Latest Advancements in Roll Forming Techniques

By:Admin

Total Roll Forming has recently expanded its facilities, adding a state-of-the-art production line that will increase their manufacturing capacity significantly. This expansion comes in response to the growing demand for their products, as well as their commitment to meeting the needs of their customers. The new production line is equipped with the latest technology and machinery, allowing Total Roll Forming to streamline their processes and improve efficiency.

In addition to the expansion of their facilities, Total Roll Forming has also introduced a new range of products to their lineup. These new products have been developed in response to the changing needs of the market and are designed to meet the demands of a wide range of industries. Total Roll Forming has always been committed to staying ahead of the curve when it comes to product development, and these new additions to their catalog are a reflection of that dedication.

This recent announcement from Total Roll Forming is a testament to the company's continued growth and success in the industry. With a focus on innovation and customer satisfaction, Total Roll Forming is well-positioned to continue leading the way in the roll forming industry. The company's expansion and introduction of new products are a clear indication of their commitment to meeting the needs of their customers and driving the industry forward.

Total Roll Forming's dedication to excellence is evident in every aspect of their business. From their top-of-the-line production facilities to their exceptional customer service, Total Roll Forming is committed to delivering the highest quality products and services to their clients. The company's team of experienced professionals is always striving to push the boundaries and set new standards for the industry, and their recent expansion and product introductions are a clear demonstration of that commitment.

In addition to their commitment to innovation and customer satisfaction, Total Roll Forming also places a strong emphasis on sustainability and environmental responsibility. The company has implemented a number of initiatives to reduce their environmental footprint and minimize waste in their production processes. By investing in sustainable practices and technologies, Total Roll Forming is demonstrating their commitment to being a responsible corporate citizen and contributing to a better, more sustainable future.

Overall, Total Roll Forming's recent announcement of their expansion and new product introductions is a clear indication of the company's continued success and commitment to excellence. With a focus on innovation, customer satisfaction, and sustainability, Total Roll Forming is poised to continue leading the way in the roll forming industry for years to come. Their dedication to continuous improvement and staying ahead of the curve is a testament to their position as a true industry leader.

Company News & Blog

Quality Corrugation Sheet Steel Tile Roll Forming Machine: Manufacturer and Exporter from China

