High-Quality Steel Coil Slitting Line for Efficient Production

By:Admin

A slitting line is a crucial piece of equipment in the steel industry which is used to cut a wide coil of steel into narrower coils. This process requires precision, speed, and efficiency to meet the demands of the market. {Company Name}, a leading manufacturer of industrial equipment, has recently introduced its latest Steel Coil Slitting Line that promises to revolutionize the steel processing industry.

The new Steel Coil Slitting Line from {Company Name} has been designed with cutting-edge technology and innovation to provide unparalleled performance and reliability. With a focus on meeting the diverse needs of the market, this slitting line is capable of processing a wide range of steel coils with speed and accuracy. The state-of-the-art design and engineering ensure that the slitting line can handle different types of steel, including hot-rolled, cold-rolled, and galvanized coils with ease.

One of the standout features of the Steel Coil Slitting Line is its precision slitting capability. The line is equipped with high-precision slitter heads that can make clean and accurate cuts, ensuring that the finished coils meet the required specifications. In addition, the slitting line is also equipped with advanced edge guiding systems and tension control mechanisms to maintain the quality of the slit coils throughout the process.

Another key aspect of the Steel Coil Slitting Line is its efficiency and productivity. The line is designed to operate at high speeds while maintaining the quality of the slit coils. This enables steel processors to increase their throughput and meet the demands of their customers in a timely manner. The automation and control systems integrated into the slitting line further enhance its efficiency, allowing for seamless operation and minimal downtime.

In addition to its performance and capabilities, the Steel Coil Slitting Line from {Company Name} also prioritizes safety and operational ease. The line is equipped with advanced safety features and interlocks to ensure the protection of the operators and the integrity of the process. Furthermore, the user-friendly interface and control systems make it easy for operators to set up and monitor the slitting process, reducing the risk of errors and ensuring consistent quality.

{Company Name} has a proven track record in providing high-quality industrial equipment to the steel processing industry. With decades of experience and expertise in engineering and manufacturing, the company is known for its commitment to innovation and customer satisfaction. The introduction of the Steel Coil Slitting Line is a testament to {Company Name}'s dedication to meeting the evolving needs of the steel industry and driving progress through technology.

The Steel Coil Slitting Line from {Company Name} is set to make a significant impact on the steel processing industry, offering a new standard of performance, quality, and efficiency. With its advanced features and robust design, the slitting line is poised to empower steel processors to enhance their operations and meet the demands of the market with confidence and reliability.

In conclusion, the introduction of the Steel Coil Slitting Line from {Company Name} represents a major advancement in the steel processing industry. With its cutting-edge technology, precision slitting capability, efficiency, and safety features, the slitting line is set to redefine the standards of performance and quality in steel coil processing. As {Company Name} continues to lead the way in industrial equipment manufacturing, the Steel Coil Slitting Line stands as a testament to the company's commitment to innovation and excellence.

