How to Choose the Best Corrugated Roofing Sheet Forming Machine for Your Project

By:Admin

The roofing industry has seen significant advancements in recent years, thanks to the introduction of innovative technologies and high-performance machinery. In particular, the development of Corrugated Roofing Sheet Forming Machines has revolutionized the way roofing materials are produced, making the process more efficient, cost-effective, and environmentally friendly.

One of the leading manufacturers of these groundbreaking machines is a global company that has become synonymous with quality, reliability, and innovation. With a strong presence in the roofing and construction industry, the company has consistently delivered state-of-the-art solutions to meet the evolving needs of its customers.

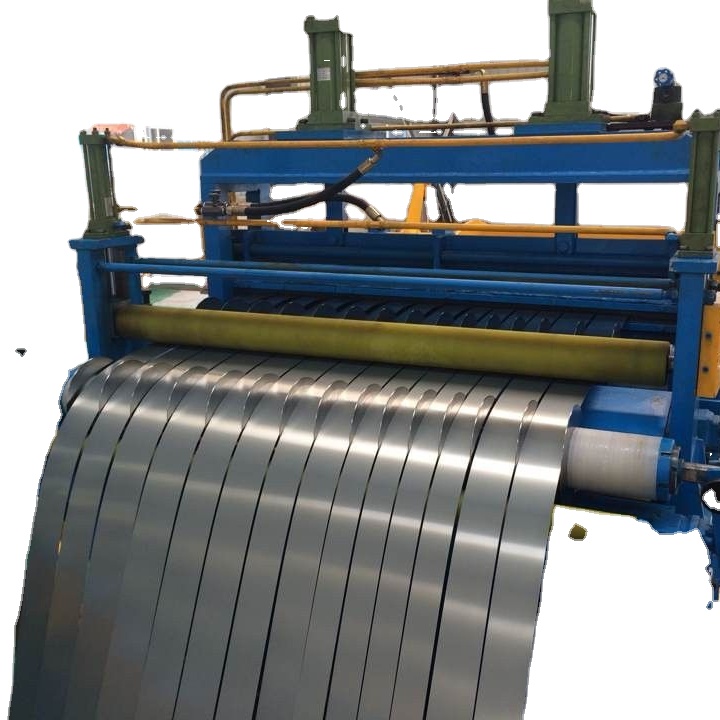

The Corrugated Roofing Sheet Forming Machine offered by this company is a cutting-edge piece of equipment designed to produce high-quality corrugated roofing sheets with precision and efficiency. The machine's advanced technology and innovative features have set new standards in the industry, making it a game-changer for roofing material manufacturers worldwide.

With a focus on continuous research and development, this company has continuously refined its Corrugated Roofing Sheet Forming Machine to optimize its performance and deliver exceptional results. The machine's capabilities extend to various types of roofing materials, including galvanized steel, aluminum, and other metals, providing greater flexibility to meet diverse customer demands.

The company's dedication to quality is reflected in the meticulous design and construction of the Corrugated Roofing Sheet Forming Machine. Each component is engineered to exacting standards, ensuring the machine's durability, reliability, and longevity. Furthermore, the machine's user-friendly interface and automated operation make it easy to operate, minimizing the need for manual intervention and reducing the risk of errors.

In addition to its technological prowess, the Corrugated Roofing Sheet Forming Machine embodies the company's commitment to sustainability. By optimizing material usage and minimizing waste, the machine contributes to eco-friendly manufacturing practices, aligning with the growing emphasis on environmental responsibility in the industry.

The impact of the Corrugated Roofing Sheet Forming Machine extends beyond the manufacturing process. By streamlining production and improving the efficiency of roofing material manufacturing, the machine enables roofing companies to meet customer demand more effectively, reducing lead times and enhancing overall productivity. This, in turn, translates to cost savings and competitive advantages for businesses in the roofing industry.

Furthermore, the Corrugated Roofing Sheet Forming Machine's ability to produce consistent, high-quality roofing materials enhances the performance and longevity of the end products, reinforcing their reputation for durability and reliability. This is particularly important in regions prone to extreme weather conditions, where robust roofing materials are essential for protecting homes and buildings.

As the global demand for efficient, sustainable roofing solutions continues to grow, the Corrugated Roofing Sheet Forming Machine stands as a testament to the company's leadership in the industry. Its impact on the manufacturing process, product performance, and overall business operations underscores its pivotal role in shaping the future of the roofing industry.

