High-Quality Steel Sheet Roll Forming Machine for Decking Projects

By:Admin

The steel industry has always been a crucial part of the infrastructure and construction sector, providing the necessary materials for building strong and durable structures. In line with this, the introduction of the latest innovation in steel sheet roll forming, the Decking Steel Sheet Roll Forming Machine, has been welcomed with enthusiasm and anticipation. Developed by a leading company in the field of manufacturing and engineering {}, this new machine is set to revolutionize the way steel decking sheets are produced.

The Decking Steel Sheet Roll Forming Machine is designed to cater to the growing demand for high-quality and precise steel decking sheets, which are widely used in the construction of commercial and industrial buildings. With its advanced technology and efficient production capabilities, this machine is expected to deliver superior performance and reliability, while also streamlining the manufacturing process for companies in the steel industry.

The key features of the Decking Steel Sheet Roll Forming Machine include a robust and durable frame, precision-engineered rollers, and a user-friendly control system. These components work together to ensure consistent and accurate forming of steel sheets, resulting in products that meet the highest standards of quality and performance. Additionally, the machine is equipped with safety features and automated functions, making it easy to operate and maintain, while also minimizing the risk of errors and accidents in the production process.

In addition to its technical capabilities, the Decking Steel Sheet Roll Forming Machine is also designed with versatility and flexibility in mind. It can accommodate a wide range of steel sheet sizes and thicknesses, allowing manufacturers to produce a variety of decking sheets according to their specific requirements. This adaptability makes the machine a valuable asset for companies that need to cater to diverse customer demands and industry standards.

The company {} has a strong reputation for delivering cutting-edge solutions in the field of roll forming and metal fabrication. With a team of experienced engineers and technicians, the company is committed to providing innovative and reliable equipment that meets the evolving needs of the industry. The introduction of the Decking Steel Sheet Roll Forming Machine is a testament to this dedication, as it represents a significant advancement in the company's product portfolio and an important contribution to the steel manufacturing sector.

The company's commitment to quality and excellence is reflected in its state-of-the-art manufacturing facilities and stringent quality control measures. Every machine undergoes thorough testing and inspection to ensure that it meets the highest standards of performance and durability. Customers can have confidence in the reliability and longevity of the Decking Steel Sheet Roll Forming Machine, knowing that it has been built and tested to deliver superior results in real-world production environments.

Furthermore, the company {} is known for its comprehensive customer support and after-sales service. From installation and training to maintenance and technical assistance, the company provides end-to-end support to its customers, ensuring that they get the most out of their investment in the Decking Steel Sheet Roll Forming Machine. This commitment to customer satisfaction and success sets the company apart as a trusted partner for businesses seeking to enhance their steel manufacturing capabilities.

In conclusion, the introduction of the Decking Steel Sheet Roll Forming Machine by {} marks a significant advancement in the field of steel sheet roll forming. With its cutting-edge technology, versatile capabilities, and unwavering commitment to quality, this machine is set to raise the bar for the production of steel decking sheets. As the industry continues to evolve and demand for high-performance steel products grows, the Decking Steel Sheet Roll Forming Machine stands ready to meet the challenges and opportunities of the future.

