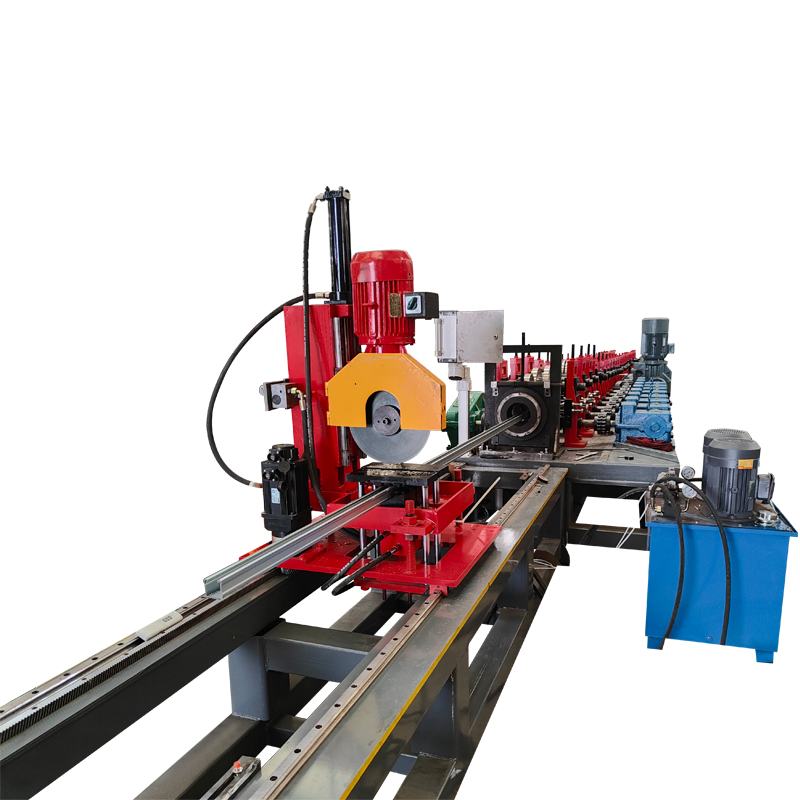

High-Quality Roofing Roll Forming Machines for Steel Material

By:Admin

One of the leading manufacturers of Steel Roofing Roll Forming Machines, {}, has been at the forefront of technological innovation and industry expertise. With a strong focus on research and development, the company has continuously improved and updated its product line to meet the evolving needs of the construction industry.

The importance of Steel Roofing Roll Forming Machines in the construction industry cannot be overstated. These machines have revolutionized the way metal roofing and cladding panels are produced, offering a highly efficient and cost-effective solution for roofing contractors and building owners. By using Steel Roofing Roll Forming Machines, manufacturers can produce large quantities of roofing panels with minimal waste and labor, resulting in significant cost savings for their customers.

The versatility of Steel Roofing Roll Forming Machines also allows for the production of a wide range of roofing profiles, including standing seam, corrugated, and concealed-fastener panels. This flexibility enables manufacturers to meet the unique design and performance requirements of different building projects, from residential homes to commercial and industrial facilities. Furthermore, the precision and consistency provided by these machines ensure that each panel meets the highest standards of quality and durability.

In addition to their efficiency and versatility, Steel Roofing Roll Forming Machines are also known for their durability and low maintenance requirements. Built with high-quality materials and advanced engineering, these machines are designed to withstand the rigors of continuous use in demanding manufacturing environments. This durability ensures that manufacturers can rely on their Steel Roofing Roll Forming Machines to consistently deliver high-quality roofing panels, year after year.

Furthermore, {} has established itself as a trusted and reliable partner for manufacturers worldwide. With a strong commitment to customer satisfaction, the company provides comprehensive support and training to ensure that customers can maximize the performance of their Steel Roofing Roll Forming Machines. This includes installation and commissioning services, as well as ongoing technical assistance and spare parts availability.

As the construction industry continues to evolve and demand for high-quality, cost-effective roofing solutions grows, Steel Roofing Roll Forming Machines will play a crucial role in meeting these needs. With their ability to efficiently produce a wide range of roofing profiles, while delivering exceptional quality and durability, these machines are well-positioned to remain a key technology in the construction industry for years to come.

