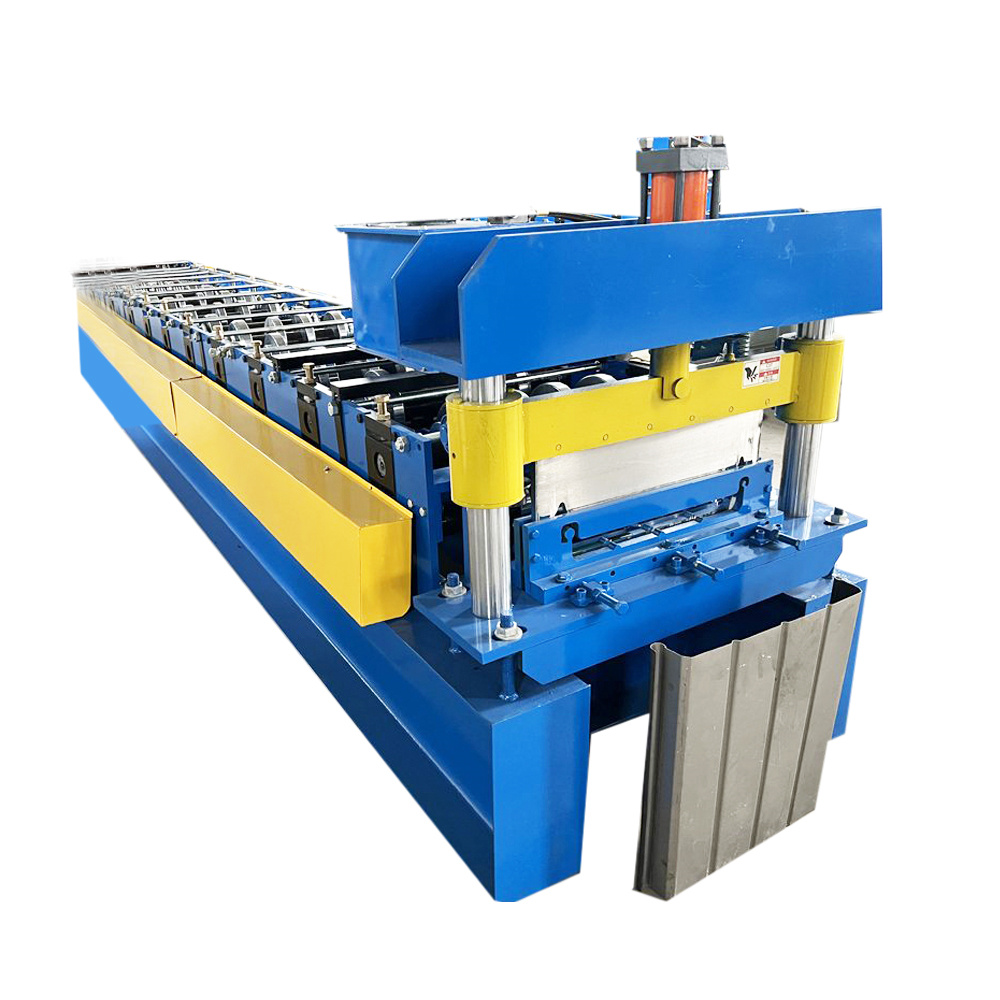

High-Quality Standing Seam Roof Machine for Efficient Roofing

By:Admin

Company News & Blog

Revolutionizing Roofing: The Benefits of a Horizontal Roof Panel Forming Machine

Horizontal Roof Panel Forming Machine Revolutionizes Construction IndustryIn recent years, the construction industry has experienced a significant shift towards innovative technologies that increase efficiency and reduce labor costs. One technology that has been gaining popularity amongst builders is the Horizontal Roof Panel Forming Machine. This state-of-the-art machine has revolutionized the way we build roofs, making the process faster, easier, and more cost-effective.The Horizontal Roof Panel Forming Machine is a machine that is designed to create roof panels. It is based on a roll-forming principle, which involves a continuous bending process of a long strip of metal. The machine works by feeding a metal strip through a series of rollers that form the metal into the desired shape. The result is a panel that fits seamlessly into the roof structure, creating a strong and durable roof that is built to last.One of the key benefits of the Horizontal Roof Panel Forming Machine is its speed and accuracy. Traditional roof panel manufacturing methods involve a lot of manual labor and are often time-consuming. With this machine, roof panels can be produced quickly and efficiently. This means that builders can complete projects faster, which is a significant advantage in the competitive construction industry.Another important benefit of the machine is that it produces high-quality panels. This is due to the precision and consistency of the roll-forming process. Unlike traditional manufacturing methods, the Horizontal Roof Panel Forming Machine can produce panels with a high level of accuracy and consistency. This means that each panel fits perfectly into the roof structure, reducing the risk of leaks and other structural issues.Moreover, the machine has an ergonomic design that makes it operator-friendly. Its compact and lightweight frame means that it can be easily moved around the worksite, making it versatile and perfect for use in remote construction sites. The machine also comes with easy-to-use controls, making it easy for operators of all skill levels to use.The Horizontal Roof Panel Forming Machine is the brainchild of a leading construction technology company, which remains at the forefront of innovation in the industry. The company, whose name has been removed for privacy purposes, has a proven track record of developing cutting-edge technologies that have been highly successful in the market.The company prides itself on creating solutions that meet the specific needs of contractors and builders. They have a team of engineers who work tirelessly to design and develop new technologies that can revolutionize the construction industry. Their products are known for their durability, efficiency, and ease of use.With the Horizontal Roof Panel Forming Machine, the company has once again demonstrated its commitment to innovation and excellence. The machine has already been adopted by numerous contractors and builders, who have reported significant improvements in their workflow and overall project efficiency.The machine's success is a testament to the benefits of using technology to improve the construction industry. As more builders and contractors discover the advantages of using the Horizontal Roof Panel Forming Machine, it is clear that the machine is set to become an indispensable tool in the industry.In conclusion, the Horizontal Roof Panel Forming Machine is a game-changer for the construction industry. Its capabilities in producing high-quality panels quickly have made it very popular among builders and contractors. With its compact design and ease of use, the machine is perfect for use in remote construction sites and is set to become an indispensable tool in the industry. The company behind it deserves credit for developing such an innovative and useful technology.