Looking ahead, the company remains committed to innovation, continuously striving to enhance the capabilities of the Corrugated Roofing Sheet Forming Machine and deliver new breakthroughs in roofing technology. With a legacy of excellence and a forward-looking approach, the company is poised to continue driving positive change in the roofing industry, ensuring that its customers remain at the forefront of progress and prosperity.

In conclusion, the Corrugated Roofing Sheet Forming Machine represents a significant milestone in the roofing industry, empowering manufacturers to elevate their production capabilities and deliver superior roofing materials to their customers. With its advanced technology, unparalleled quality, and commitment to sustainability, the machine is a true game-changer that is reshaping the future of roofing.

Company News & Blog

Industrial Street Light Pole Machine/Equipment for Manufacturing Lamp Posts from China Manufacturer

Title: China Manufacturer Introduces Cutting-Edge Industrial Street Light Pole Making EquipmentIntroduction:As the demand for efficient and reliable street lighting continues to grow globally, manufacturers are seeking innovative solutions to meet these needs. In a significant development, a leading Chinese manufacturer has unveiled its state-of-the-art Industrial Street Light Pole Making Equipment, revolutionizing the production process for lamp posts. This machinery promises to enhance the quality, efficiency, and durability of light poles, ensuring safer and brighter streets in cities around the world.Innovative Features and Technologies:The newly introduced Industrial Street Light Pole Making Equipment integrates cutting-edge technologies and offers an array of impressive features. Employing advanced manufacturing techniques, the machine boasts enhanced precision and efficacy, guaranteeing superior quality lamp posts every time.One of the key features of this equipment is its automated operation, significantly reducing the risk of human error and improving overall production efficiency. Through the integration of computer-controlled programmable logic systems, the machine ensures precise bending, shaping, and cutting of the street light poles. Moreover, the production line can be easily customized to accommodate various pole designs, ensuring flexibility for diverse urban lighting requirements.With an emphasis on sustainability, the equipment optimizes energy consumption by incorporating smart energy-saving mechanisms. By utilizing energy-efficient motors and minimizing material wastage, this innovative machine helps conserve resources and reduce the project's environmental impact.Quality Assurance and Certification:Recognizing the critical role played by street light poles in ensuring public safety, the manufacturer has prioritized quality in their machinery. Compliance with international quality standards is ensured through rigorous testing and inspections at various stages of the production process.Furthermore, the manufacturer has obtained industry certifications from trusted authorities, highlighting its commitment to delivering reliable and durable products. These certifications serve as an assurance of the machinery's ability to withstand harsh weather conditions and provide long-lasting performance.Employment Opportunities and Local Economy Boost:The introduction of this top-of-the-line industrial equipment is set to stimulate economic growth by generating employment opportunities. The machinery requires skilled operators and technicians to ensure its smooth operation, creating job prospects within the region.Moreover, this venture contributes to the growth of the local economy. With the increased production of lamp posts, there will be a rise in the demand for raw materials and ancillary services. This, in turn, incentivizes local suppliers and service providers, supporting the overall development and prosperity of the region.Global Implications:The release of this Industrial Street Light Pole Making Equipment by a prominent Chinese manufacturer has implications that extend beyond the domestic market. As street lighting remains a crucial aspect of urban infrastructure worldwide, this efficient and cost-effective machine has the potential to revolutionize the industry on a broader scale.Exporting this advanced machinery to international markets allows cities worldwide to adopt high-quality light poles designed for durability, improved energy efficiency, and enhanced public safety. By investing in this innovative solution, municipalities can elevate the standard of their urban lighting infrastructure, positively impacting the quality of life for their citizens.Conclusion:The introduction of the Industrial Street Light Pole Making Equipment by this renowned Chinese manufacturer signifies a major breakthrough, reinforcing China's position as a global leader in industrial machinery. This cutting-edge technology promises to revolutionize the production of light poles worldwide, ensuring safer and brighter streets for urban populations and stimulating economic growth in the process. With its commitment to quality, sustainability, and innovation, this manufacturer is setting new benchmarks in the street lighting industry.