In conclusion, Steel Roofing Roll Forming Machines have become an indispensable tool for the modern construction industry. With their efficiency, versatility, and durability, these machines enable manufacturers to produce high-quality metal roofing panels in a cost-effective and sustainable manner. As a leading manufacturer of Steel Roofing Roll Forming Machines, {} continues to drive innovation and excellence, ensuring that its customers can meet the evolving demands of the construction industry with confidence and success.

Company News & Blog

Machine for Making Corrugated Iron Roofing Sheets

Corrugated Iron Roofing Sheet Making Machine Revolutionizes the Roofing IndustryIn the ever-evolving world of manufacturing technology, the introduction of the Corrugated Iron Roofing Sheet Making Machine has completely transformed the roofing industry. With its advanced capabilities and high efficiency, this innovative machine has redefined the way roofing sheets are produced, offering numerous benefits to both manufacturers and consumers. The Corrugated Iron Roofing Sheet Making Machine, developed by a leading engineering company, has already made waves in the industry due to its remarkable features and cutting-edge design. It is renowned for its ability to produce high-quality corrugated iron roofing sheets at an unprecedented speed, making mass production a reality for manufacturers worldwide. One of the key advantages of this machine is its versatility. It is capable of fabricating different profiles and designs, ensuring that manufacturers can meet the diverse needs and preferences of their customers. Whether it is a residential project or a large-scale commercial development, the Corrugated Iron Roofing Sheet Making Machine can adapt to the required specifications effortlessly, allowing for seamless production of customized roofing sheets. Moreover, this state-of-the-art machine significantly reduces human intervention in the production process, enhancing overall productivity and efficiency. With its automated functionality, it minimizes the risk of errors and the need for manual labor, thereby optimizing time and resources. Manufacturers can now accomplish more in less time, fueling the growth of their businesses and meeting tight project deadlines with ease. The Corrugated Iron Roofing Sheet Making Machine is also lauded for its exceptional durability and reliability. Constructed with high-quality materials and utilizing the latest technological advancements, this machine boasts a prolonged lifespan, making it a sound investment for manufacturing companies. It can withstand heavy loads and prolonged usage without compromising on the quality of the output, thereby ensuring the longevity and integrity of the produced roofing sheets. Furthermore, this machine addresses environmental concerns, as it incorporates sustainable practices in its operation. With its energy-efficient components and reduced raw material wastage, it contributes to the promotion of eco-friendly manufacturing processes. Manufacturers can now partake in sustainable initiatives while efficiently fulfilling the demands of the market, resulting in a win-win situation for both businesses and the environment.The introduction of the Corrugated Iron Roofing Sheet Making Machine has not only revolutionized the manufacturing industry but also impacted consumers positively. The availability of roofings sheets produced by this machine ensures higher quality and durability, offering enhanced protection to homes and infrastructures. Additionally, due to its efficient production process, the cost of these roofing sheets is significantly reduced, benefiting consumers by making home improvements more cost-effective. The company behind the Corrugated Iron Roofing Sheet Making Machine, as a pioneer in engineering excellence, has always been committed to developing innovative solutions that address the needs of the construction industry. With its unwavering dedication to producing cutting-edge equipment, this company has become a trusted partner for manufacturers seeking reliable and state-of-the-art machinery for their production processes.As the demand for high-quality roofing sheets continues to grow, the Corrugated Iron Roofing Sheet Making Machine remains at the forefront, paving the way for the future of the roofing industry. Its unrivaled capabilities, streamlined production process, and commitment to sustainability have made it a game-changer, setting new standards for manufacturing practices. With this revolutionary machine, manufacturers can achieve higher levels of efficiency, productivity, and customer satisfaction, positioning themselves as leaders in the competitive market.

High-Quality Metal Roll Forming Machine Available for Purchase – Roof Panel Roll Forming Machine Supplier