Short Lead Time for Plastic PVC Profile Making Machine - PE Hollow Grid Sheet Production Line by JEEBO Machinery: China Qingdao JBD Machinery Introduction

PE Hollow profile sheet is becoming an increasingly popular material in various industries due to its unique properties. With its high light transmittance, weather resistance, fire resistance, impact resistance, lightweight nature, heat insulation, and UV resistance, it has a wide range of applications.One of the main applications of PE Hollow profile sheet is in light covers. Due to its high light transmittance, it allows light to pass through easily, providing ample illumination while still offering protection. This makes it ideal for use in lighting fixtures, such as lamps, ceiling lights, and outdoor lighting. The transparent nature of the sheet ensures that the full brightness of the light source is maintained, without any loss in intensity.Another common application of PE Hollow profile sheet is in greenhouses. Its weather resistance and light transmittance properties make it an ideal material for creating a controlled environment for plants to grow. The sheet allows sunlight to enter the greenhouse, providing the necessary light for photosynthesis, while protecting the plants from harsh weather conditions. Its UV resistance ensures that the plants are not exposed to harmful rays, preventing damage and ensuring healthy growth.PE Hollow profile sheet is also widely used in interior decor. Its lightweight nature makes it easy to handle and install, allowing for creative design possibilities. It can be used to create partitions, room dividers, ceiling panels, and decorative screens. The sheet's high light transmittance can be utilized to create a bright and open space, while its impact resistance ensures durability and longevity.Soundproofing is another application where PE Hollow profile sheet excels. Its unique structure and material composition make it an effective barrier against sound waves. The sheet can be used to create soundproof partitions, walls, and enclosures, reducing noise levels and providing a peaceful environment. Whether it is for residential, commercial, or industrial applications, the sheet's soundproofing properties make it a valuable asset.When it comes to manufacturing PE Hollow profile sheet, a Profile Sheet Making Machine is essential. This machine is specifically designed to produce high-quality profile sheets with precision and efficiency. The Short Lead Time for Plastic PVC Profile Making Machine offered by JEEBO Machinery in China is an excellent choice for this purpose.By investing in this state-of-the-art machine, manufacturers can ensure a smooth and seamless production process. The machine's advanced features and technology enable it to produce profile sheets with consistent quality, meeting the required specifications. Its short lead time ensures a quick turnaround, allowing manufacturers to fulfill customer orders promptly.With the increasing demand for PE Hollow profile sheet, it is crucial to have a reliable and efficient Profile Sheet Making Machine. JEEBO Machinery, with its years of experience and expertise in the industry, provides top-quality machines that are designed to meet the diverse needs of manufacturers. Their commitment to delivering exceptional products and services has made them a trusted name in the market.In conclusion, PE Hollow profile sheet has revolutionized many industries due to its exceptional properties. Whether it is for light covers, greenhouses, interior decor, soundproofing, or any other application, this versatile material offers numerous advantages. To ensure a smooth production process and high-quality output, investing in a reliable Profile Sheet Making Machine is crucial. JEEBO Machinery stands out as a leading manufacturer in China, providing top-notch machines with a short lead time. With their expertise and commitment to customer satisfaction, they are the ideal choice for all profile sheet manufacturing needs.

