Standing Seam Metal Roof Roll Former - A Must-Have for Roofing Professionals

By:Admin

Metal roofing has always been a popular choice for commercial and industrial buildings, thanks to its durability and longevity. However, the installation process has often been time-consuming and labor-intensive, requiring skilled labor and a considerable amount of effort. This has caused some builders and property managers to shy away from metal roofing in favor of other materials.

However, all of this is about to change with the introduction of the innovative Standing Seam Metal Roof Roll Former from (company name). This revolutionary piece of equipment has the potential to completely transform the metal roofing industry, making the installation process faster, more efficient, and more cost-effective than ever before.

The Standing Seam Metal Roof Roll Former is a state-of-the-art machine that is designed to produce standing seam metal roofing panels on-site. This eliminates the need for pre-fabricated panels, which are often costly to transport and can be challenging to maneuver and install. With this roll former, contractors can produce custom metal roofing panels of any length directly at the job site, resulting in a quicker and more streamlined installation process.

One of the key features of the Standing Seam Metal Roof Roll Former is its ability to produce panels with precise and consistent dimensions, ensuring a tight and secure fit that minimizes the risk of leaks and other issues. This level of precision is crucial for the long-term performance of the roof, as it helps to maintain the integrity of the building and protect it from water damage.

In addition to its efficiency and precision, the Standing Seam Metal Roof Roll Former is also incredibly versatile. It can be used to produce a wide range of panel profiles, allowing contractors to offer their clients a variety of design options. Whether a building owner is looking for a sleek and modern appearance or a more traditional look, this roll former can deliver the perfect solution.

Furthermore, the Standing Seam Metal Roof Roll Former from (company name) is designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to a wide range of contractors and roofing professionals. This accessibility opens up new opportunities for smaller companies and contractors who may not have had the resources to invest in traditional metal roofing equipment.

The introduction of the Standing Seam Metal Roof Roll Former is a game-changer for the metal roofing industry, and (company name) is proud to be at the forefront of this innovative technology. With this roll former, the company is committed to helping contractors and property owners take advantage of the many benefits of metal roofing, including its durability, energy efficiency, and low maintenance requirements.

The company has a long history of providing high-quality metal roofing solutions, and the Standing Seam Metal Roof Roll Former is the latest addition to its lineup of cutting-edge products. With a focus on innovation and customer satisfaction, (company name) is dedicated to pushing the boundaries of what is possible in the metal roofing industry.

As the demand for metal roofing continues to grow, the introduction of the Standing Seam Metal Roof Roll Former couldn't have come at a better time. It represents a significant step forward for the industry, making metal roofing more accessible and desirable than ever before. With this innovative technology, the future of metal roofing looks brighter than ever, and (company name) is proud to be leading the way.