Machine, Roll Forming Machine, Roof Panel Roll Forming Machine, Metal Roll Forming, Forming Machine, Metal Roll, Metal Roll Forming Machine for Sale, Buy Metal Roll Forming Machine, Metal Roll Forming Machine Wholesaler, Metal Roll Forming Machine Seller, Top-quality Metal Roll Forming Machine, Benefits of Using Metal Roll Forming Machine, Roll Forming Process, Metal Roll Forming vs Other Forming Techniques, Applications of Metal Roll Forming Machine, Factors to Consider when Buying Metal Roll Forming Machine.Title: Advancing Manufacturing with Metal Roll Forming MachineIntroduction:In the ever-evolving manufacturing industry, metal roll forming machines have become an essential tool for efficiently producing high-quality metal components. This blog will explore the benefits of using metal roll forming machines, discuss the roll forming process, compare metal roll forming with other forming techniques, highlight the applications of metal roll forming machines, and provide insights on factors to consider when purchasing these machines.Benefit 1: Top-quality Metal ComponentsMetal roll forming machines offer superior precision and accuracy in producing metal components. The continuous bending process ensures consistent dimensions, smooth edges, and precise shapes across multiple pieces, resulting in high-quality finished products. Additionally, the ability to control forming speeds and pressures allows for the production of complex and intricate designs, meeting various industry specifications.Benefit 2: Cost-effective ProductionMetal roll forming machines facilitate cost-effective production due to their ability to handle high volumes of material with minimal wastage. By using coil stock material, roll forming eliminates the need for traditional sheet metal blanks, reducing material costs and minimizing scrap. Furthermore, the continuous operation of roll formers decreases labor requirements and enhances production efficiency, ultimately reducing overall manufacturing costs.Benefit 3: Versatile ApplicationsMetal roll forming machines find applications in various industries, including automotive, construction, aerospace, and furniture. These machines offer versatility in creating a wide range of metal profiles, such as roof panels, wall cladding, gutters, window frames, and door frames. The flexibility in material thickness, width, and length allows manufacturers to cater to diverse customer requirements and adapt to market trends effectively.Roll Forming Process:The roll forming process involves feeding coil stock material into a series of contoured rolls, gradually bending and shaping the metal. As the material moves through multiple stations, the rolls progressively form the desired profile. Each station performs a specific shaping operation, such as punching, notching, embossing, or cutting. By adjusting the roll spacing, manufacturers can achieve precise dimensions and shapes. The formed metal components are then cut to the desired length using a flying shear or cut-off press.Metal Roll Forming vs Other Forming Techniques:Compared to other forming techniques like stamping and press braking, metal roll forming offers several advantages. First, roll forming allows for continuous production with minimal interruptions, reducing operational downtime. Second, roll forming eliminates the need for pre-formed blanks or separate operations for joining multiple pieces, resulting in faster production cycles. Finally, roll-formed components exhibit improved structural integrity due to the continuous grain flow, enhancing their strength and durability.Applications of Metal Roll Forming Machines:1. Automotive Industry: Metal roll forming machines are widely used in manufacturing automotive body components, including chassis, roof rails, door frames, and window frames. The ability to produce complex profiles and maintain tight tolerances makes roll forming an ideal choice for this industry.2. Construction Industry: Roll-formed profiles for roofing panels, wall cladding, and structural components are in high demand in the construction sector. The cost-effectiveness and precision of metal roll forming machines make them indispensable for producing these architectural elements.3. Furniture Industry: Roll forming technology is employed in the production of metal furniture components like frame elements, brackets, and decorative fittings. The versatility and high-quality output of metal roll forming machines contribute to the aesthetic appeal and functionality of modern furniture designs.Factors to Consider when Buying Metal Roll Forming Machines:1. Machine Size and Capacity: Consider the required profile dimensions, thickness, and material type to ensure compatibility with the selected machine's specifications.2. Material Handling and Coil Weight: Evaluate the machine's ability to handle heavy coil stock material and ensure that it suits your production requirements.3. Tooling Flexibility: Check if the machine allows for easy changeovers between different profiles and if additional tooling options are available to expand its capabilities.4. Automation and Integration: Decide if integrating automation features, like computer numerical control (CNC) systems, is necessary to enhance production efficiency and reduce human error.5. After-sales Support: Research the reputation of the manufacturer and evaluate the availability of technical support, spare parts, and maintenance services.Conclusion:Metal roll forming machines offer numerous benefits, including top-quality production, cost-effectiveness, and versatility. The roll forming process, with its continuous bending and shaping, ensures consistent dimensions and smooth edges. Metal roll forming outperforms other forming techniques in terms of efficiency, structural integrity, and faster production cycles. These machines find applications in diverse industries like automotive, construction, and furniture manufacturing. When purchasing a metal roll forming machine, considering factors such as machine size, capacity, tooling flexibility, and after-sales support will help manufacturers make informed decisions and achieve optimal results in their production processes.