Company News & Blog

Ultimate Guide to Horizontal Barrel Vault Panel Bending Machines

The leading manufacturer of sheet metal processing equipment, has recently launched its latest innovation, the Horizontal Barrel Vault Panel Bending Machine. This state-of-the-art machine is designed to meet the growing demand for efficient and precise panel bending in the construction and manufacturing industries.The Horizontal Barrel Vault Panel Bending Machine is a versatile and powerful tool that can handle a wide range of panel bending operations. It is equipped with advanced technology and features that enable it to bend large panels with extreme precision and accuracy. This machine is an ideal choice for fabricating curved panels that are used in various architectural and construction applications.One of the key features of the Horizontal Barrel Vault Panel Bending Machine is its horizontal design, which allows for easy loading and unloading of panels. This design also enables the machine to bend panels in a more efficient and consistent manner, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and maintain.The company has a rich history of providing innovative and reliable sheet metal processing equipment to its customers. With over [number] years of experience in the industry, the company has built a strong reputation for delivering high-quality products and exceptional customer service. The launch of the Horizontal Barrel Vault Panel Bending Machine further demonstrates the company's commitment to meeting the evolving needs of its customers and the industry.In addition to its technical capabilities, the company is also known for its dedication to sustainability and environmental stewardship. The Horizontal Barrel Vault Panel Bending Machine is designed with energy-efficient features that help reduce power consumption and minimize its environmental impact. This commitment to sustainability aligns with the company's larger mission to develop innovative solutions that support a more sustainable and responsible manufacturing industry.The launch of the Horizontal Barrel Vault Panel Bending Machine has already generated significant interest and excitement within the industry. Many leading construction and manufacturing companies have expressed their eagerness to explore the capabilities of this new machine and incorporate it into their operations. The company is confident that the machine will make a positive impact on the industry and help its customers achieve new levels of productivity and efficiency.As the demand for curved panels continues to grow in the construction and architecture sectors, the Horizontal Barrel Vault Panel Bending Machine is expected to play a pivotal role in meeting this demand. Its advanced technology, user-friendly design, and commitment to sustainability make it a standout choice for companies looking to enhance their panel bending capabilities.The company is poised to continue its legacy of innovation and excellence with the launch of the Horizontal Barrel Vault Panel Bending Machine. With its industry-leading expertise and dedication to customer satisfaction, the company is well-positioned to shape the future of sheet metal processing and support the evolving needs of the construction and manufacturing industries.

High-Quality Automatic Cut-To-Length Machine for Precision Cutting

Automatic Cut-To-Length Machine Revolutionizing Production ProcessThe manufacturing industry is continuously evolving with the advancement of technology, and one company at the forefront of this evolution is {}. With a commitment to innovation and efficiency, they have recently introduced their latest addition to their production line – the Automatic Cut-To-Length Machine. This state-of-the-art machine is set to revolutionize the production process, offering precision, speed, and enhanced productivity.The Automatic Cut-To-Length Machine is designed to streamline the process of cutting materials to specific lengths, catering to the diverse needs of various industries such as automotive, construction, and appliances. This machine is equipped with advanced features that enable it to effortlessly cut different materials including metals, plastics, and composites with utmost accuracy and consistency.One of the key highlights of the Automatic Cut-To-Length Machine is its cutting-edge technology that allows for automated operation. This not only reduces the need for manual labor but also minimizes the margin of error, resulting in higher quality output. Additionally, with its rapid cutting speed, the machine significantly increases production efficiency, ultimately leading to cost savings for the company.Furthermore, the Automatic Cut-To-Length Machine is integrated with intelligent software that enables precise customization and optimization of cutting processes. This ensures that the machine can meet the specific requirements of each customer, catering to a wide range of dimensions and tolerances. With such versatility, the machine offers a competitive edge in the market, allowing {} to provide tailored solutions to meet the unique demands of their clients.In addition to its technical capabilities, the Automatic Cut-To-Length Machine is designed with the operator in mind. Its user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and ensuring seamless integration into the production line. This not only enhances the overall efficiency of the manufacturing process but also creates a safer working environment for the operators.{} has a long-standing reputation for delivering high-quality, reliable machinery, and the introduction of the Automatic Cut-To-Length Machine is a testament to their commitment to continuous improvement and innovation. With a strong focus on research and development, the company has invested heavily in advancing their technological capabilities, ensuring that they remain at the forefront of the industry.The launch of the Automatic Cut-To-Length Machine underscores {}'s dedication to meeting the evolving needs of their customers. By incorporating cutting-edge technology and automation into their production line, they are not only enhancing their own operational efficiency but also empowering their clients to achieve greater success in their respective industries.Moreover, the introduction of the Automatic Cut-To-Length Machine aligns with {}'s long-term sustainability goals. By optimizing the cutting process and reducing material waste, the machine contributes to a more environmentally friendly manufacturing approach. This reflects {}'s commitment to conducting business in a responsible and ethical manner, prioritizing sustainability and resource efficiency.With the introduction of the Automatic Cut-To-Length Machine, {} is poised to set new standards within the manufacturing industry. By leveraging cutting-edge technology and innovation, they are not just meeting the current demands of the market but also shaping the future of production processes. As the industry continues to evolve, {} remains dedicated to pushing boundaries and redefining what is possible in manufacturing.