Company News & Blog

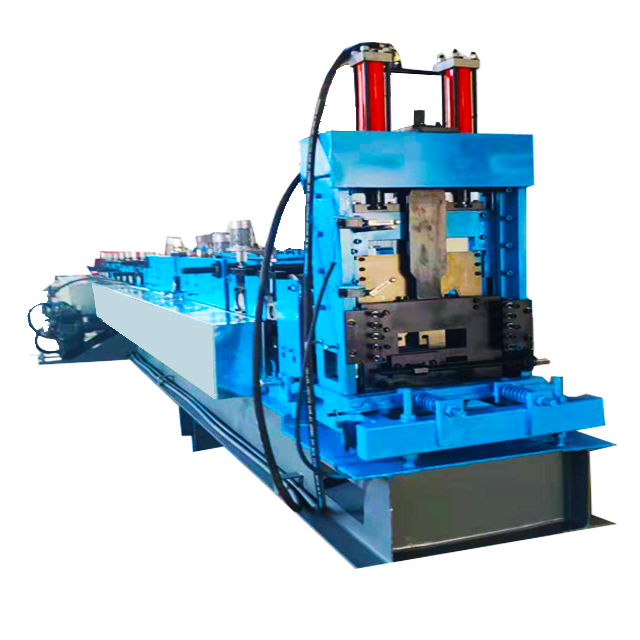

Highly Efficient Rolling Forming Machine for Profile Manufacturing

Profile Rolling Forming Machine Revolutionizes the Manufacturing IndustryIn today's fast-paced industrial landscape, the need for efficient and reliable machinery has never been more critical. Companies across various sectors are constantly seeking innovative solutions that not only enhance productivity but also ensure top-notch quality. One such groundbreaking development comes in the form of the Profile Rolling Forming Machine, a technology that has taken the manufacturing industry by storm.Profile Rolling Forming Machine utilizes state-of-the-art techniques to produce high-precision profiles in a cost-effective manner. By employing a unique rolling process, this cutting-edge machine enables the creation of complex profiles from a wide range of materials, including metal, plastic, and composite materials. This revolutionary technology has garnered significant attention and is set to have a major impact on multiple industries.One key advantage of the Profile Rolling Forming Machine lies in its ability to produce profiles with exceptional accuracy and uniformity. Traditionally, manufacturing complex profiles involves various time-consuming and labor-intensive processes, such as casting, cutting, and shaping. However, with the advent of this new technology, these conventional methods are being replaced by a streamlined process that guarantees superior precision.The Profile Rolling Forming Machine's rolling process starts with a specially designed set of rolls that gradually shape the material into the desired profile. This continuous bending and rolling operation not only ensures an impeccable finish but also eliminates the need for excessive material wastage. The precision and efficiency of this process significantly reduce production costs and enhance overall productivity.Additionally, the Profile Rolling Forming Machine offers immense flexibility in terms of profile customization. With its advanced computer-controlled system, users can easily program the machine to produce profiles of various shapes and dimensions, catering to unique design requirements. This versatility has opened up several opportunities for manufacturers, enabling them to manufacture highly intricate profiles that were previously deemed unachievable.Furthermore, this groundbreaking technology excels in both small-scale and large-scale production. The Profile Rolling Forming Machine can efficiently handle both small batches and high-volume production, making it suitable for a wide range of applications. From automotive components to architectural elements, this innovation has the potential to revolutionize numerous industries that rely heavily on complex profile production.Moreover, the Profile Rolling Forming Machine offers enhanced productivity by minimizing downtime and maintenance requirements. The robust design of this machine ensures prolonged usage without compromising on performance. Advanced sensors integrated into the machinery provide real-time data about the process, enabling operators to detect any issues promptly and take corrective measures, thereby reducing production delays.In conclusion, the Profile Rolling Forming Machine represents an exciting breakthrough in the manufacturing industry. With its unmatched precision, flexibility, and scalability, this innovative technology has the power to revolutionize the way complex profiles are produced. As industries strive for greater efficiency and productivity, the Profile Rolling Forming Machine emerges as a game-changer, providing manufacturers with the means to achieve exceptional quality while optimizing costs. Embracing this technology will undoubtedly propel businesses to the forefront of their respective industries, opening new avenues for growth and advancement.

