Steel Roll Forming Machine for GP GI Color Sheets: The Ultimate Guide

By:Admin

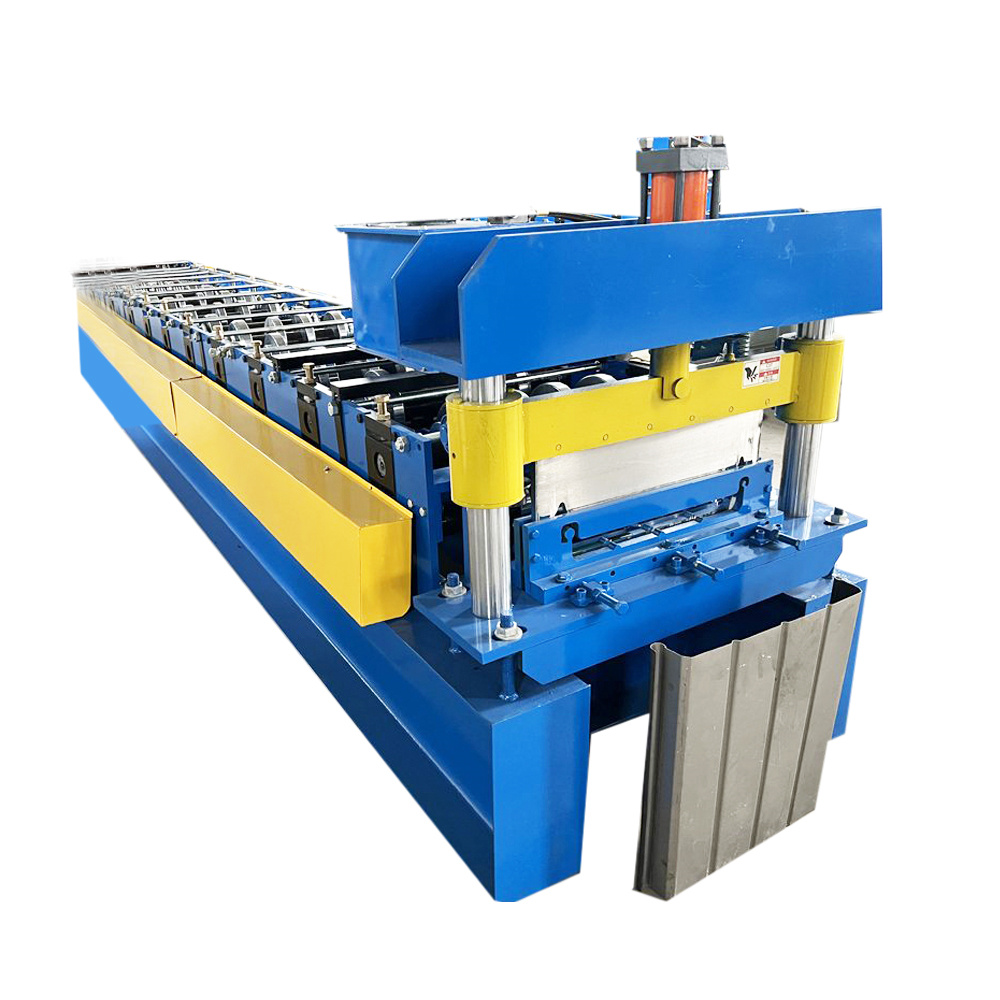

The GP GI Color Steel Roll Forming Machine is the latest addition to the company's line of roll forming equipment. With its cutting-edge technology and precision engineering, this machine is capable of producing a wide range of steel products, including roofing panels, wall cladding, and structural components with remarkable speed and accuracy. The machine's ability to work with galvanized and pre-painted steel makes it a versatile solution for a variety of applications in the construction and manufacturing industries.

The company behind this groundbreaking machine has a long history of delivering top-notch metal forming solutions to its clients. With years of experience in the industry, the company has established itself as a leader in the field of roll forming equipment, offering a comprehensive range of products and services to meet the diverse needs of its customers. From custom design and engineering to manufacturing and installation, the company provides end-to-end solutions to ensure the success of its clients' projects.