Company News & Blog

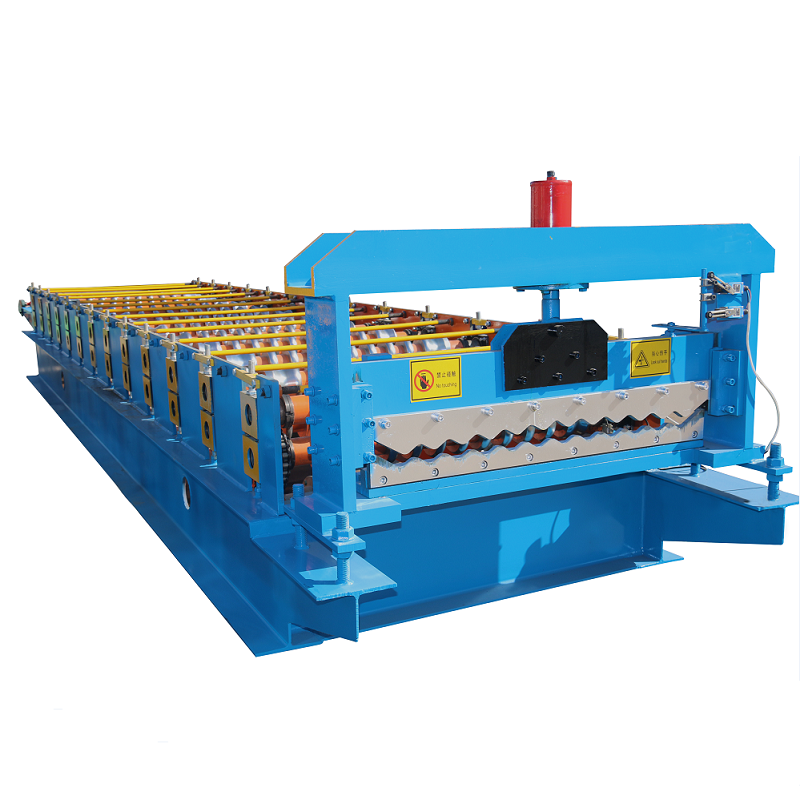

High-Quality Color Steel Roll Forming Machine for GP GI Materials

{Company Name} is a leading manufacturer of roll forming machines, specializing in the production of high-quality and efficient machines to meet the needs of various industries. With a strong focus on innovation and technology, the company has consistently delivered state-of-the-art roll forming machines that have set industry standards.The latest addition to {Company Name}’s impressive lineup of roll forming machines is the GP GI Color Steel Roll Forming Machine. This machine is designed to meet the growing demand for high-quality and durable steel roll forming solutions. With its advanced features and precise engineering, the GP GI Color Steel Roll Forming Machine is set to revolutionize the steel forming industry.One of the key features of the GP GI Color Steel Roll Forming Machine is its ability to produce a wide range of steel profiles with precision and speed. The machine is equipped with advanced roll forming technology that allows for the quick and efficient production of high-quality steel products. This versatility makes the GP GI Color Steel Roll Forming Machine an ideal choice for companies looking to expand their product offerings and meet the diverse needs of their customers.In addition to its impressive production capabilities, the GP GI Color Steel Roll Forming Machine is also designed with user-friendly features that make operation and maintenance simple and efficient. This includes a user-friendly interface, easy-to-access components, and a durable construction that ensures longevity and reliability. With these features, operators can maximize productivity and minimize downtime, leading to greater profitability and customer satisfaction.Another standout feature of the GP GI Color Steel Roll Forming Machine is its ability to produce steel products with superior surface quality and color consistency. This is achieved through the machine's advanced color coating technology, which ensures that the final products have a consistent and vibrant color finish. This is a crucial advantage for companies that require high-quality steel products with a premium aesthetic appeal.Furthermore, the GP GI Color Steel Roll Forming Machine is designed with efficiency and sustainability in mind. The machine is equipped with energy-saving features and operates with minimal waste, making it an environmentally friendly choice for companies looking to reduce their carbon footprint and operating costs.As a trusted leader in the roll forming industry, {Company Name} is committed to providing comprehensive support and service for the GP GI Color Steel Roll Forming Machine. The company offers on-site installation, training, and ongoing technical assistance to ensure that customers can maximize the potential of their investment. This dedication to customer satisfaction and support further solidifies {Company Name}’s reputation as a reliable and value-driven partner in the industry.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to uphold its reputation as a forward-thinking innovator in the roll forming industry. The machine's advanced features, precision engineering, and user-friendly design make it a standout choice for companies looking to elevate their steel forming capabilities and stay ahead of the competition.In conclusion, the GP GI Color Steel Roll Forming Machine from {Company Name} represents a significant advancement in the roll forming industry. With its advanced technology, versatility, and user-friendly design, this machine is set to redefine the standards for steel roll forming, providing companies with a reliable and efficient solution for their production needs. As {Company Name} continues to push the boundaries of innovation, the GP GI Color Steel Roll Forming Machine stands as a testament to the company's commitment to excellence and customer satisfaction.

New Innovations in Light Steel Keel Machinery Revolutionize Construction Industry