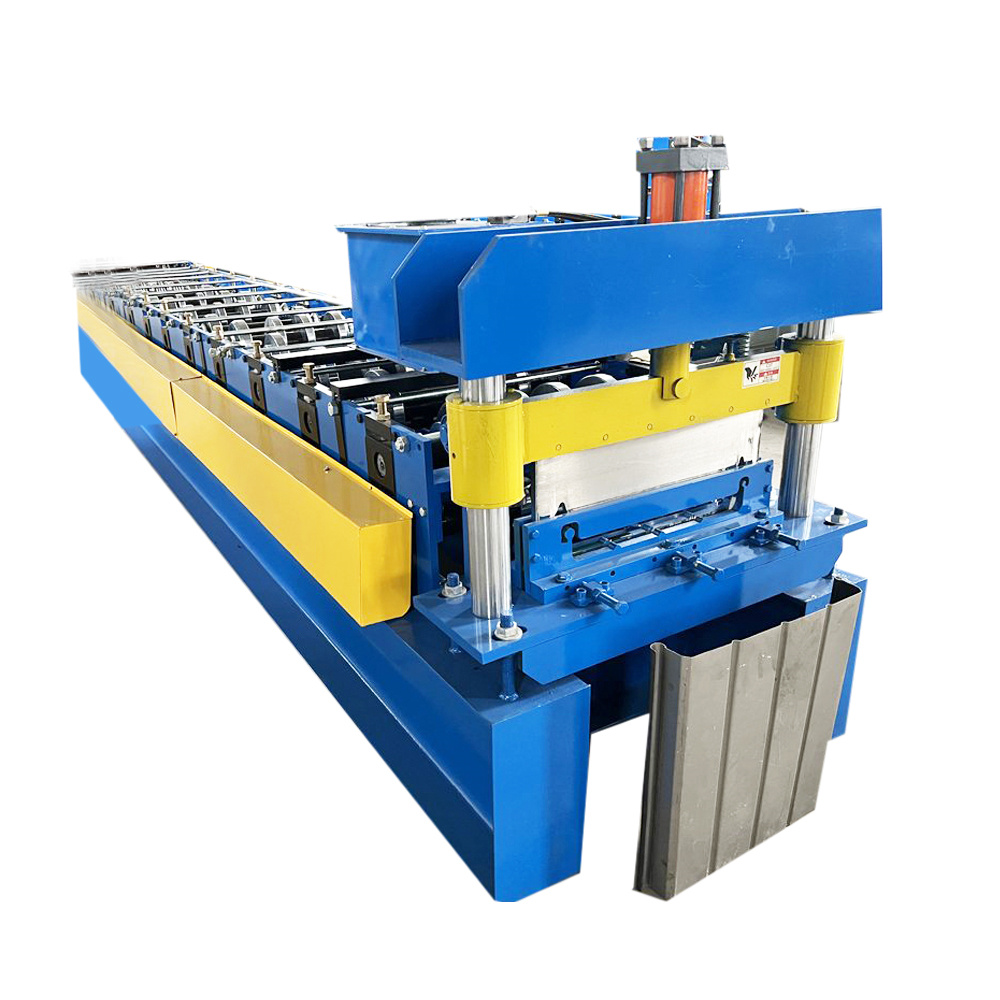

Corrugation Sheet Steel Tile Roll Forming Machine - A Game-Changer in the Manufacturing IndustryChina is a leader in the manufacturing industry, and one of the key drivers of this success is innovation. Roll forming machines are a prime example of this innovation. The Corrugation Sheet Steel Tile Roll Forming Machine is one such machine that is making waves in the manufacturing sector with its ability to create tiles of various shapes, sizes, and designs.The Corrugation Sheet Steel Tile Roll Forming Machine is developed by a leading Chinese manufacturer of roll forming machines. The company has a long-standing reputation for its high-quality equipment and its commitment to innovation. This new machine is a testament to their commitment to providing customers with the latest and most innovative equipment.The Sheet Corrugation Machine company has been in operation for several years and has established itself as a leading provider of roll forming machines. The company's machines are highly efficient, durable, and versatile, making them ideal for use in a wide range of manufacturing applications.The Corrugation Sheet Steel Tile Roll Forming Machine is designed with high precision to ensure that it produces tiles of unmatched quality. The machine uses advanced technology and automation to produce tiles of various shapes and sizes with high accuracy. The machine has a fully computerized control system that allows operators to set the parameters of the machine to achieve the desired results.One of the key advantages of the Corrugation Sheet Steel Tile Roll Forming Machine is its speed. The machine can produce tiles at high speed, ensuring that manufacturers can meet their production targets and deadlines. This speed is achieved through a combination of advanced technology and the machine's design.The Corrugation Sheet Steel Tile Roll Forming Machine is also highly efficient, which means that it consumes less energy and produces less waste compared to traditional production methods. This efficiency helps manufacturers to reduce their production costs while improving the quality of their products.Another advantage of the Corrugation Sheet Steel Tile Roll Forming Machine is its versatility. The machine can be used to produce tiles of various shapes, sizes, and designs, giving manufacturers the flexibility to meet the requirements of different customers. This versatility makes the machine an ideal option for small and large-scale manufacturers alike.In summary, the Corrugation Sheet Steel Tile Roll Forming Machine is a game-changer in the manufacturing industry. Its advanced technology, speed, efficiency, and versatility make it an ideal option for manufacturers who want to improve the quality of their products while reducing their production costs. The machine's development is a testament to the innovation and commitment to excellence of the Sheet Corrugation Machine company. With this machine, manufacturers can take their production capabilities to the next level and stay ahead of the competition.