In addition to its commitment to excellence in manufacturing, the company also prioritizes innovation and continuous improvement in its operations. The GP GI Color Steel Roll Forming Machine is a prime example of this dedication to staying at the forefront of technology and offering cutting-edge solutions to its clients. By investing in state-of-the-art equipment like this roll forming machine, the company demonstrates its commitment to meeting the evolving needs of the market and maintaining its position as a leading provider of metal forming solutions.

The GP GI Color Steel Roll Forming Machine is not only a testament to the company's expertise in metal forming but also a reflection of its dedication to sustainability and environmental responsibility. With its efficient production processes and high-quality output, this machine enables the company to minimize waste and reduce its environmental footprint. By choosing this machine for their steel forming needs, clients can be confident that they are investing in a sustainable and eco-friendly solution.

In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is backed by a team of skilled and knowledgeable professionals who are committed to providing exceptional service and support to clients. From technical assistance and training to ongoing maintenance and customer support, the company's team is dedicated to ensuring the success of every project and the satisfaction of every client. With their expertise and dedication, clients can trust that they are in good hands when they choose the GP GI Color Steel Roll Forming Machine.

In conclusion, the introduction of the GP GI Color Steel Roll Forming Machine represents a significant milestone for the company and the industry as a whole. With its advanced technology, commitment to excellence, and focus on sustainability, this machine sets a new standard for steel forming equipment. As the company continues to push the boundaries of innovation and deliver top-quality solutions to its clients, the GP GI Color Steel Roll Forming Machine stands as a testament to its dedication to excellence and its vision for the future of metal forming.

Company News & Blog

Top Color Steel Glazed Tile Corrugation Equipment for Efficient Production

Color Steel Glazed Tile Corrugation Equipment Meeting Increasing Demand for Premium Building MaterialsAs the global construction industry grows in size and complexity, the demand for high-quality building materials continues to increase. In an effort to meet this demand and drive industrial innovation, Color Steel Glazed Tile Corrugation Equipment (Name of brand removed) has designed and produced a cutting-edge system that delivers premium roofing sheets and wall panels with remarkable precision and efficiency.With over 20 years of experience in manufacturing and engineering, Color Steel Glazed Tile Corrugation Equipment is a trusted leader in the industry that helps companies around the world transform their construction operations. From metal sheets and glazed tiles to corrugated panels and roof ridges, their equipment excels in delivering high-performance building materials that are essential to the construction of modern-day structures.The new Color Steel Glazed Tile Corrugation Equipment is no exception. This innovative production line takes advantage of advanced technologies to create materials that are not only visually appealing but also highly durable and weather-resistant. With a wide range of customization options, clients can easily adapt the equipment to meet their specific requirements to create roofing and wall panel products that stand out in the market.One of the key features of the Color Steel Glazed Tile Corrugation Equipment is its high level of flexibility. The production line can be used to create a wide variety of roofing and wall panel products in various shapes and sizes, including classic corrugated panels, glazed tiles, and classical tiles, both with and without an insulated core. This flexibility enables clients to offer a diverse range of products to their customers while maintaining exceptional quality and speed of production.Another major benefit of the equipment is its high level of accuracy. The production line is computer-controlled, ensuring that products are manufactured to precise standards every time. This accuracy results in dimensional stability, consistency, and perfect curvature of the final products, each of which is important to the successful completion of any construction project.At the heart of the design is the automatic color steel coil feeding and cut-to-length system, which guarantees that materials are processed quickly and efficiently with minimal waste. Additionally, the equipment features an automatic roll forming system and a pressing system for easy panel finishing and shaping.Color Steel Glazed Tile Corrugation Equipment takes pride in its machines' quality and longevity. Each production line component is made from high-quality materials and is designed by a team of experienced engineers to ensure consistent performance and long service life. Regular maintenance and customer service are also available to ensure that the equipment is operational and exceptionally dependable throughout its lifespan.Commenting on this new equipment, a spokesperson for Color Steel Glazed Tile Corrugation Equipment said, "Our innovative production line is designed to offer exceptional performance and versatility across various applications in the construction industry. Through the delivery of high-quality materials and products, we aim to provide cutting-edge solutions to our clients that enable them to stay ahead of the competition and meet the ever-increasing demands of their customers."In conclusion, the Color Steel Glazed Tile Corrugation Equipment is a versatile production line designed for the creation of high-quality building materials. With its cutting-edge technology, precision engineering, and flexibility, it is an essential tool for construction companies looking to innovate and deliver premium products to their customers. As demand for exceptional building materials continues to grow, Color Steel Glazed Tile Corrugation Equipment's new production line will provide construction companies with the competitive edge they need to succeed.