Innovative Sheet Machine Technology: A Game Changer for the Industry

High-Tech Company Develops Innovative Profile Sheet Machine to Revolutionize Manufacturing IndustryIn today’s fast-paced and competitive manufacturing industry, the demand for advanced technologies and innovative solutions continues to rise. Recognizing this need, [Company Name], a leading high-tech company, has developed a cutting-edge Profile Sheet Machine that is set to revolutionize the way profiles and sheets are manufactured.With a focus on precision, efficiency, and versatility, the Profile Sheet Machine is designed to meet the diverse needs of various industries, including construction, automotive, aerospace, and beyond. By leveraging the latest technological advancements, [Company Name] has created a state-of-the-art machine that offers unmatched capabilities and performance.The Profile Sheet Machine is equipped with advanced automation features, allowing for seamless and precise production of profiles and sheets. This not only minimizes the margin of error but also significantly enhances productivity and throughput. The machine also boasts a user-friendly interface, making it easy for operators to set up and monitor the manufacturing process, further increasing efficiency and reducing downtime.One of the key highlights of the Profile Sheet Machine is its ability to accommodate a wide range of materials, including aluminum, stainless steel, and various alloys. This flexibility enables manufacturers to produce an extensive array of profiles and sheets to meet the specific requirements of their projects. Whether it’s creating intricate designs or large-scale components, the machine delivers consistent and high-quality results.Furthermore, the Profile Sheet Machine is designed to optimize material usage, thereby reducing waste and ultimately contributing to a more sustainable manufacturing process. By implementing advanced cutting and forming techniques, the machine ensures minimal material loss while maintaining utmost accuracy and precision.In addition to its technical capabilities, [Company Name] has also prioritized the safety and maintenance aspects of the Profile Sheet Machine. The machine is equipped with comprehensive safety features to protect operators and maintain a secure working environment. Moreover, it is designed for easy maintenance, with accessible components and a robust build that ensures longevity and reliability.As a pioneer in high-tech solutions, [Company Name] has a long-standing reputation of delivering cutting-edge products and services to its clients. With a strong focus on research and development, the company is committed to pushing the boundaries of innovation and continuously enhancing its offerings to address the evolving needs of the industry.With the launch of the Profile Sheet Machine, [Company Name] aims to set new industry standards and empower manufacturers to achieve new levels of efficiency and quality in their production processes. By providing a reliable and advanced solution that meets the demands of modern manufacturing, the company is poised to make a significant impact on the industry landscape.The unveiling of the Profile Sheet Machine is a testament to [Company Name]’s unwavering dedication to technological advancement and customer satisfaction. As the manufacturing industry continues to evolve, the company remains at the forefront, driving progress and ushering in a new era of innovation.In conclusion, the Profile Sheet Machine represents a breakthrough in manufacturing technology, offering unparalleled capabilities and performance. With its advanced features, flexibility, and commitment to quality, the machine is set to redefine the way profiles and sheets are produced, empowering manufacturers to meet the demands of the modern market. As [Company Name] continues to lead the charge in high-tech solutions, the Profile Sheet Machine stands as a testament to the company’s vision and commitment to driving progress in the industry.

High-Quality Metal Deck Roll Forming Machines Available for Export

Roll forming machines have revolutionized the way we manufacture structural components for construction projects. One such machine which has gained immense popularity in recent years is the Floor Deck Roll Forming Machine. This machine is used to produce high-quality metal decks used for flooring and roofing in various construction projects.The Floor Deck Roll Forming Machine is essentially a series of rollers and tooling which bend and shape metal sheets into the desired profile for the metal deck. With the help of a motor, the metal sheets are slowly fed through the rollers and are bent into the desired shape. The end result is a metal deck that is strong, durable, and can withstand harsh weather conditions.When it comes to manufacturing the Floor Deck Roll Forming Machine, there are many professional and experienced manufacturers available in the market. They specialize in producing a variety of Metal Deck Roll Forming Machines according to your specific requirements. Whether you want a machine to produce metal decks for commercial or residential projects, these manufacturers can deliver you the equipment that meets your needs.The Floor Deck Roll Forming Machine is not only a useful tool for construction projects but is also a profitable investment in the long run. With the demand for metal decking material on the rise, investing in this machine can help you keep up with the competition and cater to your customers' needs.There are various types of metal decks that can be produced with the help of the Floor Deck Roll Forming Machine, such as roof decks, composite floor decks, non-composite floor decks, and more. Each type serves a unique purpose in construction projects and can be custom-made to fit the individual requirements of the project.Metal decks produced by the Floor Deck Roll Forming Machine offer many advantages over traditional construction materials such as timber decking. The metal decks are stronger, more durable, and can withstand harsh weather conditions, making them a popular choice for construction projects of all types.In conclusion, investing in a Floor Deck Roll Forming Machine can be a game-changer for your construction business. It offers a range of benefits such as faster production time, customized solutions, durability, and profitability. Find a reliable and experienced manufacturer of Metal Deck Roll Forming Machines to get started and take your construction business to the next level of success.