Title: Innovative Light Steel Keel Machine Revolutionizes Construction IndustryIntroduction:In a groundbreaking move, a well-established company in the construction sector has developed a state-of-the-art Light Steel Keel Machine, which promises to revolutionize the way buildings are constructed. This advanced machine, designed and manufactured by the company, seeks to streamline the construction process, enhance cost-efficiency, and improve the overall quality of steel structures. With an unwavering commitment to innovation and excellence, the company aims to lead the industry into a new era of construction technology.Body:1. The Light Steel Keel Machine: (Company's Name) has introduced its cutting-edge Light Steel Keel Machine, a robust and highly automated equipment that fabricates light steel frames with utmost precision. By leveraging intelligent design, this machine can accurately produce light steel keels, also known as studs or channels, used to create the primary framework for various buildings. 2. Features and Functionality: The advanced Light Steel Keel Machine boasts a range of exceptional features, ensuring superior quality and efficiency. Equipped with sophisticated technology, it has the ability to roll, cut, punch, and perforate light steel keels with great accuracy and speed. Moreover, the machine is compatible with various thicknesses and dimensions, making it versatile for different building requirements. 3. Streamlined Construction Process: Integrating the Light Steel Keel Machine into the construction process significantly streamlines the entire procedure. This innovative technology removes the need for manual cutting and shaping of the steel keels, reducing labor costs and minimizing human error. By automating the fabrication process, construction timelines are expedited, accelerating the completion of projects and enabling faster occupancy of buildings. 4. Enhanced Cost-Efficiency: The Light Steel Keel Machine offers a cost-effective solution in the construction industry. By optimizing production efficiency, construction companies can save on labor expenses and reduce material waste. Additionally, the machine's compatibility with different steel thicknesses helps minimize material costs, further contributing to overall cost savings. 5. Improved Structural Stability: The precision and accuracy of the Light Steel Keel Machine ensure the creation of sound and reliable light steel frames. Through this advanced fabrication process, the machine eliminates potential human errors and inconsistencies, resulting in structurally stable buildings that meet stringent safety standards. This enhanced structural integrity increases the longevity and durability of the constructed buildings. 6. Superior Quality and Aesthetics: Light steel frames, produced using the state-of-the-art machine, boast exceptional quality and aesthetics. The machine's ability to produce standardized components with minimal variations results in consistent quality across all construction projects. Moreover, the machine's precise cutting and shaping capabilities create sleek and visually appealing steel frames, enhancing the overall aesthetic value of the buildings. 7. Environmental Benefits: The Light Steel Keel Machine aligns with the growing demand for sustainable and eco-friendly construction practices. By reducing material waste and optimizing production efficiency, the machine promotes environmental responsibility in the construction industry. Furthermore, light steel frames are inherently recyclable, minimizing the carbon footprint associated with traditional construction materials. Conclusion:As the construction industry paves the way for innovative technologies, the introduction of the Light Steel Keel Machine represents a significant milestone. This cutting-edge equipment, developed by (Company's Name), offers numerous benefits, including streamlined construction processes, enhanced cost-efficiency, improved structural stability, and superior quality and aesthetics. With the potential to revolutionize the way buildings are constructed, this remarkable machine embodies the company's commitment to innovation, advancement, and sustainable practices.

Discover How a Metal Roofing Roller Machine Enhances Efficiency and Precision in Roofing Projects