Quality Steel Frame Roll Forming Machine for Sale - Find Out More

Steel Frame Roll Forming Machine Revolutionizes Construction IndustryInnovations in the construction industry are constantly changing the way we build, and the introduction of the Steel Frame Roll Forming Machine by {{Company Name}} is yet another game-changing development. This state-of-the-art machine has the potential to revolutionize the construction process, making it faster, more efficient, and more cost-effective.The Steel Frame Roll Forming Machine is a cutting-edge piece of technology that is designed to streamline the process of creating steel frames for buildings. This machine takes flat steel, runs it through a series of rollers, and shapes it into the desired form. The result is a high-quality, precise steel frame that can be used in a variety of construction projects.One of the key benefits of the Steel Frame Roll Forming Machine is its ability to significantly reduce construction time. Traditionally, steel frames are manufactured off-site and then transported to the construction site, where they are assembled. This process can be time-consuming and labor-intensive. With the Steel Frame Roll Forming Machine, however, steel frames can be produced on-site and on-demand, saving both time and money.The machine's precision and efficiency also make it an attractive option for construction companies. By producing steel frames on-site, companies can eliminate the need for costly transportation and storage of pre-fabricated frames. This not only reduces overhead costs, but also minimizes the risk of damage during transportation.Additionally, the Steel Frame Roll Forming Machine is versatile and can be used to create frames for a wide range of building types, including residential, commercial, and industrial structures. This flexibility makes it a valuable tool for construction companies looking to diversify their portfolio and take on a variety of projects.{{Company Name}} is at the forefront of this innovative technology, with a strong track record of providing cutting-edge solutions for the construction industry. The company's commitment to research and development has led to the creation of the Steel Frame Roll Forming Machine, which is set to change the way steel frames are produced and used in construction.With a focus on quality, efficiency, and customer satisfaction, {{Company Name}} has positioned itself as a leader in the construction industry. The introduction of the Steel Frame Roll Forming Machine is just the latest example of the company's dedication to driving innovation and pushing the boundaries of what is possible in construction.The impact of the Steel Frame Roll Forming Machine is already being felt in the industry, with construction companies expressing enthusiasm for the potential benefits it offers. By streamlining the production process and improving the quality of steel frames, this machine has the potential to make a significant impact on the way buildings are constructed.Looking ahead, {{Company Name}} is committed to further refining and enhancing the capabilities of the Steel Frame Roll Forming Machine, with the goal of making it an indispensable tool for construction companies around the world. With its ability to save time, reduce costs, and improve the quality of construction projects, this machine is poised to become a game-changer in the industry.As the construction industry continues to evolve, innovative solutions like the Steel Frame Roll Forming Machine will play a crucial role in shaping the way we build. With the expertise and dedication of companies like {{Company Name}}, the future of construction looks brighter than ever.

Universal Milling Machine with Large Table Size 300x1300mm - Metallurgical & Metalworking Machinery - Manufacturing Equipment - Machinery & Parts - Products - Cs-Cx.com