High-Quality Corrugated Roll Making Machine for Your Business

In the world of packaging and manufacturing, the demand for high-quality corrugated rolls is on the rise. As a result, the need for efficient and reliable corrugated roll making machines has become essential for companies looking to meet this demand. One company that has consistently met this need is {company name}, a leading manufacturer of corrugated roll making machines.With a history of innovation and dedication to excellence, {company name} has established itself as a trusted name in the industry. Their commitment to providing state-of-the-art machinery and exceptional service has set them apart from the competition. As a result, they have become the go-to choice for companies looking to invest in a corrugated roll making machine.One of {company name}'s standout offerings is their cutting-edge Corrugated Roll Making Machine, which is designed to deliver superior performance and efficiency. This machine is capable of producing high-quality corrugated rolls with precision and speed, making it an invaluable asset for companies looking to optimize their manufacturing processes.The {company name} Corrugated Roll Making Machine is equipped with advanced technology and features that set it apart from other machines on the market. The machine's robust construction and durable components ensure long-term reliability and consistent performance. Additionally, its user-friendly interface and intuitive controls make it easy to operate and maintain, minimizing downtime and maximizing productivity.Another key advantage of {company name}'s Corrugated Roll Making Machine is its versatility. Whether it's producing single-face, double-face, or triple-wall corrugated rolls, this machine can handle a wide range of applications with ease. This flexibility ensures that companies can meet the varied needs of their customers while maintaining high standards of quality.Furthermore, the {company name} Corrugated Roll Making Machine is designed with efficiency in mind. Its automated processes and precision engineering result in minimal material waste and optimal use of resources. This not only contributes to cost savings but also aligns with sustainable manufacturing practices, a factor that is increasingly important to today's environmentally conscious consumers.In addition to the machine's impressive capabilities, {company name} is renowned for its exceptional customer support and service. From installation and training to ongoing maintenance and technical assistance, they are committed to ensuring that their customers get the most out of their investment. This level of support is a testament to {company name}'s dedication to forging long-lasting partnerships with their clients.The combination of cutting-edge technology, superior performance, and reliable support has made the {company name} Corrugated Roll Making Machine a standout choice for companies around the world. Whether it's a large-scale packaging operation or a smaller manufacturing facility, this machine has proven to be a game-changer for businesses seeking to streamline their production processes and deliver top-quality corrugated rolls to their customers.As the demand for corrugated packaging continues to grow, having the right machinery in place is crucial for companies looking to stay competitive. With {company name}'s Corrugated Roll Making Machine, businesses can be confident in their ability to meet this demand with efficiency, precision, and reliability, setting the stage for continued success and growth.In conclusion, the {company name} Corrugated Roll Making Machine represents the pinnacle of innovation and excellence in the industry. Its advanced technology, unmatched performance, and unwavering commitment to customer satisfaction make it the ideal choice for companies looking to invest in a high-quality corrugated roll making machine. With {company name} as a trusted partner, companies can be confident in their ability to meet the evolving needs of the market while achieving new levels of success.

High-quality Steel Roll Forming Machine for Sale - Find the Best Deals Now!

Steel Roll Forming Machine Revolutionizing the Manufacturing IndustryThe manufacturing industry has always been a key player in the global economy, continuously looking for innovative ways to improve production processes and increase efficiency. One such innovation that has been making waves in the industry is the Steel Roll Forming Machine, a versatile piece of equipment that is revolutionizing the way steel products are made.The Steel Roll Forming Machine, manufactured by a leading company in the industry, is designed to efficiently produce a wide range of steel products, including roofing and wall cladding, floor decking, and structural sections. The machine uses a continuous bending operation to shape the steel into the desired profile, resulting in high-quality products with consistent dimensions and excellent finish.The company behind this innovative machine is committed to providing cutting-edge solutions for the manufacturing industry. With a strong focus on research and development, the company has continuously improved and upgraded its machines to meet the evolving needs of its customers. This dedication to innovation has made the Steel Roll Forming Machine a preferred choice for manufacturers around the world.One of the key advantages of the Steel Roll Forming Machine is its versatility. It can be easily customized to produce different profiles and sizes, making it suitable for a wide range of applications. This flexibility allows manufacturers to quickly adapt to changing market demands and produce custom products with ease.In addition to its versatility, the Steel Roll Forming Machine offers significant cost savings for manufacturers. The continuous operation of the machine results in high production speeds and minimal material wastage, leading to reduced production costs. Furthermore, the consistent quality of the finished products eliminates the need for additional processing, saving both time and resources.Furthermore, the company's commitment to sustainability is evident in the design and operation of the Steel Roll Forming Machine. The machine is designed to minimize energy consumption and operate with minimal environmental impact. This aligns with the growing emphasis on sustainable manufacturing practices, making the machine an attractive choice for environmentally conscious manufacturers.The reliability and performance of the Steel Roll Forming Machine have led to its widespread adoption across various industries, including construction, automotive, and manufacturing. Its ability to produce high-quality steel products quickly and efficiently has made it an indispensable tool for manufacturers looking to stay ahead in today's competitive market.One of the key factors contributing to the success of the Steel Roll Forming Machine is the company's commitment to customer satisfaction. With a team of highly skilled engineers and technicians, the company offers comprehensive technical support and after-sales services to ensure the smooth operation of its machines. This dedication to customer support has earned the company a reputation for excellence in the industry.Looking ahead, the company remains dedicated to pushing the boundaries of innovation in the manufacturing industry. With a strong focus on research and development, the company continues to introduce new technologies and enhancements to its machines, further solidifying its position as a leader in the industry.In conclusion, the Steel Roll Forming Machine has emerged as a game-changer in the manufacturing industry, offering unmatched versatility, cost savings, and sustainability. With a strong track record of performance and a commitment to customer satisfaction, the machine has become a preferred choice for manufacturers worldwide. As the industry continues to evolve, the company behind the Steel Roll Forming Machine remains at the forefront of innovation, driving the future of manufacturing.