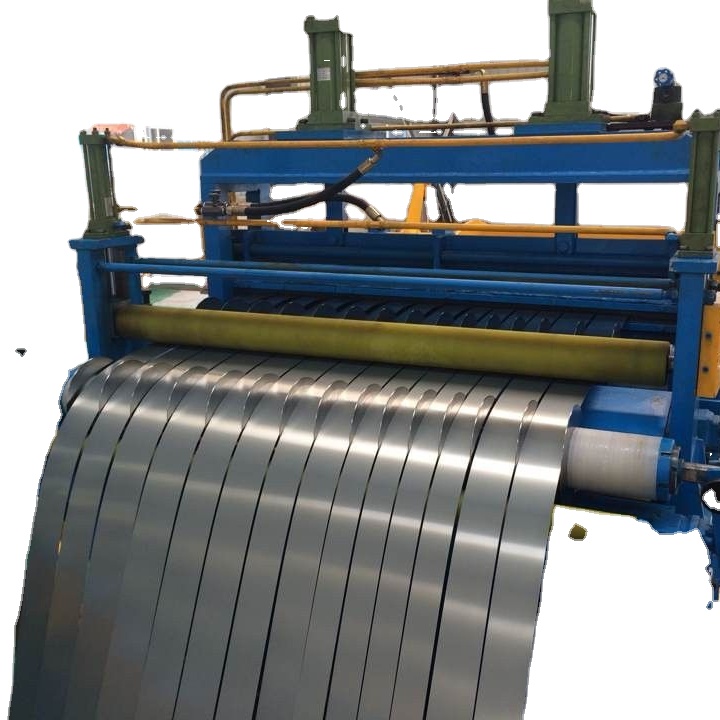

High-Quality Metal Coil Slitting Machine for Efficient Production

Metal Coil Slitting Machine Brings Cutting-Edge Technology to the Manufacturing IndustryIn today's fast-paced manufacturing industry, the demand for precision and efficiency has never been higher. As companies strive to remain competitive in a global market, the need for cutting-edge equipment has become increasingly important. This is where the Metal Coil Slitting Machine, manufactured by a leading company in the industry, comes into play.With a commitment to providing innovative solutions for metal processing, this company has established itself as a trusted provider of high-quality equipment. Their Metal Coil Slitting Machine is a testament to their dedication to meeting the evolving needs of the manufacturing industry. This state-of-the-art machine has revolutionized the process of slitting metal coils, offering a level of precision and efficiency that was previously unheard of.One of the key features of the Metal Coil Slitting Machine is its ability to accurately and consistently slit metal coils to the exact specifications required by the customer. This level of precision is made possible by advanced technology and a design that has been optimized for performance. The machine is capable of processing a wide range of metal materials, including stainless steel, aluminum, copper, and more, making it incredibly versatile and adaptable to a variety of manufacturing needs.In addition to its precision, the Metal Coil Slitting Machine also offers unmatched efficiency. With high-speed processing capabilities and an intuitive control system, the machine is able to maximize productivity and minimize downtime. This is essential for companies looking to streamline their operations and meet tight production deadlines.Furthermore, the Metal Coil Slitting Machine is designed with operator convenience in mind. The user-friendly interface and advanced automation features make it easy for operators to set up, monitor, and adjust the machine as needed. This not only reduces the risk of errors but also allows for greater flexibility in production planning.The benefits of the Metal Coil Slitting Machine are not limited to its performance capabilities. The company behind this cutting-edge equipment is known for its exceptional customer service and support. From initial consultation to installation and ongoing maintenance, they are committed to ensuring that their customers have access to the resources and expertise they need to get the most out of their investment.As the manufacturing industry continues to evolve, the demand for innovative solutions will only continue to grow. The Metal Coil Slitting Machine, with its advanced technology and proven performance, is well-positioned to meet these evolving needs. Whether it's for a small-scale operation or a large-scale production facility, this machine represents a new standard of excellence in metal processing equipment.In conclusion, the Metal Coil Slitting Machine is a game-changer for the manufacturing industry. Its advanced technology, precision, efficiency, and operator-friendly design make it an invaluable asset for companies looking to stay ahead of the competition. With the support of a trusted and experienced manufacturer, this machine is poised to redefine the way metal processing is approached, setting a new benchmark for quality and performance in the industry.

