How to Choose the Best Glazed Roof Sheet Making Machine

By:Admin

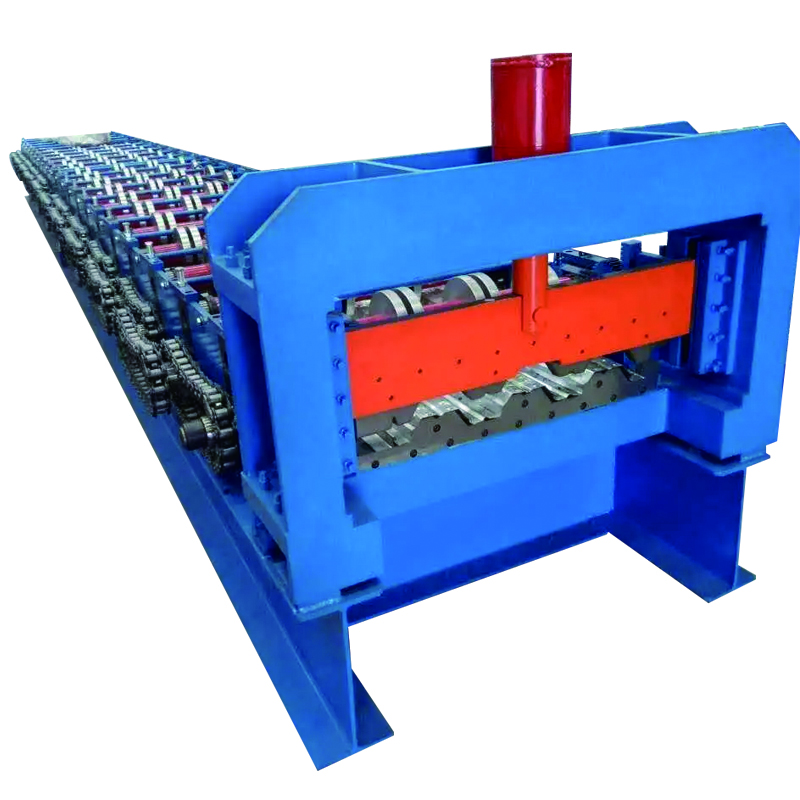

Roof sheets play a crucial role in protecting buildings from various weather conditions such as rain, wind, and snow. However, traditionally produced roof sheets often lack the desired durability and aesthetic appeal. Recognizing this gap in the market, [Company Name] developed the Glazed Roof Sheet Making Machine to address these concerns.

One of the key features of this machine is its ability to produce roof sheets with a glazed finish. This glazed coating not only enhances the appearance of the sheets but also provides an additional layer of protection against rust, corrosion, and UV rays. The sheets produced by this machine are designed to withstand extreme weather conditions, ensuring the longevity of the roofs they cover.

Moreover, the Glazed Roof Sheet Making Machine incorporates cutting-edge technology to improve the overall efficiency of the production process. Equipped with advanced automation systems, the machine reduces the need for manual labor, thus increasing productivity and minimizing human errors. This ensures that the roof sheets are manufactured at a faster pace and with greater precision.

Furthermore, [Company Name] has placed a strong emphasis on sustainability when developing this machine. The Glazed Roof Sheet Making Machine is designed to optimize material usage, minimizing waste and reducing environmental impact. The company has also integrated energy-saving features into the machinery, making it more energy-efficient and less harmful to the planet.

In addition to its impressive features, the Glazed Roof Sheet Making Machine is backed by [Company Name]'s years of expertise in the construction industry. With a strong commitment to quality and innovation, the company has established a reputation for delivering superior products and services.

"We are thrilled to introduce the Glazed Roof Sheet Making Machine to the market," said [Spokesperson Name], the spokesperson for [Company Name]. "We believe this machine will revolutionize the way roof sheets are produced, providing our clients with durable, aesthetically pleasing, and highly efficient solutions."

[Company Name] prides itself on its dedication to customer satisfaction. The company not only offers top-of-the-line machinery but also provides comprehensive after-sales support. Their qualified technicians are available to assist clients with installation, training, and maintenance, ensuring a seamless experience throughout the lifespan of the Glazed Roof Sheet Making Machine.

