine represents a significant milestone. The company remains committed to pushing the boundaries of innovation and delivering solutions that empower manufacturers to thrive in a competitive market."We are excited to introduce our latest series of steel profile manufacturing machines," said a spokesperson for Color Steel Profile Manufacturing Machine. "With their advanced features and capabilities, we believe these machines will set new standards for performance, efficiency, and reliability. We are confident that they will be a game-changer for manufacturers looking to stay ahead in the industry."The new series of machines from Color Steel Profile Manufacturing Machine is now available for order, with customization options to suit specific requirements. With its track record of excellence and a forward-looking approach to innovation, the company is poised to continue leading the way in the steel profile manufacturing sector.

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.

Leading Supplier of Roll Forming Machines: China's Top Manufacturer for Roll Forming Machine Products

Modern day life is fast, and with the increase in population, the number of vehicles on the road has multiplied immensely. This has made the need for a highway guardrail forming machine inevitable. Apart from providing safety for vehicles against accidents, the highway guardrail system also ensures the safety of road workers and pedestrians.Manufacturing highway guardrails is a highly specialized process that involves the use of standard machines. In recent years, the evolution of the roll forming machine has made it possible to produce highway guardrails more efficiently and inexpensively. The highway guardrail forming machine is a new technology that ensures the production of high-quality and reliable guardrails, which are crucial for the safety of all road users.The highway guardrail forming machine is designed to produce a variety of guardrail profiles and shapes. It is made of several components that work in tandem to deliver the desired results. The machine is highly versatile and can be used to produce different types of guardrails, including steel guardrails, W beam guardrails, and thrie beam guardrails.The process of manufacturing highway guardrails using roll forming machines is simpler and faster than traditional methods. The use of the highway guardrail forming machine eliminates the need for welding, which is a time-consuming and costly process. The machine forms the guardrails by passing the materials through a set of rollers that bend the material into the desired shape. This process ensures that the material is not distorted or weakened, ensuring the quality and strength of the completed guardrails.The highway guardrail forming machine's efficiency and cost-effectiveness have made it the primary choice for most guardrail manufacturers. It allows manufacturers to produce guardrails at a faster pace, with greater accuracy, and at a lower cost. This has resulted in an increase in production volumes, leading to faster project completion times and increased customer satisfaction.Apart from increased productivity and lower production costs, the use of the highway guardrail forming machine has other benefits. The machine guarantees a uniform quality of the guardrails produced, eliminating the human error that could lead to inconsistencies and reduced strength. Additionally, the machine is eco-friendly, eliminating the need for excessive energy usage and the production of waste.In conclusion, the highway guardrail forming machine is a significant technological advancement in the production of highway guardrails. It has revolutionized the manufacturing process, making it faster, more efficient, and cost-effective. Manufacturers who use this machine can produce high-quality guardrails that meet the highest safety requirements while reducing wastage, cost, and environmental impact. The highway guardrail forming machine is a crucial component in building safer roads and ensuring the safety of all road users, making it an essential technology for the modern-day world.