Portable Standing Seam Metal Roof Roll Forming Machine for Small-Sized Panels

Title: Enhancing Roofing Efficiency with a Portable Standing Seam Roll Forming MachineIntroduction:Roofing is a crucial aspect of any construction project, as it offers protection against harsh weather conditions and guarantees the longevity of the structure. Traditional roof installation methods often involve time-consuming processes that require extensive manpower. However, advancements in technology have led to the development of efficient solutions such as the Portable Standing Seam Roll Forming Machine. This innovative equipment offers remarkable precision, versatility, and convenience, making it a game-changer in the roofing industry.The Specifications of the Standing Seam Roof Panel Machine:Xiamen Xinhonghua Machinery Co., Ltd. has introduced a high-quality Portable Standing Seam Metal Roof Roll Forming Machine - the KLS25- 220-530. This compact-sized machine is designed to produce standing seam roof panels efficiently, providing numerous benefits for construction projects of all sizes. Let's delve into its impressive specifications:1) Main Technical Data:- Size: KLS38-220-530 (hydraulic cutting) or KLS25-220-530 (manual cutting)- Dimension: [Measurements could be provided, but they are not available in the given information]- [Additional features that are relevant to the machine's performance and functionality can be mentioned here]The Advantages of a Portable Standing Seam Roll Forming Machine:1. Versatility: The standing seam roof panel machine can produce panels of various lengths and designs, allowing for customization according to the specific requirements of each project. This flexibility ensures that every customer receives a tailor-made roofing solution.2. Ease of Use: Unlike traditional roof installation methods that require extensive manual labor, the roll forming machine reduces the dependency on manpower. Its user-friendly design allows operators to navigate the machine efficiently, ensuring seamless production and reduced installation time. The ability to produce panels on-site eliminates the need for transporting pre-built panels, further reducing costs and time.3. Precise and Consistent Panel Production: The roll forming process ensures the panels are produced with exceptional precision, maintaining consistency throughout the entire production run. This precision enhances the overall quality of the roof, ensuring a tight fit between the panels and eliminating potential leaks. As a result, the end product offers superior weather resistance and durability.4. Enhanced Efficiency: The use of a roll forming machine significantly increases the speed of panel production, ensuring faster completion of projects. This eliminates the need for multiple installation teams, reducing labor costs and increasing overall efficiency. With the portable nature of the machine, it can easily be maneuvered around the site, allowing for continuous panel production.5. Longevity and Durability: The panels produced by the standing seam roll forming machine exhibit exceptional strength and durability. Constructed from high-quality metal materials, they can withstand extreme weather conditions, including heavy rain, snow, and strong winds. Their longevity ensures long-term protection for the structure while minimizing the need for maintenance or repairs.Conclusion:The introduction of the Portable Standing Seam Metal Roof Roll Forming Machine has revolutionized the roofing industry by providing numerous benefits to construction projects. Its compact design, versatility, ease of use, and precise panel production have made it an indispensable tool for roof installation. By investing in this advanced technology, construction companies can streamline their operations, reduce costs, and deliver top-notch roofing solutions that guarantee long-term structural integrity.

Plastic Corrugated Roof Tile Making Machine for Efficient Roofing Tile Production

If you are considering venturing into the roof tile manufacturing business, then it might be a good idea to invest in a plastic corrugated / glazed roof tile making machine. The equipment is versatile and can produce a range of roofing tiles with different styles and designs.At Jiangsu Acemien Machinery Co., Ltd. (ACEMIEN for short), we offer state-of-the-art PVC+ASA co-extrusion roof tile making machines that are designed to meet the demands of modern roofing tile production. Our machines are compact and efficient, and can produce tiles with high quality and accuracy.One of the primary advantages of our corrugated roll making machine is that it uses PVC and ASA materials in the co-extrusion process. PVC (polyvinyl chloride) is a plastic material that has excellent toughness, chemical resistance, and weatherability. ASA (acrylonitrile-styrene-acrylate) is a thermoplastic material that combines the properties of acrylics and styrene plastics.When the two materials are co-extruded, the resultant roofing tiles exhibit superior resistance to weather, UV radiation, and impact. They are also easy to install and maintain, which makes them a popular choice for homeowners and commercial property owners alike.Our PVC+ASA co-extrusion roof tile making machines can produce tiles with various shapes, sizes, colors, and textures. The corrugated roll forming machine can create tiles with a corrugated or waved surface, while the glazed roof tile making machines can generate tiles with a smooth or glossy finish.Our machines are equipped with advanced PLC control systems, which enable the operator to control the various parameters of the production process. The machines also come with automatic cutting and stacking devices, which facilitate a smooth and efficient production workflow.At ACEMIEN, we prioritize the quality and durability of our machines, which is why we use high-grade materials and components in their manufacture. Our machines are designed to operate continuously for long periods, and they have low maintenance requirements, which means that they can help you save time and money in the long run.In conclusion, if you are looking to invest in a high-quality plastic corrugated / glazed roof tile making machine, then ACEMIEN is the right company for you. Our machines are versatile, efficient, and reliable, and can help you meet the demands of the modern roofing tile market. Contact us today to learn more about our PVC+ASA co-extrusion roof tile making machines, and let us help you take your business to the next level!