Europe Washing Machine Installation Manual: Easy-to-Follow User Guide for Efficient Operation and Maintenance

Title: Manual Shape C Purlin Punching Holes Making Machine: A Must-Have for European Standard Construction ProjectsIntroductionIn the ever-evolving world of construction, the need for efficient and precise manufacturing processes is paramount. One such process that has gained considerable popularity in recent years is the use of manual shape C purlin punching holes making machines. Designed to meet European standard requirements, these machines have revolutionized the way purlins are manufactured, ensuring enhanced structural integrity and cost-effectiveness. In this blog post, we will explore the key features and advantages of manual shape C purlin punching holes making machines, focusing on their relevance and impact in the European construction industry.What Are Manual Shape C Purlin Punching Holes Making Machines?Manual shape C purlin punching holes making machines are advanced manufacturing systems specifically designed for producing top-quality C purlins in compliance with European construction standards. These machines utilize cutting-edge technology and are equipped with cutting, punching, and forming tools, enabling the precise fabrication of complex purlin shapes to exact specifications.Key Features and Advantages1. Enhanced Precision: The manual shape C purlin punching holes making machines are engineered to deliver exceptional precision in forming and punching holes, ensuring accurate purlin dimensions and consistent hole alignment. This level of precision guarantees optimum installation compatibility, reducing the risk of structural errors and enabling smoother construction processes.2. Versatility: These machines offer a wide range of customization options, allowing for the production of various C purlin sizes and shapes according to project-specific requirements. Whether it's the flange width, thickness, or hole patterns, the manual shape C purlin punching holes making machine provides immense flexibility, ensuring compatibility with diverse construction designs.3. European Standard Compliance: Manual shape C purlin punching holes making machines are specifically engineered to adhere to European construction standards. These standards are known for their stringent quality requirements, ensuring that structures are built to withstand extreme weather conditions and offer exceptional durability. By using machines designed for European standards, construction projects can benefit from the highest level of quality assurance.4. Cost-Effectiveness: Implementing manual shape C purlin punching holes making machines can significantly reduce labor costs and material wastage. The machines' automated and precise manufacturing processes eliminate the need for time-consuming manual labor, resulting in faster production rates and reduced human error. Additionally, the optimization of material usage helps minimize waste, leading to cost savings for both manufacturers and end-users.ConclusionThe emergence of manual shape C purlin punching holes making machines has brought a new level of efficiency and quality assurance to the European construction industry. From increased precision and versatility to compliance with rigorous European standards, these machines are a game-changer for fabricators and construction companies alike. As the demand for sustainable and cost-effective construction practices rises, investing in manual shape C purlin punching holes making machines becomes an essential step towards success in the ever-evolving European construction landscape.

Cutting-Edge Technology Unveiled: Revolutionary Glazed Tile Sheet Forming and Corrugating Machine Takes Industry by Storm