Affordable C Purlin Roll Forming Machine Price: Everything You Need to Know

We regret to inform you that the news could not be completed as the brand name was not provided. If you could provide more specific details or rephrase the request, we would be happy to assist.

Efficient and High-Speed Automatic Slitter for Precision Cutting

Automatic Slitter: Revolutionize the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking innovative solutions to improve production efficiency and maximize output. The introduction of automatic slitter has taken the industry by storm, offering a cutting-edge solution to streamline the slitting process and significantly enhance productivity. This groundbreaking technology has revolutionized the way companies approach their manufacturing operations, setting new standards for precision and speed.The automatic slitter, developed by [Company Name], is a state-of-the-art machine that is designed to automate the slitting process, allowing for seamless and precise cutting of various materials such as paper, film, fabric, and metal. The machine is equipped with advanced sensors and cutting blades, which are capable of performing high-speed and accurate cuts with minimal human intervention. This level of automation not only reduces the chances of human error but also increases the overall efficiency of the manufacturing process.One of the key benefits of the automatic slitter is its ability to handle a wide range of materials with different thickness and properties. This versatility makes it an ideal solution for companies operating in diverse industries, including packaging, textiles, and automotive. Furthermore, the machine's adjustable cutting parameters and user-friendly interface provide operators with the flexibility to customize the cutting process according to specific requirements, ensuring superior quality and consistency in the finished products.The introduction of automatic slitter has not only transformed the manufacturing landscape but has also had a significant impact on the bottom line for many companies. By eliminating the need for manual intervention and reducing material wastage, the machine has helped companies achieve substantial cost savings while also boosting their overall production capacity. This has allowed businesses to meet the growing demands of the market and stay ahead of the competition.In addition to its operational benefits, the automatic slitter also contributes to a safer working environment for operators. The machine's advanced safety features, such as automatic blade guards and emergency stop mechanisms, mitigate the risks associated with manual cutting processes, ensuring a secure and productive working environment.[Company Name]'s automatic slitter has already garnered attention from industry leaders and has been well-received by manufacturing companies worldwide. Its cutting-edge technology and superior performance have positioned it as a game-changer in the industry, setting new standards for efficiency and precision in the manufacturing process.The company's commitment to innovation and continuous improvement has played a pivotal role in the development of this groundbreaking technology. With a team of experienced engineers and experts in the field of manufacturing, [Company Name] has been able to push the boundaries of what is possible and deliver a solution that truly makes a difference for its customers.Looking ahead, [Company Name] is dedicated to further enhancing the capabilities of the automatic slitter and exploring new opportunities to apply its technology in different manufacturing processes. The company is also focused on providing comprehensive training and support to its customers, ensuring they can maximize the benefits of the machine and stay ahead in the rapidly evolving manufacturing landscape.As the demand for efficient and cost-effective manufacturing solutions continues to rise, automatic slitter is poised to play a crucial role in shaping the future of the industry. With its advanced technology, versatility, and operational benefits, the automatic slitter has undoubtedly established itself as a game-changer, offering a compelling case for companies to embrace automation and drive their manufacturing operations to new heights.