Roll Forming Machine, Cold Roll Forming Machine, Sandwich Panel Machine, Roof Tile Roll Forming Machine, Wall Panel Roll Forming Machine, Steel Roll Forming Machine, Glazed Tile Roll Forming Machine, Ridge Cap Roll Forming Machine, IBR Roll Forming Machine, Corrugated Roll Forming Machine, Floor Deck Roll Forming Machine, Highway Guardrail Roll Forming Machine, Stud and Track Roll Forming Machine, Furring Channel Roll Forming Machine, Downpipe Roll Forming Machine, Gutter Machine, Roller Shutter Door Forming Machine, K Span Roll Forming Machine, Door Frame Roll Forming Machine, Standing Seam Roof Panel Roll Forming Machine, Bemo Panel Roll Forming Machine, Shelf Roll Forming Machine, Cable Tray Roll Forming Machine, Slitting & Cutting Machine, Roof Curving Machine, Embossing Machine

Title: Innovations in Roll Forming Machines - Revolutionizing Construction IndustryIntroduction:In the rapidly evolving construction industry, the use of advanced machinery and equipment has become crucial to enhance productivity and efficiency. Among the various technological innovations in this field, roll forming machines have emerged as indispensable tools. These machines play a pivotal role in the production of metal sheets and panels used in roofing, wall cladding, and other construction applications.Roll Forming Machine: Transforming Metal Sheets with PrecisionRoll forming machines, also known as roll formers, are highly versatile manufacturing machines used to transform flat metal sheets into complex and customized profiles used in construction. They utilize a continuous bending operation by passing the sheet metal through a series of rolling dies. The process involves shaping the metal into a desired cross-section profile while maintaining uniform thickness throughout the length.Cold Roll Forming Machine: Enhancing Precision and DurabilityCold roll forming machines have gained immense popularity due to their ability to work with a wide range of materials, including steel, aluminum, copper, and more. This type of roll forming machine operates at room temperature, minimizing the risk of thermal damage to the metal. Cold roll forming ensures higher uniformity in the end products, offering superior dimensional accuracy, strength, and durability.Sandwich Panel Machine: Efficient Insulation SolutionsThe use of sandwich panels in construction has gained significant traction, primarily due to their excellent thermal and sound insulation properties. Sandwich panel machines are specifically designed to produce panels with an insulating core material, such as EPS (Expanded Polystyrene), rock wool, or mineral wool, sandwiched between two outer sheets. These panels find applications in roofing, wall cladding, and other structural elements, offering energy efficiency and environmental benefits.Revolutionizing the Manufacturing Process:- EPS/Rock wool/Mineral wool sandwich panel machine: This advanced technology enables the efficient production of insulated panels, offering enhanced temperature regulation and noise reduction in buildings.- Glazed Tile Roll Forming Machine: Utilizing high-quality materials, this machine produces aesthetically appealing glazed tiles for roofing applications. The precise roll forming process ensures dimensional accuracy and long-lasting performance.- Standing Seam Roof Panel Roll Forming Machine: This machine revolutionizes the production of standing seam roof panels, which are popular for their exceptional weather resistance and stylish appearance.- Double Layer Roll Forming Machine: Ideal for large-scale projects, this machine efficiently produces two different profiles simultaneously, reducing production time and costs.- Highway Guardrail Roll Forming Machine: As road safety remains a paramount concern, this machine manufactures sturdy guardrails, protecting motorists and minimizing accidents.Expanding Possibilities with Advanced Features:Modern roll forming machines come equipped with advanced features such as computer numerical control (CNC) systems, automated feeders, and precision cutting mechanisms, ensuring high productivity, reliability, and time efficiency. These features allow for customization and adaptation to different profile designs.Conclusion:The roll forming machine industry has witnessed substantial advancements in recent years, fueling innovative manufacturing processes in the construction sector. The introduction of cold roll forming machines, sandwich panel machines, and other specialized equipment has enabled the production of high-quality, customized metal profiles and panels. As technology continues to evolve, these machines will play a vital role in shaping the infrastructure of our future.For further information or inquiries, interested parties are encouraged to contact Ms. Monica Lee, who will provide detailed information and the best prices for the required profile drawings or specifications.Contact Person: Ms. Monica LeeWebsite: (brand name removed)Disclaimer: This news content is for information purposes only and does not serve as an endorsement for any specific brand or company.