China Offers Comprehensive Roll Forming Solution for Diverse Applications

, Roll Forming Machine, Cold Roll Forming, China Roll Forming, One-Stop Solution, Consultation, Training, Applications.Roll forming is a common metal forming process used to shape metal into a specific profile or shape. It is achieved through a series of roll forming machines that progressively shape the metal until it reaches the desired shape. This process is commonly used in the production of metal building components, automotive parts, and consumer products.China is a major player in roll forming technology, with many domestic manufacturers providing roll forming machines and solutions. One of the leading manufacturers in China is MTC, which has built a reputation for providing high-quality roll forming machines and a one-stop solution for a range of applications.The MTC roll forming machine is a cold roll former, which means that it operates at room temperature. This is in contrast to hot roll forming, which requires the metal to be preheated before forming. The advantage of cold roll forming is that it can be used on a wider range of materials, including aluminum, steel, and other metals.MTC provides a comprehensive range of roll forming machines, including panel roll forming machines, roof panel machines, wall panel machines, and more. Each machine is tailored to the specific needs of the application, ensuring optimal performance and quality.One of the unique features of MTC is its one-stop solution for roll forming applications. This includes consultation, design, manufacturing, installation, and training. The MTC team works closely with clients to understand their needs and requirements, and then provides a tailored solution that meets those needs.The consultation phase is critical in determining the most appropriate roll forming machine for the specific application. MTC’s team of experts analyze factors such as the material being used, desired throughput, and other factors to recommend the best machine for the job.Once the design has been completed, MTC manufactures the roll forming machine to the highest standards. The company uses state-of-the-art equipment and processes to ensure maximum performance and reliability.Installation is carried out by MTC’s team of trained technicians, who work closely with the client to ensure that the machine is correctly installed and fully operational.Training is also a critical component of the MTC one-stop solution. The company provides comprehensive training to clients, ensuring that they are fully versed in the operation and maintenance of the roll forming machine. This ensures that clients are able to operate the machine to its full potential, and that any maintenance or repair needs are quickly identified and addressed.MTC’s one-stop solution has been successfully implemented across a range of applications, including building construction, automotive manufacturing, and consumer goods production. The company’s expertise and commitment to quality have made it a trusted partner for businesses around the world.In summary, MTC provides a one-stop solution for roll forming applications, including consultation, design, manufacturing, installation, and training. The company's cold roll forming machines are designed to deliver the highest levels of performance and reliability, and its team of experts works closely with clients to ensure that their specific needs are met. With a focus on quality and customer service, MTC is a trusted partner for businesses seeking roll forming solutions.