[Company Name] Revolutionizing the Metal Roofing Industry with the Introduction of the Innovative Roofing Roller Machine[date][City, State] – Metal roofing has long been sought after for its durability and longevity. However, the installation process has traditionally been time-consuming and labor-intensive. In an effort to streamline this process and provide a more efficient solution, [Company Name], a leading manufacturer of roofing solutions, has recently launched their groundbreaking Metal Roofing Roller Machine.[Company Name] has been a driving force in the roofing industry for over three decades, constantly pushing the boundaries of innovation and technology. With a team of expert engineers and designers, the company has built a reputation for delivering high-quality products that not only meet industry standards but also exceed customer expectations.The Metal Roofing Roller Machine is the latest addition to their extensive line of roofing equipment. This state-of-the-art machine is designed to revolutionize the installation process, making it faster, easier, and more cost-effective. It eliminates the need for manual sheet bending and reshaping, thereby significantly reducing labor costs and minimizing the risk of human error.One of the key features of this machine is its ability to handle a wide range of metal roofing materials. Whether it be aluminum, steel, copper, or zinc, the Metal Roofing Roller Machine can effortlessly shape and reshape these materials according to the specifications of any roofing project. This versatility ensures that contractors and roofers can tackle a variety of projects without the need for multiple machines and tools, making it a cost-effective solution for businesses of all sizes.In addition to its versatility, the Metal Roofing Roller Machine is also remarkably user-friendly. Its intuitive interface and easy-to-use controls allow even inexperienced users to operate the machine with confidence. This eliminates the training time traditionally associated with new equipment, allowing contractors to scale their workforce quickly and meet project demands efficiently.Furthermore, the Roller Machine is equipped with advanced safety features to ensure the well-being of workers. An automatic shut-off mechanism is in place to prevent accidents, such as entanglement or injury, during operation. The robust construction of the machine also adds an extra layer of protection, ensuring its durability and longevity even in demanding working conditions.Since its launch, the Metal Roofing Roller Machine has garnered significant attention and praise from industry professionals. Roofers and contractors have lauded its ability to enhance productivity and streamline their operations. The machine's efficiency has enabled businesses to complete projects in record time, opening up new avenues for growth and profitability.[Company Name] understands the importance of sustainability in the roofing industry and has taken steps to reduce the environmental impact of their products. The Metal Roofing Roller Machine is designed to optimize material usage, minimizing waste and reducing carbon emissions. With this innovative machine, businesses can not only improve their efficiency but also contribute to a greener future.In conclusion, [Company Name]'s Metal Roofing Roller Machine is a groundbreaking solution that has transformed the metal roofing industry. Its versatility, user-friendliness, and safety features have revolutionized the installation process, making it more efficient and cost-effective. With this innovative machine, [Company Name] continues to drive the roofing industry forward, delivering cutting-edge solutions that meet the evolving needs of contractors and roofers worldwide.For more information about the Metal Roofing Roller Machine and other roofing solutions offered by [Company Name], please visit [website] or contact [contact information].###About [Company Name]:[Company Name] is a leading manufacturer of roofing solutions, revolutionizing the industry with its innovative products and commitment to customer satisfaction. With over three decades of experience, the company has built a reputation for excellence and has become a trusted partner for contractors and roofers worldwide. Through continuous innovation and unwavering dedication to quality, [Company Name] aims to shape the future of the roofing industry.

How to Build a Sheet Metal Barn in 6 Simple Steps

Title: How to Build a Sheet Metal Barn in 6 Easy StepsIntroduction:Sheet metal barns provide an excellent solution for storage and shelter needs. Not only are they durable and cost-effective, but they can also be constructed relatively easily. In this article, we will outline a step-by-step guide on how to build a sheet metal barn in six simple steps. Whether you have experience in construction or are a DIY enthusiast, this guide will help you create your very own sheet metal barn.Step 1: Planning and PreparationBefore starting any project, careful planning is essential. Determine the size and design of your barn based on your requirements. Take measurements of the desired area and sketch out the barn's layout. Consult local building codes and acquire any necessary permits. Once you have a clear plan, gather the required materials.Step 2: Foundation and Frame ConstructionCreate a solid foundation for your sheet metal barn. Excavate the area, level the ground, and lay a sturdy foundation using concrete or treated wood. Next, construct the frame using the plywood pallets. Cut them to the desired size and connect them securely using screws and nuts, ensuring stability and durability.Step 3: Installing RoofingSelect the appropriate sheet metal for the roofing of your barn. Galvanized sheet metal provides excellent protection against rust and corrosion. Measure and cut the sheet metal to fit the roof frame, leaving a slight overhang for drainage. Secure the roofing sheets to the frame using screws or nails, ensuring proper alignment and sealing.Step 4: Wall ConstructionMeasure and cut additional plywood panels to serve as walls for your sheet metal barn. Attach them securely to the frame, leaving space for doors and windows as needed. Ensure tight joints and smooth surfaces for a professional finish.Step 5: Doors and WindowsInstall suitable doors and windows into the wall structure. Depending on your requirements, you can choose ready-made options or customize your own. Ensure proper insulation and weatherproofing to protect your belongings from the elements.Step 6: Finishing TouchesTake time to inspect your sheet metal barn for any loose screws or nails. Replace or tighten them as necessary. Consider adding ventilation systems, gutters, or additional storage options such as shelves or hooks. Apply a protective finish, such as paint or weather-resistant coatings, to increase the longevity and aesthetics of your barn.Conclusion:Building a sheet metal barn is a satisfying project that offers both functionality and durability. By following these six easy steps, you can construct your own barn and enjoy the benefits of efficient storage and shelter. Whether you are a DIY enthusiast or a seasoned builder, creating a sheet metal barn can be achieved with the right materials, tools, and patience. Embrace your creativity and get started on your own sheet metal barn project today!