New Innovations in Floor Forming Machines: Revolutionizing Construction Methods

Title: Innovative Floor Forming Machine Revolutionizes Construction IndustryIntroduction:In the era of rapid technological advancements, the construction industry is witnessing a wave of automation and innovation that aims to streamline processes, enhance efficiency, and ultimately deliver sustainable and quality structures. In line with this progress, an emerging player in the construction machinery sector has unveiled a state-of-the-art Floor Forming Machine, promising to reshape the way flooring is installed in buildings. This revolutionary technology is set to transform the industry by significantly reducing labor costs, minimizing material waste, and accelerating project timelines.Company Introduction:{Company Name} is a leading provider of cutting-edge construction machinery and equipment. With a dynamic team of engineers and experts, the company has consistently delivered innovative solutions that cater to the evolving needs and challenges of the construction industry. Its commitment to optimizing efficiency, promoting sustainability, and improving construction quality through advanced technologies has garnered the company numerous accolades and global recognition.Floor Forming Machine Overview:The newly introduced Floor Forming Machine showcases a comprehensive and integrated approach to floor construction. Its design revolves around four primary components, namely, the leveling system, the concrete dispensing unit, the reinforcement system, and the shuttering system. Ultimately, this complete package offers construction companies an all-in-one solution for floor formation, eliminating the need for multiple specialized machines and labor-intensive processes.The leveling system ensures precise leveling of the floor surface, allowing for accurate and consistent concrete distribution. By utilizing advanced sensors and automated controls, this component focuses on delivering a level slab foundation, thus minimizing inconsistencies caused by human error during traditional construction methods.The concrete dispensing unit, another crucial component of the Floor Forming Machine, ensures smooth and efficient concrete pouring. With the ability to adjust the rate of concrete flow and taking into account the specific requirements of each project, the machine significantly reduces material waste, resulting in cost savings and improved sustainability.The reinforcement system integrated into the machine incorporates an automated process for aligning and placing steel reinforcements within the concrete slab. By leveraging sophisticated robotics technology, the machine meticulously handles this critical aspect of flooring, ensuring structural integrity and reducing manual labor requirements.The shuttering system, the final component of the machine, caters to creating the definite shape and dimensions of the floor slab. It offers flexibility in adjusting the size and form of the slab to meet various project requirements. With its ability to seamlessly change forms and sizes, the machine can accommodate a wide range of floor designs with ease and precision.Benefits and Impact:The introduction of this Floor Forming Machine brings several noteworthy benefits to the construction industry:1. Enhanced Construction Efficiency: By streamlining multiple floor formation processes into a single automated solution, the machine significantly reduces construction timeframes. This accelerated pace allows for faster project completion, leading to potential cost savings and improved profitability.2. Reduced Labor Costs: The reliance on manual labor is considerably diminished with the implementation of the Floor Forming Machine. By automating key processes, construction companies can allocate their workforce more efficiently, reducing labor expenses and improving overall productivity.3. Minimized Material Waste: The precise control and adjustment capabilities of the machine during the concrete pouring process ensure optimal material utilization. With reduced material waste, projects become more sustainable, leading to cost savings and a reduced environmental footprint.4. Higher Quality Standards: The advanced technology implemented in the Floor Forming Machine ensures a higher level of precision during construction. This results in more accurate and level floor slabs, reducing the risk of structural issues and ensuring superior quality standards.Conclusion:The introduction of the Floor Forming Machine marks a significant step forward in modernizing the construction industry. Through its integrated approach, the machine streamlines floor formation processes, enhances construction efficiency, reduces labor costs, minimizes material waste, and upholds high quality standards. As construction companies increasingly adopt this innovative technology, it is expected to become a game-changer in the sector, fostering a new era of advanced and sustainable construction practices.