High-Quality Roll Making Machine for Efficient Production

Roll Making Machine upgrades to provide enhanced efficiency and precision for the manufacturing industry. The new and improved roll making machine has been developed by a leading company in the manufacturing industry. With advanced technology and state-of-the-art engineering, the machine is designed to meet the growing demands of the industry for higher productivity and product quality.The roll making machine is an essential tool for various manufacturing processes, including paper, plastic, metal, and textile production. It is used to fabricate rolls of different sizes and specifications, which are then integrated into various production lines to facilitate the manufacturing process. The quality and precision of the rolls produced by the machine directly impact the overall efficiency and output of the manufacturing operation.The upgraded roll making machine features advanced automation and control systems, which allow for greater precision and efficiency in roll production. The machine is equipped with high-precision cutting and shaping tools, as well as enhanced material handling and feeding mechanisms, which ensure consistent and accurate roll fabrication. The new technology also enables faster setup and changeover times, reducing downtime and increasing overall productivity.In addition to the technological upgrades, the company has also focused on enhancing the durability and reliability of the roll making machine. The machine is built with high-quality materials and components to ensure long-term performance and minimal maintenance requirements. The robust design and construction of the machine make it suitable for continuous operation in demanding manufacturing environments.Furthermore, the roll making machine is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with a user interface that provides real-time monitoring and control of the production process, allowing operators to make adjustments and corrections as needed. This not only improves the overall efficiency of the machine but also reduces the potential for errors in roll fabrication.The company behind the development of the roll making machine is a leading manufacturer of industrial machinery and equipment. With decades of experience in the industry, the company has established a reputation for delivering high-quality and innovative solutions to meet the evolving needs of the manufacturing sector. The company's commitment to research and development has led to the continuous improvement of its products, ensuring that they remain at the forefront of technological advancements.The roll making machine is the latest addition to the company's portfolio of manufacturing solutions. By leveraging its expertise in engineering and manufacturing, the company has been able to develop a machine that not only meets the current requirements of the industry but also anticipates future demands. The company's dedication to innovation and quality has positioned it as a trusted partner for manufacturing businesses seeking to enhance their production capabilities.In conclusion, the upgraded roll making machine represents a significant advancement in roll production technology. With its advanced automation, precision, and durability, the machine is poised to have a positive impact on the manufacturing industry, enabling businesses to achieve higher efficiency and product quality. As a leading company in the manufacturing sector, the company's continuous commitment to innovation underscores its role as a key contributor to the advancement of the industry.