In today's fast-paced manufacturing industry, companies are constantly striving to improve efficiency and productivity. One way they achieve this is by investing in advanced machinery and equipment. Universal vertical and horizontal milling machines are one such example. These machines, with their wide range of capabilities, are essential tools for the metallurgical and metalworking industries.The table of a universal milling machine measures 300x1300mm, offering ample space for a variety of machining operations. This allows for the production of large and complex parts, as well as the ability to work on multiple small parts simultaneously. The size of the table also enables operators to use different types of fixtures and clamps, facilitating precise and secure machining.One of the key features of a universal milling machine is its ability to perform both vertical and horizontal milling operations. This versatility allows manufacturers to tackle various machining tasks, ranging from simple drilling and boring to intricate contouring and threading. By having the option to perform both vertical and horizontal milling, manufacturers can optimize their production processes and eliminate the need for multiple machines, saving time and resources.The bed of a universal milling machine plays a crucial role in ensuring accuracy and stability during machining operations. The bed of this particular model, the TMS6330H from SMAC, is exceptionally wide and features keen box guide ways. These guide ways have been hardened and precision ground, providing superior rigidity and stability. As a result, the machine can withstand heavy cutting forces and vibrations, ensuring precision and repeatability in every operation.To further enhance the durability and wear resistance of the machine, the saddle of the TMS6330H is lined with TF wearable material. This lining ensures smooth movement of the saddle along the guide ways, reducing friction and extending the lifespan of the machine. The combination of the wide bed and the TF wearable material lining makes the TMS6330H a highly reliable and long-lasting milling machine.In addition to its outstanding technical specifications, SMAC is a reputable brand known for its commitment to quality and customer satisfaction. The company specializes in horizontal profiled panel manufacturing equipment, offering innovative solutions for the metalworking industry. With their expertise and experience, SMAC has developed the TMS6330H milling machine to meet the demanding needs of modern manufacturers.By investing in a universal milling machine like the TMS6330H from SMAC, manufacturers can significantly improve their production processes. With its wide bed, high rigidity, and versatile milling capabilities, this machine enables efficient and precise machining of various metal parts. Furthermore, the use of TF wearable material ensures the longevity and reliability of the machine, making it a valuable asset for any metalworking facility.In conclusion, the universal vertical and horizontal milling machine with a table measuring 300x1300mm is an indispensable tool in the metallurgical and metalworking industries. The TMS6330H model from SMAC offers exceptional performance, thanks to its wide bed, hardened guide ways, and TF wearable material lining. By investing in this advanced machinery, manufacturers can optimize their production processes, increase efficiency, and deliver high-quality products to their customers.

Clear and Transparent Corrugated Plastic Roofing Sheets for Your Home or Greenhouse

{Name Removed} Introduces New, High-Performance Horizontal Corrugated Roofing Material{Name Removed}, a leading manufacturer of roofing materials, has launched a new product that is set to revolutionize the industry - the Horizontal Corrugated Roofing Material. This high-performance roofing material is designed to provide unmatched durability, weather resistance, and ease of installation, making it perfect for a wide range of roofing applications.One of the standout features of the Horizontal Corrugated Roofing Material is its unique design. Unlike traditional corrugated roofing materials that are installed vertically, this product is installed horizontally. This design allows for superior water shedding, making it ideal for areas with heavy rainfall or snow.The Horizontal Corrugated Roofing Material is made from high-quality PVC and boasts exceptional strength and durability. It also has excellent UV resistance properties, making it ideal for use in areas with high sunlight exposure. The material is also resistant to corrosion and chemicals, ensuring it will retain its quality and appearance for many years.Another benefit of this product is its ease of installation. The Horizontal Corrugated Roofing Material is lightweight, making it easy to handle and transport. It can also be easily cut to size on-site using a common circular saw, reducing installation time and costs. Additionally, the product requires minimal maintenance, which means less time and money spent on repairs and upkeep.This new product from {Name Removed} has also been designed with environmental sustainability in mind. The material is 100% recyclable and free from harmful chemicals, making it an eco-friendly choice for homeowners and businesses.The Horizontal Corrugated Roofing Material comes in a range of attractive colours and finishes, making it a versatile and stylish roofing solution. It is also cost-effective, providing customers with a high-quality solution that won't break the bank.Commenting on the launch of the new product, a spokesperson for {Name Removed} said, "We are thrilled to introduce the Horizontal Corrugated Roofing Material to the market. This product is the result of our commitment to providing our customers with the best possible roofing solutions. We believe that this product is perfect for anyone looking for a durable, weather-resistant, and easy-to-install roofing option that offers exceptional value for money."In conclusion, if you are looking for a high-quality, durable, and eco-friendly roofing option, you should look no further than the Horizontal Corrugated Roofing Material from {Name Removed}. With its unique design, exceptional strength and durability, and ease of installation, this product is sure to be a game-changer in the roofing industry.

