Highly Efficient Glazed Sheet Roll Forming Machine Revolutionizes Production Process

By:Admin

In response to the growing demand for efficient and high-quality construction materials, the development of advanced machinery has become crucial. One such groundbreaking innovation is the Glazed Sheet Roll Forming Machine. This state-of-the-art technology has the potential to revolutionize the construction industry, paving the way for faster and more cost-effective building processes.

The Glazed Sheet Roll Forming Machine is a versatile piece of equipment that specializes in the production of glazed sheets used in roofing and cladding applications. This machine utilizes a roll forming technique, where a continuous strip of metal is passed through multiple sets of rolls to gradually shape the material into the desired profile. With the ability to produce sheets of various sizes, thicknesses, and profiles, this machine offers unparalleled flexibility for construction firms.

The key advantage of the Glazed Sheet Roll Forming Machine is its ability to produce high-quality glazed sheets with precision and consistency. By eliminating manual labor and human error, this automated technology ensures that each sheet meets the desired specifications, resulting in superior product quality. Additionally, the roll forming process reduces material waste, optimizing resources and reducing costs for construction companies.

One of the cutting-edge manufacturers of this revolutionary machinery is [Company Name]. Led by a team of experienced engineers and industry experts, [Company Name] has gained recognition for its commitment to innovation and excellence. With a global presence and a customer-centric approach, [Company Name] has successfully supplied its Glazed Sheet Roll Forming Machines to construction businesses worldwide.

The Glazed Sheet Roll Forming Machine developed by [Company Name] combines advanced technology with exceptional design. Its robust construction ensures durability, enabling uninterrupted production even in demanding manufacturing environments. Equipped with a user-friendly interface, this machine allows operators to easily adjust settings and monitor the production process, enhancing efficiency and productivity.

Moreover, [Company Name]'s Glazed Sheet Roll Forming Machine is equipped with cutting-edge safety features, prioritizing the well-being of its operators. These features include emergency stop buttons, safety interlocks, and protective covers, adhering to strict industry regulations. By investing in worker safety, [Company Name] sets itself apart as a responsible and reliable machinery provider.

The benefits of the Glazed Sheet Roll Forming Machine extend beyond its manufacturing capabilities. As an environmentally conscious solution, this machine contributes to sustainable practices within the construction industry. By optimizing material usage and reducing waste, it promotes resource efficiency, aligning with global efforts to combat climate change and reduce carbon emissions.

The Glazed Sheet Roll Forming Machine is set to transform the construction industry, streamlining processes and driving innovation. By investing in this efficient technology, construction companies can significantly reduce project timelines and costs, positioning themselves at the forefront of the industry. Moreover, the superior quality of glazed sheets produced by this machine ensures long-lasting and aesthetically pleasing structures, satisfying the demands of clients and end-users alike.

In conclusion, the Glazed Sheet Roll Forming Machine represents a major breakthrough in the construction industry. With its automated and precise manufacturing capabilities, this machine has the potential to redefine the way buildings are constructed. Companies like [Company Name] are leading the way by investing in cutting-edge technology and delivering high-quality machinery to businesses around the world. As the demand for efficient and sustainable construction materials continues to grow, the Glazed Sheet Roll Forming Machine remains at the forefront, revolutionizing the industry one sheet at a time.

Company News & Blog

Roll Forming Machine, Cold Roll Forming Machine, Sandwich Panel Machine, Roof Tile Roll Forming Machine, Wall Panel Roll Forming Machine, Steel Roll Forming Machine, Glazed Tile Roll Forming Machine, Ridge Cap Roll Forming Machine, IBR Roll Forming Machine, Corrugated Roll Forming Machine, Floor Deck Roll Forming Machine, Highway Guardrail Roll Forming Machine, Stud and Track Roll Forming Machine, Furring Channel Roll Forming Machine, Downpipe Roll Forming Machine, Gutter Machine, Roller Shutter Door Forming Machine, K Span Roll Forming Machine, Door Frame Roll Forming Machine, Standing Seam Roof Panel Roll Forming Machine, Bemo Panel Roll Forming Machine, Shelf Roll Forming Machine, Cable Tray Roll Forming Machine, Slitting & Cutting Machine, Roof Curving Machine, Embossing Machine