New Steel Product Quickly Gains Popularity in Construction Industry

[Company Name] Launches Robust Purlins to Support Construction Industry[date][Location] [Company Name], a leading manufacturer and supplier of construction materials, has announced the release of their latest innovation in the building industry – robust purlins. These high-quality steel components are set to revolutionize the way construction projects are carried out, offering increased durability, ease of installation, and cost-effectiveness.Purlins, commonly used in roofing and cladding systems, play a crucial role in providing structural support to buildings. They are horizontal, load-bearing beams that span between trusses or rafters and help transfer the weight of the roof to the main support structure. With [Company Name]'s new range of robust purlins, builders and contractors can now have peace of mind knowing that they are using a dependable and long-lasting product.The concept behind [Company Name]'s robust purlins lies in their meticulous design and precise engineering. Crafted from high-strength galvanized steel, these purlins offer exceptional structural integrity, ensuring stability and longevity of the buildings they are used in. The galvanization process protects against corrosion and adds an extra layer of resilience, making the purlins suitable for a variety of environmental conditions.Installing the new purlins is a breeze, thanks to their innovative design. Their lightweight nature allows for easy handling, reducing the time and effort required during the construction process. The purlins have also been designed to fit seamlessly with existing building components, making them adaptable for both new constructions and renovation projects.One of the standout features of [Company Name]'s robust purlins is their cost-effectiveness. By using these high-quality purlins, builders can reduce the need for additional support structures and minimize material wastage. The purlins' strength-to-weight ratio ensures they can withstand heavy loads, reducing the number of purlins required, ultimately saving on project costs.In line with [Company Name]'s commitment to sustainable practices, the new purlins are made from recycled materials. By utilizing these eco-friendly purlins, builders and designers can contribute to reducing their carbon footprint, promoting a greener, more sustainable construction industry."We are extremely excited to introduce our new range of robust purlins to the market," says [Company Name]'s CEO, [CEO Name]. "With their impressive strength, ease of installation, and cost-effectiveness, we believe these purlins will make construction projects more efficient while providing durable support structures."As a company dedicated to customer satisfaction, [Company Name] aims to provide exceptional after-sales assistance and technical support. With a team of experienced engineers on standby, customers can expect seamless integration of the purlins into their building projects, along with any necessary guidance or troubleshooting.[Company Name]'s robust purlins are now available for purchase and can be ordered through their website or authorized distributors. The company also plans to conduct workshops and training sessions to educate builders and contractors on the benefits and proper installation of these purlins.In conclusion, [Company Name]'s launch of their robust purlins marks a significant milestone in the construction industry. With enhanced durability, ease of installation, and cost-effectiveness, these purlins are set to become the go-to choice for builders and contractors worldwide. By incorporating these innovative components into their projects, construction professionals can expect increased efficiency, reduced costs, and durable structures that stand the test of time.

High-Quality Color Steel Sheeting Roofing Panel Cold Roll Forming Machine - Efficient and Easy to Operate This hand-operated rolling machine is an affordable and reliable solution for producing high-quality color steel sheeting roofing panels. It boasts low energy consumption and a yield strength of 32MPa, making it ideal for small-scale production. The equipment includes a roll forming system, hydraulic cutter, hydraulic station, electric control system, counter, and product supporter. With a processing speed of 8m/min and thickness range of 0.3-1mm, this machine is efficient and easy to operate.