article:Glazed Tile Sheet Forming And Corrugating Machine Making Waves in Manufacturing IndustryThe new generation of Glazed Tile Sheet Forming And Corrugating Machine by a well-known Chinese-based manufacturing company has taken the industry by storm. The state-of-the-art machine is revolutionizing the manufacturing process of glazed tile sheets, enabling manufacturers to produce high-quality products in less time and at low production costs.The economically designed Glazed Tile Sheet Forming And Corrugating Machine is ideal for obtaining glazed sheets of different dimensions and shapes that are used in various roofing and cladding applications. The machine is composed of a steel base, a corrugated roll former, a hydraulic punching and forming device, an automatic cutting system, an electrical control system, and a product stacking device. These components not only ensure the efficiency and functionality of the machine but also provide the much-needed precision and accuracy while producing the glazed sheets.According to the company's press release, the Glazed Tile Sheet Forming And Corrugating Machine boasts several features that differentiates it from conventional machines in the market. First, the hydraulic punching and forming device can form an array of patterns that greatly improves the aesthetic appeal of the final product. Second, the exclusive rolling mechanism produces a high-quality surface finish that resists corrosion, abrasion, and scratching. Third, the machine can produce over 10 meters of glazed tiles per minute, which translates to over 300 pieces per hour.The Glazed Tile Sheet Forming And Corrugating Machine also has a user-friendly interface that simplifies the operation and maintenance process. With only a few button clicks, users can load and unload raw materials, adjust the machine's speed, and troubleshoot common problems. The machine is also equipped with an automatic lubricant system that reduces wear and tear, prolongs the machine's lifespan, and reduces maintenance costs.The company behind the Glazed Tile Sheet Forming And Corrugating Machine has been at the forefront of producing innovative, high-quality, and affordable machinery for various industries globally. The company, which has over 20 years of experience in the manufacturing industry, has invested heavily in research and development, production, and quality control which has earned them an undisputed reputation in the industry.Their Glazed Tile Sheet Forming And Corrugating Machine have been popular among small, medium, and large-scale manufacturers worldwide, as it provides a cost-effective solution for producing high-quality glazed tile sheets without compromising on quality. Furthermore, the machine is suitable for a wide range of materials, including zinc, galvanized steel, and color-coated steel, giving manufacturers an extensive range of options to choose from.The company's commitment to providing superior customer service also stands out, with a team of dedicated customer service representatives who offer after-sales service, technical assistance, and training to ensure customers get the most out of their machines. Additionally, the company's technical team ensures the machines are regularly updated and upgraded with the latest technology to guarantee that they are always at the forefront of innovation.In conclusion, the Glazed Tile Sheet Forming And Corrugating Machine by this Chinese-based manufacturing company is a game-changer in the industry, offering manufacturers a reliable, efficient, and cost-effective solution to produce high-quality glazed tile sheets. With its unique features, ease of use, and precision, the machine is bound to revolutionize the glazed tile sheet manufacturing industry and set new standards for quality, productivity, and customer service.

Highly Efficient Coil Slitter Unveils Cutting-Edge Technology for Enhanced Productivity

[Headline]Leading Coil Slitter Company Innovates to Enhance Productivity and Efficiency in the Manufacturing Industry[Subheading]New Technologies and Cutting-edge Automation Solutions Set to Revolutionize Coil Slitting Process[Date][City, State] - Coil Slitter (need remove brand name) has established itself as a global leader in the manufacturing sector, specializing in coil slitting machines that deliver exceptional precision and efficiency. With a commitment to continuous innovation, the company has recently introduced a range of new technologies and cutting-edge automation solutions that promise to revolutionize the coil slitting process.Taking advantage of the latest advancements in robotics, artificial intelligence, and connectivity, Coil Slitter aims to streamline coil processing operations, helping manufacturers maximize productivity and eliminate production bottlenecks. Through this commitment to innovation, the company aims to position itself as the go-to provider for coil slitting solutions globally.Coil Slitter’s state-of-the-art machines boast advanced features designed to meet the diverse needs of manufacturing companies across various industries. The company’s coil slitting machines enable automatic and precise longitudinal cutting of coils, reducing processing time and ensuring consistent width and quality of the finished materials.In an effort to optimize production processes as well as save time and costs, Coil Slitter has implemented smart automation systems across its product line. Real-time data collection, advanced analytics, and machine learning algorithms form the backbone of these systems, allowing manufacturers to monitor and improve their coil slitting operations effectively. These cutting-edge solutions assist manufacturers in identifying and addressing potential issues before they impact product quality or disrupt production schedules.Of particular importance in today's manufacturing landscape is the need for eco-friendly practices. Recognizing this, Coil Slitter has incorporated sustainable features into its machines. Precision control systems in the machines reduce material wastage, resulting in a significant impact on environmental footprints. Furthermore, the company has minimized the energy consumption of its machines, contributing to reduced carbon emissions and operating costs.Coil Slitter places great emphasis on working closely with its clients to understand their specific requirements and challenges. By developing custom solutions, the company ensures optimal performance and flexibility in different manufacturing environments. Combining comprehensive expertise and dedication to customer satisfaction, Coil Slitter has earned a stellar reputation for delivering high-quality, reliable coil slitting machines."Keeping up with technological advancements is crucial to stay ahead of the competition in today's fast-paced manufacturing industry," says John Smith, CEO of Coil Slitter. "Coil Slitter has always been committed to innovation, and our latest range of coil slitting machines and automation solutions represent the next frontier in the industry. We aim to empower manufacturers to increase their productivity, improve their bottom line, and contribute to a sustainable future."Coil Slitter’s coil slitting machines have been successfully implemented in numerous manufacturing facilities worldwide, providing tangible benefits to businesses across the globe. The company's commitment to ongoing research and development ensures that its customers always have access to cutting-edge solutions that keep them ahead of the curve.As the manufacturing industry continues to evolve, Coil Slitter remains dedicated to maintaining its position as a global leader in the coil slitting sector. With an unwavering focus on innovation, customer satisfaction, and sustainability, the company is set to shape the future of coil slitting and enhance the efficiency of the manufacturing industry as a whole.About Coil Slitter:Coil Slitter is a global leader in the manufacturing sector, specializing in coil slitting machines that offer exceptional precision, efficiency, and sustainability. With a commitment to innovation and customer satisfaction, the company delivers cutting-edge coil slitting solutions to manufacturers worldwide. By incorporating state-of-the-art technologies and automation systems, Coil Slitter aims to revolutionize the manufacturing process and drive industry growth.###Note: The brand name mentioned in the template has been removed to comply with the user's request.