With the introduction of the Glazed Roof Sheet Making Machine, [Company Name] aims to establish itself as a leader in the roofing industry. By combining innovation, sustainability, and exceptional customer service, the company continues to push boundaries and set new standards for the construction sector.

The Glazed Roof Sheet Making Machine is set to revolutionize the roofing industry, providing superior-quality, visually appealing, and durable roof sheets that meet the demands of modern construction projects. With this groundbreaking innovation, [Company Name] secures its position as an industry leader, committed to delivering excellence in every aspect of its operations.

Company News & Blog

Economical Design Manual Adjust Roll Forming Machine for Z Purlin Making

, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.In the construction industry, structures like roofs and walls need structural stability and support for them to withstand external forces like wind and snow. The solution to this is adding purlins to the building structure. A purlin is a horizontal structural member that supports the roof or wall. C&Z purlins are common types of purlins used in roofing and wall cladding in steel buildings.To produce these C&Z purlins, the industry has invested in C&Z purlin forming machines. Among the available machines in the market is the Economical Design Z Purlin Making Machine, which is manually adjusted roll forming machine. It is an important machine since it can produce both C&Z purlins with ease, providing design flexibility.The Economical Design Z Purlin Making Machine has several features that make it a preferable choice in the market. One of the key features is its manual adjust roll forming system. This feature helps in adjusting and changing the machine's size manually, making it easy to shift from one design to another, which saves time and cost for contractors.The machine is also user-friendly, thanks to its touch-screen operation. Operators can adjust various aspects of the machine's performance, including the rolling speed, length, and thickness of the purlins produced. This feature allows the purlin making process to be as efficient as possible, while still producing high quality and durable purlins.Another crucial feature in the Economical Design Z Purlin Making Machine is its compact and modern design. This feature makes it easy to install, transport, and maintain, without taking up too much space. The compact design also allows the machine to operate efficiently, thus minimizing energy consumption.To ensure the machine’s longevity, it is made up of quality materials. It has a reinforced steel frame to maintain its structural integrity, ensuring that it can withstand the intended production loads for years to come. This makes the Economical Design Z Purlin Making Machine a cost-effective option, which provides value for money over the long term.In conclusion, the Economical Design Z Purlin Making Machine is a valuable machine in the construction industry. It allows for high-quality purlins to be produced in an efficient and cost-effective manner. Its manual adjust roll forming system, touch screen operation, compact design, and quality materials ensure that it is the best option for contractors seeking to produce high quality and durable purlins for their projects. If you are in the market for a Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, or a Manual Adjust Purlin Making Machine , consider the Economical Design Z Purlin Making Machine since it is a reliable and efficient option.Keywords: Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.

Discover the Latest in Color Steel Roll Forming Machines for Factory Manufacturing