High-quality Pultrusion Machine for FRP Cable Trays

The FRP Cable Tray Pultrusion Machine is a cutting-edge piece of equipment that is being hailed as a game changer in the manufacturing industry. This innovative machine, which is manufactured by an industry-leading company, is designed to produce high-quality FRP cable trays with enhanced durability and strength.The pultrusion process is a manufacturing method that involves pulling and shaping continuous fiber reinforcements through a liquid resin bath. This process results in a high-strength, lightweight, and corrosion-resistant product that is ideal for a wide range of industrial applications. The FRP Cable Tray Pultrusion Machine utilizes advanced technology to precisely control the pultrusion process, ensuring that the resulting cable trays meet the highest quality standards.With the growing demand for durable and corrosion-resistant cable management systems, the FRP Cable Tray Pultrusion Machine is poised to revolutionize the industry. The machine is capable of producing a wide range of cable tray profiles, including ladder, perforated, and solid-bottom designs, to accommodate various installation requirements. Additionally, the machine can be customized to produce cable trays in different widths, depths, and load capacities, making it a versatile solution for diverse project specifications.The company behind the FRP Cable Tray Pultrusion Machine is a renowned industry leader with a proven track record of delivering innovative solutions for the composite manufacturing sector. With years of experience and expertise in pultrusion technology, the company has earned a reputation for producing high-quality machinery that meets the evolving needs of the market.In addition to the FRP Cable Tray Pultrusion Machine, the company offers a comprehensive range of pultrusion equipment and systems for various applications, including structural profiles, grating, rods, and tubes. The company's commitment to research and development has led to the continual advancement of its pultrusion machinery, ensuring that customers receive state-of-the-art solutions that deliver superior performance and reliability.The FRP Cable Tray Pultrusion Machine is equipped with advanced features that enhance productivity and efficiency. Its automated control system allows for precise monitoring and adjustment of the pultrusion parameters, ensuring consistent product quality and dimensional accuracy. The machine's robust construction and durable components contribute to its reliability and long-term performance, making it a valuable investment for manufacturers seeking to streamline their production processes.Moreover, the company provides comprehensive technical support and training services to assist customers in maximizing the potential of the FRP Cable Tray Pultrusion Machine. From installation and commissioning to maintenance and troubleshooting, the company's team of experts is dedicated to ensuring that customers achieve optimal results with their pultrusion equipment.As the demand for high-performance cable management solutions continues to grow, the FRP Cable Tray Pultrusion Machine is poised to be a valuable asset for manufacturers looking to stay ahead in the market. Its ability to deliver superior quality, flexibility, and efficiency makes it a standout solution for producing FRP cable trays that meet the stringent requirements of modern industrial and commercial projects.In conclusion, the FRP Cable Tray Pultrusion Machine represents a significant advancement in pultrusion technology, offering manufacturers a competitive edge in producing high-quality and durable cable management systems. With the backing of a leading industry player, this innovative machine is set to make a lasting impact on the composite manufacturing sector, driving efficiency and excellence in cable tray production.

Europe Washing Machine Installation Manual: Easy-to-Follow User Guide for Efficient Operation and Maintenance