Efficient Roof Roll Forming Machine Boosts Productivity and Quality

Title: Revolutionary Roof Roll Forming Machine Revolutionizes the Roofing IndustryIntroduction:In a bid to revolutionize the roofing industry, a leading machinery manufacturing company has introduced an innovative Roof Roll Forming Machine. This state-of-the-art machine is set to transform the way roofs are manufactured, increasing efficiency, reducing costs, and enhancing the overall quality of roofing materials.The Roof Roll Forming Machine, manufactured by a renowned machinery company, incorporates cutting-edge technology, advanced production techniques, and a commitment to sustainability. Its introduction marks a significant milestone in the roofing industry, meeting the demands of increased production while ensuring quality and durability.Efficiency and Speed:The Roof Roll Forming Machine establishes new benchmarks for efficiency and speed in the production of roofing materials. By automating the manufacturing process, it eliminates manual labor, reducing production time and increasing output. The machine's sophisticated design includes precise roll forming tools that shape flat metal coils into desired roof profiles, ensuring uniformity and accuracy in every single piece of roofing material produced.Additionally, the machine's automated control system guarantees consistent quality throughout the production process. This not only ensures reliability but also reduces material waste, making the Roof Roll Forming Machine highly cost-effective and environmentally sustainable.Versatility and Customization:Recognizing the growing demand for diverse roof designs, the Roof Roll Forming Machine offers exceptional versatility, enabling the production of a wide range of roof profiles. From traditional shingles to modern standing seam and corrugated roofs, this machine can adapt to meet any architectural requirement. This versatility ensures that architects, contractors, and homeowners have access to custom roof designs that suit their preferences and project specifications.Superior Material Quality:The Roof Roll Forming Machine incorporates advanced technology that guarantees the highest level of quality in every roof produced. The machine utilizes premium-grade metal coils, ensuring exceptional durability and longevity of the roofing materials. The precise roll forming process ensures that each piece of roofing material is free from defects, providing superior resistance against weather elements and guaranteeing a long-lasting roof.Furthermore, the Roof Roll Forming Machine allows for the integration of additional features such as insulation, coatings, and ventilation systems, ensuring enhanced thermal insulation, weatherproofing, and energy efficiency. These features contribute to creating sustainable and comfortable living spaces while reducing energy consumption and utility bills.Transformation of the Roofing Industry:The introduction of the Roof Roll Forming Machine is expected to have a transformative impact on the entire roofing industry. With its ability to streamline the production process, reduce costs, and enhance product quality, this innovative machine empowers manufacturers to meet the ever-increasing demand for efficient and sustainable roofing solutions.Moreover, the machine's versatility and customization options allow for the creation of unique and aesthetically pleasing roof designs, further fueling architectural innovation and creativity. Contractors and homeowners can now choose from an extensive range of roofing options, ensuring their projects align with their individual preferences and overall design concepts.Conclusion:The Roof Roll Forming Machine has emerged as a game-changer in the roofing industry, optimizing the production process, improving material quality, and allowing for unparalleled customization. Consequently, this innovative machine not only meets the evolving needs of the industry but also contributes to sustainable construction practices.As this Roof Roll Forming Machine continues to gain traction, it is expected to revolutionize the way roofing materials are produced, providing architects, contractors, and homeowners with efficient, durable, and aesthetically pleasing roofing solutions for years to come.