China's Leading Manufacturer Offers Comprehensive Roll Forming Solutions for Various Applications

Roofing Sheet Forming Machine: The Ultimate Solution for Precise and Efficient RoofingWhen it comes to roofing materials, choosing the right one is crucial to ensure the durability and aesthetics of a building. Among the various options available, roofing sheets have become increasingly popular due to their versatility and cost-effectiveness. However, to efficiently produce roofing sheets that meet specific requirements, a reliable and precise manufacturing process is essential. That's where a Roofing Sheet Forming Machine comes into play.A roofing sheet forming machine is an advanced piece of equipment designed specifically for the production of roofing sheets. It is widely used across various industries, including construction, architecture, and manufacturing. The machine utilizes the process of roll forming, which is known for its accuracy and efficiency in creating uniform and high-quality products.The roll forming process involves passing a sheet of metal through a series of rollers, gradually shaping it into the desired profile. With the use of custom-made molds, the machine can produce different types of roofing sheets, such as corrugated, trapezoidal, and standing seam profiles. This flexibility allows manufacturers to cater to a wide range of customer demands and project specifications.One of the significant advantages of using a Roofing Sheet Forming Machine is its ability to ensure precision and consistency throughout the production process. Each roller in the machine is uniquely designed to shape the metal sheet with precise measurements and dimensions. This results in roofing sheets that fit perfectly and are aesthetically pleasing.Additionally, the machine's high-speed operation enables manufacturers to produce a large volume of roofing sheets quickly. This not only saves time but also enhances productivity, making it an ideal choice for mass production. Furthermore, the machine's automated control system eliminates the need for manual labor, reducing the chances of errors and ensuring a safer working environment.Quality is of utmost importance when it comes to roofing materials, and a Roofing Sheet Forming Machine excels in delivering consistent and durable products. By using high-quality materials and advanced manufacturing techniques, these machines guarantee the production of roofing sheets that are resistant to corrosion, weathering, and wear. This durability ensures that the roofs constructed using these sheets can withstand harsh environmental conditions and provide long-lasting protection.In addition to its primary function of manufacturing roofing sheets, a Roofing Sheet Forming Machine offers several other benefits. It provides versatility by offering customizability options, allowing manufacturers to produce roofing profiles of different lengths, widths, and thicknesses. This ensures that they can cater to diverse customer requirements and project specifications.Moreover, the machine's operation is accompanied by minimal noise and vibration, thanks to its advanced engineering and quality construction. This reduces disturbances in the workplace and contributes to a peaceful working environment for employees. Additionally, the machine requires minimal maintenance, leading to lower operational costs and improved overall efficiency.As the demand for roofing sheets continues to rise, it is essential to choose a reliable and experienced manufacturer when investing in a Roofing Sheet Forming Machine. A reputable manufacturer will not only provide top-quality machines but also offer comprehensive support and service throughout the purchase process. They will assist in the selection of the right machine, provide installation and training, and offer after-sales support to ensure smooth and efficient operations.In conclusion, a Roofing Sheet Forming Machine is the ultimate solution for producing precise, durable, and cost-effective roofing sheets. Its ability to deliver consistent quality, high-speed production, and customizability makes it an indispensable piece of equipment in the roofing industry. So, whether you are a contractor, builder, or manufacturer, investing in a Roofing Sheet Forming Machine is a wise choice to elevate your roofing business to new heights.