Automatic Reinforcement Iron Bar Making Machine: Everything You Need to Know

Ibr Making Machine: Revolutionizing the Roofing IndustryIn the world of construction and roofing, innovation and technology play a vital role in improving efficiency and quality of work. One such innovation that has recently been making waves in the industry is the Ibr Making Machine. This state-of-the-art machine is changing the way roofing materials are manufactured and is set to revolutionize the roofing industry as we know it.The Ibr Making Machine, produced by a leading manufacturing company in the field of construction machinery, is a fully automated, high-speed machine that is capable of producing a wide range of roofing materials with precision and efficiency. From galvanized steel to aluminum, the machine can effortlessly handle various materials, ensuring versatility and high quality in the final products.One of the key features of this machine is its ability to produce IBR (Inverted Box Rib) profiles, a popular choice for roofing material due to its strength and durability. The machine's precision rollers and cutting mechanisms ensure that each sheet produced is of consistent quality and precise dimensions, meeting the highest standards in the industry. This consistency is crucial for roofing projects, as it ensures a seamless and watertight installation, ultimately leading to greater customer satisfaction and long-lasting roofs.Furthermore, the Ibr Making Machine is equipped with advanced technology that allows for seamless customization of roofing materials. This means that contractors and builders can easily adjust the dimensions, thickness, and even colors of the roofing sheets to suit the specific requirements of each project. This level of customization not only provides flexibility but also reduces material waste, ultimately leading to cost savings for the roofing companies and their clients.The company behind the Ibr Making Machine prides itself on its commitment to innovation and quality. With a team of experienced engineers and technicians, the company has dedicated extensive resources to research and development, ensuring that their machines are at the forefront of technological advancements in the industry. In addition, the company places great emphasis on customer service and support, ensuring that their clients are well-trained and supported in the operation and maintenance of the machines.The impact of the Ibr Making Machine on the roofing industry has been profound. Many roofing companies that have adopted this technology have reported significant improvements in their production processes, from faster turnaround times to higher quality products. The machine's efficiency has also allowed these companies to take on larger and more complex projects, expanding their business and ultimately improving their bottom line.Moreover, the Ibr Making Machine has had a positive environmental impact as well. By reducing material waste and energy consumption, the machine contributes to sustainable and eco-friendly manufacturing practices, aligning with the global push for greener and more sustainable construction methods.As the demand for high-quality roofing materials continues to grow, the Ibr Making Machine is poised to become an indispensable asset for roofing companies around the world. Its ability to produce top-notch roofing materials with speed, efficiency, and customization capabilities make it a game-changer in the industry. With the backing of a reputable and innovative manufacturing company, the Ibr Making Machine is set to shape the future of roofing, providing solutions that meet the evolving needs of the construction industry.

High-quality Cold Roller Former for Efficient Metal Processing

Cold Roller Former, a cutting-edge technology developed by a leading manufacturing company, is making waves in the industry with its innovative and efficient cold rolling process. This revolutionary machine is designed to shape metallic materials into various components, providing a cost-effective and high-quality solution for a wide range of applications.The cold rolling process is a critical step in metal forming, as it helps to improve the surface finish and mechanical properties of the material. Unlike traditional hot rolling, cold rolling occurs at room temperature, which results in a smoother and more precise finish. This method is particularly important for industries such as automotive, aerospace, and construction, where the quality and integrity of the metal components are paramount.With the introduction of Cold Roller Former, manufacturers can now benefit from a streamlined and advanced cold rolling process. This machine is equipped with state-of-the-art technology, including precision control systems and high-speed capabilities, allowing for the efficient production of complex and high-quality components. Additionally, its modular design and customizable features make it adaptable to various production needs, providing flexibility and versatility to manufacturers.One of the key advantages of Cold Roller Former is its ability to produce parts with tighter tolerances and improved surface finish, resulting in higher precision and quality. This is particularly beneficial for industries that require components with intricate geometries and superior mechanical properties. With Cold Roller Former, manufacturers can achieve a level of consistency and accuracy that is not possible with traditional cold rolling methods, leading to enhanced product performance and reliability.Furthermore, Cold Roller Former is designed with efficiency in mind, offering a significant increase in productivity and cost savings for manufacturers. Its high-speed capabilities and advanced control systems enable faster production cycles and reduced material waste, resulting in a more streamlined and economical manufacturing process. This not only helps to improve the overall competitiveness of manufacturers but also contributes to a more sustainable and environmentally friendly production environment.In addition to its technological advancements, Cold Roller Former is backed by a dedicated team of experts who provide comprehensive support and expertise to ensure the successful implementation and operation of the machine. From initial consultation to ongoing maintenance and training, the company's commitment to customer satisfaction and knowledge sharing sets a new standard for excellence in the industry.As a testament to its success, Cold Roller Former has already made significant strides in the market, garnering attention and accolades from industry experts and customers alike. Its proven track record of delivering superior performance, cost-effectiveness, and reliability has positioned it as the go-to solution for manufacturers seeking to elevate their cold rolling capabilities.Looking ahead, the company is committed to further advancing and enhancing Cold Roller Former to meet the evolving needs of the industry. With ongoing research and development efforts, the company is dedicated to pushing the boundaries of cold rolling technology, ultimately redefining the standards of excellence and innovation in metal forming.In conclusion, Cold Roller Former represents a significant breakthrough in cold rolling technology, offering a game-changing solution for the manufacturing industry. With its advanced capabilities, efficiency, and reliability, this revolutionary machine is poised to shape the future of cold rolling and set a new benchmark for excellence in metal forming.