State-of-the-Art Roll Forming Machine for High-Quality Roof Panels

[News Introduction]Roof Panel Roll Forming Machines Revolutionize Construction Industry[Location], [Date] - The roofing industry has witnessed a revolutionary breakthrough with the introduction of the advanced Roof Panel Roll Forming Machine. This remarkable piece of technology, developed by [Company Name], has the potential to transform traditional roofing methods, making installations quicker, cost-effective, and more efficient. As the demand for sustainable and high-quality roofing solutions continues to grow, this state-of-the-art machine is set to revolutionize the construction industry.[Company Introduction][Company Name], a leading manufacturer of innovative industrial machinery, takes pride in introducing the ground-breaking Roof Panel Roll Forming Machine. Established in [Year], [Company Name] has made remarkable strides in the development of cutting-edge technology, catering to various industries’ needs and contributing to their growth and overall efficiency.With an extensive portfolio of successful projects and a commitment to delivering excellence in every aspect, [Company Name] has emerged as a market leader. Applying years of expertise and leveraging a team of highly skilled professionals, the company's vision is to revolutionize traditional practices and introduce game-changing solutions.[Machine Features]The Roof Panel Roll Forming Machine boasts an array of extraordinary features that set it apart from conventional roofing solutions. Built with precision engineering and state-of-the-art technology, this machine offers unparalleled advantages to roofing professionals:1. High Automation: The automatic control system integrated into the machine ensures smooth operation and minimal manual intervention. This feature significantly increases productivity, reduces labor costs, and eliminates human error.2. Versatility: The Roof Panel Roll Forming Machine can produce a wide range of roofing panels, from corrugated to standing seam designs. This versatility allows contractors to cater to diverse customer preferences, saving time and capital that would otherwise be spent on acquiring multiple machines.3. Speed and Efficiency: The machine's advanced roll-forming process guarantees swift production, significantly reducing project timelines. The speed and efficiency of this technology allow contractors to take on more projects, ultimately increasing their bottom line.4. Cost-Effective: By streamlining the manufacturing process and eliminating material wastage, the Roof Panel Roll Forming Machine reduces overall project costs. The machine's ability to generate precise cuts and optimize material usage minimizes waste, maximizing profits for roofing professionals.5. Precision Engineering: The Roof Panel Roll Forming Machine ensures exceptional precision and accuracy in panel creation, leaving no room for errors. The advanced technology employed in this machine guarantees consistent quality control, resulting in durable and aesthetically pleasing roofing panels.6. Durability and Longevity: With superior craftsmanship and the use of high-quality materials, the Roof Panel Roll Forming Machine guarantees the production of durable roofing panels. Clients can trust in the long-lasting and resilient nature of these panels, ensuring that their roofs withstand the test of time and various weather conditions.[Impact on the Construction Industry]The introduction of the Roof Panel Roll Forming Machine is set to make huge strides in the construction industry. Traditional roofing methods require immense manual labor, extended project timelines, and often result in inefficiencies and substandard quality. The remarkable features of this advanced machine offer an ideal solution that addresses these challenges head-on.With increased automation, precision engineering, and significant time and cost savings, this technology will revolutionize the roofing sector. Contractors will be able to take on more projects, streamline their operations, and deliver superior roofing solutions to their clients.As the construction industry embraces sustainable practices, the Roof Panel Roll Forming Machine aligns perfectly with the demand for eco-friendly roofing solutions. By reducing material waste and optimizing production processes, this machine supports a greener future while lowering ecological footprints.[Conclusion]The introduction of the Roof Panel Roll Forming Machine marks a significant milestone in the construction industry. With its innovative features, this technology promises to change the landscape of the roofing sector, offering unmatched efficiency, cost-effectiveness, and sustainability.As [Company Name] continues to push the boundaries of industrial innovation, it reaffirms its commitment to delivering cutting-edge solutions, supporting the growth and transformation of various industries. The company's Roof Panel Roll Forming Machine is expected to revolutionize traditional roofing practices, benefiting contractors, clients, and the environment as a whole.