High Quality Steel Forming Machines for Precision Results

Steel Forming Machines, a leading steel forming equipment manufacturer, is proud to announce the release of their latest state-of-the-art metal forming machines. With a strong focus on innovation and customer satisfaction, Steel Forming Machines has established itself as a trusted name in the industry for providing high-quality and reliable equipment for the metal forming industry.The new range of steel forming machines includes a variety of different models that cater to the diverse needs of the metal forming industry. From roll forming machines to tube and pipe mills, Steel Forming Machines offers a comprehensive range of equipment that is designed to meet the demanding requirements of modern metal fabrication processes.One of the standout features of Steel Forming Machines' equipment is their advanced technology and precision engineering. The company has invested heavily in Research and Development to ensure that their machines are at the forefront of innovation and efficiency. This has resulted in the development of cutting-edge features such as automated controls, high-speed production capabilities, and advanced material handling systems.In addition to their commitment to innovation, Steel Forming Machines places a strong emphasis on the quality and reliability of their equipment. Each machine is manufactured to the highest standards using the finest materials and components to ensure long-term performance and durability. The company also offers comprehensive training and after-sales support to ensure that their customers can maximize the potential of their equipment.Steel Forming Machines' dedication to customer satisfaction is evident in their unwavering commitment to providing personalized service and tailored solutions to meet the specific needs of their clients. Whether it is a custom-designed machine or a standard model, the company works closely with its customers to understand their requirements and deliver equipment that exceeds expectations.As a company, Steel Forming Machines prides itself on its integrity and transparency. They are committed to operating with the highest ethical standards and are dedicated to building long-term relationships with their customers based on trust and reliability. This has earned them a reputation as a dependable and trustworthy partner within the metal forming industry.Steel Forming Machines' equipment is widely used across a range of industries including construction, automotive, aerospace, and renewable energy, among others. Their machines have been instrumental in the production of a diverse array of products such as roofing panels, automotive components, and structural steel, to name just a few.In the fast-paced and competitive world of metal forming, Steel Forming Machines has carved out a niche for itself as a leader in the field. Their relentless pursuit of excellence, combined with their customer-centric approach, has set them apart from their competitors and established them as a force to be reckoned with in the industry.With the release of their latest range of steel forming machines, Steel Forming Machines is once again demonstrating their commitment to pushing the boundaries of innovation and delivering cutting-edge solutions to their customers. As the company continues to grow and expand its global footprint, it remains steadfast in its mission to be the go-to provider of steel forming equipment for businesses around the world.