Quality Glazed Tile Roll Forming Machine and Corrugating Equipment for Sale

Glazed Tile Roll Forming And Corrugating Machine is a revolutionary piece of equipment that is set to change the game in the construction industry. This high-tech machine is designed to produce glazed tiles and corrugated sheets with precision and efficiency, making it an indispensable tool for construction companies and contractors all over the world.The Glazed Tile Roll Forming And Corrugating Machine is equipped with advanced technology and a state-of-the-art design that allows for seamless production of high-quality tiles and sheets. It is capable of working with a variety of materials, including steel, aluminum, and copper, making it a versatile choice for any construction project. The machine features a user-friendly interface, allowing operators to easily input their desired specifications and produce custom tiles and sheets with ease.One of the key features of the Glazed Tile Roll Forming And Corrugating Machine is its speed and efficiency. With the ability to produce up to 60 tiles or sheets per minute, this machine can significantly increase productivity and reduce production time, saving construction companies time and money. It also boasts a high degree of accuracy, ensuring that each tile or sheet meets the strictest quality standards.In addition to its impressive performance, the Glazed Tile Roll Forming And Corrugating Machine is also designed with sustainability in mind. It is equipped with energy-efficient components and is built to minimize waste, making it an environmentally-friendly choice for construction projects. This focus on sustainability aligns with our company's commitment to reducing our environmental impact and contributing to a greener future.Our company is a leading manufacturer of construction machinery, known for our innovative designs and commitment to quality. With over 20 years of experience in the industry, we have a proven track record of delivering reliable and efficient equipment that meets the needs of our customers. Our team of engineers and designers are dedicated to staying at the forefront of technological advancements, ensuring that our products are always cutting-edge and able to support the evolving needs of the construction industry.As part of our commitment to customer satisfaction, we offer comprehensive support services for the Glazed Tile Roll Forming And Corrugating Machine. Our team of technicians are available to provide training, technical support, and maintenance services, ensuring that our customers are able to maximize the performance of their equipment and achieve the best possible results. We also offer a range of financing options to make our equipment more accessible to a wider range of customers, allowing them to take advantage of the benefits of our cutting-edge technology.The introduction of the Glazed Tile Roll Forming And Corrugating Machine represents a significant advancement in the construction industry, offering a solution that is both efficient and sustainable. With its speed, precision, and versatility, this machine is set to revolutionize the way that construction companies produce tiles and sheets, allowing them to meet their project requirements with ease. As a leading manufacturer in the industry, we are proud to be at the forefront of this innovation and to continue supporting the success of our customers with our state-of-the-art equipment.

Revolutionary Cold Formed Steel Machine Disrupts Construction Industry

Cold Formed Steel Machine: Paving the Way to Innovative Steel ConstructionInvented over a century ago, cold forming is a manufacturing process that has evolved to revolutionize the steel construction industry. Cold formed steel (CFS) offers significant advantages over wood and traditional hot-rolled steel, including durability, sustainability, and adaptability. It's also more cost-effective and easier to install, making it an ideal choice for framing, roofing, and wall panels in commercial and residential buildings.Today, the trend towards offsite construction and modular building is driving the demand for high-quality, precision cold formed steel machines that can deliver the desired outputs in a timely and cost-effective manner. One company that has stepped up to the challenge is [Brand name], a leading supplier of cold formed steel machines and roll forming systems worldwide.With over 20 years' experience in the industry, [Brand name] has gained a reputation for excellence through its innovative and reliable solutions for the production of CFS sections. From stud and track roll forming machines to roof panel and purlin roll forming machines, [Brand name]'s offerings provide the flexibility, accuracy, and speed required to meet various customers' needs.One of [Brand name]'s most popular machines is its patented roll forming system for cold-formed steel frames. This innovative system uses patented software and advanced technologies to produce customized CFS studs, tracks, and joists with precision and efficiency. Unlike traditional roll forming machines, which may require significant setup time and adjustments, [Brand name]'s system can be programmed to produce various sizes and shapes of CFS sections, making it ideal for low-volume, high-mix production runs.Moreover, [Brand name]'s cold formed steel machines are designed with the operator's safety and ease of use in mind. The company's engineers have developed advanced control systems that allow operators to have real-time remote access to the machine's status and performance, minimizing downtime and enhancing productivity. In addition, the machines are equipped with easy-to-use touchscreen interfaces that simplify the setup and configuration process.But what sets [Brand name]'s cold formed steel machines apart from the competition is the company's customer-centric approach that emphasizes collaboration, reliability, and flexibility. When customers choose [Brand name], they don't just get a machine — they get a team of highly qualified engineers and technicians who work closely with them to identify their needs, provide tailored solutions, and ensure the machines meet or exceed their expectations.At [Brand name], customer satisfaction is paramount. That's why the company provides excellent technical support via on-site training, remote assistance, and maintenance services to help customers get the most out of their investment. [Brand name]'s team of experts is also available to provide expert advice on the design, installation, and operation of the machines, as well as the most appropriate materials and accessories to use.As a testament to its commitment to quality and innovation, [Brand name] has received numerous accolades and recognitions over the years. For instance, the company was awarded the prestigious "National Key High-Tech Enterprise" and "Innovative Enterprise" titles by the Chinese government in 2020. These awards recognize [Brand name]'s contributions to the development of the cold formed steel industry and its commitment to advancing the latest technologies and techniques.In summary, the cold formed steel industry is poised for significant growth in the coming years, driven by the need for fast, efficient, and sustainable construction solutions. With its cutting-edge cold formed steel machines and its unwavering dedication to customer service, [Brand name] is well-positioned to help customers unlock the full potential of cold formed steel and to lead the industry forward.