Title: Innovations in Roll Forming Machines - Revolutionizing Construction IndustryIntroduction:In the rapidly evolving construction industry, the use of advanced machinery and equipment has become crucial to enhance productivity and efficiency. Among the various technological innovations in this field, roll forming machines have emerged as indispensable tools. These machines play a pivotal role in the production of metal sheets and panels used in roofing, wall cladding, and other construction applications.Roll Forming Machine: Transforming Metal Sheets with PrecisionRoll forming machines, also known as roll formers, are highly versatile manufacturing machines used to transform flat metal sheets into complex and customized profiles used in construction. They utilize a continuous bending operation by passing the sheet metal through a series of rolling dies. The process involves shaping the metal into a desired cross-section profile while maintaining uniform thickness throughout the length.Cold Roll Forming Machine: Enhancing Precision and DurabilityCold roll forming machines have gained immense popularity due to their ability to work with a wide range of materials, including steel, aluminum, copper, and more. This type of roll forming machine operates at room temperature, minimizing the risk of thermal damage to the metal. Cold roll forming ensures higher uniformity in the end products, offering superior dimensional accuracy, strength, and durability.Sandwich Panel Machine: Efficient Insulation SolutionsThe use of sandwich panels in construction has gained significant traction, primarily due to their excellent thermal and sound insulation properties. Sandwich panel machines are specifically designed to produce panels with an insulating core material, such as EPS (Expanded Polystyrene), rock wool, or mineral wool, sandwiched between two outer sheets. These panels find applications in roofing, wall cladding, and other structural elements, offering energy efficiency and environmental benefits.Revolutionizing the Manufacturing Process:- EPS/Rock wool/Mineral wool sandwich panel machine: This advanced technology enables the efficient production of insulated panels, offering enhanced temperature regulation and noise reduction in buildings.- Glazed Tile Roll Forming Machine: Utilizing high-quality materials, this machine produces aesthetically appealing glazed tiles for roofing applications. The precise roll forming process ensures dimensional accuracy and long-lasting performance.- Standing Seam Roof Panel Roll Forming Machine: This machine revolutionizes the production of standing seam roof panels, which are popular for their exceptional weather resistance and stylish appearance.- Double Layer Roll Forming Machine: Ideal for large-scale projects, this machine efficiently produces two different profiles simultaneously, reducing production time and costs.- Highway Guardrail Roll Forming Machine: As road safety remains a paramount concern, this machine manufactures sturdy guardrails, protecting motorists and minimizing accidents.Expanding Possibilities with Advanced Features:Modern roll forming machines come equipped with advanced features such as computer numerical control (CNC) systems, automated feeders, and precision cutting mechanisms, ensuring high productivity, reliability, and time efficiency. These features allow for customization and adaptation to different profile designs.Conclusion:The roll forming machine industry has witnessed substantial advancements in recent years, fueling innovative manufacturing processes in the construction sector. The introduction of cold roll forming machines, sandwich panel machines, and other specialized equipment has enabled the production of high-quality, customized metal profiles and panels. As technology continues to evolve, these machines will play a vital role in shaping the infrastructure of our future.For further information or inquiries, interested parties are encouraged to contact Ms. Monica Lee, who will provide detailed information and the best prices for the required profile drawings or specifications.Contact Person: Ms. Monica LeeWebsite: (brand name removed)Disclaimer: This news content is for information purposes only and does not serve as an endorsement for any specific brand or company.