, Sheet Hand Operated Rolling Machine, Cold Roll Forming Machine, Roofing Panel Roll Forming Machine, Mechanical Kingdom.Sheet Hand Operated Rolling Machine - A Reliable and Low-Cost Solution for Color Steel Sheeting Roofing Panel ManufacturingThe sheet hand operated rolling machine is a cost-effective and efficient solution for manufacturing color steel sheeting roofing panels. With its reliable working mechanism, easy operation, and low energy consumption, the machine is an excellent choice for small to medium-scale manufacturing units.Certificate and SpecificationsThe sheet hand operated rolling machine adheres to the CE certification and comes with a 7.5 KW main motor power and 4 KW hydraulic station power. The machine's sprocket is P-25.4, with 20 roller station capacity, which can produce a yield strength of up to 32MPa. The diameter of the principal axis is 70mm, and the roller material is made of 45# steel hard chrome plating. The machine can process sheets with a thickness of 0.3-1mm and has an installation dimension of about (L*W*H) 10*1.5*0.8M.Functional Features and AdvantagesThe sheet hand operated rolling machine is designed with several functional features that make it a robust and reliable option for color steel sheeting roofing panel manufacturing. Some notable features include:Low-Cost and High Efficiency: The machine is a low-cost and high-efficiency solution that can complete the manufacturing process quickly and efficiently.Reliable Working Mechanism: The machine's working mechanism is reliable, ensuring that the quality of the products is consistent.Easy Operation: The machine is easy to operate, even for those with no prior experience in the field.Low Energy Consumption: The machine consumes minimal energy, making it an eco-friendly option that reduces the energy bills.Equipment PartsThe machine includes several equipment parts, including roll forming, hydraulic cutter, hydraulic station, electric controlling system, counter, and product supporter. These parts work together to ensure that the machine can produce high-quality color steel sheeting roofing panels.Manufacturers of Roll Forming MachinesMechanical Kingdom is a renowned manufacturer of roll forming machines, operating in this field for the past 12 years. They offer a wide range of products, including tile-crushing computer control systems, ancient glazed tile copy machines, Laura machines, beam-free arch making machines, great-span, and beam-free structure equipment, as well as motor car plate making machines.ConclusionIn conclusion, the sheet hand operated rolling machine is a reliable, low-cost, and efficient solution for color steel sheeting roofing panel manufacturing. With its easy operation, low energy consumption, and robust working mechanism, it is an excellent choice for small to medium-scale manufacturing units. Mechanical Kingdom is a reputable manufacturer of roll forming machines, offering a range of products that cater to various requirements.

Fully Automatic C Purlin Roll Forming Machine: A Complete Guide

Fully Automatic C Purlin Roll Forming Machine Revolutionizing the Steel Structure IndustryThe steel structure industry has been revolutionized by the introduction of the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field. This innovative machine has significantly enhanced the efficiency and productivity of producing C purlins, which are essential components in the construction of steel buildings.With the increase in demand for steel structures due to their durability, cost-effectiveness, and flexibility, the need for advanced manufacturing equipment has become more critical. The Fully Automatic C Purlin Roll Forming Machine meets this demand by automating the production process, reducing manual labor, and increasing output.The machine's advanced technology allows for precise and accurate forming of C purlins, ensuring consistent quality and dimensional accuracy. This level of precision is essential for the seamless assembly and construction of steel buildings, where even the slightest deviation in the dimensions of components can result in installation challenges and structural issues.The Fully Automatic C Purlin Roll Forming Machine is designed to handle a wide range of materials, including galvanized steel, stainless steel, and aluminum, making it versatile for various construction requirements. This flexibility has made it an ideal choice for manufacturers, contractors, and construction companies looking to streamline their production processes and deliver high-quality steel structures to their clients.In addition to its advanced technology, the machine's fully automated operation has significantly reduced production time, allowing for faster turnaround times and increased production capacity. This has had a direct impact on the overall efficiency and profitability of steel structure manufacturing companies, enabling them to meet deadlines and fulfill orders more effectively.Furthermore, the machine's automated operation has also improved workplace safety by reducing the need for manual handling of heavy materials and minimizing the risk of work-related injuries. This has not only created a safer work environment for employees but has also contributed to the overall productivity of production facilities.The company behind the Fully Automatic C Purlin Roll Forming Machine has a long-standing reputation for delivering high-quality and reliable manufacturing equipment to the steel structure industry. With a team of experienced engineers and technicians, the company has been at the forefront of innovation, continuously developing and refining its products to meet the evolving needs of the industry.The company's commitment to research and development has resulted in the creation of cutting-edge technologies that have set new standards for efficiency, reliability, and performance in the manufacturing of steel components. The Fully Automatic C Purlin Roll Forming Machine is a testament to this dedication, as it represents the pinnacle of modern engineering and design in the steel structure industry.In addition to its technological expertise, the company also takes pride in its commitment to customer satisfaction, providing comprehensive support and service to ensure the seamless integration of its equipment into production facilities. This customer-centric approach has earned the company a loyal clientele and a reputation for being a trusted partner in the success of steel structure manufacturing businesses.Looking ahead, the Fully Automatic C Purlin Roll Forming Machine is poised to continue shaping the future of the steel structure industry, driving greater efficiency, precision, and profitability for manufacturers and construction companies. As the demand for steel structures continues to grow, this innovative machine will play a crucial role in meeting the industry's evolving needs and delivering exceptional results to clients around the world.In conclusion, the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field, has set new benchmarks for efficiency and productivity in the manufacturing of steel structures. With its advanced technology, automated operation, and versatile capabilities, this innovative machine has become an indispensable asset for the industry, driving greater precision, safety, and profitability for businesses. As the steel structure industry continues to evolve, the Fully Automatic C Purlin Roll Forming Machine stands ready to lead the way towards a future of excellence and innovation.