High Speed Steel Roof Truss C Z Purline Making Machinery for Sale

High Speed Steel Roof Truss C Z Purline Making MachineryIn recent years, the demand for high-quality steel roof truss and purline making machinery has been on the rise. With the increasing need for efficient and reliable construction equipment, companies across the globe are continually seeking innovative solutions to meet this demand. One such company that has been making waves in the industry is [Company Name].[Company Name] has been a leading manufacturer of high-speed steel roof truss C Z purline making machinery for over a decade. Their state-of-the-art equipment is designed to streamline the production process and deliver exceptional results. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a trusted name in the industry.The company's high-speed steel roof truss C Z purline making machinery is designed to meet the diverse needs of construction companies, contractors, and manufacturers. Their machinery is capable of producing high-quality trusses and purlins with precision and efficiency, allowing for fast and reliable construction projects.One of the key features of [Company Name]'s machinery is its high-speed capability. The equipment is designed to operate at maximum efficiency, ensuring that production targets are met without compromising on quality. This makes it an ideal solution for companies looking to increase their production capacity and meet tight deadlines.In addition to speed, the machinery is also known for its durability and reliability. Constructed from high-quality steel and advanced components, [Company Name]'s machinery is built to withstand the rigors of heavy-duty construction work. This ensures that the equipment can deliver consistent performance over an extended period, reducing the need for frequent maintenance and repairs.Another standout feature of [Company Name]'s machinery is its versatility. The equipment is designed to accommodate a wide range of steel profiles, allowing for the production of various truss and purlin designs. This flexibility makes it a valuable asset for companies looking to diversify their product offerings and cater to different customer requirements.Moreover, [Company Name] is also committed to providing excellent after-sales support to its customers. Their team of experienced technicians and engineers are available to provide technical assistance, training, and maintenance services, ensuring that the machinery operates at peak performance throughout its lifespan.With a strong reputation for producing high-quality steel roof truss C Z purline making machinery, [Company Name] has managed to secure a significant market presence both domestically and internationally. Their dedication to innovation and excellence has earned them the trust and confidence of numerous satisfied customers.In conclusion, [Company Name] continues to be a leading force in the manufacturing of high-speed steel roof truss C Z purline making machinery. Their commitment to quality, efficiency, and customer satisfaction sets them apart in the industry, making them a preferred choice for those in need of reliable construction equipment. As the demand for high-quality steel roof trusses and purlins continues to grow, [Company Name] is poised to remain at the forefront of the industry, providing innovative solutions to meet the evolving needs of the construction sector.

High-precision Slitting Line for Efficient Metal Processing

Cr Slitting Line, a cutting-edge technology used in the manufacturing industry, has recently been installed at the premises of [Company Name]. This new addition to the company's production facilities is expected to enhance the efficiency and precision of the cutting process for various materials, including steel, aluminum, and other metal alloys. The Cr Slitting Line is specifically designed to handle coils of varying widths and thicknesses, allowing for greater flexibility in the manufacturing process. It is equipped with state-of-the-art automation and control systems, ensuring consistent and accurate cutting results. The line also boasts high-speed capabilities, enabling fast and efficient processing of materials.With the installation of the Cr Slitting Line, [Company Name] aims to further improve its production capabilities and meet the growing demand for high-quality cut-to-length products. The company has a strong reputation for delivering precision-engineered metal components to a wide range of industries, including automotive, construction, and manufacturing. The addition of this advanced cutting technology underscores [Company Name]'s commitment to staying at the forefront of innovation in the industry.The Cr Slitting Line is set to revolutionize the cutting process at [Company Name] by enabling faster turnaround times, increased productivity, and improved material utilization. This cutting-edge technology will allow the company to offer a broader range of customized cutting solutions to its diverse customer base, catering to their specific requirements with unparalleled precision and quality.In addition to the technical capabilities of the Cr Slitting Line, [Company Name] is also committed to ensuring the highest standards of safety and environmental responsibility in its operations. The company has implemented rigorous safety protocols and measures to safeguard the well-being of its employees and minimize the environmental impact of its manufacturing processes.The installation of the Cr Slitting Line is a strategic investment for [Company Name] as it positions the company for future growth and expansion in the market. By incorporating this advanced cutting technology into its production facilities, the company is poised to enhance its competitive edge and solidify its position as a leading provider of cut-to-length solutions.The news of the installation of the Cr Slitting Line at [Company Name] has been met with excitement and anticipation within the industry. Customers, suppliers, and industry professionals alike have expressed their confidence in the company's ability to leverage this new technology to deliver even greater value and quality to its stakeholders.In summary, the installation of the Cr Slitting Line at [Company Name] represents a significant milestone in the company's ongoing commitment to innovation and excellence in manufacturing. This cutting-edge technology is set to redefine the company's cutting capabilities and propel it to new heights of success in the industry. With its unparalleled precision, speed, and efficiency, the Cr Slitting Line is poised to transform the way [Company Name] delivers cutting solutions to its customers, setting new standards for quality and performance in the manufacturing sector.