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

Revolutionary Cold Formed Steel Machine Disrupts Construction Industry

Cold Formed Steel Machine: Paving the Way to Innovative Steel ConstructionInvented over a century ago, cold forming is a manufacturing process that has evolved to revolutionize the steel construction industry. Cold formed steel (CFS) offers significant advantages over wood and traditional hot-rolled steel, including durability, sustainability, and adaptability. It's also more cost-effective and easier to install, making it an ideal choice for framing, roofing, and wall panels in commercial and residential buildings.Today, the trend towards offsite construction and modular building is driving the demand for high-quality, precision cold formed steel machines that can deliver the desired outputs in a timely and cost-effective manner. One company that has stepped up to the challenge is [Brand name], a leading supplier of cold formed steel machines and roll forming systems worldwide.With over 20 years' experience in the industry, [Brand name] has gained a reputation for excellence through its innovative and reliable solutions for the production of CFS sections. From stud and track roll forming machines to roof panel and purlin roll forming machines, [Brand name]'s offerings provide the flexibility, accuracy, and speed required to meet various customers' needs.One of [Brand name]'s most popular machines is its patented roll forming system for cold-formed steel frames. This innovative system uses patented software and advanced technologies to produce customized CFS studs, tracks, and joists with precision and efficiency. Unlike traditional roll forming machines, which may require significant setup time and adjustments, [Brand name]'s system can be programmed to produce various sizes and shapes of CFS sections, making it ideal for low-volume, high-mix production runs.Moreover, [Brand name]'s cold formed steel machines are designed with the operator's safety and ease of use in mind. The company's engineers have developed advanced control systems that allow operators to have real-time remote access to the machine's status and performance, minimizing downtime and enhancing productivity. In addition, the machines are equipped with easy-to-use touchscreen interfaces that simplify the setup and configuration process.But what sets [Brand name]'s cold formed steel machines apart from the competition is the company's customer-centric approach that emphasizes collaboration, reliability, and flexibility. When customers choose [Brand name], they don't just get a machine — they get a team of highly qualified engineers and technicians who work closely with them to identify their needs, provide tailored solutions, and ensure the machines meet or exceed their expectations.At [Brand name], customer satisfaction is paramount. That's why the company provides excellent technical support via on-site training, remote assistance, and maintenance services to help customers get the most out of their investment. [Brand name]'s team of experts is also available to provide expert advice on the design, installation, and operation of the machines, as well as the most appropriate materials and accessories to use.As a testament to its commitment to quality and innovation, [Brand name] has received numerous accolades and recognitions over the years. For instance, the company was awarded the prestigious "National Key High-Tech Enterprise" and "Innovative Enterprise" titles by the Chinese government in 2020. These awards recognize [Brand name]'s contributions to the development of the cold formed steel industry and its commitment to advancing the latest technologies and techniques.In summary, the cold formed steel industry is poised for significant growth in the coming years, driven by the need for fast, efficient, and sustainable construction solutions. With its cutting-edge cold formed steel machines and its unwavering dedication to customer service, [Brand name] is well-positioned to help customers unlock the full potential of cold formed steel and to lead the industry forward.

Machine for Making Corrugated Iron Roofing Sheets

Corrugated Iron Roofing Sheet Making Machine Revolutionizes the Roofing IndustryIn the ever-evolving world of manufacturing technology, the introduction of the Corrugated Iron Roofing Sheet Making Machine has completely transformed the roofing industry. With its advanced capabilities and high efficiency, this innovative machine has redefined the way roofing sheets are produced, offering numerous benefits to both manufacturers and consumers. The Corrugated Iron Roofing Sheet Making Machine, developed by a leading engineering company, has already made waves in the industry due to its remarkable features and cutting-edge design. It is renowned for its ability to produce high-quality corrugated iron roofing sheets at an unprecedented speed, making mass production a reality for manufacturers worldwide. One of the key advantages of this machine is its versatility. It is capable of fabricating different profiles and designs, ensuring that manufacturers can meet the diverse needs and preferences of their customers. Whether it is a residential project or a large-scale commercial development, the Corrugated Iron Roofing Sheet Making Machine can adapt to the required specifications effortlessly, allowing for seamless production of customized roofing sheets. Moreover, this state-of-the-art machine significantly reduces human intervention in the production process, enhancing overall productivity and efficiency. With its automated functionality, it minimizes the risk of errors and the need for manual labor, thereby optimizing time and resources. Manufacturers can now accomplish more in less time, fueling the growth of their businesses and meeting tight project deadlines with ease. The Corrugated Iron Roofing Sheet Making Machine is also lauded for its exceptional durability and reliability. Constructed with high-quality materials and utilizing the latest technological advancements, this machine boasts a prolonged lifespan, making it a sound investment for manufacturing companies. It can withstand heavy loads and prolonged usage without compromising on the quality of the output, thereby ensuring the longevity and integrity of the produced roofing sheets. Furthermore, this machine addresses environmental concerns, as it incorporates sustainable practices in its operation. With its energy-efficient components and reduced raw material wastage, it contributes to the promotion of eco-friendly manufacturing processes. Manufacturers can now partake in sustainable initiatives while efficiently fulfilling the demands of the market, resulting in a win-win situation for both businesses and the environment.The introduction of the Corrugated Iron Roofing Sheet Making Machine has not only revolutionized the manufacturing industry but also impacted consumers positively. The availability of roofings sheets produced by this machine ensures higher quality and durability, offering enhanced protection to homes and infrastructures. Additionally, due to its efficient production process, the cost of these roofing sheets is significantly reduced, benefiting consumers by making home improvements more cost-effective. The company behind the Corrugated Iron Roofing Sheet Making Machine, as a pioneer in engineering excellence, has always been committed to developing innovative solutions that address the needs of the construction industry. With its unwavering dedication to producing cutting-edge equipment, this company has become a trusted partner for manufacturers seeking reliable and state-of-the-art machinery for their production processes.As the demand for high-quality roofing sheets continues to grow, the Corrugated Iron Roofing Sheet Making Machine remains at the forefront, paving the way for the future of the roofing industry. Its unrivaled capabilities, streamlined production process, and commitment to sustainability have made it a game-changer, setting new standards for manufacturing practices. With this revolutionary machine, manufacturers can achieve higher levels of efficiency, productivity, and customer satisfaction, positioning themselves as leaders in the competitive market.