China's Leading Manufacturer Offers Comprehensive Roll Forming Solutions for Various Applications

Roofing Sheet Forming Machine: The Ultimate Solution for Precise and Efficient RoofingWhen it comes to roofing materials, choosing the right one is crucial to ensure the durability and aesthetics of a building. Among the various options available, roofing sheets have become increasingly popular due to their versatility and cost-effectiveness. However, to efficiently produce roofing sheets that meet specific requirements, a reliable and precise manufacturing process is essential. That's where a Roofing Sheet Forming Machine comes into play.A roofing sheet forming machine is an advanced piece of equipment designed specifically for the production of roofing sheets. It is widely used across various industries, including construction, architecture, and manufacturing. The machine utilizes the process of roll forming, which is known for its accuracy and efficiency in creating uniform and high-quality products.The roll forming process involves passing a sheet of metal through a series of rollers, gradually shaping it into the desired profile. With the use of custom-made molds, the machine can produce different types of roofing sheets, such as corrugated, trapezoidal, and standing seam profiles. This flexibility allows manufacturers to cater to a wide range of customer demands and project specifications.One of the significant advantages of using a Roofing Sheet Forming Machine is its ability to ensure precision and consistency throughout the production process. Each roller in the machine is uniquely designed to shape the metal sheet with precise measurements and dimensions. This results in roofing sheets that fit perfectly and are aesthetically pleasing.Additionally, the machine's high-speed operation enables manufacturers to produce a large volume of roofing sheets quickly. This not only saves time but also enhances productivity, making it an ideal choice for mass production. Furthermore, the machine's automated control system eliminates the need for manual labor, reducing the chances of errors and ensuring a safer working environment.Quality is of utmost importance when it comes to roofing materials, and a Roofing Sheet Forming Machine excels in delivering consistent and durable products. By using high-quality materials and advanced manufacturing techniques, these machines guarantee the production of roofing sheets that are resistant to corrosion, weathering, and wear. This durability ensures that the roofs constructed using these sheets can withstand harsh environmental conditions and provide long-lasting protection.In addition to its primary function of manufacturing roofing sheets, a Roofing Sheet Forming Machine offers several other benefits. It provides versatility by offering customizability options, allowing manufacturers to produce roofing profiles of different lengths, widths, and thicknesses. This ensures that they can cater to diverse customer requirements and project specifications.Moreover, the machine's operation is accompanied by minimal noise and vibration, thanks to its advanced engineering and quality construction. This reduces disturbances in the workplace and contributes to a peaceful working environment for employees. Additionally, the machine requires minimal maintenance, leading to lower operational costs and improved overall efficiency.As the demand for roofing sheets continues to rise, it is essential to choose a reliable and experienced manufacturer when investing in a Roofing Sheet Forming Machine. A reputable manufacturer will not only provide top-quality machines but also offer comprehensive support and service throughout the purchase process. They will assist in the selection of the right machine, provide installation and training, and offer after-sales support to ensure smooth and efficient operations.In conclusion, a Roofing Sheet Forming Machine is the ultimate solution for producing precise, durable, and cost-effective roofing sheets. Its ability to deliver consistent quality, high-speed production, and customizability makes it an indispensable piece of equipment in the roofing industry. So, whether you are a contractor, builder, or manufacturer, investing in a Roofing Sheet Forming Machine is a wise choice to elevate your roofing business to new heights.

New Innovations in Light Steel Keel Machinery Revolutionize Construction Industry