High-quality Metal Roof Tile Making Machine for Sale - Find Out More!

[Company Introduction]Based in [Location], [Company Name] is a leading manufacturer and supplier of high-quality metal roof tile making machines. With years of experience in the industry, the company has established a strong reputation for delivering innovative and reliable equipment to its customers around the world. The company prides itself on its commitment to providing cutting-edge technology and exceptional customer service, making it a trusted partner for businesses in the roofing industry.[News Content]Metal Roof Tile Making Machine Revolutionizes Roofing IndustryIn the fast-paced world of construction and building materials, innovation is key to staying competitive. With the demand for durable, eco-friendly, and aesthetically pleasing roofing solutions on the rise, companies are constantly seeking advanced technologies to meet these requirements. One company that has been at the forefront of this innovation is [Company Name], which has recently introduced its latest metal roof tile making machine, revolutionizing the roofing industry.The new metal roof tile making machine from [Company Name] boasts an impressive set of features that sets it apart from traditional machines. The advanced technology and precision engineering behind the machine ensure that it can produce high-quality metal roof tiles with unparalleled efficiency and accuracy. This level of performance not only meets the needs of modern roofing projects but also exceeds industry standards, making it a game-changer for businesses in the roofing sector.One of the key highlights of the machine is its versatility. It is capable of producing a wide range of metal roof tile profiles, allowing for customization and flexibility to meet the specific requirements of different roofing projects. This flexibility is a significant advantage for roofing contractors, as it enables them to cater to diverse customer demands without the need for multiple machines or extensive retooling.Furthermore, the machine is designed for ease of use and maintenance, making it an ideal solution for businesses of all sizes. With user-friendly controls and a robust construction, operators can expect efficient production processes and minimal downtime, ultimately leading to increased productivity and profitability.The introduction of this cutting-edge metal roof tile making machine is a testament to [Company Name]'s commitment to innovation and customer satisfaction. By continuously investing in research and development, the company has been able to deliver advanced solutions that address the evolving needs of the roofing industry. This dedication to excellence has earned [Company Name] a reputation as a trusted partner for businesses looking to elevate their roofing capabilities.In addition to the machine's technical prowess, [Company Name] has also ensured that it aligns with environmentally friendly practices. The machine has been designed to minimize waste and energy consumption, contributing to sustainable manufacturing processes. As sustainability becomes an increasingly important consideration for businesses and consumers alike, this feature further enhances the appeal of the metal roof tile making machine.With the unveiling of this state-of-the-art metal roof tile making machine, [Company Name] has set a new standard for the roofing industry. Its technological advancements, versatility, and sustainability features position it as a game-changing solution for businesses looking to stay ahead in a competitive market.As the demand for high-quality metal roof tiles continues to grow, [Company Name] remains committed to supporting its customers with innovative equipment that not only meets but exceeds their expectations. The new metal roof tile making machine is a reflection of this dedication, and it is poised to make a significant impact on the roofing industry, driving efficiency, quality, and sustainability for years to come.