Roll Form Machine: The Future of Metal Fabrication" can be rewritten as "Revolutionizing Metal Fabrication with Roll Form Machinery".

Roll Form Machine revolutionizes production processes for manufacturing industriesThe manufacturing industry has been a critical part of global economic growth, innovation, and development for centuries now. Over the years, this industry has seen tremendous improvement, growth, and advancement, thanks to industrialization, advancements in technology, and innovation. However, with the increase in competition, changing market trends, and customer demands, manufacturers are always looking for new and innovative ways to optimize their production processes, reduce costs, save time, and enhance the quality of their products.In light of this, a new production technology, the Roll Form Machine, has emerged, and it is transforming the manufacturing industry. The roll forming machine is an innovative technology that helps manufacturers produce high-quality products efficiently, cost-effectively, and with less lead time. This machine is widely used in various industries such as automotive, construction, aerospace, home appliance manufacturing, and many others.The Roll Form Machine (removed brand name) is a reliable, highly functional, and robust machine that can handle multiple processes, including roll forming, punching, cutting, and welding. It can produce highly precise and accurate products, ensuring uniformity and consistency in finished products. Also, the roll forming machine can handle different types of raw materials such as stainless steel, aluminum, copper, brass, and galvanized steel, among others.The roll forming process involves feeding a flat strip of metal into a series of rollers to gradually bend and form it into a specific cross-sectional shape. The Roll Form Machine has several rollers, each with a unique shape that corresponds to the desired cross-sectional profile of the finished product. As the strip of metal passes through the rollers, it undergoes a series of bending operations that gradually form it into the desired shape.One of the benefits of the Roll Form Machine is its flexibility, allowing manufacturers to create a wide variety of products with different shapes, sizes, and profiles. This machine can fabricate products such as shelves, automotive frames, door frames, window frames, railings, roofing, and many others. The machine's versatility and flexibility also make it suitable for small and large-scale manufacturing industries.Notable features of the roll forming machine include its low installation cost, high production speed, and ability to minimize production wastage and remakes. The machine can produce products within a short lead time, allowing manufacturers to satisfy customer demands while reducing turnaround time.Moreover, the Roll Form Machine can readily adapt to changes and updates in customers' requirements without the need for extensive retooling or expensive equipment. Its flexibility makes it critical in the dynamic and fast-paced manufacturing industry.With over (number of years) years of experience in the manufacturing industry, (company name), a leading manufacturer of roll forming machines, has been at the forefront of providing innovative solutions to the production challenges facing manufacturers. The company specializes in the manufacturing of high-quality roll form machines that offer reliability, efficiency, and cost-effectiveness.Our Roll Form Machines are designed to deliver exceptional performance, protecting manufacturers' investments while ensuring optimal return on investment. Our machines come in different configurations and models, depending on customers' needs. We offer customized solutions to meet specific production needs, including the integration of additional features such as punching, cutting, welding, and stacking.With a dedicated team of engineers and technicians, (company name) delivers end-to-end service, including installation, commissioning, and after-sales support for all our Roll Form Machines. Our technicians work closely with customers to ensure the machines operate at maximum efficiency while providing training, maintenance, and repairs whenever necessary.(Company name) is committed to delivering exceptional performance, offering innovative solutions to meet the evolving production needs of the manufacturing industry. Our Roll Form Machines are tested and proven, ensuring that they meet international quality standards and regulations. We take pride in supplying our machines to a global market, providing efficient, reliable, and affordable roll-forming solutions to manufacturers worldwide.In conclusion, the Roll Form Machine is a game-changing technology that is revolutionizing the manufacturing industry. With its versatility, speed, and efficiency, the Roll Form Machine offers manufacturers an opportunity to enhance production processes, optimize costs and productivity while meeting customer demands. (Company name)'s expertise in the manufacturing of Roll Form Machines makes it a suitable partner for any manufacturer looking for innovative and efficient solutions that will take their production to new heights.