New Steel Product Quickly Gains Popularity in Construction Industry

[Company Name] Launches Robust Purlins to Support Construction Industry[date][Location] [Company Name], a leading manufacturer and supplier of construction materials, has announced the release of their latest innovation in the building industry – robust purlins. These high-quality steel components are set to revolutionize the way construction projects are carried out, offering increased durability, ease of installation, and cost-effectiveness.Purlins, commonly used in roofing and cladding systems, play a crucial role in providing structural support to buildings. They are horizontal, load-bearing beams that span between trusses or rafters and help transfer the weight of the roof to the main support structure. With [Company Name]'s new range of robust purlins, builders and contractors can now have peace of mind knowing that they are using a dependable and long-lasting product.The concept behind [Company Name]'s robust purlins lies in their meticulous design and precise engineering. Crafted from high-strength galvanized steel, these purlins offer exceptional structural integrity, ensuring stability and longevity of the buildings they are used in. The galvanization process protects against corrosion and adds an extra layer of resilience, making the purlins suitable for a variety of environmental conditions.Installing the new purlins is a breeze, thanks to their innovative design. Their lightweight nature allows for easy handling, reducing the time and effort required during the construction process. The purlins have also been designed to fit seamlessly with existing building components, making them adaptable for both new constructions and renovation projects.One of the standout features of [Company Name]'s robust purlins is their cost-effectiveness. By using these high-quality purlins, builders can reduce the need for additional support structures and minimize material wastage. The purlins' strength-to-weight ratio ensures they can withstand heavy loads, reducing the number of purlins required, ultimately saving on project costs.In line with [Company Name]'s commitment to sustainable practices, the new purlins are made from recycled materials. By utilizing these eco-friendly purlins, builders and designers can contribute to reducing their carbon footprint, promoting a greener, more sustainable construction industry."We are extremely excited to introduce our new range of robust purlins to the market," says [Company Name]'s CEO, [CEO Name]. "With their impressive strength, ease of installation, and cost-effectiveness, we believe these purlins will make construction projects more efficient while providing durable support structures."As a company dedicated to customer satisfaction, [Company Name] aims to provide exceptional after-sales assistance and technical support. With a team of experienced engineers on standby, customers can expect seamless integration of the purlins into their building projects, along with any necessary guidance or troubleshooting.[Company Name]'s robust purlins are now available for purchase and can be ordered through their website or authorized distributors. The company also plans to conduct workshops and training sessions to educate builders and contractors on the benefits and proper installation of these purlins.In conclusion, [Company Name]'s launch of their robust purlins marks a significant milestone in the construction industry. With enhanced durability, ease of installation, and cost-effectiveness, these purlins are set to become the go-to choice for builders and contractors worldwide. By incorporating these innovative components into their projects, construction professionals can expect increased efficiency, reduced costs, and durable structures that stand the test of time.

Glazed Tile Roll Forming Machine: A Reliable Solution for Roofing Sheet Production