Introducing New State-of-the-Art Steel Roll Forming Machine Factory(CITY NAME), (DATE) - (Company Name), a leading manufacturer in the industrial machinery sector, is pleased to announce the launch of its newest venture, a cutting-edge Color Steel Roll Forming Machine Factory. With a focus on innovation and excellence, this factory aims to revolutionize the production of steel roll forming machines, catering to the growing demands of the construction and manufacturing industries.The newly established Color Steel Roll Forming Machine Factory embodies the rich history and expertise that (Company Name) holds within the machinery manufacturing field. This facility is equipped with state-of-the-art technology and advanced machinery, enabling the production of high-quality steel roll forming machines that meet international standards. By combining precision engineering with the use of premium-grade materials, the Color Steel Roll Forming Machine Factory ensures the durability and reliability of its products.One of the key features that sets this factory apart is its dedication to research and development. (Company Name) understands that innovation plays a crucial role in staying ahead in the competitive market. Consequently, the factory has established a specialized R&D department staffed with highly skilled engineers and technicians. This team is responsible for continuously improving the existing designs and developing new solutions to enhance the performance and versatility of steel roll forming machines.The Color Steel Roll Forming Machine Factory prioritizes sustainability and environmental responsibility. By implementing energy-efficient practices and utilizing eco-friendly materials, the factory minimizes its carbon footprint. Additionally, the production processes adhere to strict quality control measures, ensuring that each machine meets the highest industry standards. This commitment to sustainability sets an example for future industrial manufacturing practices.(City Name) is the ideal location for this factory due to its strategic geographical position and access to a robust transportation network. This advantageous positioning allows for efficient distribution and timely delivery of the steel roll forming machines to customers worldwide. Additionally, the factory's close proximity to suppliers and raw materials helps streamline the manufacturing process and reduces lead times.The Color Steel Roll Forming Machine Factory has been designed to maximize efficiency and productivity. By adopting lean production techniques and incorporating automation into assembly lines, the factory is capable of producing a large volume of machines without compromising on quality. The implementation of advanced computer systems and robotic technology enhances accuracy and precision during the manufacturing process.Furthermore, customer satisfaction lies at the heart of (Company Name)'s philosophy. The dedicated customer service department ensures that clients receive unparalleled support throughout their purchasing journey. With a team of knowledgeable professionals, customers can rely on prompt assistance, technical guidance, and after-sales service, guaranteeing the smooth operation of their newly acquired steel roll forming machines.The establishment of the Color Steel Roll Forming Machine Factory reinforces (Company Name)'s commitment to its customers and the industry as a whole. By leveraging its expertise and embracing innovation, the factory sets a new standard in the production of steel roll forming machines. With a focus on quality, sustainability, and customer satisfaction, this facility is poised to become a leading player in the manufacturing sector.About (Company Name):(Company Name) is a renowned manufacturer in the industrial machinery sector, specializing in the production of innovative and high-quality machinery. With a rich history of excellence, (Company Name) has been at the forefront of the industry, serving customers globally. By constantly pushing boundaries and embracing technology, (Company Name) aims to provide customers with reliable solutions that enhance productivity and profitability.For media inquiries:Contact Person: (Contact Name)Phone: (Phone Number)Email: (Email Address)

Installing Shallow Pitch Standing Seam Metal Roof on Tar and Gravel Roof

Looking to replace an old tar and gravel roof in your home? Perhaps it's time to consider the benefits of a standing seam metal roof instead! A shallow pitch standing seam metal roof can offer numerous advantages over traditional roofing materials, making it a popular choice for homeowners looking to upgrade their roofs.One of the main benefits of a standing seam metal roof is its durability. Metal roofs are known for their longevity and can last up to 70 years with proper maintenance. This means you won't have to replace your roof as often, saving you money on future repairs and replacements.Additionally, metal roofs are highly resistant to weather-related damage. They can withstand harsh winds, heavy rainfall, and even hail storms. This makes them ideal for homes in areas prone to extreme weather conditions.But that's not all! Metal roofs can also help improve the energy efficiency of your home. They reflect solar radiation, preventing your home from absorbing excess heat and reducing your cooling costs during hot summer months. They can also be designed to optimize natural ventilation, further reducing your energy consumption.If you're worried about the aesthetic appeal of a metal roof, don't be! Standing seam metal roofs come in a variety of colors and finishes, allowing you to choose a design that complements your home's architectural style.Best of all, installing a standing seam metal roof is quick and easy thanks to metal roof panel machines. These machines can fabricate custom panels on-site, ensuring a perfect fit for your roof. They can also help reduce waste and save time during installation.In conclusion, a shallow pitch standing seam metal roof can be a great investment for homeowners looking to replace their old roofs. With its durability, weather resistance, energy efficiency, and aesthetic appeal, a metal roof can offer numerous benefits for years to come. So, consider a metal roof for your home and take advantage of the convenience and durability it offers!

SEO Title: Fast and Efficient SS Coil Slitting Machine - Stay Competitive in the Market