Efficient and High-Speed Automatic Slitter for Precision Cutting

Automatic Slitter: Revolutionize the Manufacturing IndustryIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking innovative solutions to improve production efficiency and maximize output. The introduction of automatic slitter has taken the industry by storm, offering a cutting-edge solution to streamline the slitting process and significantly enhance productivity. This groundbreaking technology has revolutionized the way companies approach their manufacturing operations, setting new standards for precision and speed.The automatic slitter, developed by [Company Name], is a state-of-the-art machine that is designed to automate the slitting process, allowing for seamless and precise cutting of various materials such as paper, film, fabric, and metal. The machine is equipped with advanced sensors and cutting blades, which are capable of performing high-speed and accurate cuts with minimal human intervention. This level of automation not only reduces the chances of human error but also increases the overall efficiency of the manufacturing process.One of the key benefits of the automatic slitter is its ability to handle a wide range of materials with different thickness and properties. This versatility makes it an ideal solution for companies operating in diverse industries, including packaging, textiles, and automotive. Furthermore, the machine's adjustable cutting parameters and user-friendly interface provide operators with the flexibility to customize the cutting process according to specific requirements, ensuring superior quality and consistency in the finished products.The introduction of automatic slitter has not only transformed the manufacturing landscape but has also had a significant impact on the bottom line for many companies. By eliminating the need for manual intervention and reducing material wastage, the machine has helped companies achieve substantial cost savings while also boosting their overall production capacity. This has allowed businesses to meet the growing demands of the market and stay ahead of the competition.In addition to its operational benefits, the automatic slitter also contributes to a safer working environment for operators. The machine's advanced safety features, such as automatic blade guards and emergency stop mechanisms, mitigate the risks associated with manual cutting processes, ensuring a secure and productive working environment.[Company Name]'s automatic slitter has already garnered attention from industry leaders and has been well-received by manufacturing companies worldwide. Its cutting-edge technology and superior performance have positioned it as a game-changer in the industry, setting new standards for efficiency and precision in the manufacturing process.The company's commitment to innovation and continuous improvement has played a pivotal role in the development of this groundbreaking technology. With a team of experienced engineers and experts in the field of manufacturing, [Company Name] has been able to push the boundaries of what is possible and deliver a solution that truly makes a difference for its customers.Looking ahead, [Company Name] is dedicated to further enhancing the capabilities of the automatic slitter and exploring new opportunities to apply its technology in different manufacturing processes. The company is also focused on providing comprehensive training and support to its customers, ensuring they can maximize the benefits of the machine and stay ahead in the rapidly evolving manufacturing landscape.As the demand for efficient and cost-effective manufacturing solutions continues to rise, automatic slitter is poised to play a crucial role in shaping the future of the industry. With its advanced technology, versatility, and operational benefits, the automatic slitter has undoubtedly established itself as a game-changer, offering a compelling case for companies to embrace automation and drive their manufacturing operations to new heights.

High-Quality Metal Roofing Roller Machine for Sale - Get Yours Today!

Metal Roofing Roller Machine Boosts Production and Quality for {Company}{City, State} - {Company}, a leading manufacturer of metal roofing products, has recently invested in state-of-the-art metal roofing roller machine to enhance its production capabilities. The new machine promises to boost production efficiency and improve the quality of the company's metal roofing products, strengthening its position in the competitive roofing industry.The metal roofing roller machine, which was custom-designed and manufactured by a reputable equipment supplier, is equipped with advanced technology and features that enable precise and efficient rolling of metal sheets. This allows {Company} to produce a wide range of metal roofing products with varying profiles and specifications, catering to the diverse needs of its customers.In addition to increasing production capacity, the new machine also provides greater flexibility in terms of customization. {Company} can now quickly adjust the settings of the roller machine to accommodate specific customer requests, such as custom color coating or unique profile designs. This level of flexibility sets {Company} apart from its competitors, as it can offer tailor-made metal roofing solutions to meet the individual requirements of its clients.The metal roofing roller machine also brings significant improvements in product quality. With precise and uniform rolling capabilities, the machine ensures that the metal sheets maintain their structural integrity and uniformity throughout the production process. This results in metal roofing products that are free from defects, such as warping or uneven thickness, ensuring the durability and longevity of the roofs installed by {Company}.The investment in the metal roofing roller machine reflects {Company}'s commitment to innovation and continuous improvement. By integrating advanced technology into its production processes, {Company} aims to stay ahead of the curve in the rapidly evolving roofing industry. The new machine not only enhances the company's capabilities but also demonstrates its dedication to delivering superior metal roofing products to its customers.Furthermore, the introduction of the metal roofing roller machine has had a positive impact on {Company}'s operations. The increased efficiency and productivity have allowed the company to fulfill orders in a timelier manner, leading to greater customer satisfaction and loyalty. With the ability to produce a wider variety of metal roofing products, {Company} has also expanded its market reach and appeal, attracting new clients and opportunities for growth."We are thrilled to announce the addition of the metal roofing roller machine to our production facility," said {Spokesperson}, CEO of {Company}. "This investment represents a significant milestone for {Company} and underlines our dedication to providing high-quality metal roofing solutions to our customers. The new machine will enable us to meet the growing demand for our products while maintaining the highest standards of excellence."{Company} has a strong track record in the metal roofing industry, with a reputation for delivering superior products and exceptional customer service. The investment in the metal roofing roller machine further solidifies the company's position as an industry leader, setting the bar for quality and innovation in the market.With the new metal roofing roller machine in place, {Company} is poised to elevate its production capabilities and set new standards for metal roofing solutions. As the company continues to leverage advanced technology and expertise, customers can expect top-notch metal roofing products that meet their specific needs and exceed their expectations.As {Company} propels forward with its commitment to excellence, the future looks bright for both the company and its customers. The investment in the metal roofing roller machine is a testament to {Company}'s dedication to staying at the forefront of the industry, and as a result, customers can look forward to even more reliable, durable, and aesthetically appealing metal roofing solutions from {Company}.