Title: Innovative Light Steel Keel Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking move, a well-established company in the construction sector has developed a state-of-the-art Light Steel Keel Machine, which promises to revolutionize the way buildings are constructed. This advanced machine, designed and manufactured by the company, seeks to streamline the construction process, enhance cost-efficiency, and improve the overall quality of steel structures. With an unwavering commitment to innovation and excellence, the company aims to lead the industry into a new era of construction technology.Body:1. The Light Steel Keel Machine: (Company's Name) has introduced its cutting-edge Light Steel Keel Machine, a robust and highly automated equipment that fabricates light steel frames with utmost precision. By leveraging intelligent design, this machine can accurately produce light steel keels, also known as studs or channels, used to create the primary framework for various buildings. 2. Features and Functionality: The advanced Light Steel Keel Machine boasts a range of exceptional features, ensuring superior quality and efficiency. Equipped with sophisticated technology, it has the ability to roll, cut, punch, and perforate light steel keels with great accuracy and speed. Moreover, the machine is compatible with various thicknesses and dimensions, making it versatile for different building requirements. 3. Streamlined Construction Process: Integrating the Light Steel Keel Machine into the construction process significantly streamlines the entire procedure. This innovative technology removes the need for manual cutting and shaping of the steel keels, reducing labor costs and minimizing human error. By automating the fabrication process, construction timelines are expedited, accelerating the completion of projects and enabling faster occupancy of buildings. 4. Enhanced Cost-Efficiency: The Light Steel Keel Machine offers a cost-effective solution in the construction industry. By optimizing production efficiency, construction companies can save on labor expenses and reduce material waste. Additionally, the machine's compatibility with different steel thicknesses helps minimize material costs, further contributing to overall cost savings. 5. Improved Structural Stability: The precision and accuracy of the Light Steel Keel Machine ensure the creation of sound and reliable light steel frames. Through this advanced fabrication process, the machine eliminates potential human errors and inconsistencies, resulting in structurally stable buildings that meet stringent safety standards. This enhanced structural integrity increases the longevity and durability of the constructed buildings. 6. Superior Quality and Aesthetics: Light steel frames, produced using the state-of-the-art machine, boast exceptional quality and aesthetics. The machine's ability to produce standardized components with minimal variations results in consistent quality across all construction projects. Moreover, the machine's precise cutting and shaping capabilities create sleek and visually appealing steel frames, enhancing the overall aesthetic value of the buildings. 7. Environmental Benefits: The Light Steel Keel Machine aligns with the growing demand for sustainable and eco-friendly construction practices. By reducing material waste and optimizing production efficiency, the machine promotes environmental responsibility in the construction industry. Furthermore, light steel frames are inherently recyclable, minimizing the carbon footprint associated with traditional construction materials. Conclusion:As the construction industry paves the way for innovative technologies, the introduction of the Light Steel Keel Machine represents a significant milestone. This cutting-edge equipment, developed by (Company's Name), offers numerous benefits, including streamlined construction processes, enhanced cost-efficiency, improved structural stability, and superior quality and aesthetics. With the potential to revolutionize the way buildings are constructed, this remarkable machine embodies the company's commitment to innovation, advancement, and sustainable practices.

Efficient and Reliable Tile Roll Forming Machine for Step Tile Production

Step Tile Roll Forming Machine Revolutionizes Roofing IndustryIn today's fast-paced world, technological advancements are not only changing the way we live and work but also revolutionizing industries across the board. One such industry that is currently experiencing a transformation is the roofing industry, thanks to the innovative Step Tile Roll Forming Machine.The XYZ Company has recently introduced the Step Tile Roll Forming Machine, which is set to redefine the way roofing materials are manufactured and installed. This cutting-edge machine is designed to produce high-quality step tile roofing sheets with incredible precision and efficiency, making it a game-changer for roofing companies and construction projects.The Step Tile Roll Forming Machine utilizes state-of-the-art technology to roll and form metal sheets into step tiles, which are widely used in residential and commercial roofing applications. The machine is equipped with advanced features such as automatic material feeding, precise profiling, and adjustable cutting systems, allowing for seamless and accurate production of step tile roofing sheets.One of the key advantages of the Step Tile Roll Forming Machine is its ability to increase productivity and reduce production costs for roofing companies. With its high-speed operation and minimal material wastage, the machine enables manufacturers to meet the growing demand for step tile roofing sheets while maintaining a competitive edge in the market.Furthermore, the Step Tile Roll Forming Machine offers unparalleled versatility, allowing for the customization of step tile profiles to meet specific project requirements. This flexibility ensures that roofing contractors can cater to a wide range of architectural designs and building styles, providing their clients with tailored roofing solutions.The introduction of the Step Tile Roll Forming Machine is a testament to XYZ Company's commitment to innovation and excellence in the roofing industry. With years of experience and expertise in manufacturing roll forming machines, the company has established itself as a leader in the field, delivering cutting-edge solutions that meet the evolving needs of the market.In addition to the Step Tile Roll Forming Machine, XYZ Company also offers comprehensive training and technical support to help roofing professionals integrate the machine into their operations seamlessly. This dedication to customer satisfaction and after-sales service sets the company apart and reinforces its position as a trusted partner for roofing businesses.The impact of the Step Tile Roll Forming Machine is already being felt across the roofing industry, with early adopters praising its efficiency, reliability, and cost-saving benefits. As more companies embrace this innovative technology, it is expected to drive a significant shift in the way step tile roofing sheets are manufactured and installed, setting new standards for quality and performance.In conclusion, the Step Tile Roll Forming Machine from XYZ Company marks a significant milestone in the roofing industry, ushering in a new era of efficiency and precision in the production of step tile roofing sheets. With its advanced features and unparalleled capabilities, the machine is poised to revolutionize the way roofing materials are made, ultimately benefiting roofing companies, construction projects, and the end-users. As the demand for high-quality and customizable roofing solutions continues to rise, the Step Tile Roll Forming Machine stands ready to meet the challenges of the future and redefine the standards of excellence in the industry.