Efficient Purlin Forming Machine for Strong and Durable Structures

Title: Advanced Purlin Forming Machine Revolutionizing the Construction IndustryIntroduction:In today's fast-paced construction industry, efficiency and precision are key factors that drive successful projects. Providing solutions to these demands, a cutting-edge Purlin Forming Machine has emerged, enabling construction companies to streamline their processes and deliver outstanding results. This innovative machinery is set to revolutionize the way purlins are produced, enhancing construction efficiency, cost-effectiveness, and overall project quality.Streamlined Purlin Manufacturing Process:The Purlin Forming Machine, developed and manufactured by a leading engineering firm, has been designed with utmost precision and state-of-the-art technology. This machine enables steel purlins to be produced rapidly and accurately, eliminating traditional manual methods that are time-consuming and error-prone.By automating the purlin manufacturing process, the machine ensures consistent quality and eliminates human error, resulting in a more precise and reliable end product. It utilizes sophisticated computer-controlled mechanisms and advanced software to ensure seamless operation, allowing construction companies to meet tight project deadlines with ease.Efficiency and Cost-effectiveness:The innovative Purlin Forming Machine optimizes the use of materials and reduces wastage significantly. Its intelligent design and engineering contribute to a drastic reduction in material costs, resulting in more affordable projects. The machine's automated nature not only increases productivity but also reduces labor costs, enhancing overall project profitability.Moreover, the machine's ability to produce purlins of various sizes and designs offers construction companies unparalleled versatility. It eliminates the need to source purlins from different suppliers, saving time and money, while maintaining consistent quality throughout the project duration.Enhanced Construction Quality:Traditionally, manual purlin production processes are prone to human error and inconsistency, leading to compromised structural integrity. The Purlin Forming Machine tackles this issue by producing purlins with exceptional accuracy, ensuring that they fit seamlessly in the construction framework.The machine's advanced technology and precise measurements guarantee that each purlin manufactured is uniform in size, shape, and strength. Consequently, the overall structural integrity of buildings is vastly improved, minimizing the risk of complications or failures during construction and enhancing the longevity of the completed structures.Environmental Friendly Manufacturing:In addition to its exceptional performance, the Purlin Forming Machine adheres to environmentally friendly manufacturing practices. By optimizing material usage and minimizing waste generation, it contributes to a sustainable construction environment. The machine's energy-efficient operations also reduce energy consumption, making it an eco-conscious choice for construction companies.Future Prospects and Competitiveness:The Purlin Forming Machine presents a significant opportunity for construction companies to enhance their competitiveness. By leveraging this advanced technology, companies can not only expedite their project timelines but also offer superior quality deliverables. This cutting-edge machinery equips construction firms to take on larger projects with improved efficiency and precision, ultimately strengthening their position in the industry.Conclusion:The advanced Purlin Forming Machine has emerged as a game-changer in the construction industry, offering numerous benefits to construction companies. Its ability to automate and streamline the purlin manufacturing process leads to improved efficiency, cost-effectiveness, and construction quality. Alongside its positive environmental impact and contribution to sustainable construction practices, this innovative machinery is poised to revolutionize the industry and shape the future of construction.