High-Quality Metal Stud Roll Formers: Enhance Efficiency in Stud Construction

Title: Revolutionary Metal Stud Roll Former Offers Unmatched Efficiency and VersatilityIntroduction:In the ever-evolving construction industry, the demand for innovative machinery and solutions has reached new heights. One such ground-breaking addition is the Metal Stud Roll Former, a cutting-edge machine that promises a paradigm shift in efficiency and versatility. Developed by a leading manufacturer in the industry, this industry-transforming solution aims to streamline the process of metal stud production, ensuring faster turnaround times and higher quality output.Unmatched Efficiency:Traditionally, the production of metal studs has relied heavily on manual labor and outdated machinery, resulting in a slow and labor-intensive process. With the introduction of the Metal Stud Roll Former, manufacturers can now experience unparalleled efficiency. This revolutionary machine automates the stud production process, reducing human error, and significantly increasing the speed of manufacturing.Equipped with advanced technology, the Metal Stud Roll Former boasts an impressive production rate of [insert production per hour], enabling manufacturers to meet tight project deadlines without compromising quality. By eliminating the need for manual labor, this machinery also minimizes the risk of workplace injuries and fatigue, promoting a safer working environment.Versatility Redefined:The Metal Stud Roll Former stands out from its predecessors due to its exceptional versatility. Unlike traditional roll formers, which limit manufacturers to specific stud dimensions, this technologically advanced machine accommodates an extensive range of stud sizes, shapes, and profiles. From standard C and U profiles to custom designs, the Metal Stud Roll Former offers limitless possibilities, making it an ideal choice for diverse construction projects.The machine's adjustable settings empower manufacturers to effortlessly switch between different stud dimensions, eliminating the need for multiple production lines and reducing production costs significantly. Moreover, the Metal Stud Roll Former adapts to various metal gauges, accommodating the ever-expanding range of material preferences in the industry.Precision and Quality Control:The Metal Stud Roll Former incorporates state-of-the-art sensors and precision mechanisms that ensure impeccable accuracy and consistent quality. These sensors detect and correct any irregularities throughout the production process, resulting in studs that meet the highest industry standards. Manufacturers can rely on this machinery to deliver flawless, dimensionally accurate studs that are ready for assembly, minimizing delays and rework.Ease of Operation and Maintenance:To enhance user experience, the Metal Stud Roll Former is designed with user-friendly controls and intuitive interfaces. Operators can quickly learn to operate the machine, reducing training time and improving overall productivity. Additionally, the machine's low maintenance requirements result in reduced downtime and increased profitability for manufacturers.Contribution to Sustainability:In an era where environmental sustainability is a significant concern, the Metal Stud Roll Former stands out as an environmentally responsible solution. By minimizing material waste through precise measurements and efficient manufacturing processes, this machinery significantly reduces the carbon footprint associated with stud production. Manufacturers can take pride in utilizing this innovative technology, playing their part in the sustainable growth of the construction industry.Conclusion:The Metal Stud Roll Former introduces a new era of efficiency, versatility, and precision to the construction industry. Its ability to enhance production rates, facilitate custom designs, and ensure consistent quality makes it an indispensable asset for metal stud manufacturers. By adopting this revolutionary machine, manufacturers can unlock new levels of productivity while keeping pace with the ever-changing demands of the construction market. As the industry continues to evolve, the Metal Stud Roll Former sets the benchmark for cutting-edge technology and marks a significant milestone in improving construction productivity.