Title: Manual Shape C Purlin Punching Holes Making Machine: A Must-Have for European Standard Construction ProjectsIntroductionIn the ever-evolving world of construction, the need for efficient and precise manufacturing processes is paramount. One such process that has gained considerable popularity in recent years is the use of manual shape C purlin punching holes making machines. Designed to meet European standard requirements, these machines have revolutionized the way purlins are manufactured, ensuring enhanced structural integrity and cost-effectiveness. In this blog post, we will explore the key features and advantages of manual shape C purlin punching holes making machines, focusing on their relevance and impact in the European construction industry.What Are Manual Shape C Purlin Punching Holes Making Machines?Manual shape C purlin punching holes making machines are advanced manufacturing systems specifically designed for producing top-quality C purlins in compliance with European construction standards. These machines utilize cutting-edge technology and are equipped with cutting, punching, and forming tools, enabling the precise fabrication of complex purlin shapes to exact specifications.Key Features and Advantages1. Enhanced Precision: The manual shape C purlin punching holes making machines are engineered to deliver exceptional precision in forming and punching holes, ensuring accurate purlin dimensions and consistent hole alignment. This level of precision guarantees optimum installation compatibility, reducing the risk of structural errors and enabling smoother construction processes.2. Versatility: These machines offer a wide range of customization options, allowing for the production of various C purlin sizes and shapes according to project-specific requirements. Whether it's the flange width, thickness, or hole patterns, the manual shape C purlin punching holes making machine provides immense flexibility, ensuring compatibility with diverse construction designs.3. European Standard Compliance: Manual shape C purlin punching holes making machines are specifically engineered to adhere to European construction standards. These standards are known for their stringent quality requirements, ensuring that structures are built to withstand extreme weather conditions and offer exceptional durability. By using machines designed for European standards, construction projects can benefit from the highest level of quality assurance.4. Cost-Effectiveness: Implementing manual shape C purlin punching holes making machines can significantly reduce labor costs and material wastage. The machines' automated and precise manufacturing processes eliminate the need for time-consuming manual labor, resulting in faster production rates and reduced human error. Additionally, the optimization of material usage helps minimize waste, leading to cost savings for both manufacturers and end-users.ConclusionThe emergence of manual shape C purlin punching holes making machines has brought a new level of efficiency and quality assurance to the European construction industry. From increased precision and versatility to compliance with rigorous European standards, these machines are a game-changer for fabricators and construction companies alike. As the demand for sustainable and cost-effective construction practices rises, investing in manual shape C purlin punching holes making machines becomes an essential step towards success in the ever-evolving European construction landscape.

Cutting-Edge Technology Unveiled: Revolutionary Glazed Tile Sheet Forming and Corrugating Machine Takes Industry by Storm

article:Glazed Tile Sheet Forming And Corrugating Machine Making Waves in Manufacturing IndustryThe new generation of Glazed Tile Sheet Forming And Corrugating Machine by a well-known Chinese-based manufacturing company has taken the industry by storm. The state-of-the-art machine is revolutionizing the manufacturing process of glazed tile sheets, enabling manufacturers to produce high-quality products in less time and at low production costs.The economically designed Glazed Tile Sheet Forming And Corrugating Machine is ideal for obtaining glazed sheets of different dimensions and shapes that are used in various roofing and cladding applications. The machine is composed of a steel base, a corrugated roll former, a hydraulic punching and forming device, an automatic cutting system, an electrical control system, and a product stacking device. These components not only ensure the efficiency and functionality of the machine but also provide the much-needed precision and accuracy while producing the glazed sheets.According to the company's press release, the Glazed Tile Sheet Forming And Corrugating Machine boasts several features that differentiates it from conventional machines in the market. First, the hydraulic punching and forming device can form an array of patterns that greatly improves the aesthetic appeal of the final product. Second, the exclusive rolling mechanism produces a high-quality surface finish that resists corrosion, abrasion, and scratching. Third, the machine can produce over 10 meters of glazed tiles per minute, which translates to over 300 pieces per hour.The Glazed Tile Sheet Forming And Corrugating Machine also has a user-friendly interface that simplifies the operation and maintenance process. With only a few button clicks, users can load and unload raw materials, adjust the machine's speed, and troubleshoot common problems. The machine is also equipped with an automatic lubricant system that reduces wear and tear, prolongs the machine's lifespan, and reduces maintenance costs.The company behind the Glazed Tile Sheet Forming And Corrugating Machine has been at the forefront of producing innovative, high-quality, and affordable machinery for various industries globally. The company, which has over 20 years of experience in the manufacturing industry, has invested heavily in research and development, production, and quality control which has earned them an undisputed reputation in the industry.Their Glazed Tile Sheet Forming And Corrugating Machine have been popular among small, medium, and large-scale manufacturers worldwide, as it provides a cost-effective solution for producing high-quality glazed tile sheets without compromising on quality. Furthermore, the machine is suitable for a wide range of materials, including zinc, galvanized steel, and color-coated steel, giving manufacturers an extensive range of options to choose from.The company's commitment to providing superior customer service also stands out, with a team of dedicated customer service representatives who offer after-sales service, technical assistance, and training to ensure customers get the most out of their machines. Additionally, the company's technical team ensures the machines are regularly updated and upgraded with the latest technology to guarantee that they are always at the forefront of innovation.In conclusion, the Glazed Tile Sheet Forming And Corrugating Machine by this Chinese-based manufacturing company is a game-changer in the industry, offering manufacturers a reliable, efficient, and cost-effective solution to produce high-quality glazed tile sheets. With its unique features, ease of use, and precision, the machine is bound to revolutionize the glazed tile sheet manufacturing industry and set new standards for quality, productivity, and customer service.