Glazed Tile Roll Forming Machine: A Reliable Solution for Roofing Sheet Production

Title: Introducing Dahezb's Cutting-Edge Glazed Tile Roll Forming Machine for Metal RoofingIntroduction:In the fast-paced world of construction and manufacturing, technological advancements are constantly emerging to improve efficiency and quality. Dahezb Metal presents its latest innovation, the Glazed Tile Roll Forming Machine, a state-of-the-art solution for producing metal roof tiles. With its ability to transform metal sheets into refined glazed roofing tiles, this machine proves to be a game-changer in the industry.Redefining Metal Roofing:Dahezb's Glazed Tile Roll Forming Machine is designed to cater to the specific needs of customers looking for robust metal roofing solutions. Capable of molding metal sheets ranging from 0.3mm to 0.6mm in thickness, this machine delivers top-notch precision and durability.Key Features and Benefits:1. Enhanced Efficiency: The Glazed Tile Roll Forming Machine operates with remarkable efficiency, allowing for smooth and continuous production. By eliminating the need for manual tile cutting, this machine saves time, labor, and material costs.2. Customized Solutions: Dahezb understands that every customer has unique requirements. Therefore, the Glazed Tile Roll Forming Machine offers flexibility in terms of tile shapes, sizes, and profiles. Whether it is a traditional or modern design, this machine can adapt to produce the desired glazed tiles for any roofing project.3. High-Quality Output: The Glazed Tile Roll Forming Machine ensures impeccable quality, maintaining consistency in tile thickness and dimensions. With precise control and advanced technology, it guarantees an aesthetically pleasing finish, giving metal roofing a sophisticated appeal.4. Durability: Metal roofs are known for their longevity, and the tiles produced by this machine are no exception. The Glazed Tile Roll Forming Machine manufactures tiles of exceptional strength, able to withstand harsh weather conditions and provide long-lasting protection.5. Advanced Automation: The machine's automation features streamline the production process, reducing the chances of human error. With user-friendly controls and easy-to-understand functions, operators can swiftly adapt to the machine's operations.6. Environmentally Friendly: Contributing to sustainable construction practices, the Glazed Tile Roll Forming Machine minimizes waste generated during production. By optimizing material usage and reducing scrap, it aligns with the industry's increasing focus on eco-friendly solutions.Growing Demand for Metal Roofing:The demand for metal roofing has been steadily rising due to its numerous advantages over traditional roofing materials. Metal roofs offer superior durability, remarkable energy efficiency, and significant cost savings in the long run. Additionally, they are fire-resistant and require minimal maintenance, making them an attractive choice for homeowners and businesses alike.Company Introduction: Dahezb Metal is a renowned manufacturer and provider of high-quality roll forming machines. Their expertise lies in designing and producing roofing and construction machinery that meets the evolving industry requirements. With a strong commitment to innovation and customer satisfaction, Dahezb Metal continues to be a trusted collaborator for businesses worldwide.Conclusion:With its cutting-edge Glazed Tile Roll Forming Machine, Dahezb Metal is revolutionizing the metal roofing industry. This advanced technology not only saves time and facilitates efficient production but also delivers outstanding quality and durability. As demands for eco-friendly and sustainable construction practices increase, Dahezb's Glazed Tile Roll Forming Machine stands as a valuable solution for any roofing project.