New Innovations in Floor Forming Machines: Revolutionizing Construction Methods

Title: Innovative Floor Forming Machine Revolutionizes Construction IndustryIntroduction:In the era of rapid technological advancements, the construction industry is witnessing a wave of automation and innovation that aims to streamline processes, enhance efficiency, and ultimately deliver sustainable and quality structures. In line with this progress, an emerging player in the construction machinery sector has unveiled a state-of-the-art Floor Forming Machine, promising to reshape the way flooring is installed in buildings. This revolutionary technology is set to transform the industry by significantly reducing labor costs, minimizing material waste, and accelerating project timelines.Company Introduction:{Company Name} is a leading provider of cutting-edge construction machinery and equipment. With a dynamic team of engineers and experts, the company has consistently delivered innovative solutions that cater to the evolving needs and challenges of the construction industry. Its commitment to optimizing efficiency, promoting sustainability, and improving construction quality through advanced technologies has garnered the company numerous accolades and global recognition.Floor Forming Machine Overview:The newly introduced Floor Forming Machine showcases a comprehensive and integrated approach to floor construction. Its design revolves around four primary components, namely, the leveling system, the concrete dispensing unit, the reinforcement system, and the shuttering system. Ultimately, this complete package offers construction companies an all-in-one solution for floor formation, eliminating the need for multiple specialized machines and labor-intensive processes.The leveling system ensures precise leveling of the floor surface, allowing for accurate and consistent concrete distribution. By utilizing advanced sensors and automated controls, this component focuses on delivering a level slab foundation, thus minimizing inconsistencies caused by human error during traditional construction methods.The concrete dispensing unit, another crucial component of the Floor Forming Machine, ensures smooth and efficient concrete pouring. With the ability to adjust the rate of concrete flow and taking into account the specific requirements of each project, the machine significantly reduces material waste, resulting in cost savings and improved sustainability.The reinforcement system integrated into the machine incorporates an automated process for aligning and placing steel reinforcements within the concrete slab. By leveraging sophisticated robotics technology, the machine meticulously handles this critical aspect of flooring, ensuring structural integrity and reducing manual labor requirements.The shuttering system, the final component of the machine, caters to creating the definite shape and dimensions of the floor slab. It offers flexibility in adjusting the size and form of the slab to meet various project requirements. With its ability to seamlessly change forms and sizes, the machine can accommodate a wide range of floor designs with ease and precision.Benefits and Impact:The introduction of this Floor Forming Machine brings several noteworthy benefits to the construction industry:1. Enhanced Construction Efficiency: By streamlining multiple floor formation processes into a single automated solution, the machine significantly reduces construction timeframes. This accelerated pace allows for faster project completion, leading to potential cost savings and improved profitability.2. Reduced Labor Costs: The reliance on manual labor is considerably diminished with the implementation of the Floor Forming Machine. By automating key processes, construction companies can allocate their workforce more efficiently, reducing labor expenses and improving overall productivity.3. Minimized Material Waste: The precise control and adjustment capabilities of the machine during the concrete pouring process ensure optimal material utilization. With reduced material waste, projects become more sustainable, leading to cost savings and a reduced environmental footprint.4. Higher Quality Standards: The advanced technology implemented in the Floor Forming Machine ensures a higher level of precision during construction. This results in more accurate and level floor slabs, reducing the risk of structural issues and ensuring superior quality standards.Conclusion:The introduction of the Floor Forming Machine marks a significant step forward in modernizing the construction industry. Through its integrated approach, the machine streamlines floor formation processes, enhances construction efficiency, reduces labor costs, minimizes material waste, and upholds high quality standards. As construction companies increasingly adopt this innovative technology, it is expected to become a game-changer in the sector, fostering a new era of advanced and sustainable construction practices.

Boost Your Steel Coil Cutting Efficiency with a Cutting-Edge Slitting Line

Steel Coil Slitting Line Boosts Production Efficiency in Metal IndustryIn the ever-evolving metal industry, optimizing production processes has become essential for businesses to stay competitive. With the need for precise cuts and efficient operations, manufacturers are constantly seeking innovative solutions to streamline their processes and improve overall productivity. One such solution is the introduction of the Steel Coil Slitting Line, a cutting-edge machinery that has revolutionized the metal slitting process.Developed by a leading industry player, the Steel Coil Slitting Line has garnered attention for its advanced features and superior performance. This state-of-the-art equipment is designed to precisely cut and slit large steel coils into narrower strips, catering to the diverse needs of various industries such as automotive, construction, and manufacturing. By adapting this technology, companies can significantly enhance their operational efficiency and achieve higher output levels.The Steel Coil Slitting Line is fitted with cutting-edge automation systems and employs cutting-edge technology. It incorporates advanced sensors and control mechanisms to ensure precise and accurate cutting measurements, eliminating human error and guaranteeing consistent strip sizes. The automated feeding and rewinding systems further contribute to uninterrupted production, resulting in improved overall productivity.The technology's efficiency is complemented by its versatility, allowing businesses to handle a wide range of materials and thicknesses. From hot-rolled coils to stainless steel sheets, the Steel Coil Slitting Line caters to diverse metal requirements seamlessly. This versatility translates into greater flexibility for manufacturers, enabling them to meet the demands of their customers more effectively.Moreover, the Steel Coil Slitting Line's rapid setup and changeover times enable businesses to switch between different coil sizes and specifications quickly. This feature proves invaluable in today's fast-paced market, where quick turnaround times and adaptability often determine a company's success. With reduced downtime for adjustments, businesses can maximize their production capabilities and enjoy a competitive edge.By incorporating the Steel Coil Slitting Line into their operations, companies can also expect significant cost savings. The machinery's cutting-edge technology reduces material wastage, as it utilizes precise cutting measurements, minimizing the leftover scraps. Additionally, the improved production efficiency translates into higher output levels, allowing businesses to meet the market demands without having to invest in additional machinery or workforce.The Steel Coil Slitting Line's installation not only brings advantages to individual companies but also positively impacts the industry as a whole. With increased production efficiency, the lead times for delivering metal products are reduced. This, in turn, contributes to smoother supply chain management, benefiting customers who rely on timely deliveries for their projects.Furthermore, the utilization of advanced technology, such as the Steel Coil Slitting Line, showcases the industry's commitment to sustainability. By significantly reducing material wastage and increasing production capabilities, businesses can minimize their environmental footprint, promoting a greener approach to manufacturing.In conclusion, the introduction of the Steel Coil Slitting Line has undoubtedly raised the bar for production efficiency in the metal industry. With its advanced features, including precise cutting measurements, versatility, rapid changeover times, and cost-saving benefits, the technology proves to be invaluable for businesses seeking to optimize their operations and stay ahead in a highly competitive market. By embracing this cutting-edge machinery, manufacturers can elevate their productivity, reduce waste, and contribute to a more sustainable industrial landscape.