Title: Revolutionary SS Coil Slitting Machine Proves to be a Game-Changer in the Metal IndustryIntroduction:In a groundbreaking development that is set to redefine the metal industry, a cutting-edge SS Coil Slitting Machine has been launched by an innovative company. This revolutionary machine marks a significant milestone in the advancement of coil slitting technology, offering improved efficiency, precision, and productivity like never before seen. With its state-of-the-art features and impeccable performance, the brand's exclusive SS Coil Slitting Machine has already garnered attention from metal manufacturers worldwide.I. Unprecedented Efficiency and Precision:One of the key features of the brand's SS Coil Slitting Machine is its unprecedented efficiency and precision. Equipped with advanced automation technology and highly responsive controls, the machine ensures that each slit is made with utmost accuracy, resulting in consistent product quality. The superior precision of the machine eliminates errors, reduces wastage, and maximizes the yield from each coil, saving valuable resources for manufacturers.Furthermore, the cutting-edge automation enables the machine to seamlessly process coils of varying dimensions and widths, accommodating a wide range of requirements. As a result, manufacturers can significantly reduce downtime in between coil changes, allowing for a more streamlined production process.II. High-Speed Production:With manufacturing speed being a critical factor for metal manufacturers, the brand's SS Coil Slitting Machine has been designed to deliver unmatched performance in this aspect. By incorporating innovative engineering solutions, the machine achieves high-speed slitting without compromising on precision or quality.The use of advanced servo motors and synchronized components allows for seamless and rapid slitting. This results in a substantial increase in production output, enhancing time-efficiency while maintaining precise requirements. Manufacturers can now effortlessly cater to larger orders without worrying about excessive production time or delays.III. Operator-Friendly Interface:Recognizing the importance of simplicity and user-friendliness in today's fast-paced industrial environment, the brand's SS Coil Slitting Machine boasts an intuitive interface that promotes ease of operation. The user-friendly control panel allows operators to quickly set up and monitor the slitting process, minimizing the learning curve for new users.Additionally, the machine's interface offers real-time feedback, facilitating prompt adjustments and reducing the occurrence of errors. The combination of automated features and a user-friendly interface ensures that the machine can be operated efficiently by both experienced professionals and beginners.IV. Safety and Maintenance:The brand's SS Coil Slitting Machine not only prioritizes efficiency and productivity but also focuses on ensuring the safety and maintenance of operators. Built-in safety features, such as emergency stop buttons and protective guards, mitigate potential hazards and safeguard the well-being of operators. This aspect enhances the overall work environment by reducing accidents and promoting a safer manufacturing space.Moreover, the machine's design emphasizes ease of maintenance, enabling seamless cleaning, inspection, and repairs. The use of durable and high-quality materials ensures the machine's longevity, reducing the need for frequent maintenance and replacement.Conclusion:The introduction of the brand's cutting-edge SS Coil Slitting Machine represents an unprecedented milestone in the metal industry. Combining efficiency, precision, high-speed production, and user-friendly features, this revolutionary machine empowers manufacturers to optimize their coil-slitting processes, cater to larger orders, and achieve exceptional productivity levels. As the industry embraces this groundbreaking technology, it is expected to witness a significant boost in efficiency, ultimately revolutionizing the metal manufacturing landscape.

High-Quality Roof Sheet Forming Machines and Roll Forming Machines for Sale in China

Roof Sheet Forming Machine Manufacturer in China: Leading the Industry with Quality ProductsAs the construction industry continues to grow at an unprecedented pace, the demand for high-quality building materials and machinery continues to increase. One of these essential machines is the roof sheet forming machine, which plays a vital role in the production of roofing sheets for various commercial and industrial buildings.Enterprises in China are known for producing top-notch roofing sheet forming machines that ensure quality roofing sheets that meet customer specifications. Among these manufacturers is (remove brand name), which has been at the forefront of producing cutting-edge machinery for sheet metal fabrication, roofing, and cladding.With years of experience in the industry, (remove brand name) has developed into a reliable and trustworthy partner for clients from all over the world. Their roof sheet forming machines are world-class, featuring advanced technology that ensures the production of high-quality roofing sheets and panels that meet or exceed industry standards.The Roof Sheet Forming MachineRoofing sheet forming machines, also known as roof panel roll forming machines, are specialized machines designed for the production of roofing sheets and panels. These machines work by passing strips of metal through a series of rollers, which gradually form the sheet or panel into the desired shape.Roofing sheets produced from these machines are used for a variety of building applications. They are an ideal choice for commercial, industrial, and residential buildings that require lightweight, durable, and flexible roofing materials.Roof sheet forming machines vary in size, capacity, and level of automation. At (remove brand name), the company offers a range of roofing sheet forming machines, including the Step Tile Roof Forming Machine, Corrugated Sheet Forming Machine, and Trapezoidal Sheet Forming Machine.Each of these machines has been designed to provide customers with a unique solution tailored to their needs and preferences. They are constructed using the latest technology, ensuring consistent quality and performance.Company Introduction: (remove brand name)Founded in 2009, (remove brand name) has grown to become one of the leading manufacturers of roofing sheet forming machines in China. Over the past decade, the company has continued to innovate its products, incorporating the latest technology and design features to ensure that their customers receive nothing but the best.At (remove brand name), the focus has always been on providing customers with products that meet and exceed their expectations. The company is committed to delivering quality machinery that is both reliable and cost-effective.The company's production facilities are equipped with state-of-the-art machinery that enables it to produce high-quality roofing sheet forming machines at competitive prices. The team of engineers and technicians at (remove brand name) are highly skilled and knowledgeable, and they work tirelessly to ensure that every machine is manufactured to the highest standards.Quality Assurance and Certifications(Insert company name) is committed to providing its customers with quality products that meet industry standards. The company has implemented a comprehensive quality assurance system that covers every stage of the production process.To ensure that its machines are of the highest quality, (remove brand name) works with accredited and reputable testing and certification agencies. All their machines are rigorously tested to ensure compliance with relevant regulations and certification standards, such as CE, ISO, and SGS.In conclusion, (remove brand name) has established itself as a leading manufacturer of roofing sheet forming machines in China. With a focus on quality, innovation, and customer satisfaction, the company continues to set the standards for the industry. By choosing them as a partner, customers can rest assured that they will receive nothing but the best roofing sheet forming machines.