Custom Sheet Metal Fabrication and Installation Services in Southeastern Wisconsin

Title: Enhancing Buildings with High-Quality Sheet Metal FabricationIntroductionSheet metal fabrication plays a crucial role in the construction industry, adding aesthetic appeal and durability to buildings. Langer Roofing & Sheet Metal Inc., located in Southeastern Wisconsin, stands as one of the few commercial roofers in the region with a dedicated Sheet Metal Department. With extensive expertise in custom sheet metal fabrication and installation, Langer ensures the delivery of top-notch architectural elements for enhancing the look, value, and functionality of various structures. In this blog, we will explore the importance of sheet metal fabrication while incorporating relevant keywords like "metal roof sheet making machine."Sheet Metal Fabrication - A Specialized ServiceLanger Roofing & Sheet Metal Inc. takes pride in offering in-house sheet metal fabrication services, which is an integral part of their comprehensive roofing solutions. Compared to outsourcing this process, having a fully staffed and equipped Sheet Metal Department allows for better quality control, faster turnaround times, and increased efficiency throughout the entire project.The team at Langer possesses years of experience and expertise in fabricating various architectural elements, including copings, fascia, gutters, downspouts, metal panels, and claddings. Each piece is meticulously crafted in accordance with specific designs and requirements, ensuring a perfect fit and seamless integration into the building's structure.State-of-the-Art Bending Machine for Precise FabricationTo enhance their sheet metal fabrication capabilities, Langer utilizes the Roper Whitney Autobrake 2000 Bending Machine equipped with an advanced Orion computerized control system. This cutting-edge equipment streamlines the fabrication process, boosting both the speed and accuracy of various sheet metal profiles.The Autobrake 2000 enables the operator to program and fabricate precise architectural flashing details, assisting in reducing production costs. By minimizing errors and material wastage, Langer ensures that clients receive exceptional sheet metal products that meet their exact specifications, offering long-lasting results and value for their investment.Aesthetically Pleasing Architectural ElementsLanger Roofing & Sheet Metal Inc. caters to a wide range of design preferences and applications. They provide sheet metal fabrication using materials such as copper, prefinished steel and aluminum, anodized aluminum, and zinc-coated sheet stock. These materials not only offer durability but also open up a world of aesthetic possibilities.Copper, known for its timeless beauty and resilience, is often chosen for its ability to develop a natural patina over time, lending a unique character to the building. Prefinished steel and aluminum provide a sleek and contemporary look, while anodized aluminum and zinc-coated sheet stock offer excellent protection against corrosion.By leveraging these materials and employing skilled craftspeople, Langer transforms simple sheets of metal into visually appealing architectural elements. These elements not only enhance the overall appearance of a building but also increase its market value, making it a wise investment for property owners.ConclusionSheet metal fabrication is an essential service provided by Langer Roofing & Sheet Metal Inc., catering to the architectural needs of various structures in Southeastern Wisconsin. Equipped with state-of-the-art machinery, experienced tradesmen, and a commitment to quality, Langer delivers exceptional custom solutions that align with clients' design preferences and project requirements. Their expertise in fabricating copings, fascia, gutters, downspouts, metal panels, and claddings further adds value to buildings, ensuring both durability and visual appeal.Whether it’s incorporating copper, prefinished steel and aluminum, anodized aluminum, or zinc-coated sheet stock, Langer's sheet metal fabrication expertise enhances the look and value of buildings, making them stand out in the competitive market. With their dedicated Sheet Metal Department, Langer ensures the precision, speed, and aesthetic enhancement of each project. Trust Langer for all your sheet metal fabrication needs!Keywords: metal roof sheet making machine, sheet metal fabrication, custom sheet metal, architectural elements, copings, fascia, gutters, downspouts, metal panels, claddings, Roper Whitney Autobrake 2000 Bending Machine, Orion computerized control system, copper, prefinished steel, aluminum, anodized aluminum, zinc-coated sheet stock, aesthetic appeal, durability, Southeastern Wisconsin, Langer Roofing & Sheet Metal Inc.