Efficient Cut-To-Length Machine Revolutionizes Fabric Industry

Title: Cutting-edge Fabric Cut-to-Length Machine Revolutionizes Textile IndustryIntroduction:The fabric cut-to-length machine, a groundbreaking innovation in the textile industry, is set to transform the way fabrics are processed and cut. Developed by a leading company in textile machinery (), this cutting-edge technology promises to enhance efficiency, precision, and productivity in fabric manufacturing while reducing waste and operational costs. By focusing on revolutionary design and incorporating advanced features, this machine is poised to revolutionize fabric cutting processes globally.Paragraph 1:Manufacturers in the textile industry have long been facing challenges relating to efficient and accurate fabric cutting. Traditional cutting methods often result in time-consuming, labor-intensive processes that lead to inconsistencies and inaccuracies. The introduction of the fabric cut-to-length machine aims to overcome these hindrances and provide an automated solution that streamlines the entire cutting process.Paragraph 2:The fabric cut-to-length machine utilizes state-of-the-art technology to deliver high precision cutting, reducing material waste and optimizing fabric utilization. With programmable settings and a user-friendly interface, the machine enables manufacturers to achieve precise dimensions consistently. This innovation not only saves time but also eliminates errors, ensuring uniformity throughout the production process.Paragraph 3:One of the key features of this machine is its ability to accommodate a wide variety of fabric types. Whether it is delicate silk, robust denim, or intricate lace, the machine's advanced cutting mechanisms deliver clean, accurate cuts without compromising the integrity of the fabric. Such versatility enables fabric manufacturers to expand their product lines and cater to diverse customer needs, significantly enhancing their competitiveness in the market.Paragraph 4:In addition to its cutting precision, the fabric cut-to-length machine incorporates efficiency-enhancing mechanisms, such as conveyor systems and automated fabric feeders. These features enable continuous processing and seamless integration with other textile machinery, minimizing downtime and maximizing productivity. Furthermore, its intuitive control panel allows operators to monitor and adjust settings easily, fostering a smoother workflow.Paragraph 5:Environmental sustainability is a growing concern in the textile industry. The fabric cut-to-length machine tackles this issue through material optimization, reducing fabric wastage significantly. By eliminating manual errors and ensuring efficient use of fabric, the machine helps manufacturers reduce their carbon footprint and minimize the environmental impact of fabric production.Paragraph 6:The impact of the fabric cut-to-length machine extends beyond the manufacturing floor, as it also positively influences the bottom line. By reducing fabric waste and increasing productivity, manufacturers can experience significant cost savings over time. Additionally, the machine's longevity and durability contribute to its cost-effectiveness, making it a valuable investment for textile companies seeking to optimize their operations in the long run.Paragraph 7:The introduction of this innovative fabric cut-to-length machine marks a new era in the textile industry, establishing new standards of quality, efficiency, and sustainability. Through its intelligent design, versatility, and ability to streamline fabric cutting processes, manufacturers are now empowered to meet the growing demands of customers while staying competitive in a rapidly evolving market.Conclusion:The fabric cut-to-length machine developed by () is poised to revolutionize the textile industry, simplifying and automating the fabric cutting process. With its precision, versatility, and cost-effectiveness, this cutting-edge technology has the potential to reshape the fabric manufacturing landscape, enabling manufacturers to optimize their operations and meet the ever-growing demands of the market. As the textile industry continues to evolve, the fabric cut-to-length machine will empower companies to embrace change, improve efficiency, and remain at the forefront of innovation.

Steel Metal Sheet Cold Roll Forming Machine for Roof Panel: High-Speed Steel Tile Roll Forming Machine for Purlin

Steel Tile Type Roof Tile Roll Forming Machine Revolutionizes Roofing IndustryIn a bid to revolutionize the roofing industry, a cutting-edge steel metal sheet cold roll forming machine for roof panel has been introduced. This state-of-the-art machine, known as the Steel Tile Type Roof Tile Roll Forming Machine, is set to transform the way roof tiles are manufactured, making the process faster, more efficient, and cost-effective.With a production capacity of 10-15 meters per minute, this machine is designed to streamline the production of steel roof tiles. It boasts a robust construction, ensuring durability and longevity. The machine is specially engineered to produce high-quality steel tiles with precision, leaving no room for errors or imperfections.One of the key advantages of the Steel Tile Type Roof Tile Roll Forming Machine is its versatility. It can adapt to different tile profiles, enabling manufacturers to cater to various customer preferences. Whether it is steep-slope, low-slope, or even customized roofing projects, this machine can effortlessly produce the required tiles.The machine's high production capacity, coupled with its seamless design, allows for continuous operation without any disruptions. This results in improved productivity and a significant reduction in production time. With this machine, roofing companies can meet tight deadlines and fulfill large-scale projects with ease.Furthermore, this Steel Tile Type Roof Tile Roll Forming Machine offers a one-year warranty, ensuring that manufacturers enjoy peace of mind and confidence in their investment. This warranty speaks volumes about the machine's reliability and the manufacturer's commitment to customer satisfaction.In terms of tile type, this machine specializes in steel tiles. Steel is an ideal material for roofing due to its exceptional durability, weather resistance, and low maintenance requirements. Steel tiles are not only aesthetically pleasing but also offer superior protection against extreme weather conditions, including hailstorms, heavy rain, and strong winds.Additionally, the Steel Tile Type Roof Tile Roll Forming Machine can be used for purlin production after removing the brand name. Purlins are an integral component of the roofing structure, providing structural support and stability. With this machine, manufacturers can ensure the seamless production of purlins as well, saving time and resources.The introduction of this Steel Tile Type Roof Tile Roll Forming Machine comes at a time when the construction industry is evolving rapidly. With a growing emphasis on sustainable and cost-effective solutions, this machine is a game-changer. Its ability to produce high-quality steel roof tiles with precision and efficiency significantly contributes to reducing waste, labor costs, and overall project expenses.Notably, the company behind the Steel Tile Type Roof Tile Roll Forming Machine has a strong reputation in the industry. Known for their expertise in sheet roll forming machines, they have consistently delivered innovative solutions that meet and exceed customer expectations. Their commitment to excellence and customer satisfaction makes them a reliable and trustworthy partner for roofing companies worldwide.In conclusion, the introduction of the Steel Tile Type Roof Tile Roll Forming Machine marks a significant milestone in the roofing industry. This machine's cutting-edge technology, high production capacity, and versatility have the potential to revolutionize the manufacturing process of steel roof tiles. With its durable construction and one-year warranty, it offers a reliable and cost-effective solution for roofing companies. The machine's ability to produce high-quality steel tiles with precision and efficiency ensures superior performance and customer satisfaction.