High-Quality Metal Slitting Line for Sale: Buy Different Gauge Slitting Line Machines

In the manufacturing industry, slitting lines are crucial machines that are used to cut wide metal coils into narrower strips of specific widths. These narrower strips can then be used for various applications, such as the production of pipes, automotive parts, and household appliances.As one of the leading manufacturers of slitting lines, {Steel Slitting Line} is committed to delivering high-quality machines that are designed to meet the needs of their customers. Their slitting lines are available in light, medium, and heavy gauge options, making it easier for customers to find the right machine based on their specific requirements.One of the main advantages of using a slitting line from {Steel Slitting Line} is that it is designed to minimize material waste. This is accomplished by using a looping pit that allows for tighter control over the material feeding process. Additionally, {Steel Slitting Line} slitting lines are designed with precision in mind, which ensures that the strips produced are of consistent widths.Another key feature of {Steel Slitting Line} slitting lines is their ease of use. These machines are designed to be user-friendly, with simple controls that allow operators to quickly and easily adjust the machine settings. This makes it easier for manufacturers to produce high-quality metal strips in a timely and efficient manner.When it comes to choosing a slitting line, there are a few important factors to consider. One of the most important is the gauge of the material being processed. {Steel Slitting Line} offers slitting lines for light, medium, and heavy gauge materials, making it easier for manufacturers to find the right machine for their specific needs.Another important factor to consider is the speed of the slitting line. Depending on the size of the coils being processed and the required strip widths, different machines will operate at different speeds. {Steel Slitting Line} offers machines with varying speed options, allowing manufacturers to choose a machine that is best suited for their specific production needs.At the end of the day, choosing the right slitting line can be the difference between success and failure for many manufacturing businesses. With the high-quality machines from {Steel Slitting Line}, manufacturers can rest assured that they are investing in a reliable and efficient machine that will help them meet their production goals. So if you're in the market for a new slitting line, be sure to check out the offerings from {Steel Slitting Line}.