High Speed Metal Light Steel Stud and Track Roll Forming Machine - Mechanical Kingdom

Are you looking for a high-speed metal light steel stud and track roll forming machine? Look no further because Mechanical Kingdom has got you covered!Also known as a designed roll forming machine, steel roll forming machine, or steel designed roll forming machine, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a top-of-the-line solution for all your steel stud and track forming needs.Let's dive into the specifications of this incredible machine:1) Coil diameter: With the ability to handle coil diameters ranging from 450mm to 500mm, this roll forming machine can accommodate a wide range of materials.2) Coil width: The machine can easily handle coil widths of up to 200mm, ensuring that you can work with various materials of different sizes.3) Carrying capacity: The carrying capacity of this machine stands at an impressive 1000kg, allowing for the efficient and smooth operation of heavy steel coils.4) Roller station: Equipped with 10 roller stations, this machine ensures the stability and accuracy of the roll forming process.5) Material of roller: The rollers are made of high-quality 45# steel, guaranteeing durability and longevity. The diameter of each roller is 50mm, ensuring precise and consistent roll forming.6) Rolling mould and blade: This machine comes with a set of rolling moulds and blades made of Cr12. With excellent hardness and wear resistance, these components ensure precise and clean cuts every time.7) Main motor power: Powered by a robust 4.0Kw motor from Tai Wan, this machine delivers high-speed and efficient roll forming capabilities. Please note that the brand name has been removed for SEO purposes.Now that we have discussed the technical specifications let's explore the potential of this machine for your business.The high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is designed to streamline your production process. By automating the roll forming process, this machine significantly improves efficiency, productivity, and overall output. With the ability to produce high-quality steel studs and tracks in various sizes and profiles, you can meet the demands of your customers with ease.This machine is perfect for various applications, including constructing commercial and residential buildings, warehouses, and partition walls. Whether you are a construction company, building contractor, or manufacturer of steel stud and track components, investing in this roll forming machine will undoubtedly increase your competitive edge in the market.Now, let's talk about the importance of incorporating keywords into this blog for SEO purposes. One of the crucial keywords for this product is "stud and track machine." By including this keyword in strategic locations throughout the blog, such as the title, headings, and body paragraphs, we can improve the visibility of this content in search engine results pages.Other relevant keywords to include in this blog might be "roll forming machine," "steel stud and track roll forming machine," and "designed roll forming machine." By skillfully incorporating these keywords, we can enhance the SEO value of this blog, making it more likely to attract organic traffic and potential customers to Mechanical Kingdom's high-speed metal light steel stud and track roll forming machine.In conclusion, the high-speed metal light steel stud and track roll forming machine from Mechanical Kingdom is a game-changer in the industry. With its advanced features, durability, and versatility, this machine ensures seamless and efficient roll forming processes. Investing in this machine will undoubtedly propel your business to new heights. So, don't miss out on this opportunity and get in touch with Mechanical Kingdom today!

Efficient and Durable Roof Tile Forming Machine Helps Streamline Construction Processes