Modern Manual Handling Solutions: Electric Lifters & Walkie Stackers for Pallet Stacking Jobs

Manual Stacker for the Shape C Purline Machine: Introducing Modern Manual Handling SolutionsIn the world of manufacturing and industrial operations, forklifts have always been the go-to solution for various material handling tasks. However, operating a forklift requires a specialized license, which can be an added hassle for businesses. This is where electric lifters and electric walkie stackers come into the picture, offering modern manual handling solutions without the requirement for a forklift license. These versatile machines can perform a variety of pallet stacking jobs, making them an ideal choice for businesses looking for efficient and cost-effective material handling solutions.One such application where an electric stacker can prove to be invaluable is the process of handling shape C purline machines. Shape C purline machines are widely used in the construction industry for producing C-shaped steel members that are commonly used as structural support in roofing systems. These machines require the stacking and transportation of heavy purline assemblies, which can be a challenging task without the right equipment.By utilizing an electric stacker with a capacity of 1 to 1.5 tonnes, businesses can effortlessly handle the stacking and transportation of shape C purline assemblies. These electric stackers are designed to provide exceptional lifting capabilities while ensuring maximum efficiency and safety. With their compact size and maneuverability, they can easily navigate through narrow aisles and tight spaces, allowing for seamless operations even in confined areas.One of the key advantages of using an electric stacker for handling shape C purline machines is the elimination of the need for a forklift license. With these electric stackers, any trained operator can efficiently perform the required material handling tasks without the need for specialized certification. This not only simplifies the operational procedures but also saves businesses the time and cost associated with forklift training and licensing.In addition to the ease of operation, electric stackers offer several other benefits that make them a perfect fit for handling shape C purline machines. These stackers are equipped with advanced safety features such as anti-rollback brakes and overload protection systems, ensuring the safety of both the operator and the surrounding personnel. Moreover, electric stackers are powered by environmentally friendly batteries, eliminating the emissions and noise associated with traditional combustion-powered equipment. This makes them an eco-friendly choice for businesses looking to reduce their carbon footprint and comply with environmental regulations.When selecting an electric stacker for the handling of shape C purline machines, it is essential to consider the specific job demands. The capacity of the stacker, ranging from 1 to 1.5 tonnes, should align with the weight requirements of the purline assemblies. Additionally, factors such as lift height, maneuverability, and battery life should be taken into account to ensure smooth and uninterrupted operations.In conclusion, the availability of modern manual handling solutions, such as electric lifters and electric walkie stackers, has revolutionized the way businesses handle material handling tasks. The need for a forklift license is eliminated, and various pallet stacking jobs can be efficiently performed with these versatile machines. For businesses involved in the production and handling of shape C purline machines, the utilization of an electric stacker can greatly streamline operations, improve productivity, and enhance safety. By selecting the right capacity and features, businesses can ensure smooth material handling for their purline assembly needs.