Title: Introducing Dahezb's Cutting-Edge Glazed Tile Roll Forming Machine for Metal RoofingIntroduction:In the fast-paced world of construction and manufacturing, technological advancements are constantly emerging to improve efficiency and quality. Dahezb Metal presents its latest innovation, the Glazed Tile Roll Forming Machine, a state-of-the-art solution for producing metal roof tiles. With its ability to transform metal sheets into refined glazed roofing tiles, this machine proves to be a game-changer in the industry.Redefining Metal Roofing:Dahezb's Glazed Tile Roll Forming Machine is designed to cater to the specific needs of customers looking for robust metal roofing solutions. Capable of molding metal sheets ranging from 0.3mm to 0.6mm in thickness, this machine delivers top-notch precision and durability.Key Features and Benefits:1. Enhanced Efficiency: The Glazed Tile Roll Forming Machine operates with remarkable efficiency, allowing for smooth and continuous production. By eliminating the need for manual tile cutting, this machine saves time, labor, and material costs.2. Customized Solutions: Dahezb understands that every customer has unique requirements. Therefore, the Glazed Tile Roll Forming Machine offers flexibility in terms of tile shapes, sizes, and profiles. Whether it is a traditional or modern design, this machine can adapt to produce the desired glazed tiles for any roofing project.3. High-Quality Output: The Glazed Tile Roll Forming Machine ensures impeccable quality, maintaining consistency in tile thickness and dimensions. With precise control and advanced technology, it guarantees an aesthetically pleasing finish, giving metal roofing a sophisticated appeal.4. Durability: Metal roofs are known for their longevity, and the tiles produced by this machine are no exception. The Glazed Tile Roll Forming Machine manufactures tiles of exceptional strength, able to withstand harsh weather conditions and provide long-lasting protection.5. Advanced Automation: The machine's automation features streamline the production process, reducing the chances of human error. With user-friendly controls and easy-to-understand functions, operators can swiftly adapt to the machine's operations.6. Environmentally Friendly: Contributing to sustainable construction practices, the Glazed Tile Roll Forming Machine minimizes waste generated during production. By optimizing material usage and reducing scrap, it aligns with the industry's increasing focus on eco-friendly solutions.Growing Demand for Metal Roofing:The demand for metal roofing has been steadily rising due to its numerous advantages over traditional roofing materials. Metal roofs offer superior durability, remarkable energy efficiency, and significant cost savings in the long run. Additionally, they are fire-resistant and require minimal maintenance, making them an attractive choice for homeowners and businesses alike.Company Introduction: Dahezb Metal is a renowned manufacturer and provider of high-quality roll forming machines. Their expertise lies in designing and producing roofing and construction machinery that meets the evolving industry requirements. With a strong commitment to innovation and customer satisfaction, Dahezb Metal continues to be a trusted collaborator for businesses worldwide.Conclusion:With its cutting-edge Glazed Tile Roll Forming Machine, Dahezb Metal is revolutionizing the metal roofing industry. This advanced technology not only saves time and facilitates efficient production but also delivers outstanding quality and durability. As demands for eco-friendly and sustainable construction practices increase, Dahezb's Glazed Tile Roll Forming Machine stands as a valuable solution for any roofing project.

High-Quality Floor Decking Roll Forming Machine Available in China - Wholesale and Export to Worldwide Market

and China Manufacturers.Floor decking roll forming machines are becoming increasingly popular in the construction industry. These machines are used to create floor decking panels, which are then used as a base for flooring systems in construction projects. These machines are capable of producing high-quality, consistent panels that are cost-effective and durable. If you are looking for a reliable and high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers.China manufacturers of floor decking roll forming machines offer a wide range of machines with varying specifications and features. These machines are designed to cater to the needs of various construction companies, ranging from small to large-scale operations. These machines are made using high-quality materials and are manufactured with precision, ensuring that they are durable and long-lasting. They are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity.When purchasing a floor decking roll forming machine from Chinese manufacturers, there are several important factors to consider. Firstly, you should consider the quality of the machine. You should look for machines that are made from high-quality materials and are manufactured with precision to ensure that the machine is durable and efficient. Secondly, you should consider the features and specifications of the machine. You should look for machines that have the features that you need for your specific business requirements. Finally, you should consider the price of the machine. You should look for machines that are competitively priced and offer good value for money.In conclusion, if you are in the market for a high-quality floor decking roll forming machine, then you should consider purchasing from China manufacturers. Chinese manufacturers offer a wide range of machines that are made using high-quality materials and are manufactured with precision to ensure that they are durable and efficient. These machines are also easy to operate, which makes them an ideal choice for businesses that want to increase their productivity. When purchasing a machine from China manufacturers, you should consider factors such as the quality of the machine, its features and specifications, and its price. With these factors in mind, you can find the perfect machine for your business needs.