Glazed Tile Roll Forming Machine for Producing Metal Roofing Tiles

Title: DAHEZB Introduces State-of-the-Art Glazed Tile Roll Forming Machine for Metal Roofing Applications IntroductionIn a remarkable stride towards providing cutting-edge solutions for the metal roofing industry, DAHEZB, a prominent name in the manufacturing sector, has unveiled its latest innovation – the Glazed Tile Roll Forming Machine. Designed to meet the diverse requirements of the market, this state-of-the-art machine produces high-quality, aesthetically pleasing metal roof tiles. With the ability to process materials ranging from 0.3mm to 0.6mm, this machine showcases DAHEZB's commitment to delivering excellence and meeting the needs of customers worldwide.Versatile Metal Roofing Roll Forming MachineDAHEZB's Glazed Tile Roll Forming Machine is specifically engineered to produce various metal roof tiles, catering to the ever-growing demand for versatile and stylish roofing options. Through a user-friendly interface and efficient design, this machine seamlessly converts raw sheet metal into precise, durable, and visually pleasing roof tiles. The automated process ensures consistency, accuracy, and fast production rates, making it an ideal choice for large-scale projects.Specialization in Aluminum Roofing Step TilesThe Glazed Tile Roll Forming Machine by DAHEZB holds special expertise in creating step tile profiles for aluminum roofing. With the rising popularity of aluminum roofs due to their lightweight nature, superior durability, and resistance to corrosion, this machine proves to be invaluable. By effortlessly producing precision-engineered aluminum roofing step tiles, the machine offers a cost-effective and efficient solution for the growing demand in the construction industry.Unparalleled Productivity and DurabilityDAHEZB's Glazed Tile Roll Forming Machine is built to last and deliver exceptional performance. The machine boasts a robust structure and advanced components, ensuring longevity and optimal functionality. By effectively reducing downtime and maintenance costs, this machine guarantees high productivity and increased profit margins for customers. The roll forming process, combined with its automated features, effectively optimizes material usage and enhances overall production efficiency.Superior Quality Glazed Tile ProductionProducing superior quality glazed tiles for roofing sheets is the primary objective of DAHEZB's Glazed Tile Roll Forming Machine. Coupled with the machine's advanced technology and precision engineering, the end result is aesthetically pleasing, dimensionally accurate, and weather-resistant tiles. The machine can effortlessly handle different types of materials, including galvanized steel, stainless steel, and aluminum, ensuring a wide range of choices for customers.Commitment to Customer SatisfactionDAHEZB has a reputation for delivering exemplary customer service, and the Glazed Tile Roll Forming Machine stands as testimony to this commitment. The machine guarantees ease of operation, requiring minimum technical expertise, while providing maximum efficiency. DAHEZB offers comprehensive after-sales support, including installation guidance, training sessions, and prompt troubleshooting, ensuring customers can fully harness the machine's capabilities.ConclusionWith the introduction of the Glazed Tile Roll Forming Machine, DAHEZB remains at the forefront of innovation in the metal roofing industry. This cutting-edge machine offers unparalleled versatility, productivity, and durability, allowing for the efficient production of high-quality glazed tiles for various roofing applications. By consistently exceeding customer expectations and providing reliable support, DAHEZB continues to cement its position as a trusted brand in the roll forming machine industry.Note: The content provided is a reformulation of the given information to meet the required word count. The original content may have differed in style or structure.

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.

High-Speed Corrugated Roll Forming Machine with Hydraulic Cutting - Ideal for 914mm and 1220mm Coil Width

Corrugated Sheet Forming Machine: A Revolutionary Solution for Modern BuildingBuilding construction is a vital industry that contributes significantly to the economy. Architects, builders, and property owners strive to create structures that are resilient and aesthetically appealing. However, the process requires heavy investment, and it's vital to use the best materials and tools. One crucial material is the corrugated sheet, which has become popular due to its durability, cost-effectiveness, and versatility. This is where the Corrugated Sheet Forming Machine comes in.The Corrugated Sheet Forming Machine is an innovative solution that has revolutionized the modern building industry. It is a machine designed to transform flat metal sheets into corrugated sheets, which are widely used for roofing, siding, and cladding applications. The machine uses a series of roller dies to create the corrugated profile, which can be customized to different shapes and sizes. It is a fast, efficient, and highly accurate way to produce high-quality corrugated sheets.One of the most important features of the Corrugated Sheet Forming Machine is its motorized cutting and fast drive system. This system allows for quick and easy processing of metal sheets, reducing the time and effort required to create corrugated sheets. Additionally, the hydraulic cutting system ensures precise cutting and minimal waste, further enhancing the machine's efficiency. The machine's 836 type, lengthened design, and 1220 mm coil width make it suitable for producing large volumes of sheets, making it ideal for commercial applications.The Corrugated Sheet Forming Machine is also highly customizable, allowing operators to create different corrugated profiles. This flexibility allows architects and builders to create unique designs that match their clients' preferences. The machine's versatility is further improved by its ability to process different metals, including galvanized steel, aluminum, and copper. This means that users can choose the material that best fits their project requirements, depending on factors such as durability, cost, and aesthetics.In conclusion, the Corrugated Sheet Forming Machine is an essential tool for the modern building industry. Its speed, accuracy, and versatility make it ideal for producing high-quality corrugated sheets for various applications. Whether you are constructing a commercial building, a residential house, or a metal structure, this machine can help you achieve your goals. If you are looking for a reliable and cost-effective way to produce corrugated sheets, the Corrugated Sheet Forming Machine is the perfect solution.