High-Quality Sheet Metal Forming Rollers for Efficient Manufacturing

[Company Name] is a leading manufacturer of sheet metal forming rollers and has been serving the industry for over two decades. The company takes pride in its innovative approach to sheet metal forming technology and is known for providing high-quality, durable, and reliable products to its customers.The latest addition to [Company Name]'s line of sheet metal forming rollers is set to revolutionize the industry. With a focus on precision engineering and advanced materials, the new rollers promise to deliver superior performance and efficiency for a wide range of applications.The development of these new rollers is a result of [Company Name]'s commitment to investing in research and development. By leveraging the latest technologies and engineering expertise, the company has been able to create a product that meets the ever-evolving needs of the sheet metal forming industry."We are thrilled to introduce our latest sheet metal forming rollers to the market," said [Company Name]'s CEO. "These rollers are the culmination of years of hard work, dedication, and a relentless pursuit of excellence. We believe that they will set a new standard for performance and reliability in the industry."The new rollers have been designed to offer a number of key benefits to their users. They are made from high-quality materials that are engineered to withstand the rigors of sheet metal forming processes. This ensures that they will have a long service life and require minimal maintenance, ultimately lowering the total cost of ownership for customers.In addition to their durability, the new rollers also offer improved precision and accuracy. This is essential for ensuring that the formed sheet metal meets the required specifications, which is particularly important in industries such as automotive manufacturing and aerospace.The design of the rollers also takes into account the need for flexibility. They are compatible with a wide range of sheet metal forming equipment, making them suitable for use in various manufacturing environments. This versatility ensures that [Company Name]'s customers can maximize the value they get from their investment in the new rollers.To support the launch of the new rollers, [Company Name] is also providing comprehensive technical support and training to its customers. This includes on-site assistance with installation and setup, as well as ongoing maintenance and troubleshooting support. This is part of the company's commitment to ensuring that its customers get the maximum benefit from their investment in its products.The introduction of the new sheet metal forming rollers represents a significant milestone for [Company Name]. It is a testament to the company's dedication to pushing the boundaries of what is possible in the sheet metal forming industry. With these new rollers, [Company Name] is poised to continue its leadership in the market and provide its customers with the tools they need to succeed.In conclusion, [Company Name]'s new sheet metal forming rollers represent a significant advancement in the industry. With their focus on durability, precision, and flexibility, these rollers are set to become an essential tool for manufacturers looking to optimize their sheet metal forming processes. As [Company Name] continues to innovate and invest in new technologies, it is clear that the company will remain at the forefront of the sheet metal forming industry for years to come.