Short Lead Time for Plastic PVC Profile Making Machine - PE Hollow Grid Sheet Production Line by JEEBO Machinery: China Qingdao JBD Machinery Introduction

PE Hollow profile sheet is becoming an increasingly popular material in various industries due to its unique properties. With its high light transmittance, weather resistance, fire resistance, impact resistance, lightweight nature, heat insulation, and UV resistance, it has a wide range of applications.One of the main applications of PE Hollow profile sheet is in light covers. Due to its high light transmittance, it allows light to pass through easily, providing ample illumination while still offering protection. This makes it ideal for use in lighting fixtures, such as lamps, ceiling lights, and outdoor lighting. The transparent nature of the sheet ensures that the full brightness of the light source is maintained, without any loss in intensity.Another common application of PE Hollow profile sheet is in greenhouses. Its weather resistance and light transmittance properties make it an ideal material for creating a controlled environment for plants to grow. The sheet allows sunlight to enter the greenhouse, providing the necessary light for photosynthesis, while protecting the plants from harsh weather conditions. Its UV resistance ensures that the plants are not exposed to harmful rays, preventing damage and ensuring healthy growth.PE Hollow profile sheet is also widely used in interior decor. Its lightweight nature makes it easy to handle and install, allowing for creative design possibilities. It can be used to create partitions, room dividers, ceiling panels, and decorative screens. The sheet's high light transmittance can be utilized to create a bright and open space, while its impact resistance ensures durability and longevity.Soundproofing is another application where PE Hollow profile sheet excels. Its unique structure and material composition make it an effective barrier against sound waves. The sheet can be used to create soundproof partitions, walls, and enclosures, reducing noise levels and providing a peaceful environment. Whether it is for residential, commercial, or industrial applications, the sheet's soundproofing properties make it a valuable asset.When it comes to manufacturing PE Hollow profile sheet, a Profile Sheet Making Machine is essential. This machine is specifically designed to produce high-quality profile sheets with precision and efficiency. The Short Lead Time for Plastic PVC Profile Making Machine offered by JEEBO Machinery in China is an excellent choice for this purpose.By investing in this state-of-the-art machine, manufacturers can ensure a smooth and seamless production process. The machine's advanced features and technology enable it to produce profile sheets with consistent quality, meeting the required specifications. Its short lead time ensures a quick turnaround, allowing manufacturers to fulfill customer orders promptly.With the increasing demand for PE Hollow profile sheet, it is crucial to have a reliable and efficient Profile Sheet Making Machine. JEEBO Machinery, with its years of experience and expertise in the industry, provides top-quality machines that are designed to meet the diverse needs of manufacturers. Their commitment to delivering exceptional products and services has made them a trusted name in the market.In conclusion, PE Hollow profile sheet has revolutionized many industries due to its exceptional properties. Whether it is for light covers, greenhouses, interior decor, soundproofing, or any other application, this versatile material offers numerous advantages. To ensure a smooth production process and high-quality output, investing in a reliable Profile Sheet Making Machine is crucial. JEEBO Machinery stands out as a leading manufacturer in China, providing top-notch machines with a short lead time. With their expertise and commitment to customer satisfaction, they are the ideal choice for all profile sheet manufacturing needs.

Leading Supplier of Roll Forming Machines: China's Top Manufacturer for Roll Forming Machine Products