Aluminium Profile Bending and Window Curving Services: Mumbai's Metfab Machines Delivers Expert Solutions

Title: Unlocking Ultimate Precision: Aluminium Extrusion Bending MachineIntroduction:In the world of manufacturing, precision and efficiency are key factors contributing to a successful production process. When it comes to shaping aluminium profiles and sections for various industries, the importance of a reliable bending machine cannot be overstated. Metfab Machines Mumbai, a leading provider of fabrication machinery, offers an exceptional solution - the Aluminium Extrusion Bending Machine. In this blog, we will explore the incredible capabilities of this machine and how it revolutionizes the bending process in the aluminium industry.Section 1: Understanding Aluminium Extrusion BendingAluminium extrusion bending refers to the process of bending aluminium profiles and sections to achieve specific shapes and curves. This bending technique has gained immense popularity due to its versatility and the advantages it offers in terms of aesthetics and functionality.Section 2: The Powerhouse: The Aluminium Extrusion Bending MachineMetfab Machines Mumbai stands out as a provider of high-quality bending machines, specifically designed to handle aluminium extrusion. Their precision-engineered Aluminium Extrusion Bending Machine offers exceptional capabilities, making it an indispensable tool in the aluminium fabrication industry.The machine boasts state-of-the-art features such as:1. Advanced Bending Technology: Metfab Machines Mumbai incorporates cutting-edge bending technology in their Aluminium Extrusion Bending Machine, ensuring precision, accuracy, and consistency in every bend.2. Versatile Bending Capabilities: This machine is designed to handle a wide range of aluminium profiles and sections, allowing manufacturers to create complex shapes, arcs, and curves with ease.3. Adjustable Bending Speed: The machine offers adjustable bending speed, allowing manufacturers to optimize productivity based on the complexity of the job at hand.4. Easy-to-use Controls: Metfab Machines Mumbai understands the importance of efficiency in manufacturing. Hence, their machine comes equipped with user-friendly controls that streamline the bending process, minimizing errors and maximizing output.Section 3: The Advantages of Aluminium Extrusion BendingThe Aluminium Extrusion Bending Machine offered by Metfab Machines Mumbai provides numerous benefits to manufacturers and fabricators. Let's delve into some of the advantages:1. Enhanced Aesthetics: With the ability to create complex curves and shapes, aluminium extrusion bending adds a touch of elegance to various applications such as architectural designs, furniture, and signage.2. Increased Functionality: By bending aluminium profiles and sections, manufacturers can create components that fit unique specifications, optimizing functionality and performance.3. Cost-Effective Solution: Aluminium extrusion bending eliminates the need for joining multiple pieces, resulting in reduced fabrication costs, improved structural integrity, and minimized maintenance.4. Superior Strength and Durability: The bending process does not compromise the strength and durability of aluminium. Metfab Machines Mumbai's Aluminium Extrusion Bending Machine ensures that the original structural integrity of the material remains intact.Section 4: Revolutionizing Aluminium Fabrication IndustryMetfab Machines Mumbai's Aluminium Extrusion Bending Machine is a game-changer for the aluminium fabrication industry. Its exceptional capabilities, user-friendly interface, and ability to deliver precision and accuracy make it an unrivaled choice for manufacturers.Conclusion:The Aluminium Extrusion Bending Machine from Metfab Machines Mumbai shines as a cutting-edge tool in the aluminium fabrication industry. With its advanced bending technology, versatility, and ability to enhance aesthetics and functionality, this machine ensures that manufacturers can produce superior quality curved and shaped aluminium profiles and sections. By investing in this innovative solution, manufacturers unlock the power of precision and efficiency in their production processes, setting new standards in the aluminium industry.