Steel Edging Machine: Achieve the Perfect Finish for Your Steel Coils

: A Guide to Choosing the Right Steel Edge FinisherSteel edge conditioning is an important and necessary process for anyone working with steel coils. It involves rolling the edge of the coil to a specific shape, ensuring that it is safe for any exposed applications. This process not only enhances the appearance of the finished product but also ensures that the edge is safe to handle and does not pose a risk to anyone during use.One of the essential tools for edge conditioning is a Rolled Coil Steel Edging Machine. This machine is designed to produce high-quality edges that are free of sharp edges and burrs. It can be used for a wide range of applications, including industrial processing, automotive manufacturing, and construction.Choosing Your Edge Finish SWhen looking for a Rolled Coil Steel Edging Machine, it is essential to select one that meets your specific needs. There are different types of edge finishers, and each one has its advantages and disadvantages.Popular edge finishes include rounded edges, beveled edges, and deburred edges.Rounded EdgesThere are different types of rounded edges, including full-round, half-round, and quarter-round. When choosing a rounded edge, you need to consider the material thickness, the coil width, and the edge radius. The machine should be capable of producing the desired radius within a specific tolerance range.Beveled EdgesBeveled edges are inclined edges that angle down from the edge of the steel coil. They improve the appearance of the finished product and provide additional strength and durability. Beveled edges can be used in industrial applications, automotive manufacturing, and construction.Deburred EdgesA deburred edge is one that is free of any sharp edges or burrs. This type of edge is essential for any application where the edge of the steel coil will be exposed. It is also critical when handling the material, as sharp edges can cause injury to the worker.Metal Coil Slitting MachineIn addition to the Rolled Coil Steel Edging Machine, a Metal Coil Slitting Machine is another essential tool for working with steel coils. It is used to cut large coils of steel into smaller, more manageable sizes. This machine saves time and labor costs, making it an essential tool for any industrial operation.When choosing a Metal Coil Slitting Machine, you need to consider the material thickness and gauge, the number of cutting blades, and the feed speed. It should also be easy to operate, with minimal maintenance requirements.SummaryEdge conditioning is an important process for anyone working with steel coils. Rolled Coil Steel Edging Machines are essential tools for producing high-quality edges that are safe and free of sharp edges and burrs. When choosing an edge finish, you need to consider your specific needs and the type of application you are working on.In addition to an edging machine, a Metal Coil Slitting Machine is also essential for cutting large coils into smaller, more manageable sizes. When choosing a Metal Coil Slitting Machine, it is essential to consider the material thickness and gauge, the number of cutting blades, and the feed speed.In conclusion, investing in the right equipment for edge conditioning and coil slitting will increase efficiency, enhance productivity, and improve the quality of the finished product, leading to client satisfaction and business growth.

How to Choose the Best Wall Panel Roll Forming Machine for Your Color Steel Project

Color Steel Wall Panel Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has witnessed a remarkable transformation. With the introduction of advanced technology and machinery, the process of constructing buildings has become faster, more efficient, and cost-effective. Among these technological advancements, the Color Steel Wall Panel Roll Forming Machine stands out as a game-changer, revolutionizing the construction industry.The Color Steel Wall Panel Roll Forming Machine, developed by a leading company in the field of construction machinery manufacturing, has become the go-to solution for producing high-quality steel wall panels. These panels are widely used in various applications, including residential, commercial, and industrial constructions.The machine excels in transforming raw materials into precisely shaped steel wall panels, ensuring uniformity and durability. Its automated system enables a seamless and continuous production process, eliminating the need for manual intervention and reducing the chances of errors. This streamlined process not only saves time but also greatly improves the overall efficiency of construction projects.One of the key factors that sets the Color Steel Wall Panel Roll Forming Machine apart is its ability to produce a wide range of panel profiles. Whether the construction project requires corrugated panels, trapezoidal panels, or any other specific profile, this machine can meet the diverse needs of builders and architects. This versatility allows for greater design flexibility and enables construction professionals to create unique structures that stand out from the crowd.Moreover, the Color Steel Wall Panel Roll Forming Machine ensures superior product quality. By employing advanced hydraulic and electrical components, the machine guarantees precision and accuracy in every step of the production process. The panels produced are of high strength, weather resistance, and thermal insulation, making them ideal for both exterior and interior applications. This high-quality output not only enhances the overall aesthetics of buildings but also offers long-lasting protection against harsh environmental conditions.Additionally, the Color Steel Wall Panel Roll Forming Machine contributes to sustainable construction practices. The machine's energy-efficient operation minimizes power consumption, reducing the overall carbon footprint of construction projects. Furthermore, the use of steel wall panels eliminates the need for traditional construction materials like bricks and cement, which require extensive natural resources during their production. This eco-friendly approach aligns with the growing global emphasis on sustainable development and supports the construction industry's efforts to reduce environmental impact.In line with its commitment to customer satisfaction, the company behind the Color Steel Wall Panel Roll Forming Machine also offers comprehensive after-sales services. A team of experienced technicians provides installation guidance, training programs, and maintenance support to ensure the smooth operation of the machine throughout its lifespan. This commitment to customer support has established the company as a reliable partner in the construction industry, attracting clients from all around the world.As the demand for efficient and sustainable construction practices continues to rise, the Color Steel Wall Panel Roll Forming Machine has emerged as an indispensable tool for builders and architects. Its ability to produce high-quality steel wall panels with precision, versatility, and efficiency has transformed the construction industry. By investing in this innovative machine, construction professionals can streamline their operations, reduce costs, and contribute to a greener future.In conclusion, the Color Steel Wall Panel Roll Forming Machine has revolutionized the construction industry, offering a superior and sustainable solution for producing steel wall panels. Its advanced technology, versatility, and commitment to customer support have made it a staple in modern construction practices. As the industry continues to evolve, the importance of embracing innovative machinery like the Color Steel Wall Panel Roll Forming Machine cannot be overstated. This powerful tool is reshaping the way we build, enabling architects and builders to bring their creative visions to life while improving efficiency and sustainability.