China's Leading Manufacturer Offers Comprehensive Roll Forming Solutions for Various Applications

Roofing Sheet Forming Machine: The Ultimate Solution for Precise and Efficient RoofingWhen it comes to roofing materials, choosing the right one is crucial to ensure the durability and aesthetics of a building. Among the various options available, roofing sheets have become increasingly popular due to their versatility and cost-effectiveness. However, to efficiently produce roofing sheets that meet specific requirements, a reliable and precise manufacturing process is essential. That's where a Roofing Sheet Forming Machine comes into play.A roofing sheet forming machine is an advanced piece of equipment designed specifically for the production of roofing sheets. It is widely used across various industries, including construction, architecture, and manufacturing. The machine utilizes the process of roll forming, which is known for its accuracy and efficiency in creating uniform and high-quality products.The roll forming process involves passing a sheet of metal through a series of rollers, gradually shaping it into the desired profile. With the use of custom-made molds, the machine can produce different types of roofing sheets, such as corrugated, trapezoidal, and standing seam profiles. This flexibility allows manufacturers to cater to a wide range of customer demands and project specifications.One of the significant advantages of using a Roofing Sheet Forming Machine is its ability to ensure precision and consistency throughout the production process. Each roller in the machine is uniquely designed to shape the metal sheet with precise measurements and dimensions. This results in roofing sheets that fit perfectly and are aesthetically pleasing.Additionally, the machine's high-speed operation enables manufacturers to produce a large volume of roofing sheets quickly. This not only saves time but also enhances productivity, making it an ideal choice for mass production. Furthermore, the machine's automated control system eliminates the need for manual labor, reducing the chances of errors and ensuring a safer working environment.Quality is of utmost importance when it comes to roofing materials, and a Roofing Sheet Forming Machine excels in delivering consistent and durable products. By using high-quality materials and advanced manufacturing techniques, these machines guarantee the production of roofing sheets that are resistant to corrosion, weathering, and wear. This durability ensures that the roofs constructed using these sheets can withstand harsh environmental conditions and provide long-lasting protection.In addition to its primary function of manufacturing roofing sheets, a Roofing Sheet Forming Machine offers several other benefits. It provides versatility by offering customizability options, allowing manufacturers to produce roofing profiles of different lengths, widths, and thicknesses. This ensures that they can cater to diverse customer requirements and project specifications.Moreover, the machine's operation is accompanied by minimal noise and vibration, thanks to its advanced engineering and quality construction. This reduces disturbances in the workplace and contributes to a peaceful working environment for employees. Additionally, the machine requires minimal maintenance, leading to lower operational costs and improved overall efficiency.As the demand for roofing sheets continues to rise, it is essential to choose a reliable and experienced manufacturer when investing in a Roofing Sheet Forming Machine. A reputable manufacturer will not only provide top-quality machines but also offer comprehensive support and service throughout the purchase process. They will assist in the selection of the right machine, provide installation and training, and offer after-sales support to ensure smooth and efficient operations.In conclusion, a Roofing Sheet Forming Machine is the ultimate solution for producing precise, durable, and cost-effective roofing sheets. Its ability to deliver consistent quality, high-speed production, and customizability makes it an indispensable piece of equipment in the roofing industry. So, whether you are a contractor, builder, or manufacturer, investing in a Roofing Sheet Forming Machine is a wise choice to elevate your roofing business to new heights.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