Highly Efficient and Versatile Corrugated Roll Making Machine Unveiled in Recent News

Title: Corrugated Roll Making Machine Revolutionizes Packaging IndustryIntroduction:The packaging industry is witnessing a remarkable technological advancement with the introduction of the state-of-the-art Corrugated Roll Making Machine. This innovative machinery is set to revolutionize the production process of corrugated rolls, boosting efficiency and meeting the ever-increasing demand for sustainable packaging solutions. Developed by an industry-leading company, the machine serves as a game-changer by enhancing productivity, reducing material wastage, and providing cost-effective solutions.Increased Efficiency and Productivity:The Corrugated Roll Making Machine offers exceptional speed and accuracy, ensuring a significant increase in productivity compared to conventional methods. By automating the process, it reduces labor costs and minimizes human error. The machine can handle large volumes of corrugated rolls, making it ideal for industries dealing with high-demand packaging requirements. With its high-speed production capabilities, businesses can meet tight deadlines without compromising on quality.Advanced Design and Customization:The cutting-edge technology integrated into the Corrugated Roll Making Machine enables it to produce corrugated rolls in various sizes and designs. The machine features adjustable settings, allowing businesses to cater to their specific packaging needs. Whether it is producing rolls for fragile electronics or heavy-duty products, this versatile machinery adapts effortlessly, providing tailor-made solutions to a diverse range of industries.Precision and Durability:Precision is a fundamental requirement in the packaging industry, and the Corrugated Roll Making Machine ensures exceptional accuracy throughout the production process. The machine's robust construction and premium quality components guarantee durability and longevity, resulting in continuous high-performance. Businesses can rely on this machine to consistently deliver superior quality corrugated rolls, meeting the stringent standards of packaging regulations.Sustainability and Cost-effectiveness:In today's environmentally conscious world, sustainable packaging solutions are in high demand. The Corrugated Roll Making Machine addresses this need by reducing material wastage to a minimum. Its efficient design optimizes the usage of raw materials, minimizing both costs and environmental impact. The machine also offers recyclable options, contributing to a circular economy and meeting the demands of eco-friendly packaging practices.Integration of IoT and Smart Technology:The Corrugated Roll Making Machine incorporates internet of things (IoT) and smart technology capabilities. This integration enables real-time monitoring of the production process, ensuring maximum efficiency and minimizing downtime. The machine can detect any issues and send instant notifications, allowing operators to quickly address them. The incorporation of smart technology streamlines operations and enhances the overall production cycle.Future Prospects and Market Impact:The introduction of the Corrugated Roll Making Machine is poised to have a significant impact on the packaging industry. As businesses strive for higher productivity and sustainability, this advanced machinery provides a competitive edge. With its ability to meet diverse packaging requirements and reduce operational costs, this innovation promises increased efficiency and profitability for manufacturers. Additionally, its adherence to sustainability practices will appeal to environmentally conscious businesses and consumers alike.Conclusion:The Corrugated Roll Making Machine represents a breakthrough in the packaging industry. Combining speed, precision, sustainability, and smart technology, this state-of-the-art machinery stands at the forefront of packaging solution advancements. With its ability to boost productivity, reduce material wastage, and provide tailored packaging options, it has the potential to reshape how businesses approach packaging manufacturing. Embracing this innovation will undoubtedly lead to increased profitability, meeting market demands, and ensuring sustainable practices in the packaging industry.