Steel Roll Forming Machine for GP GI Color Sheets: The Ultimate Guide

Introducing the GP GI Color Steel Roll Forming Machine, a state-of-the-art equipment designed to meet the growing demand for high-quality steel products in the construction industry. This advanced technology is set to revolutionize the way steel products are manufactured, and it comes from a company that prides itself on delivering excellence and innovation in the field of metal forming.The GP GI Color Steel Roll Forming Machine is the latest addition to the company's line of roll forming equipment. With its cutting-edge technology and precision engineering, this machine is capable of producing a wide range of steel products, including roofing panels, wall cladding, and structural components with remarkable speed and accuracy. The machine's ability to work with galvanized and pre-painted steel makes it a versatile solution for a variety of applications in the construction and manufacturing industries.The company behind this groundbreaking machine has a long history of delivering top-notch metal forming solutions to its clients. With years of experience in the industry, the company has established itself as a leader in the field of roll forming equipment, offering a comprehensive range of products and services to meet the diverse needs of its customers. From custom design and engineering to manufacturing and installation, the company provides end-to-end solutions to ensure the success of its clients' projects.In addition to its commitment to excellence in manufacturing, the company also prioritizes innovation and continuous improvement in its operations. The GP GI Color Steel Roll Forming Machine is a prime example of this dedication to staying at the forefront of technology and offering cutting-edge solutions to its clients. By investing in state-of-the-art equipment like this roll forming machine, the company demonstrates its commitment to meeting the evolving needs of the market and maintaining its position as a leading provider of metal forming solutions.The GP GI Color Steel Roll Forming Machine is not only a testament to the company's expertise in metal forming but also a reflection of its dedication to sustainability and environmental responsibility. With its efficient production processes and high-quality output, this machine enables the company to minimize waste and reduce its environmental footprint. By choosing this machine for their steel forming needs, clients can be confident that they are investing in a sustainable and eco-friendly solution.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is backed by a team of skilled and knowledgeable professionals who are committed to providing exceptional service and support to clients. From technical assistance and training to ongoing maintenance and customer support, the company's team is dedicated to ensuring the success of every project and the satisfaction of every client. With their expertise and dedication, clients can trust that they are in good hands when they choose the GP GI Color Steel Roll Forming Machine.In conclusion, the introduction of the GP GI Color Steel Roll Forming Machine represents a significant milestone for the company and the industry as a whole. With its advanced technology, commitment to excellence, and focus on sustainability, this machine sets a new standard for steel forming equipment. As the company continues to push the boundaries of innovation and deliver top-quality solutions to its clients, the GP GI Color Steel Roll Forming Machine stands as a testament to its dedication to excellence and its vision for the future of metal forming.