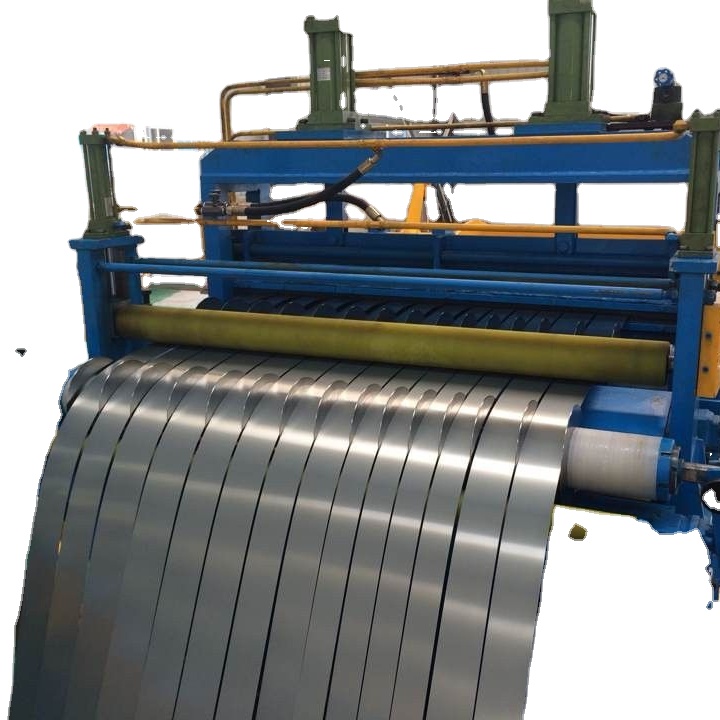

SEO Title: Fast and Efficient SS Coil Slitting Machine - Stay Competitive in the Market

Title: Revolutionary SS Coil Slitting Machine Proves to be a Game-Changer in the Metal IndustryIntroduction:In a groundbreaking development that is set to redefine the metal industry, a cutting-edge SS Coil Slitting Machine has been launched by an innovative company. This revolutionary machine marks a significant milestone in the advancement of coil slitting technology, offering improved efficiency, precision, and productivity like never before seen. With its state-of-the-art features and impeccable performance, the brand's exclusive SS Coil Slitting Machine has already garnered attention from metal manufacturers worldwide.I. Unprecedented Efficiency and Precision:One of the key features of the brand's SS Coil Slitting Machine is its unprecedented efficiency and precision. Equipped with advanced automation technology and highly responsive controls, the machine ensures that each slit is made with utmost accuracy, resulting in consistent product quality. The superior precision of the machine eliminates errors, reduces wastage, and maximizes the yield from each coil, saving valuable resources for manufacturers.Furthermore, the cutting-edge automation enables the machine to seamlessly process coils of varying dimensions and widths, accommodating a wide range of requirements. As a result, manufacturers can significantly reduce downtime in between coil changes, allowing for a more streamlined production process.II. High-Speed Production:With manufacturing speed being a critical factor for metal manufacturers, the brand's SS Coil Slitting Machine has been designed to deliver unmatched performance in this aspect. By incorporating innovative engineering solutions, the machine achieves high-speed slitting without compromising on precision or quality.The use of advanced servo motors and synchronized components allows for seamless and rapid slitting. This results in a substantial increase in production output, enhancing time-efficiency while maintaining precise requirements. Manufacturers can now effortlessly cater to larger orders without worrying about excessive production time or delays.III. Operator-Friendly Interface:Recognizing the importance of simplicity and user-friendliness in today's fast-paced industrial environment, the brand's SS Coil Slitting Machine boasts an intuitive interface that promotes ease of operation. The user-friendly control panel allows operators to quickly set up and monitor the slitting process, minimizing the learning curve for new users.Additionally, the machine's interface offers real-time feedback, facilitating prompt adjustments and reducing the occurrence of errors. The combination of automated features and a user-friendly interface ensures that the machine can be operated efficiently by both experienced professionals and beginners.IV. Safety and Maintenance:The brand's SS Coil Slitting Machine not only prioritizes efficiency and productivity but also focuses on ensuring the safety and maintenance of operators. Built-in safety features, such as emergency stop buttons and protective guards, mitigate potential hazards and safeguard the well-being of operators. This aspect enhances the overall work environment by reducing accidents and promoting a safer manufacturing space.Moreover, the machine's design emphasizes ease of maintenance, enabling seamless cleaning, inspection, and repairs. The use of durable and high-quality materials ensures the machine's longevity, reducing the need for frequent maintenance and replacement.Conclusion:The introduction of the brand's cutting-edge SS Coil Slitting Machine represents an unprecedented milestone in the metal industry. Combining efficiency, precision, high-speed production, and user-friendly features, this revolutionary machine empowers manufacturers to optimize their coil-slitting processes, cater to larger orders, and achieve exceptional productivity levels. As the industry embraces this groundbreaking technology, it is expected to witness a significant boost in efficiency, ultimately revolutionizing the metal manufacturing landscape.