Modern day life is fast, and with the increase in population, the number of vehicles on the road has multiplied immensely. This has made the need for a highway guardrail forming machine inevitable. Apart from providing safety for vehicles against accidents, the highway guardrail system also ensures the safety of road workers and pedestrians.Manufacturing highway guardrails is a highly specialized process that involves the use of standard machines. In recent years, the evolution of the roll forming machine has made it possible to produce highway guardrails more efficiently and inexpensively. The highway guardrail forming machine is a new technology that ensures the production of high-quality and reliable guardrails, which are crucial for the safety of all road users.The highway guardrail forming machine is designed to produce a variety of guardrail profiles and shapes. It is made of several components that work in tandem to deliver the desired results. The machine is highly versatile and can be used to produce different types of guardrails, including steel guardrails, W beam guardrails, and thrie beam guardrails.The process of manufacturing highway guardrails using roll forming machines is simpler and faster than traditional methods. The use of the highway guardrail forming machine eliminates the need for welding, which is a time-consuming and costly process. The machine forms the guardrails by passing the materials through a set of rollers that bend the material into the desired shape. This process ensures that the material is not distorted or weakened, ensuring the quality and strength of the completed guardrails.The highway guardrail forming machine's efficiency and cost-effectiveness have made it the primary choice for most guardrail manufacturers. It allows manufacturers to produce guardrails at a faster pace, with greater accuracy, and at a lower cost. This has resulted in an increase in production volumes, leading to faster project completion times and increased customer satisfaction.Apart from increased productivity and lower production costs, the use of the highway guardrail forming machine has other benefits. The machine guarantees a uniform quality of the guardrails produced, eliminating the human error that could lead to inconsistencies and reduced strength. Additionally, the machine is eco-friendly, eliminating the need for excessive energy usage and the production of waste.In conclusion, the highway guardrail forming machine is a significant technological advancement in the production of highway guardrails. It has revolutionized the manufacturing process, making it faster, more efficient, and cost-effective. Manufacturers who use this machine can produce high-quality guardrails that meet the highest safety requirements while reducing wastage, cost, and environmental impact. The highway guardrail forming machine is a crucial component in building safer roads and ensuring the safety of all road users, making it an essential technology for the modern-day world.

High-Quality Portable Roll Forming Machine for Sale

Portable Roll Forming Machine Provides Efficient Solution for On-site Metal Fabrication[Company Name], a leading provider of innovative metal forming solutions, has introduced a state-of-the-art portable roll forming machine that is designed to revolutionize on-site metal fabrication processes. This cutting-edge machine offers unparalleled flexibility and efficiency, allowing contractors and builders to streamline their operations and achieve superior results in metal roofing, siding, and other construction applications.The portable roll forming machine is the latest addition to [Company Name]'s comprehensive lineup of metal forming equipment, and it is set to redefine the way metal products are fabricated in the field. With its advanced technology and user-friendly design, this machine enables operators to produce custom metal profiles directly at the job site, eliminating the need for transportation and reducing material waste. This not only saves time and money, but also minimizes the environmental impact of metal fabrication processes.One of the key advantages of the portable roll forming machine is its ability to handle a wide variety of metal materials, including steel, aluminum, and copper. This versatility allows contractors to take on a diverse range of projects without the need for multiple machines, making it an invaluable asset for construction firms of all sizes. In addition, the machine's compact size and lightweight construction make it easy to transport and set up, further enhancing its appeal for on-site fabrication applications.In terms of performance, the portable roll forming machine is engineered to deliver exceptional accuracy and consistency in metal profiling. Its precision roller system and automated controls ensure that each profile meets the exact specifications, resulting in high-quality finished products that meet or exceed industry standards. Furthermore, the machine's adjustable speed and feed settings enable operators to optimize production efficiency and adapt to different material thicknesses with ease.To support users in maximizing the capabilities of the portable roll forming machine, [Company Name] provides comprehensive training and technical support services. Their team of experienced metal forming specialists is on hand to offer guidance on machine setup, operation, and maintenance, ensuring that customers can make the most of their investment and achieve superior results in their metal fabrication projects. This commitment to customer satisfaction is a cornerstone of [Company Name]'s business philosophy, and it has helped them build a reputation as a trusted partner in the metal forming industry."We are thrilled to introduce our portable roll forming machine to the market, as we believe it represents a major breakthrough in on-site metal fabrication technology," said [Spokesperson Name], the CEO of [Company Name]. "This machine is the result of years of research and development, and we are confident that it will empower our customers to take their metal forming capabilities to the next level. From its portable design to its advanced performance features, every aspect of this machine has been engineered with the needs of on-site fabricators in mind."With the introduction of the portable roll forming machine, [Company Name] is poised to set a new standard for on-site metal fabrication efficiency and quality. As construction and renovation projects continue to demand faster turnaround times and superior craftsmanship, this innovative machine is expected to become an indispensable tool for contractors, builders, and metal fabricators seeking to stay ahead of the curve in the industry. [Company Name] remains committed to driving the advancement of metal forming technology, and their portable roll forming machine is a testament to their dedication to innovation and excellence.