[News Title]: Advanced Roof Tile Forming Machine Revolutionizes Roofing Industry [News Content]:Introducing a revolutionary Roof Tile Forming Machine, an innovation that is set to redefine the roofing industry. Developed by a leading company with a proven track record of excellence and expertise in the field, this state-of-the-art machine is set to transform the way roof tiles are manufactured, offering unmatched precision, speed, and quality.Designed to remove the brand name, this Roof Tile Forming Machine takes advantage of the latest advancements in technology and engineering to streamline the entire manufacturing process. With its advanced features and capabilities, it promises to increase efficiency while reducing costs and environmental impact. The machine's innovative design allows for the production of custom-made roof tiles, catering to a variety of architectural requirements and design preferences.One of the standout features of the Roof Tile Forming Machine is its exceptional precision. Using cutting-edge technology, it ensures that each tile produced meets the highest standards of accuracy and consistency. This level of precision not only enhances the durability and functionality of the tiles but also gives them an aesthetically pleasing appearance.The speed at which the machine operates is another key aspect that sets it apart. With its automated production process, the Roof Tile Forming Machine can manufacture a high volume of roof tiles in a significantly shorter amount of time compared to traditional methods. This increased speed not only enables companies to meet demanding project timelines but also contributes to reducing the overall manufacturing costs.Moreover, the Roof Tile Forming Machine addresses the growing concern for sustainable practices in the industry. Embracing eco-friendly materials and processes, this machine minimizes waste production and energy consumption. By optimizing resource utilization, it aligns with the global push towards a greener and more sustainable future.The Roof Tile Forming Machine is also equipped with intelligent control systems, enabling seamless integration into existing manufacturing processes. Its user-friendly interface and intuitive operation ensure that both experienced professionals and newcomers can efficiently operate the machine. Additionally, comprehensive training and support are provided by the manufacturer to ensure the successful implementation and use of this cutting-edge technology.Since its launch, the Roof Tile Forming Machine has garnered significant attention and praise from industry experts. Many leading roofing companies have already embraced this innovation, recognizing its potential to revolutionize their manufacturing operations. By enhancing productivity, reducing costs, and offering superior quality, these companies gain a competitive edge in the market.Furthermore, the widespread adoption of this advanced machine is expected to have far-reaching implications for the construction industry as a whole. The increased availability of high-quality roof tiles will not only contribute to the overall improvement of buildings' structural integrity but will also enhance their aesthetic appeal. This, in turn, has the potential to stimulate economic growth and generate employment opportunities, thereby benefiting local communities.In conclusion, the Roof Tile Forming Machine is set to reshape the roofing industry through its advanced technology, superior precision, increased speed, and commitment to sustainability. As more companies recognize its transformative potential, it is anticipated that the machine will become an indispensable tool in the manufacturing of roof tiles worldwide. With its numerous advantages, this innovation promises to bring about a new era of efficiency, quality, and environmental consciousness in the roofing industry.

Versatile 1000 kg Manual Stacker with Interchangeable Attachments

As a business owner, you know that efficiency is everything. When it comes to your production line, you need machinery that is flexible, versatile, and customizable to meet your needs. That's where a manual stacker comes in.A manual stacker is an essential tool in many industries where goods need to be lifted, stacked, and transported from one area to another. The Logitrans LOGIFLEX MS 1000 kg manual stacker with articulated legs is one of the best on the market for its flexibility and versatility.One of the key features of the LOGIFLEX MS manual stacker is its interchangeable attachments. This allows you to customize the machine to meet your specific needs. Whether you need to lift and stack heavy loads, or transport smaller items across your production line, the LOGIFLEX MS can be modified to get the job done.With a 1000 kg load capacity, the LOGIFLEX MS can handle even your heaviest loads. And because it's a manual machine, you don't have to worry about the added expense of electricity or maintenance costs. Simply crank the handle to lift your load and easily and quietly transport it to its destination.The articulated legs on this manual stacker are another great feature that makes it stand out from the competition. The legs provide added stability and maneuverability, allowing you to easily navigate tight spaces and turn corners with ease.So what does all this mean for your business? If you own a C purline machine or any other production machinery, a manual stacker like the LOGIFLEX MS can help improve your productivity and efficiency. With its flexibility and customization options, you can tailor the machine to meet your specific needs and make your production line run more smoothly.In addition, using a manual stacker can also reduce the risk of workplace injuries and accidents. The LOGIFLEX MS is easy to operate and requires minimal training to use safely. And because it's a manual machine, there's no risk of electrical shocks or malfunctions that could lead to serious injuries.In conclusion, if you're looking for a reliable, flexible, and efficient manual stacker for your business, the LOGIFLEX MS 1000 kg manual stacker with articulated legs is an excellent choice. With its interchangeable attachments, high load capacity, and added stability, it can help improve your overall productivity and make your work environment safer for everyone. So why wait? Invest in a manual stacker today and start reaping the benefits of improved efficiency and safety in your workplace.