Highly Efficient Coil Slitter Unveils Cutting-Edge Technology for Enhanced Productivity

[Headline]Leading Coil Slitter Company Innovates to Enhance Productivity and Efficiency in the Manufacturing Industry[Subheading]New Technologies and Cutting-edge Automation Solutions Set to Revolutionize Coil Slitting Process[Date][City, State] - Coil Slitter (need remove brand name) has established itself as a global leader in the manufacturing sector, specializing in coil slitting machines that deliver exceptional precision and efficiency. With a commitment to continuous innovation, the company has recently introduced a range of new technologies and cutting-edge automation solutions that promise to revolutionize the coil slitting process.Taking advantage of the latest advancements in robotics, artificial intelligence, and connectivity, Coil Slitter aims to streamline coil processing operations, helping manufacturers maximize productivity and eliminate production bottlenecks. Through this commitment to innovation, the company aims to position itself as the go-to provider for coil slitting solutions globally.Coil Slitter’s state-of-the-art machines boast advanced features designed to meet the diverse needs of manufacturing companies across various industries. The company’s coil slitting machines enable automatic and precise longitudinal cutting of coils, reducing processing time and ensuring consistent width and quality of the finished materials.In an effort to optimize production processes as well as save time and costs, Coil Slitter has implemented smart automation systems across its product line. Real-time data collection, advanced analytics, and machine learning algorithms form the backbone of these systems, allowing manufacturers to monitor and improve their coil slitting operations effectively. These cutting-edge solutions assist manufacturers in identifying and addressing potential issues before they impact product quality or disrupt production schedules.Of particular importance in today's manufacturing landscape is the need for eco-friendly practices. Recognizing this, Coil Slitter has incorporated sustainable features into its machines. Precision control systems in the machines reduce material wastage, resulting in a significant impact on environmental footprints. Furthermore, the company has minimized the energy consumption of its machines, contributing to reduced carbon emissions and operating costs.Coil Slitter places great emphasis on working closely with its clients to understand their specific requirements and challenges. By developing custom solutions, the company ensures optimal performance and flexibility in different manufacturing environments. Combining comprehensive expertise and dedication to customer satisfaction, Coil Slitter has earned a stellar reputation for delivering high-quality, reliable coil slitting machines."Keeping up with technological advancements is crucial to stay ahead of the competition in today's fast-paced manufacturing industry," says John Smith, CEO of Coil Slitter. "Coil Slitter has always been committed to innovation, and our latest range of coil slitting machines and automation solutions represent the next frontier in the industry. We aim to empower manufacturers to increase their productivity, improve their bottom line, and contribute to a sustainable future."Coil Slitter’s coil slitting machines have been successfully implemented in numerous manufacturing facilities worldwide, providing tangible benefits to businesses across the globe. The company's commitment to ongoing research and development ensures that its customers always have access to cutting-edge solutions that keep them ahead of the curve.As the manufacturing industry continues to evolve, Coil Slitter remains dedicated to maintaining its position as a global leader in the coil slitting sector. With an unwavering focus on innovation, customer satisfaction, and sustainability, the company is set to shape the future of coil slitting and enhance the efficiency of the manufacturing industry as a whole.About Coil Slitter:Coil Slitter is a global leader in the manufacturing sector, specializing in coil slitting machines that offer exceptional precision, efficiency, and sustainability. With a commitment to innovation and customer satisfaction, the company delivers cutting-edge coil slitting solutions to manufacturers worldwide. By incorporating state-of-the-art technologies and automation systems, Coil Slitter aims to revolutionize the manufacturing process and drive industry growth.###Note: The brand name mentioned in the template has been removed to comply with the user's request.