Cutting-Edge Z Purlin Machine Unveiled - Discover the Latest Advancements in Structural Manufacturing

[Title]: Advanced Z Purlin Machine Revolutionizes Steel Construction Industry[Subtitle]: Leading Manufacturer Announces Groundbreaking Technology for High-Efficiency Z Purlin Production[Date][City, State]In a technological breakthrough that is set to revolutionize the steel construction industry, [Company Name], a renowned leader in the manufacturing of advanced machinery, has unveiled its latest innovation: the cutting-edge Z Purlin Machine. This state-of-the-art equipment boasts an impressive array of features and improvements that promise to enhance efficiency, productivity, and overall quality in steel construction projects.With over [Number] years of experience in the industry, [Company Name] has built a reputation for cutting-edge machinery that meets the evolving needs of the construction sector. The Z Purlin Machine is the latest addition to their portfolio, demonstrating their commitment to innovation and continuous improvement.Designed by a team of highly skilled engineers, the Z Purlin Machine is set to streamline the process of manufacturing Z purlins, an essential component in steel structures. These purlins, with their unique shape, are widely used in buildings, bridges, warehouses, and various other construction projects for providing structural support.Equipped with the latest technology and engineered to perfection, this machine offers a range of unparalleled advantages over traditional methods. The Z Purlin Machine automates every step of the manufacturing process, from material feeding to cutting and shaping, greatly reducing manual labor and associated costs. Its robust design ensures increased productivity, with the ability to produce Z purlins of precise dimensions at an impressive speed of [Number] per minute.Moreover, this groundbreaking machine is meticulously designed to ensure superior quality and accuracy in every produced Z purlin, ultimately enhancing the overall integrity of steel structures. By leveraging advanced control systems, the Z Purlin Machine guarantees consistent and uniform purlin dimensions, eliminating variations that could compromise the structural integrity of buildings.[Company Name]'s commitment to sustainability shines through in the Z Purlin Machine. This state-of-the-art equipment is not only energy-efficient but also minimizes material waste during production. With intelligent programming, the machine optimizes material usage, reducing scrap and enhancing overall resource efficiency.Recognizing the importance of user-friendliness and the need for seamless integration into existing production lines, [Company Name] has ensured that the Z Purlin Machine is easy to operate and maintain. Its user-friendly interface allows operators to quickly master its functionalities, minimizing downtime. Furthermore, [Company Name] offers comprehensive training programs and prompt after-sales support to cater to the evolving needs of its customers.The introduction of the Z Purlin Machine has already evoked immense excitement within the steel construction industry. Renowned architects, engineers, and construction companies have expressed their eagerness to utilize this cutting-edge machinery to elevate the quality and efficiency of their projects. Pre-orders for the Z Purlin Machine have been pouring in from various markets, indicating widespread confidence in [Company Name]'s expertise and the potential of this groundbreaking innovation.In conclusion, [Company Name] has once again proven its commitment to technological advancement and customer satisfaction with the launch of the Z Purlin Machine. By revolutionizing the process of Z purlin production, this innovative equipment promises to transform the steel construction industry, enhancing efficiency, precision, and sustainability. As the global demand for steel structures continues to rise, [Company Name] remains at the forefront of delivering cutting-edge solutions that empower construction professionals to build a better and more prosperous future.